Abstract

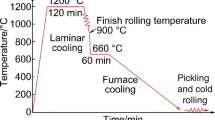

Application of quenching and partitioning process in hot stamping has proven to be an effective method to improve the plasticity of advanced high-strength steels (AHSSs). In this study, the hot stamping and partitioning process of advanced high-strength steel 30CrMnSi2Nb is investigated with a hot stamping mold. Given the specific partitioning time and temperature, the influence of quenching temperature on the volume fraction of microstructure evolution and mechanical properties of the above steel are studied in detail. In addition, a model for quenching and partitioning process is applied to predict the carbon diffusion and interface migration during partitioning, which determines the retained austenite volume fraction and final properties of the part. The predicted trends of the retained austenite volume fraction agree with the experimental results. In both cases, the volume fraction of retained austenite increases first and then decreases with the increasing quenching temperature. The optimal quenching temperature is approximately 290 °C for 30CrMnSi2Nb with the partition conditions of 425 °C and 20 seconds. It is suggested that the model can be used to help determine the process parameters to obtain retained austenite as much as possible.

Similar content being viewed by others

References

R.M. Wu, X.J. Jin, C.L. Wang, and L. Wang: J. Mater. Eng. Perform., 2016, vol. 25, pp. 1603–10.

A. Turetta, S. Bruschi, and A. Ghiotti: J. Mater. Process. Technol., 2006, vol.177, pp. 396–400.

H. Karbasian and A.E. Tekkaya: J. Mater. Process. Technol., 2010, vol. 210, pp. 2103–18.

P.X. Liu, B. Zhu, Y.L. Wang, and Y.S. Zhang: Metall. Mater. Trans. A, 2016, vol. 64, pp. 4325–33.

J.G. Speer, E.D. Moor, K.O. Findley, D.K. Matlock, B.C. DeCooman, and D.V. Edmonds: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3591–3601.

C. Wang, H. Ding, M.H. Cai, and B. Rolfe: Mater. Sci. Eng., 2014, vol. 610, pp. 436–44.

Y. Sakuma, O. Matsumura, and H. Takechi: Metall. Trans. A, 1991, vol. 22A, pp. 489–98.

H.P. Liu, X.W. Lu, X.J. Jin, D. Han, and J. Shi: Scr. Mater., 2011, vol. 64, pp. 749–52.

E.J. Seo, L. Cho, Y. Estrin, and B.C. De Cooman: Acta Mater., 2016, vol. 113, pp. 124–139.

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611–22.

A.J. Clarke, J.G. Speer, D.K. Matlock, F.C. Rizzo, D.V. Edmondsd, and M.J. Santofimia: Scr. Mater., 2009, vol. 61, pp. 149–52.

J.G. Speer, D.K. Matlock, B.C. Decooman, and J.G. Schroth: Scr. Mater., 2005, vol. 52, pp. 83–85.

N. Zhong, X.D. Wang, Y.H. Rong, and L. Wang: J. Mater. Sci. Technol., 2006, vol. 22, pp. 751–55.

M.J. Santofimia, L. Zhao, and J. Sietsma: Scr. Mater., 2008, vol. 59, pp. 159–62.

B. Kim, J. Sietsma, M.J. Santofimia: Mater. Des., 2017, vol. 127, pp. 336–345.

Y. Chang, G.Z. Li, C.Y. Wang, X.D. Li, and D. Han: J. Mater. Eng. Perform., 2015, vol. 24, pp. 3194–200.

J. Svoboda, F.D. Fischer, P. Fratzl, E. Gamsjager, and N.K. Simha: Acta Mater., 2001, vol. 49, pp. 1249–59.

J. Crank: The Mathematics of Diffusion, 2nd ed., Oxford University Press, London, 1975, pp. 137–59.

J. Mahieu, J. Maki, B.C. De Cooman, and S. Claessens: Metall. Mater. Trans. A, 2002, vol. 33, pp. 2573–80.

F.C. Rizzo, D.V. Edmonds, K. He, J.G. Speer, D.K. Matlock, and A.J. Clarke: Proceedings of an International Conference on Solid-Solid Phase Transformations in Inorganic Materials 2005[C], Phoenix, AZ, unpublished research, 2005.

M. Hillert and J. Ågren: Scr. Mater., 2004, vol. 50, pp. 697–99.

J.G. Speer, D.V. Edmonds, F.C. Rizzo, and D.K. Matlock: Curr. Opin.Solid State Mater. Sci., 2004, vol. 8, pp. 219–37.

Y. Sakuma, O. Matsumura, and H.Takechi: Metall. Mater. Trans. A, 1991, vol. 22, pp. 489–98.

S.M.C. van Bohemen: Mater. Sci. Technol., 2012, vol. 28, pp. 487–95.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant No. 51405171) and the National Natural Science Foundation of China (Grant No. U1564203). The authors would like to thank the State Key Lab of Materials Processing and Die and mold Technology for their assistance in the tensile experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 17, 2017.

Rights and permissions

About this article

Cite this article

Zhu, B., Liu, Z., Wang, Y. et al. Application of a Model for Quenching and Partitioning in Hot Stamping of High-Strength Steel. Metall Mater Trans A 49, 1304–1312 (2018). https://doi.org/10.1007/s11661-018-4484-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4484-8