Abstract

In this study, mesoporous silica nanoparticles previously prepared from the rice husk ash were utilized as nanofillers to fabricate thin films of polyimide/silica hybrid nanocomposites with different ratios (0, 6, 8, 10, and 12%). Subsequently, all hybrid films were further subjected to comprehensive characterization using XRD, SEM, AFM, and contact angle analyzers. The films exhibited a variety of optoelectronic properties depending on the silica nanoparticles' content. Where the silica nanofillers affected the optical clarity of polyimide films and increasing the silica ratio resulted in decreasing in films transmittance which led to reducing the transparency and enhanced the absorption coefficient of films in the UV range. Besides, the dielectric constant value and free charge carrier concentrations have increased which promoted the optical conductivity of the films. Moreover, increasing silica content resulted in converting the films from hydrophobic to hydrophilic surfaces, and has improved their wettability at all pH values.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays many studies introduced hybrid nanocomposites as alternatives to bulk polymers by including the nanoparticles in polymeric matrices (Li et al. 2010; Hamdy et al. 2021; Jeevanandam et al. 2018). When the polymers are matrixed with nanoparticles, they generate sympathetic advanced polymeric materials that can be broadly used in many applications such as food stabilizing systems, energy storage, biotechnology, catalysts, optical devices, microelectronics, and packaging (Tripathy and Sahoo 2017; Hore 2019; Ding et al. 2018; Glogowski et al. 2006; Kalia and Haldorai 2015; Elawwad et al. 2020). In general, the polymeric nanocomposites filled with silica and silicates display extraordinary enhancements in electrical, optical, and mechanical properties. For instance, organic–inorganic nanocomposites exhibited hybrid properties to be used in conducting materials, optical waveguides, and photoelectronic devices (Tommalieh et al. 2011; Seo et al. 2020; Jeon and Baek 2010; Matĕjka and Merhari 2009; Sanchez et al. 2005). Thanks to their excellent thermal stability dielectric, and mechanical properties, polyimides have known as high-temperature polymers that are used for optoelectronic applications (Tsai et al. 2016; Wu et al. 2017; Zha et al. 2020). The transparency of polyimide-silica thin films becomes more perspicuity through enhancing the interaction between the inorganic network and the organic moiety utilizing certain coupling agents of different molecular weights. Accordingly, the covalent bonding between the inorganic and organic moieties increases (Lü and Yang 2009; Tommalieh and Zihlif 2010; Wahab et al. 2003). It was found that increasing the silica content and decreasing the silica particle size enhances the interaction between silica and polyimides without phase separation (Rehman et al. 2006; Al-Kandary et al. 2005).

Polyimides consider one of the thermoplastic polymers, which can be used in high-temperature environments as fire-resistant agents by improving their flame resistance (Ha and Mathews 2011; Mehdipour-Ataei and Tabatabaei-Yazdi 2002; Kim et al. 2021). Polyimides are one of the types of polymers that are particularly suited to the sol–gel technique for the fabrication of nanocomposite materials (Al-Kandary et al. 2006; Ragosta and Musto 2009). Where, polyimides have excellent properties such as mechanical properties, resistance to solvents, thermal and oxidative stability, and high glass transition temperature, and else exceedingly utilized in some electronic and electrical applications (Musto et al. 2004; Haque et al. 2021; Feng and Liu 2018; Hicyilmaz and Bedeloglu 2021). Polyimides nanocomposites based on hybrid inorganic–organic components are classified as novel materials with tailored physical properties (Raman et al. 2012). The sol–gel method has been used to prepare many hybrid polyimide systems, which have nanostructured morphology. Moreover, these nanostructured systems are produced by introducing coupling agents in the precursor solution to generate high adhesion between the polymeric matrix and silica filler (Zhao et al. 2015; Müller et al. 2017; Ali et al. 2021). Consequently, at higher temperature ranges, the polyimides nanocomposites manifested better mechanical properties than micron-composites (Fu et al. 2019, 2008; Cho et al. 2006). Recently, the sol–gel exhibited worthy advantages in the production of polyimide/silica nanocomposites by increasing the interfacial interactions between the polymer and silica, which help in improving the compatibility between them (Rahman and Padavettan 2012; Chruściel and Ślusarski 2003; Zou et al. 2008). Many researchers, for example, Issa and Luyt (2019), Al Arbash et al. (2006), and Máková et al. (2021) have been interested in employing different organosilanes with tetra alkoxysilane to produce a silica network in a polyimide matrix. In the meantime, applications of the polyimide/silica nanocomposites have extended to different fields such as aerospace, photorefractive materials, microelectronics devices, nonlinear optics, photonics fields, and optical guides in addition to optoelectronic (Nouh et al. 2015; Li et al. 2015; Moon et al. 2019).

