Abstract

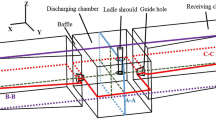

This paper presents computational fluid dynamics (CFD) simulation results of inclusions macroscopic transport as well as dynamic removal in tundishes. A novel treatment was implemented using the deposition velocity calculated by a revised unified Eulerian deposition model to replace the widely used Stokes rising velocity in the boundary conditions for inclusions removal at the steel–slag interface in tundishes. In this study, the dynamic removal for different size groups of inclusions at different steel–slag interfaces (smooth or rough) with different absorption conditions at the interface (partially or fully absorbed) in two tundish designs was studied. The results showed that the dynamic removal ratios were higher for larger inclusions than for smaller inclusions. Besides, the dynamic removal ratio was higher for rough interfaces than for smooth interfaces. On the other hand, regarding the cases when inclusions are partially or fully absorbed at a smooth steel–slag interface, the removal ratio values are proportional to the absorption proportion of inclusions at the steel–slag interface. Furthermore, the removal of inclusions in two tundish designs, i.e., with and without a weir and a dam were compared. Specifically, the tundish with a weir and a dam exhibited a better performance with respect to the removal of bigger inclusions (radii of 5, 7, and 9 μm) than that of the case without weir and dam. That was found to be due to the strong paralleling flow near the middle part of the top surface. However, the tundish without weir and dam showed a higher removal ratio of smaller inclusions (radius of 1 μm). The reason could be the presence of a paralleling flow near the inlet zone, where the inclusions deposition velocities were much higher than in other parts.

Similar content being viewed by others

Notes

The terminology deposition rate refers to a variable with the unit of (kg/s). The terminology deposition velocity has the unit of (m/s). The deposition velocity is derived from the deposition rate per unit area divided by the bulk density of the particles (mass of particles per unit volume). However, this deposition velocity is neither the fluid velocity nor the individual particle velocity in a physical meaning.

The estimation was based on the following data: (1) 2.3 × 109 inclusions per kilogram of steel (from studies by Kiessling[98]), (2) the inclusions with density of 3690 kg/m3, (3) the average radius of inclusion is assumed as 3 μm, and (4) the density of liquid steel 7020 kg/m3. The calculation was performed based on the following equation: \( {{2.3 \times 10^{9} \times \frac{4}{3}\pi \times \left( {3 \times 10^{ - 6} } \right)^{3} \times 3690} \mathord{\left/ {\vphantom {{2.3 \times 10^{9} \times \frac{4}{3}\pi \times \left( {3 \times 10^{ - 6} } \right)^{3} \times 3690} {7020}}} \right. \kern-0pt} {7020}} = 137{\text{mg/L}} \).

The “upper” and “lower” boundary represents the upper and lower of the height of the boundary layer. For the steel–slag interface, on the contrary, the lower boundary is located at the top of the interface and vice visa for the upper boundary. The deposition of inclusion at the interface is in the upward direction.

References

[1] O.J. Ilegbusi and J. Szekely: ISIJ Int., 1989, vol. 29, no. 12, pp. 1031-1039.

[2] K. Marukawa, M. Kawasaki, K. Nakajima and J. Yoshiyama: Trans. ISIJ, 1984, vol. 24, pp. B14.

H. Nakajima, F. Sebo, S. Tanaka, L. Dumitru, D.J. Harris, and R.I.L. Guthrie: Proceedings of the 69th Steelmaking Conference, Washington, DC, I&S Society AIME, 1986, pp. 705–15.

[4] E. Martinez, M. Maeda, L.J. Heaslip, G. Rodriguez and A. McLean: Trans. ISIJ, 1986, vol. 26, no. 8, pp. 724-731.

[5] K. Nakajima and M. Kawasaki: Tetsu-to-Hagané, 1987, vol. 73, no. 7, pp. 852-859.

[6] S. Joo and R.I.L. Guthrie: Metall. Trans. B, 1993, vol. 24B, pp. 755-765.

