Abstract

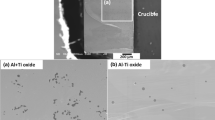

Fundamental work on the effect of alkali oxides including Li2O, Na2O, and K2O on the absorption ability of inclusions in a typical basic tundish flux for 321 stainless steels has been studied. The effects on the absorption ability are dependent on the type of alkali oxides and the amount composed within the tundish flux. Results from kinetics studies using an induction furnace at 1823 K (1550 °C) on the reaction of tundish fluxes containing alkali oxides with 321 stainless steels suggest minimal improvement with Li2O and Na2O additions and in some cases hindered inclusion removal, but K2O additions seems to significantly improve the cleanliness in the as-quenched 321 stainless steel melts compared to preexisting tundish flux compositions. Both Li2O and Na2O significantly lower the viscosity of the melt, while K2O increases the viscosity. Although alkali oxides have a propensity to enhance the cohesion of aluminate melts due to the ionic compensation effect in [AlO4]5−-tetrahedral structural units, this effect was not pronounced for Li2O and Na2O compared to K2O additions, which may be due to the large ionic radius size of potassium. An automated SEM–EDS analysis was utilized to identify the inclusion morphology and abundance within the steel. Fourier transform infrared spectroscopy was used to identify the effects of alkali oxides on the tundish flux structure for improved absorption capability and described the characteristic effect of K2O on increasing the asymmetric stretching vibrations of [AlO4]5−-tetrahedral structural units and Si-O-Al bonding within the flux, thus polymerizing the flux and selectively absorbing inclusions.

Similar content being viewed by others

References

L. Zhang and B.G. Thomas : ISIJ Int., Vol.43 (2003), pp.271-91.

J.-Y. Park and I. Sohn : Metall. Mater. Trans. B., Vol.44B (2013), pp.123-32.

N. Bessho, H. Yamasaki, T. Fujii, T. Nozaki, and S. Hiwasa : ISIJ Int., Vol.32 (1992), pp.157-63.

M. Byrne and A.W. Cramb, and T.W. Fenicle : Iron Steelmaker, Vol.15 (1988), pp.41-50.

E.T. Turkdogan : Archiv. Fur Das Eisenhuttenwessen, Vol.54 (1983), pp.1-10.

E.T. Turkdogan : Archiv. Fur Das Eisenhuttenwessen, Vol.54 (1983), pp.45-52.

R. Kiessling : Met. Sci., Vol.15 (1980), pp.161-72.

A.W. Cramb: in Impurities in Engineering Materials: Impact, Reliability, and Control, C.L. Briant, Marcel Decker Inc., New York, 1999, pp. 49–90.

C.-B. Shi, X.-C. Chen, H.-J. Guo, Z.-J. Zhu, and X.-L. Sun : Metall. Mater. Trans. B, Vol.44 (2013), pp.378-89.

P. Kaushik, J. Lehman, and M. Nadif : Metall. Mater. Trans. B, Vol.43B (2012), pp.710-25.

P. Poncin and J. Droft: Materials and Processes for Medical Devices Conference, 8–10 September 2003.

P. Tassot and N. Reichert : Revue de Metallurgie, Vol.107 (2010), pp.179-85.

P.K. Jha, P.S. Rao, and A. Dewan : ISIJ Int., Vol.48 (2008), pp.154-60.

S.K. Roy, M. Isac, and R.I.L Guthrie: Ironmak. Steelmak., 2011, vol. 38, pp. 759–68.

L. Holappa, M. Kekkonen, S. Lachenkilpi, R. Hagemann, C. Schroder, and P. Scheller: Steel Res. Int., 2013, vol. 84, DOI:10.1002/srin.201200209.

F. Li, B. Wang, Z. Jiang, S. He, and Q. Wang : Advanced Materials Research, Vol.284-286 (2011), pp.1284-90.

S.K. Kim, H. Suito, and R. Inoue : ISIJ Int., Vol. 52 (2012), pp.1935-1944.

H. Fan, G. Gao, G. Wang, and L. Hu, Solid State Sci., Vol. 12 (2010), pp. 541-545.

H. Li, P, Hrma, J.D. Vienna, M. Qian, Y. Su, and D.E. Smith: J. Non-Cryst. Solids, 2003, vol. 311, pp. 202–16.

G.H. Kim and I. Sohn: ISIJ Int., Vol. 52 (2012), pp. 68-73.

W.H. Kim, I. Sohn, and D.J. Min : Steel Res. Int., Vol. 81 (2010), pp.735-41.

Acknowledgments

The authors are grateful to Prof. J.J. Pak of Hanyang University for the use of the induction furnace and the facilities at the Erica campus. Special appreciation is also warranted to POSCO technical research lab for support in the inclusion analysis and Mr. Sung Suk Jeong of Yonsei University for the SEM–EDS analysis. This study was partially supported by the Brain Korea 21 (BK21 PLUS) Project at the Creative Materials Division and by the Ministry of Trade, Industry and Energy (RCMS10044705, 2013-11-1079).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 14, 2013.

Rights and permissions

About this article

Cite this article

Yu, J.Y., Kang, Y. & Sohn, I. Novel Application of Alkali Oxides in Basic Tundish Fluxes for Enhancing Inclusion Removal in 321 Stainless Steels. Metall Mater Trans B 45, 113–122 (2014). https://doi.org/10.1007/s11663-013-0013-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-0013-8