Although some authors dealt with studying polyimide/mesoporous silica hybrid nanocomposites films or polyimide blends, except that this study reported the prepared films exhibited photonic energy ≥ 3.1 eV in the UV region supporting their strong UV light absorbing tendencies in contrast to visible light and suggesting highly flexible and visibly transparent nanocomposite films for UVA shielding (Subramani et al. 2016). In addition, the addition of silica nanoparticles affected some optical parameters, which significantly contributed to decreasing the band gap (Eg), transmittance, and transparency of prepared films, and increasing refractive index and dielectric constant. Those optical quantities exhibited high values due to the formation of the nanostructured composites, which improved the UV–Vis absorption, optical conductivity, optical transmittance, and reflectance and enhanced the surface properties of films posteriorly offering a wide range of applications (Huang et al. 2021).

Thus, the purposes of this work are (1) synthesis and characterization of polyimide/mesoporous silica hybrid nanocomposites films, (2) studying the effect of nano-silica ratio on the properties of the prepared nanocomposites films, and (3) optimizing the surface energy properties of polyimide films after treating them by different concentrations of silica nanoparticles. In addition, this study was expanded to investigate the suitability of the prepared nanocomposites films for optoelectronic applications.

2 Materials and methods

2.1 Materials

RH was collected from agricultural fields, in Giza, Egypt. Hydrochloric acid (HCl), extra pure with 35% purity and molecular weight of 36.46 g/mol was obtained from Loba Chemie. Sodium hydroxide pellets (NaOH), ACS reagent with assay ≥ 97%, and molecular weight of 39.99 g/mol were obtained from Fisher Scientific. Ammonia solution (NH4OH), AR with 18–20% purity, and molecular weight of 35.05 g/mol were obtained from Loba Chemie. Ethanol solution (C2H5OH), with a purity of 96% and molecular weight of 46.07 was purchased from the Merck group.

2.2 Raw material analysis

Rice waste is an agricultural waste with a high content of amorphous silica. However, the presence of metal ion impurities and unburned carbon may present an adverse effect on product color and purity. In this regard, different extraction techniques were applied to produce high-quality SiO2 NPs. The silica extraction process was carried out under diverse conditions to evaluate the effect of different pretreatments on produced silica; these conditions include different types of acid with varying concentrations and various calcination temperatures. In the present study, silica was produced by the sol–gel method. In the case of the combustion method, the best conditions for pretreatment of rice wastes to produce silica were using HCl in the demineralization process at room temperature and a concentration range of 3 M for rice husk under the temperature of calcination was 800 °C for 1 h. The lower temperatures were found to contain unburned carbon as it was clear from the gray color. The yield of resulted silica was 13%. Table 1 shows the chemical analysis of rice husk. The results of lignin, holocellulose, α-Cellulose, lignin, and hemicelluloses are based on extract-free raw materials.

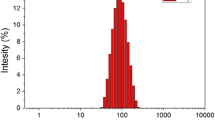

2.3 Preparation of mesoporous silica nanoparticles

Mesoporous silica nanoparticles were obtained from the rice husk ash through the following steps; firstly, the rice husk ash was soaked and washed in distilled water to remove the dust and other soluble organic and inorganic materials. Then, the washed rice husk ash was dried in an oven at 120 °C for 24 h. To remove the carbonate materials from the rice husk ash, the dried rice husk ash was soaked in an acidic solution for 24 h. Afterward, it was washed with distilled water several times to remove the excess acid and then was air-dried for 24 h. The purified rice husk ash was burned in a muffle furnace at 800 °C for 1 h. Following, 2.5 M of NaOH was mixed with 10 g of the burned rice husk ash and was boiled for 4 h followed by a filtration step. Thereafter, 1 g of the filtrate was dissolved in a mixture of (ethanol, H2O, and ammonia solution), and was stirred for 1 h at room temperature. A cationic quaternary ammonium surfactant was added to the above mixture with continuous stirring for 4 h at room temperature. Subsequently, the mixture was left for 48 h to evaporate the solvent and form a gel. Finally, the gel was dried at 600 °C for 2 h to obtain mesoporous silica nanoparticles.