M.M. Collur, D.B. Love, and B.V. Patil: Proceedings of the 80th Steelmaking Conference, Chicago, I&S Society AIME, 1997, pp. 313–24.

[8] A. Rückert, M. Warzecha, R. Koitzsch, M. Pawlik and H. Pfeifer: Steel Res. Int., 2009, vol. 80, no. 8, pp. 568-574.

A. Rückert, C. Wuppermann, and H. Pfeifer: 7th Euro. Conference Continuous Casting, Düsseldorf, 27 June–1 July, 2011. In CD Form.

[10] K. Chattopadhyay, M. Isac and R.I.L. Guthrie: Ironmak. Steelmak., 2012, vol. 39, no. 6, pp. 454-462.

A. Mukhopadhyay, Y.Y. Perng, J. Lam and B. Desai: 18 th Process Technology Conference Proceedings, I&S Society AIME, 2000, pp. 947-54.

[12] T. Debroy and J.A. Sychterz: Metall. Trans. B, 1985, vol. 16B, pp. 497-504.

K.C. Hsu and C.L. Chou: Proceedings of the 71st Steelmaking Conference, Toronto, I&S Society AIME. 1988, pp. 405–11.

J. Szekely and G. Trapaga: Proceedings of 2 nd Euro. Conf. Continuous Casting, Düsseldorf, June 20–22, 1994, pp. 40–45.

E. Santa Maria, P. Bellomo, M. De Santis, G. Polli and M. Arnò: Proceedings of 2 nd Euro. Conf. Continuous Casting, Düsseldorf, Germany, June 20-22, 1994, pp. 55-62.

S. Chakraborty: Proceedings of the 82 nd Steelmaking Conference, Chicago, I&S Society AIME, 1999, pp. 175–82.

[17] Y. Miki and B.G. Thomas: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 639-654.

[18] T. Nakaoka, T. Miyake, T. Mimura and H. Tai: Tetsu-to-Hagané, 2000, vol. 86, no. 4, pp. 231-238.

S. López-Ramirez, J. de Barreto, J. Palafox-Ramos, R.D. Morales and D. Zacharias: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 615–627.

[20] R. Schwarze, F. Obermeier and D. Janke: Modelling Simul. Mater. Sci. Eng., 2001, vol. 9, pp. 279-287.

R. Schwarze, F. Obermeier, J. Hantusch, A. Franke and D. Janke: Steel Res., 2001, vol. 72, no. 5+6, pp. 215-20.

[22] C. M. Fan, R.J. Shie and W.S. Hwang: Ironmak. Steelmak., 2003, vol. 30, no. 5, pp. 341-347.

[23] J. Hülstrung, M. Zeimes, A. Au, W. Oppermann and G. Radusch: Steel Res. Int., 2005, vol. 76, no. 1, pp. 59-63.

[24] L. Zhang: Steel Res. Int., 2005, vol. 76, no. 11, pp. 784-796.

[25] L. Zhang: J. Iron Steel Res. Int., 2005, vol. 12, no. 5, pp. 11-17.

[26] P.K. Jha, P.S. Rao and A. Dewan: ISIJ Int., 2008, vol. 48, no. 2, pp. 154-160.

[27] K. Raghavendra, S. Sarkar, S.K. Ajmani, M.B. Denys and M.K. Singh: App. Math. Model., 2013, vol. 37, pp. 6284-300.

[28] M. Warzecha, T. Merder, P. Warzecha and G. Stradomski: ISIJ Int., 2013, vol. 53, no. 11, pp. 1983-1992.

[29] Q. Wang, F. Qi, B. Li and F. Tsukihashi: ISIJ Int., 2014, vol. 54, no. 12, pp. 2796-2805.

[30] R. Schwarze, D. Haubold and C. Kratzsch: Ironmak. Steelmak., 2015, vol. 42, pp. 148-153.

[31] K.H. Tacke and J.C. Ludwig: Steel Res., 1987, vol. 58, no. 6, pp. 262-270.

[32] S. Joo, J.W. Han and R.I.L. Guthrie: Metall. Trans. B, 1993, vol. 24B, no. 5, pp. 779-788.

