Abstract

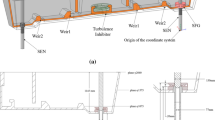

Knowledge on the behavior of inclusions in molten steel is crucial to study the fluid flow in the tundish. In this study, an inclusion mass/population conservation model and fluid mass/momentum/energy conservation model were coupled to investigate the spatial distribution of the inclusion volume concentration and inclusion size in the tundish. In this model, collision-coalescence among inclusions occurs due to turbulent collisions and Stokes collisions. The numerical results predict an inclusion size distribution that agrees with experimental data. The inclusion volume concentration decreases while the inclusion characteristic radius increases along the flow path of the molten steel. Furthermore, it is easy for inclusions to collide and aggregate with each other at the guide hole of the baffle, because there is strong turbulent flow there. Also, the inclusion characteristic radius in the distributing chamber is greater than that in the receiving chamber, while the inclusion volume concentration in the distributing chamber is less than that in the receiving chamber.

Similar content being viewed by others

Abbreviations

- N :

-

Inclusion number density (1/m3)

- C :

-

Inclusion volume concentration (–)

- A :

-

Constant (–)

- B :

-

Constant (–)

- r * :

-

Inclusion characteristic radius (m)

- μ :

-

Dynamic viscosity (kg/m s)

- \( \upsilon \) :

-

Kinematic viscosity (m2/s)

- \( A^{*} \) :

-

Hamaker constant (–)

- \( \vec{u}_{{\rm f}} \) :

-

Velocity of molten steel (m/s)

- \( F_{{\rm C}}^{{\rm c}} \) :

-

Transport flux of inclusion volume concentration (m/s)

- \( F_{{\rm N}}^{{\rm c}} \) :

-

Transport flux of inclusion number density [1/(m2 s)]

- \( F_{{\rm C}}^{{\rm d}} \) :

-

Diffusion flux of inclusion volume concentration (m/s)

- \( F_{{\rm N}}^{{\rm d}} \) :

-

Diffusion flux of inclusion number density [1/(m2 s)]

- \( \beta \) :

-

Collision rate (m3/s)

- \( \kappa \) :

-

Boltzmann’s constant (–)

- \( N_{{\rm T}} \) :

-

Dimensionless ratio of viscous and van der Waals forces (–)

- \( {\text{Sc}} \) :

-

Schmidt number (–)

- \( f \) :

-

Fractional inclusion number density (1/m4)

- \( g \) :

-

Gravitational acceleration (m/s2)

- \( \vec{u}_{{\rm p}} \) :

-

Inclusion velocity (m/s)

- \( \vec{u}_{{\rm C}} ,\vec{u}_{{\rm N}} \) :

-

Inclusion slipping velocity (m/s)

- t :

-

Time (s)

- \( \tau_{0} \) :

-

Wall friction [kg/(s2 m)]

- \( D_{{\rm eff}} \) :

-

Effective diffusivity of molten steel (m2/s)

References

S. Lopez-Ramirez, J. Palafox-Ramos, R.D. Morales, J.D.J. Barreto, and D. Zacharias, Metall. Mater. Trans. B 32, 615 (2001).

R.D. Morales, J. Palafox-Ramos, J.D.J. Barreto, S. Lopez-Ramirez, and D. Zacharias, Metall. Mater. Trans. B 31, 1505 (2000).

R.D. Morales, M. Diaz-Cruz, J. Palafox-Ramos, S. Lopez-Ramirez, and J.de J. Barreto-Sandoval, Steel Res. 72, 11 (2001).

S.G. Zheng and M.Y. Zhu, Ironmak. Steelmak. 33, 398 (2006).

D.F. Chen, X. Xie, M.J. Long, M. Zhang, L.L. Zhang, and Q. Liao, Metall. Mater. Trans. B 45, 392 (2014).

P.K. Jha, P.S. Rao, and A. Dewan, ISIJ Int. 48, 154 (2008).

S. Chang, L.C. Zhong, and Z.S. Zou, ISIJ Int. 55, 837 (2015).

Y. Miki, H. Kitaoka, N. Bessho, T. Sakuraya, S. Ogura, and M. Kuga, Tetsu-to-Hagane 82, 498 (1996).

S. Taniguchi and J.K. Brimacombe, ISIJ Int. 34, 722 (1994).

Y. Miki and B.G. Thomas, Metall. Mater. Trans. B 60B, 639 (1999).

K. Raghavendra, S. Sarkar, S.K. Ajmani, M.B. Denys, and M.K. Singh, Appl. Math. Model. 37, 6284 (2013).

L. Zhang, S. Taniguchi, and K. Cai, Metall. Mater. Trans. B 31B, 253 (2000).

L. Zhang, J. Aoki, and B.G. Thomas, Metall. Mater. Trans. B 37B, 361 (2006).

H. Ling, L. Zhang, and H. Li, Metall. Mater. Trans. B 47, 2991 (2016).

L.T. Wang, S.H. Peng, Q.Y. Zhang, and Z.B. Li, Steel Res. 77, 25 (2006).

T. Nakaoka, S. Taniguchi, K. Matsumoto, and S.T. Johansen, ISIJ Int. 41, 1103 (2001).

H. Lei, K. Nakajima, and J.C. He, ISIJ Int. 50, 1735 (2010).

M.Y. Zhu, S.G. Zheng, Z.Z. Huang, and W.P. Gu, Steel Res. 76, 718 (2013).

H. Lei, D.Q. Geng, and J.C. He, ISIJ Int. 49, 1575 (2009).

L. Zhao and K. Liu, J. Iron. Steel Res. 14, 19 (2002).

H. Lei, Y. Zhao, and D. Geng, ISIJ Int. 54, 1629 (2014).

H. Lei, J.M. Jiang, B. Yang, Y. Zhao, H.W. Zhang, W.X. Wang, and G.W. Dong, Metall. Mater. Trans. B 49, 666 (2018).

Acknowledgements

The research is supported by the National Natural Science Foundation of China and Shanghai Baosteel (No. U1460108) and the Fundamental Research Funds for the Central Universities (No. N170906004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, B., Lei, H., Bi, Q. et al. Numerical Simulation of Collision-Coalescence and Removal of Inclusions in a Tundish. JOM 70, 2950–2957 (2018). https://doi.org/10.1007/s11837-018-3061-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3061-3