To further check the chemical composition of purified rice husk and the produced mesoporous silica nanoparticles, an ICP analysis was conducted to examine the purity of silica nanoparticles extracted from the rice husk. The analysis of heavy metal species was performed using the inductively coupled plasma-mass spectrometer (X-Series 2 ICP-MS, Thermo Scientific). The contents of metal species in the treated biomass and the yielded silica nanoparticles were given in Table 2. The obtained results showed that the acid treatment helps in reducing the impurities, and has resulted in more pure mesoporous silica nanoparticles.

2.4 Preparation of polyimide/mesoporous silica hybrid nanocomposites films

A polyamic acid (PAA) of poly (pyromellitic dianhydride-co-4, 4´-oxydianiline), amic acid (PM) was supplied by Sigma Aldrich. The PAA-PM is a 15.0–16.0 wt.% solution in N–methyl–2–pyrrolidone (NMP) with a viscosity of 50–70 poise. Dimethylformamide (DMF, ACS reagent, ≥ 99.8%, Merck) was used as a solvent.

1 g of PAA-PM in NMP solution was added to 1 gm of DMF. The mixture was stirred for 1 h, and then they were sonicated for 30 min. Finally, the solution was cast onto soda-lime glass plates and was cured in an oven under the air atmosphere. Imidization was achieved by placing the films in an air oven for three successive 1 h durations, at 100, 200, and 300 °C, respectively.

To prepare polyimide/mesoporous silica hybrid nanocomposites films, 1 g of PAA-PM in NMP solution was added to 1 g of DMF. An appropriate amount of the prepared mesoporous silica nanoparticles according to different molar ratios based on 0, 6, 8, 10, and 12 wt.% was dissolved in 1 g of DMF and mixed with the dissolved PAA-PM in DMF, respectively. The mixture was stirred for 1 h, and then they were sonicated for 30 min. Finally, the solution was cast onto soda-lime glass plates and was cured in an oven under the air atmosphere. Imidization was achieved by placing the films in an air oven for three successive 1 h duration at 100, 200, and 300 °C, respectively. Meanwhile, the silica network formation simultaneously took place with the imidization process. Figure 1 presents a schematic diagram for the preparation process of the polyimide/mesoporous silica hybrid nanocomposites films.

2.5 Characterization of polyimide/mesoporous silica hybrid nanocomposites films

X-ray diffraction analyses were performed on the prepared polyimide/mesoporous silica hybrid nanocomposites films using the Bruker D8 Discover instrument. The X-ray measurements were performed using grazing incidence diffraction (GID) geometry. The prepared films were scanned in a range of 2θ = 5°–80° with a scan speed of 2°/min. Where, the Cu radiation source provided a high-intensity Cu-Kα1 parallel beam with a wavelength of 1.54060 Å and resolution of 1.5 Å under an applied voltage of 40 kV and a current of 40 mA. The morphological structures of prepared film surfaces were investigated for different ratios at various magnifications and acceleration voltage using a scanning electron microscopy (JEOL JXA-840A, Japan) analyzer. The Raman spectroscopy (Horiba labRAM HR evolution visible single spectrometer) was used to obtain the Raman shift spectrum of prepared polyimide/ mesoporous silica hybrid nanocomposites films at room temperature. The instrument was equipped with a He–Cd edge green laser line with a wavelength of 532 nm and a diffraction grating of 1800 gr/mm (450–850 nm) supported by a 25% ND filter and an objective of 50X offering a high throughput diffraction-limited lateral spatial resolution of 0.5 µm and spectral resolution of 1 cm−1. Atomic Force Microscope (AFM, 5600LS, Agilent) was used in non-contact mode to provide 2D and 3D topographic images besides the surface roughness profiles of the prepared polyimide/mesoporous silica hybrid nanocomposites films. The analysis of AFM images and data was carried out using Pico image basics software version 6.2. The optical properties of prepared polyimide/mesoporous silica hybrid nanocomposite films with different silica ratios were obtained using a computerized double-beam ultraviolet–visible spectrophotometer SPECORD 200 PLUS Analytik Jena with 1 nm steps. Attension Theta Topography analyzer by Biolin Scientific, model T200 under the condition of sessile drop recipe, distilled water droplet volume of 4 μm, and measurement time of 10 s was used to study the effect of surface roughness on the contact angle, wettability, and the hydrophilic properties of the prepared polyimide/ mesoporous silica hybrid nanocomposites films. The analyzer was equipped with a manual fine focusing on optics, and software-controlled autofocus. The results were analyzed using OneAttension software including all measurement modes.