[33] A.K. Sinha and Y. Sahai: ISIJ Int., 1993, vol. 33, no. 5, pp. 556-566.

[34] B. Kaufmann, A. Niedermayr, H. Sattler and A. Preuer: Steel Res., 1993, vol. 64, no. 4, pp. 203-209.

H-P. Narzt, K. Jandl, T. Fastner, K. Antlinger, and H. Preßlinger: Proceedings of 2nd European Conference on Continuous Casting, Düsseldorf, June 20–22, 1994, pp. 63–69.

H. Tozawa, Y. Kato, K. Sorimachi and T. Nakanishi: ISIJ Int., 1999, vol. 39, no. 5, pp. 426-434.

[37] L. Zhang, S. Taniguchi and K. Cai: Metall. Mater. Trans. B, 2000, vol. 31B, no. 2, pp. 253-266.

[38] H. Ling and L. Zhang: JOM, 2013, vol. 65, no. 9, pp. 1155-1163.

T.A. Engh, C.J. Simensen, and O. Wijk: Principles of Metal Refining, 1992, Oxford University Press, Oxford, p. 268.

M.R. Sippola and W.W. Nazaroff: Lawrence Berkeley National Laboratory Report, 2002, LBNL-51432.

V.G. Levich: Physico-chemical hydrodynamics, 1962, Englewood Cliffs, New York, pp. 144–154, 171–73.

[42] S. Linder: Scand. J. Metall., 1974, vol. 3, pp. 137-150.

[43] T.A. Engh and N. Lindskog: Scand. J. Metall., 1975, vol. 4, pp. 49-58.

S.T. Johansen, F. Boysan, and T.A. Engh: Proceedings of 4th Japan-Nordic Countries Joint Symposiums on Science and Technology of Process Metallurgy, Tokyo, ISIJ, 1986, pp. 182–215.

[45] M. Hallberg, P.G. Jönsson, L.T.I. Jonsson and R. Eriksson: Scand. J. Metall., 2005, vol. 34, pp. 41-56.

L. Jonsson: Theories for inclusion deposition at surfaces. International Seminars on Inclusion Engineering, Oulu, 5–6 Sep., 2006. In CD Form.

P. Jönsson, L. Jonsson, J. Alexis and L. Bentell: Int. Conf. on Clean Steel 7, Balatonfüred, 4–6 June, 2007. In CD Form.

[48] S.T. Johansen: Int. J. Multiphase Flow, 1991, vol. 17, no. 3, pp. 355-376.

[49] J. Young and A. Leeming: J. Fluid Mech., 1997, vol. 340, pp. 129-159.

[50] A. Guha: J. Aerosol Sci., 1997, vol. 28, no. 8, pp. 1517-1537.

[51] A. Guha: Ann. Rev. Fluid Mech., 2008, vol. 40, pp. 311-341.

[52] P. Ni, L.T.I. Jonsson, M. Ersson and P.G. Jönsson: Int. J. Multiphase Flow, 2014, vol. 62, pp. 152-160.

[53] P. Ni, L.T.I. Jonsson, M. Ersson and P.G. Jönsson: Metall. Mater. Trans. B, 2014, vol. 45B, no. 6, pp. 2414-2424.

P. Ni: A Study on Particle Motion and Deposition velocity: Application in Steel Flows, Doctoral thesis of KTH Royal Institute of Technology, 2015, ISBN 978-91-7595-448-6.

C. Chen: Some Aspects on Macroscopic Mixing in a Tundish, Doctoral thesis of KTH Royal Institute of Technology, 2015, ISBN 978-91-7595-632-9.

A. McLean: Proceedings of the 71st Steelmaking Conference, Toronto, I&S Society AIME. 1988, pp. 3–23.

[57] K. Nakanishi and J. Szekely: Trans. ISIJ, 1975, vol. 15, pp. 522-530.

[58] K. Nakanishi, J. Szekely, T. Fujii, Y. Mihara and S. Iwaoka: Metall. Trans. B, 1975, vol. 6B, no. 1, pp. 111-118.

