Abstract

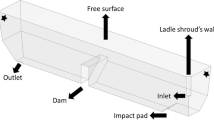

The attributes of various tundish designs and flow modifiers have been studied based on the computational and physical modeling efforts developed in parts I and II. The importance of thermal natural convection effects in such vessels has been demonstrated. Flow patterns and residual ratios (RR) for various tundish designs of equal volume and metal throughput showed that a conventional biflow, twin-strand, trough-type tundish fitted with flow modifiers allows for the greatest removal of inclusions, while a one-way flow, twin-strand, wedge-shaped tundish performs best in the absence of flow modifiers. More detailed analyses of the conventional trough-type tundish were performed to assess the effects of double-weir-double-dam and single-weir-double-dam arrangements. The effectiveness of steeply sloping sidewalls for enhanced removal of inclusions was demonstrated; however, this measure was associated with penalties in the form of greater metal temperature losses.

Similar content being viewed by others

Abbreviations

- d :

-

inclusion diameter (m)

- g :

-

gravity (m/s2)

- H :

-

tundish depth (m)

- K :

-

turbulence kinetic energy in unit mass (m2/s2)

- L :

-

tundish length (m)

- Q :

-

flow rate (m3/s)

- R :

-

residual ratio (—)

- S ϕ :

-

source term ϕ

- u s :

-

stokes velocity (m/s)

- u :

-

x-direction velocity component (m/s)

- v :

-

y-direction velocity component (m/s)

- w :

-

z-direction velocity component (m/s)

- W :

-

tundish width (m)

- ρ :

-

inclusion density (kg/m3)

- ρ s :

-

density of molten steel (kg/m3)

- ϕ :

-

dependent variable

- μ :

-

viscosity of molten steel (kg/m/s)

- Г gf :

-

exchange coefficient ϕ

- ε :

-

energy dissipation rate per unit mass (m2/s3)

- θ :

-

residence time (s)

References

F. Sebo, F. Dallaire, S. Joo, and R.I.L. Guthrie:Proc. Int. Symp. on Production and Processing of Fine Particles, A. Plumpton, ed., CIM, Montreal, 1988, pp. 103–10.

R.I.L. Guthrie, S. Joo, and H. Nakajima:Proc. Met. Soc. of CIM, Int. Symp. on Direct Rolling and Charging of Strand Cast Billets, Montreal, 1988, Pergamon Press, Elmsford, NY, 1988, vol. 10, pp. 193–212.

B.E. Launder and D.B. Spalding:Comp. Math. Appl. Mech. Eng., 1974, vol. 3, pp. 269–89.

S. Joo: Ph.D. Thesis, McGill University, Montreal, 1989.

S.V. Patankar:Numerical Heat Transfer and Fluid Flow, McGraw-Hill, New York, NY, 1980.

M. Byrne, T.W. Fenicle, and A.W. Cramb:Iron Steelmaker, 1988, vol. 16 (6), pp. 41–50.

R.I.L. Guthrie:Engineering in Process Metallurgy, 2nd ed. Clarendon Press, Oxford Science Publications, Oxford, 1992.

R.I.L. Guthrie and H.C. Lee:Steelmaking Proc, Iron and Steel Society, Toronto, 1992, pp. 799–805.

Author information

Authors and Affiliations

Additional information

Formerly Doctoral Candidate.

Formerly Postdoctoral Fellow, Department of Mining and Metallurgical Engineering, McGill Metals Processing Centre, McGill University.

Macdonald Professor of Metallurgy.

Rights and permissions

About this article

Cite this article

Joo, S., Han, J.W. & Guthrie, R.I.L. Inclusion behavior and heat-transfer phenomena in steelmaking tundish operations: part III. applications—computational approach to tundish design. Metall Trans B 24, 779–788 (1993). https://doi.org/10.1007/BF02663138

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02663138