3 Results and discussion

3.1 X-Ray analysis

The XRD patterns for the prepared hybrid nanocomposites films were shown in Fig. 2. The XRD pattern for the pure polyimide sample is characterized by a significant barrow. According to the obtained XRD patterns, the prepared silica nanoparticles revealed a partial crystallinity with a predominantly amorphous phase. As silica nanoparticles with different ratios (6–12 wt.%) were incorporated into the polymer matrixes, an amorphous broad peak with Bragg angle at 2θ = 19–21° was obtained for all prepared nanocomposites films, which attributed to the presence of silica nanoparticles. Moreover, another small hump was observed at about 46° probably assigned to the silica nanoparticles. These results are in accordance with the standard pattern of silica in the Standards Joint Committee on Powder Diffraction (JCPDS) database with card number COD#9,000,520. In addition, the corresponding silica pattern confirmed the formation of tridymite silica with monoclinic crystal lattice structure and space group C1c1. These obtained results are in good agreement with other previous studies (Prasetyo et al. 2022; abualnoun et al. 2020; Sun et al. 2017).

The different ratios of mesoporous silica nanoparticles added to the polymer matrixes caused a shift in the positions of both peaks and small humps in the XRD patterns of prepared polyimide/mesoporous silica hybrid nanocomposites films as shown in Fig. 3a, b. Accordingly, the discrepancy between these diffraction angles at 2θ = 19–21° and 2θ = 46° for the differently prepared nanocomposites films with silica ratios (0–12 wt.%) might be ascribed to the difference in the degree of imidization process of the polyimide/mesoporous silica hybrid nanocomposites films blend during the processing of the samples. It could observe that the diffraction peaks of produced films are broadened. This could be described as during the formation of the blend films; a partial rearrangement of the crystalline parts occurs inside the polymer. Thus, when a different ratio of SiO2 nanoparticles is added to polyimide blends, a little shift occurs in the prepared nanocomposites films diffractograms resulting due to masking effect of polyimide films blend matrixes for the small contents of the SiO2 nanoparticles. These results are in good match with the literature (Gaabour 2019; Lee et al. 2009). Moreover, Joly et al. (1999) mentioned that X-ray diffraction shows that the presence of silicon species induces modifications in the microstructure of the polyimide chains. These modifications have been confirmed by a shift in the glass transition temperature and density variations.

As above-mentioned, the position of the peaks and humps observed in patterns of films were shifted. This is due to the presence of mesoporous silica nanoparticles within the polyimide matrix. Lorentz function fitting was used to obtain information about the presented full width at half maximum (FWHM) of the barrow. Figure 4 depicts the relationship between the FWHM values of polyimide/mesoporous silica hybrid nanocomposites films and different ratios of mesoporous silica nanoparticles.

The increases in mesoporous silica nanoparticles ratios from 0 to 10 wt.% causes the gradually decreasing FWHM values. While increasing the silica ratio to 12 wt.%, a rapid increase in the FWHM value occurred. Thus, it could conclude that the XRD peaks of nanocomposite films became narrower indicating that at lower ratios of SiO2 nanoparticles, the SiO2 nanoparticles were covered by polyimide polymer blends and the polymer vacancies did not fully occupy by the SiO2 nanoparticles during the film deposition. Therefore, a probable decrease in the FWHM occurred. On contrary, an increase in FWHM value and peak intensity at the highest ratio of SiO2 nanoparticles indicates that smaller crystallite sizes were formed, which increased the disordered phase inside the obtained hybrid nanocomposites films and indicated a distortion of crystalline structures due to the crosslinking. In general, the peak broadening of the XRD line width could be caused by a variety of factors, including crystallite size, non-uniform strain, and stacking defects. As a result, the distinguishing crystallization process in the structure is thought to be responsible for the increase in XRD line width. Previous studies in the literature mentioned similar results (Kadhim et al. 2015; Ha et al. 2011; Al-Hardan et al. 2010).