[59] K. Shirabe and J. Szekely: Trans. ISIJ, 1983, vol. 23, pp. 465-474.

[60] N. Bannenberg and K. Harste: La Revue de Métallurgie-CIT, 1993, vol. 90, no. 1, pp. 71-76.

B. Hoh, H. Jacobi, H.E. Wiemer, and K. Wünnenberg: Proceedings of 4th International Conference on Continuous Casting, 1988, Brussels, Organized by CRM and VDEh, Vol. 1, p. 211–222.

H. Jacobi, H. Nilsson, H.J. Ehrenberg and K. Wünnenberg: Proceedings of 2nd European Conference on Continuous Casting, Düsseldorf, June 20–22, 1994, pp. 46–54.

[63] T. Bolender, H. Jacobi, M. Weinberg and K. Wünnenberg: Steel Res. Int., 2007, vol. 78, no. 1, pp. 31-38.

[64] H. Tanaka, R. Nishihara, R. Miura, R. Tsujino, T. Kimura, T. Nishi and T. Imoto: ISIJ Int., 1994, vol. 34, no. 11, pp. 868-875.

C. Cicutti, A. Martin, J. Mendez, M. Romero and G. Di Gresia: 7 th Euro. Conf. Continuous Casting, Düsseldorf, Germany, 27 June-1 July, 2011. In CD Form.

[66] G. Yang, X. Wang, F. Huang, W. Wang, Y. Yin and C. Tang: Steel Res. Int., 2014, vol. 85, no. 1, pp. 26-34.

P. Rasmussen: Proceedings of the 77th Steelmaking Conference, I&S Society AIME, 1994, pp. 219–24.

R.W. Crowley and G.D. Lawson: Proceedings of the 78th Steelmaking Conference, Nashville, I&S Society AIME, 1995, pp. 629–36.

C. Marique: Proceedings of SCANINJECT VII-7th International Conference on Refining Processes, MEFOS, Luleå, June 7–8, 1995, Part II, pp. 107–43.

B. Bergmann, H.A. Jungblut, F.J. Schmitt, and A. Ghilardi: 1st European Continuous Casting Conference, Florence, Italy, Sep. 23–25, 1991, pp. 2.235–2.244.

L. Kuchar and L. Holappa: Proceedings of the 76th Steelmaking Conference, Dallas, I&S Society AIME, March 1993, pp. 495–502.

J. Van der Stel, R. Boom, and B. Deo: Proceedings of the 76th Steelmaking Conference, Dallas, I&S Society AIME, March 1993, pp. 503–16.

V. Ludlow, H. Watkinson, K.G. Bain, and A.S. Normanton: Proceedings of 2nd European Conference on Continuous Casting, Düsseldorf, June 20–22, 1994, pp. 32–39.

[74] L. Holappa, M. Kekkonen, S. Louhenkilpi, R. Hagemann, C. Schröder and P. Scheller: Steel Res. Int., 2013, vol. 84, no. 7, pp. 638-648.

[75] J.Y. Yu, Y. Kang and IL Sohn: Metall. Mater. Trans. B, 2014, vol. 45B, no. 1, pp. 113-22.

[76] P. Yan, S. Arnout, M.A. Vanende, E. Zinngrebe, T. Jones, B. Blanpain and M. Guo: Metall. Mater. Trans. B, 2015, vol. 46B, no. 3, pp. 1242-1251.

[77] Y. Chung and A.W. Cramb: Metall. Mater. Trans. B, 2000, vol. 31B, no. 5, pp. 957-971.

D. Aganofer, G.L. Liao, and D.B. Spalding: Proceedings of the EEP Application of CAE/CAD to Electronic Systems, ASME International Mechanical Engineering Congress and Exposition, Atlanta, GA. 1996.

[79] H. Solhed, L. Jonsson and P. Jönsson: Metall. Mater. Trans. B, 2002, vol. 33B, no. 2, pp. 173-185.

[80] H. Solhed and L. Jonsson: Scand. J. Metall., 2003, vol. 32, pp. 15-32.

[81] H. Solhed, L. Jonsson and P. Jönsson: Steel Res. Int., 2008, vol. 79, no. 5, pp. 348-357.

[82] C. Chen, L.T.I. Jonsson, A. Tilliander, G. Cheng and P.G. Jönsson: Chem. Eng. Sci., 2015, vol. 137, pp. 914-937.

[83] E. Cunningham: Proc. R. Soc. Lond. Ser. A, 1910, vol. 83, pp. 357-365.

J.O. Hinze: Turbulence. 2nd Edition, 1975, McGraw-Hill, New York, p. 466.

[85] L. Talbot, R.K. Cheng, R.W. Schefer and D.R. Willis: J. Fluid Mech., 1980, vol. 101, pp. 737-758.

[86] G.A. Kallio and M.W. Reeks: Int. J. Multiphase Flow, 1989, vol. 15, pp. 433-446.

[87] N.B. Wood: J. Aerosol Sci., 1981, vol. 12, no. 3, pp. 275-290.

J.M. Kay and R.M. Nedderman: Fluid Mechanics and Transfer Process, 1988, Cambridge University Press, Cambridge.

[89] G.A. Sehmel: J. Aerosol Sci., 1973, vol. 4, pp. 125-138.

[90] C. Chen, G. Cheng, H. Sun, Z. Hou, X. Wang and J. Zhang: Steel Res. Int., 2012, vol. 83, no. 12, pp. 1141-51.

[91] C. Chen, L.T.I. Jonsson, A. Tilliander, G. Cheng and P.G. Jönsson: Metall. Mater. Trans. B, 2015, vol. 46B, no. 1, pp. 169-190.

[92] S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corp., New York, 1980, p. 13.

Y.S. Chen and S.W. Kim: NASA Report, NASA CR-179204, 1987.

[94] H.J. Odenthal, M. Javurek, M. Kirschen and N. Vogl: Steel Res. Int., 2010, vol. 81, no. 7, pp. 529-541.

[95] N.J. Themelis: Transport and Chemical Rate Phenomena, Gordon and Breach Science Publishers SA, Yverdon, 1995, p. 83.

[96] B.E. Launder and D.B. Spalding: Comp. Meth. Appl. Mech. Eng., 1974, vol. 3, no. 2, pp. 269–289.

[97] B.J. Lees: Geo-Mar. Lett., 1981, vol. 1, no. 3-4, pp. 249-254.

R. Kiessling: Proceedings of Second International Conference on Clean Steel, Balatonfüred, Hungary, June, 1981, pp. 1–9.

[99] O. Levenspiel: Chem. Eng. Sci., 2002, vol. 57, pp. 4691-4696.

PHOENICS-VR Reference Guide, CHAM, London, 2012.

P.H. Gaskell and A.K.C. Lau: Int. J. Num. Methods Fluids, 1988, vol. 8, no. 6, pp. 617–41.

D.B. Spalding: Report HTS/80/1, Mechanical Engineering Department, Imperial College of Science, Technology and Medicine, London, 1980.

[103] H.J. Odenthal, R. Bölling and H. Pfeifer: Steel Res., 2003, vol. 74, no. 1, pp. 44-55.

[104] R. Bölling, H.J. Odenthal and H. Pfeifer: Steel Res. Int., 2005, vol. 76, no. 1, pp. 71-80.

[105] R. Schwarze and A. Rückert: Steel Res. Int., 2007, vol. 78, no. 2, pp. 151-155.

[106] M. Javurek, B. Kaufmann, G. Zuba and P. Gittler: Steel Res., 2002, vol. 73, no. 5, pp. 186-193.

[107] Y.S. Lee, S.M. Jung and D.J. Min: Ironmak. Steelmak., 2014, vol. 41, no. 3, pp. 213-218.

K. Nakajima and K. Okamura: Proceedings of 4th International Conference on Molten Slags and Fluxes, Sendai, ISIJ, 1992, pp. 505–10.