3.2 SEM analysis

Figure 5 showed the SEM images of prepared films that depict the divergences in the surface morphologies of polyimide/mesoporous silica hybrid nanocomposites films including different SiO2 nanoparticle ratios. It could be observed that for 6 wt.% of silica ratios, a small amount of mesoporous SiO2 nanoparticles were sprinkled inconsistently in the polyimide matrix. However, there was some interlinkage between mesoporous SiO2 nanoparticles in interrupted regions. On the other hand, with the further increasing addition of mesoporous SiO2 nanoparticles with ratios of 6, 8, 10, and 12 wt.%, it could be seen an intensive distribution of mesoporous SiO2 nanoparticles over the polyimide matrix, and these distributions were homogeneity spread to most regions. In addition, the mesoporous SiO2 nanoparticles became more in contact with each other, which resulted in more efficient optical and electrical properties and decreases in the dielectric constant of the hybrid nanocomposite films. Meanwhile, it could be observed that as the silica content in the polyimide matrix increased, slight agglomeration among the nanoparticles occurred, while the overall dispersion of SiO2 nanoparticles in the polyimide matrix was still better. Moreover, in the SEM image of 12 wt.% films, the silica nanoparticles are entirely aggregate, leading to phase separation between the nanoparticles and the polyimide matrix, resulting in the generation of pores in the film and, subsequently, producing a deterioration in the mechanical properties of the film (Huang et al. 2022). In addition, the corresponding EDS spectrum of 12 wt.% ratios confirmed the chemical composition of the prepared films, where the spectrum demonstrated the major presence of Si and O elements in the prepared film.

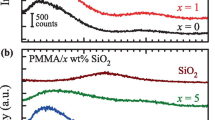

3.3 Raman analysis

The Raman spectra of polyimide and hybrid composite films are displayed in Fig. 6a and the related enlarged graph (Fig. 6b). The characteristic absorption bands and the corresponding chemical bonds are present in Table 3. Both hybrid samples and polyimide films exhibit the distinctive imide group peaks at 1780 and 1711 cm−1 (asymmetric and symmetric C=O stretching vibrations, imide I), 1460 cm−1 (aromatic C=C stretch), 1368 cm−1 (C–N–C axial vibration, imide II), 1092, and 730 cm−1 (C–N–C transverse vibration, imide III). The peak at 1711 cm−1 is attributed to the imide group, and the peak at 1780 cm−1 represents the cyclic five-membered ring that confirmed the imide formation. While the bands at 1368, 1092, and 730 cm−1 are assigned to the C–N–C bond and the imide ring deformation. The bands at 1502 and 830 cm−1 represented C6H4 and Si–O–Si, respectively. The band at 1173 cm−1 refers to C6H4 or C6H2. The peak at 677 cm−1 originated from C–C=O in-plane swing vibration. Raman spectra confirmed the succeeded imidization of polyimide films via disappearing the band at 1650 cm−1 and the expansion of the imide group at 1711 cm−1. This observation showed a good agreement with the earlier studies (Ma et al. 2016; Gao and Holmes 2004). The sharp band near 1080 cm−1 and the appearance of peaks at 633, 541, 500, and 475 cm−1 induced by the existence of the Si–O–Si bond indicate that the mesoporous silica nanoparticles have been successfully incorporated into the hybrid composites films. As can be observed in the enlarged spectra, these peaks became much stronger and increased with increasing ratios of the mesoporous silica. While the peaks in the range of 50–200 cm−1 reflect the absence of the imide II and aromatic C=C stretch bands suggesting the cleavage of C–N and C=C bonds and the polyimide molecules were disintegrated in friction. The variation in relative intensity of these bands reflects their re-orientation concerning the phenyl ring in the imide structure, which is related to polyimide friction and wear. These observations showed a good agreement with the earlier studies (Martínez-Gómez et al. 2015; Yang et al. 2013).