[109] D. Bouris and G. Bergeles: Metall. Mater. Trans. B, 1998, vol. 29B, no. 3, pp. 641-649.

[110] J. Strandh, K. Nakajima, R. Eriksson and P. Jönsson: ISIJ Int., 2005, vol. 45, no. 11, pp. 1597-1606.

[111] J. Strandh, K. Nakajima, R. Eriksson and P. Jönsson: ISIJ Int., 2005, vol. 45, no. 12, pp. 1838-1847.

J. Wikström: A Mathematical and Experimental Study of Inclusion Behavior at a Steel–slag Interface, Doctoral thesis of KTH Royal Institute of Technology, 2007, ISBN 978-91-7178-781-1.

G.N. Shannon: Oxide Inclusion Behavior at the Steel/Slag Interface, Doctoral thesis of Carnegie Mellon University, 2007.

[114] S. Yang, W. Liu and J. Li: JOM, 2015, vol. 67, no. 12, pp. 2993-3001.

Acknowledgments

Dr. Michael R. Malin of CHAM Limited is acknowledged for the help to implement the drift-flux model in PHOENICS. The comments and discussions on the deposition model from Professor Stein Tore Johansen of SINTEF Materials and Chemistry and Professor John B. Young of Cambridge University are acknowledged. Chao Chen and Peiyuan Ni are grateful for the awards of CSC (China Scholarship Council) scholarships for financial supports of their individual studies at KTH, respectively. At last, the anonymous reviewers are acknowledged for their comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 31, 2015.

Appendix: Turbophoretic Model (Unified Eulerian deposiTion Model)

Appendix: Turbophoretic Model (Unified Eulerian deposiTion Model)

1. Model descriptions

The dimensionless particle deposition velocityV +dep is defined as follows:

where J is the deposition flux onto the steel–slag interface (hereafter interface) and C Pis the particle mass concentration (with the unit of mass of particles per unit volume). As a further note, C +P = C P/C 0 is the dimensionless particle mass concentration and C 0 is the bulk concentration.

The equation for V +dep which is derived from particle continuity equation can be expressed as follows by Eq. [A2]:

where D B and ɛ p are Brownian diffusivity and turbulent diffusivity for particles. The kinematic viscosity for liquid steel ν was 8.5 × 10−7 m2/s. D T is the coefficient of diffusion due to temperature gradient. \( \overline{{V_{{{\text{P}}y}}^{{{\text{C}} + }} }} = {{\overline{{V_{{{\text{P}}y}}^{\text{C}} }} } \mathord{\left/ {\vphantom {{\overline{{V_{{{\text{P}}y}}^{\text{C}} }} } {u^{*} }}} \right. \kern-0pt} {u^{*} }} \) is the dimensionless form of the particle convective velocity in the y-direction (perpendicular to the wall).

The Brownian diffusivity for particles D B can be calculated by the following relationship:

where k is the Boltzmann constant, T is the absolute temperature: 1803.15 K (1530 °C), ρ f is the density of fluid (steel): 7020 kg/m3, and r is the radius of the particle. C c is the Cunningham correction factor[83] which describes the rarefied effect of particles in a gas system[51] and retained the in inclusion-steel system.[52] It can be calculated by the following relationship:

where Kn is the Knudsen number and is defined as follows:

where λ is the mean-free length of the fluid. The value for steel was chosen as 1 × 10−10 m.[52]

The turbulent diffusivity for particles ɛ p is assumed as equal to the fluid turbulent viscosity ν turb.[84] The following expression from Johansen[48] was used for the fluid turbulent viscosity:

The D T is calculated from the following relationship:[50]

where η is the thermophoretic force coefficient and is expressed by:[50,85]

where λ r is the ratio of the thermal conductivity of the fluid to that of the particles. This ratio for liquid steel to inclusions was chosen as 37.[52]

The particle momentum equation in the normal direction (y-direction) to the interface is normalized in Eq. [A9] as follows:

where ρ P is the density of particles (inclusions): 3690 kg/m3, g is the gravity acceleration rate (9.81 m2/s). τ +C is the normalized form of the Cunningham corrected particle relaxation time, which could be expressed as follows:

where τ P is the particle relaxation time that follows from Stokes drag.

The variable \( \overline{{V^{\prime}_{{{\text{P}}y}} V^{\prime}_{{{\text{P}}y}} }} \) is the ensemble-averaged squared particle fluctuating velocity (V ′Py ) normal to the interface.[48] The variable \( \overline{{V^{\prime}_{{{\text{P}}y}} V^{\prime}_{{{\text{P}}y}} }} \) was assumed to be equal to the Reynolds normal stress of the fluid \( \overline{{V^{\prime}_{{{\text{f}}y}} V^{\prime}_{{{\text{f}}y}} }} \).[52] The latter could be obtained by the relationship \( \overline{{V^{\prime}_{{{\text{f}}y}} V^{\prime}_{{{\text{f}}y}} }} = \left( {\sqrt {\overline{{V^{\prime 2}_{{{\text{f}}y}} }} } } \right)^{2} \), where the RMS velocity of fluid was modified by Guha[50,51] from the result of Kallio and Reeks[86] and are expressed as follows:

2. Boundary conditions, numerical solution, and validation

At the upper‡ boundary y + = 60, the dimensionless particle convective velocity \( \overline{{V_{{{\text{P}}y}}^{{{\text{C}} + }} }} = 0 \) and the dimensionless particle mass concentration C +P = 1, i.e., the same with the bulk concentration. The location of the lowerFootnote 4 boundary is affected by the interface roughness.[50] The expression of Wood[87] was used at the lower boundary as follows:

where k S and k + S are the roughness height and its normalized form, respectively. At the lower boundary, the dimensionless particle mass concentration C +P = 0, which represents that no inclusions exist at the interface.

The treatment of the thermophoretic force by Guha[50] and the temperature file at the turbulent BL from Kay and Nedderman[88] are retained in this study. Specifically, the temperature can be obtained as follows:

where ΔT +60 = 5Pr + 5ln(1 + 5Pr) + 2.5ln(60/30). T I is the temperature at the interface: 1818 K (1545 °C), ΔT is the temperature difference between the upper boundary and the interface: 5 K (5 °C), and Pr is Prandtl number: 0.08.

The numerical solution procedure is provided in Reference 52. Essentially, the one-dimensional turbulent BL was discretized into 10,000 grids. First, \( \frac{\partial }{{\partial y^{ + } }}\left\{ {{\text{Eq}} .\left[ {\text{A2}} \right]} \right\} = 0 \) with the BCs were solved and the inclusion mass concentration profile were obtained. Second, the \( \overline{{V_{{{\text{P}}y}}^{{{\text{C}} + }} }} \) of all the grids were obtained by solving the discretized Eq. [A9] with the BCs. Finally, the deposition velocity was calculated by using Eq. [A2] with the inputs of inclusion mass concentration and \( \overline{{V_{{{\text{P}}y}}^{{{\text{C}} + }} }} \).

The experimental data of the gravity-driven aerosol particle deposition onto horizontal walls at floor were chosen for validation. The deposition process is similar to the buoyancy-driven inclusion particle deposition onto top slags. Since in these cases, the buoyancy and the gravity play a similar role for inclusions and aerosol particles deposition. The input parameters of the aerosol particle and air system are the same as those used in a previous study.[52] The validation with the experimental data of Sehmel[89] is shown in Figure A1. The agreement is good for the extension of the turbophoretic model to study the inclusion-liquid steel system.

Comparison of the calculated deposition velocities with the experimental data (Sehmel[89]) for aerosol particle deposition on floors

Rights and permissions

About this article

Cite this article

Chen, C., Ni, P., Jonsson, L.T.I. et al. A Model Study of Inclusions Deposition, Macroscopic Transport, and Dynamic Removal at Steel–Slag Interface for Different Tundish Designs. Metall Mater Trans B 47, 1916–1932 (2016). https://doi.org/10.1007/s11663-016-0637-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0637-6