3.4 Polyimide/mesoporous silica films surface morphology

The AFM was used to investigate the effects of mesoporous silica nanoparticles incorporation on polyimide surface morphology. In comparison to pure polyimide, the typical peak-and-valley structure of polyimide morphology was smoothened by the incorporation of mesoporous silica nanoparticles, as shown in Fig. 7. Mesoporous silica nanoparticles were also observed on the surface of polyimide films. The AFM images show that the fluorinated silica nanoparticles were thoroughly embedded in the polyimide layers. Moreover, the surface morphology of the polyimide film with 0 wt.% of SiO2 NPs has the same homogeneity with flakes-like bumps. While for the hybrid polyimide nanocomposites with 6, 8, 10, and 12% wt.% SiO2 NPs, the surface morphology of prepared films began to vary. Where the films seemed smoother with little gulfs and meander on the surface. In addition, gradually increasing of ratios silica nanoparticles helped fill the gaps and gave a more crowded surface with regular stacking. Where the embedded silica nanoparticles appeared clearly on the surface of films at the ratios of 10 and 12 wt.%. Generally, the AFM results demonstrated that the surface of polyimide films has improved with the addition of silica nanoparticles, which can be due to charge accumulation, as well as the surface partial charge.

The 3D AFM images of the prepared films are presented in Fig. 8. The images further showed the homogenous distribution of silica nanoparticles throughout the polyimide films and could easily observe the little agglomeration of silica nanoparticles with increasing silica ratios.

The surface roughness of polyimide/mesoporous silica hybrid nanocomposites films was also assessed (Fig. 9). It was found that the total height roughness (Rt) of polyimide film with 0.12% (w/v) silica nanoparticles decreased from 86.5 to 2.14 nm. Accordingly, could conclude that the addition of silica nanoparticles smoothed the peak-and-valley structure of the surface morphology, and subsequently, the surface area dropped as the roughness decreased.

These results are well-matched with the previous study by Chang and Chen (2002). Where they reported that for the SP system, the mean square roughness ranged from 0.26 to 0.34 nm, while for the SF hybrid thin films, it was between 0.28 and 0.30 nm. The mean square roughness of these systems is less than that of the model polyimide thin films (0.63 for PMDA-ODA and 0.41 for 6FDA-ODA), which confirms the excellent planarity of the prepared hybrid thin films. Consequently, the produced polyimide-silica hybrid thin films are expected to produce good optical waveguides because low roughness reduces the surface scattering loss at the waveguide surface.

3.5 Optical properties of polyimide/mesoporous silica hybrid nanocomposites films

3.5.1 UV–Vis absorption

Figure 10a shows the absorbance of polyimide/mesoporous silica hybrid nanocomposites films as a function of the wavelength (λ). It is worth noting that as the silica ratio rises, the absorbance rises because of the increased number of light-absorbing molecules. A wide absorption peak may see in the wavelength range of 430–450 nm. The surface plasmon resonance (SPR) of silica nanoparticles causes the oscillation of free conduction electrons to increase under the influence of the electromagnetic field, resulting in this broad peak. Besides, Fig. 10a demonstrates how the absorption edge in the visible region shifts towards longer wavelengths (red shift) as silica nanoparticles are added to thin films. Where the shift in absorption edge was increased from (λ ≈ 636 nm) to (λ ≈ 744 nm) for 0 wt.% (SiO2 NPs) and 10 wt.% (SiO2 NPs), respectively. This could be attributed to several parameters including the increase in vacancies, an increase in disorder, an increase in grain size and atom agglomerations, and the rearrangement of film constituents.

Furthermore, the absorption coefficient should be studied to investigate the occurrence of any alterations in the band structure. The absorption coefficient (α) expresses the quantified absorption of light by the optical medium. This is defined as the fraction of energy absorbed per unit length of medium (Aziz et al. 2017). The absorption coefficient (α(λ)) was estimated from the absorption data using the following relation (Afroze and Bhuiyan 2013):

where (A) is absorbance and (d) is the thickness of thin films.

The absorption coefficient (α(λ)) of produced films with different SiO2 nanoparticle ratios (0, 6, 8, 10, 12 wt.%) as a function of photon energy (hυ) is shown in Fig. 10b. It could observe that the increasing addition of silica nanoparticle ratios shifted the absorption edge of polyimide/mesoporous silica hybrid nanocomposites films to lower photon energy. This shift in photon energy from 1.76 to 1.22 eV suggests the shrinking of optical band gaps of the nanocomposite films. Likewise, in a previous study, Alsaad et al. (2020) reported that by the addition of 2%, 4%, and 8% SiO2 NPs concentrations to the polymer solution, α increase to 0.00032, 0.00033, and 0.000355, respectively. Interestingly, α increase considerably to 0.00038, as SiO2 NPs concentration increases to 16%. It retains almost constant value in the visible spectrum region as the content of SiO2 NPs increase constantly. As a result, (PMMA-PVA)/SiO2 NPs nanocomposite thin films may act as light filters for the entire range of visible regions with constant partial absorption depending on the concentration of SiO2 NPs.

However, the produced nanocomposite films had a maximum absorption coefficient in the UV range with photonic energy of 3.1 eV. The strong ability to absorb all UV subtypes (UVA, UVB, and UVC) was confirmed by the sharp absorption coefficient for polyimide/mesoporous silica hybrid nanocomposites films at photon energy 3.1 eV, which opens the door for using our prepared hybrid nanocomposites films in many optoelectronic applications such as UV shielding films. Whereas Knežević et al. (2018) studied the ability of mesoporous silica and organosilica nanomaterials as UV-blocking materials and they concluded that the MSN and PMO materials concerning their potential for skin protection from the UVA/UVB sun irradiation exhibited to be promising sunscreen agents.

3.5.2 Optical energy band gap

Tauc's relation was used to calculate the direct optical band gap (Mir et al. 2014):

where A is a constant, Eg is the material band gap, and n is the transition type's exponent. Direct transitions are allowed; n = 1/2, indirect transitions are allowed; n = 2, direct transitions are forbidden; n = 3/2, and indirect transitions are forbidden; n = 3. Figure 11 depicted the relationship between (αhv)2 and (hv) for all prepared hybrid nanocomposites films and Table 4 shows the Eg values that were calculated.

The data clearly shows that raising the silica percentage inside the hybrid nanocomposites films lowers the Eg values. The energy states between the valence and conduction bands altered due to changing the silica ratios. Additionally, increasing the silica ratios aids in the integration of mesoporous silica nanoparticles into the polymer matrix, resulting in the development of localized electronic states in the optical band gap, which acts as trapping centers.

3.5.3 Optical transmittance and reflectance

Figures 12 a, b demonstrate the optical transmittance T percent and reflectance R percent of the developed hybrid nanocomposites films . As shown in Fig. 12a, the optical clarity of polyimide films is affected by silica nanofillers. Subsequently, increasing the ratio of mesoporous silica nanoparticles leads to a decrease in the transmittance of polyimide films. This is because silica nanofillers increase the density of localized states, which reduces transmittance. While the reflectance of the developed hybrid nanocomposites films increases as the wavelength range increases, as shown in Fig. 12b.

3.5.4 Refractive indices and extinction coefficient

The refractive index (n) and the extinction coefficient are the most essential factors in optoelectronics (k). Figures 13 and 14 show the fluctuations of n and k for polyimide/mesoporous silica hybrid nanocomposites films as a function of photon energy (a, b). Based on the following relationship, the refractive index (n) could be calculated from the reflectance (R) and absorption coefficient (Hassanien and Akl 2018; Mistrik et al. 2017):

The refractive index of all samples increases with photon energy, as shown in Fig. 13a. Furthermore, as the silica ratio increases, the refractive index increases. This is due to a decrease in the polymer matrix's interatomic spacing, which leads to an increase in the density of hybrid nanocomposite film as the silica ratio increases. In addition, the formation of new energy states is evidenced by the increase in refractive index, and consequently, a decrease in the energy bandgap of polyimide blends is observed with the addition of various silica nanoparticle ratios. The following equation could be used to compute the extinction coefficient (k), which relates to the amount of energy lost inside the material (Nofal et al. 2021):

The value of k is decreased by photon energy, and the k value is increased by raising the silica ratio, as shown in Fig. 13b. This is owing to an increase in the density of the hybrid nanocomposite film due to higher silica ratios, which enhances the absorption coefficient.

The capacity of the generated hybrid nanocomposite films for UV shielding applications is confirmed by raising k values in the UV range, as their transparency in the UV range is lowered and the absorption coefficient is increased by increasing the silica ratio.

Moreover, it could observe the appearance of two peaks at wavelengths of λ ≈ 370 nm and λ ≈ 810 nm in Figs. 10 and 12 for all prepared polyimide/mesoporous silica hybrid nanocomposites films with 0, 6, 8, 10, and 12 wt.% ratios of silica nanoparticles. It is expected that these peaks are mainly designated to the polyimide blend, which was found in the polymer film in the absence of silica nanoparticles (0 wt.%), however, the addition of silica nanoparticles may be contributed to appearing of these peaks. This may be attributed to that the optical transparency and colorlessness of the polyimides are influenced by intramolecular conjugation and intermolecular charge transfer (CT) complex formation. It is expected that the incorporation of the aliphatic unit in the polyimide backbone results in reduced conjugation and CT complex formation (Yu et al. 2015). Thus, it was expected that the iso-propylidene group and phthalic ether groups present in dianhydride and diamine moieties were effective in decreasing the charge-transfer complex between polymer backbone chains through steric hindrance leading to an increase in the intermolecular distance and thus decreased the interaction between the polyimide chains resulting in a fluctuated transparency (Dhakshnamoorthy et al. 2012). Consequently, the two absorption peaks may be correlated with the electronic transition occurring in the imide group (NC = O). It is well known that the compounds with oxygen and nitrogen, containing non-bonding electrons can show these types of characteristic absorptions (Virk et al. 2001).

On the other hand, the increasing feed ratio of SiO2 NPs resulted in films with higher transparency. This is probably because the bulky SiO2 NPs are helpful for the disruption of charge transfer between polyimide chains, which is assumed responsible for the usually deep color of polyimide film. Where the polyimide film has an intrinsically yellowish coloration problem related to the diimide fragment conjugation as a liquid crystal alignment layer (Ju et al. 2017). Besides, the silane group of SiO2 NPs cage is strongly electron-withdrawing because the silanes group easily forms covalent bonds making SiO2 NPs weaken the electron-donating ability of the diamines and suppressing the intermolecular charge-transfer complexing (CTC) between alternating electron donor (diamine residue) and electron acceptor (dianhydride residue) moieties (Deng et al. 2018).

Another reason is due to the strong intermolecular interactions and charge transfer complex (CTC) of aromatic polyimides, aromatic polyimides exhibited strong absorption between the UV and visible area (Deng et al. 2018). However, the introduction of SiO2 NPs increased the steric hindrance, thereby reducing the formation of transfer complexes and disrupting the structural integrity of the chain. Consequently, the introduction of SiO2 NPs improved the transparency of the polyimide. Where the electron-withdrawing effect of SiO2 NPs slightly influences the charge transfer of imide groups.

3.5.5 Optical dielectric constant

Because the optical dielectric constant is so crucial in real-world applications like optical device design and optical communications. Therefore, based on the following relationships, we will use the acquired values of n and k to research and analyze the complex dielectric constant (ε* = εr + εi) for all created hybrid nanocomposites films (Ren et al. 2000):

where εr and εi represented the real and imaginary dielectric constants, respectively. Figures 14a, b illustrate the εr and εi as a function of photon energy.

As demonstrated in the picture, raising the silica ratio raises the r and I values. These findings show that raising the silica ratio increases the energy density of stats, which leads to an increase in the polarization process and a greater dielectric constant. The direct relationship between the I and k spectra is revealed by their form constancy. As can be observed in the image, I spectra in the UV region are moved to lower photon energy, indicating that increasing charge carrier concentration reduces optical relaxation time.

Accordingly, the longer absorption bands for the polyimide copolymer systems could attribute to the intramolecular charge transfer between donors and acceptor moieties in the polymer network. Therefore, the polyimide copolymer of pyromellitic dianhydride absorbs and emits light with different energies exhibiting multiple absorption bands. These multi bands absorption and emission peaks may be due to the presence of many aryl substituents (Hariharan et al. 2018). In general, pyromellitic dianhydride-co-4, 4´-oxydianiline, and N-methyl-2-pyrrolidone-based systems show a strong multi-absorption band due to conjugation of poly aryl molecule π–π* transition, thus the corresponding polyimide also possess a strong multi absorption and a red-shift due to the influence of aryl-substituted. Nevertheless, these polymers have a small absorption n-π* transition for the carbonyl (C=O) and imine (N=C) groups. Consequently, this may explain the appearance of signals at 1.5 eV and 3.2 eV in the spectrums of Figs. 13, 14, and 17.

3.5.6 Optical dispersion constants

The refractive index dispersion is one of the most significant parameters to consider when designing optical devices and optical communications applications. As a result, in this section, we will utilize the Wemple-DiDomenico (W-D), single oscillator model, to find the dispersion parameters according to the following relationship (Yakuphanoglu et al. 2004):

where E0 is the oscillator energy and Ed is the dispersion energy.

The Eo and Ed can be calculated from the slope and intercept of the relationship between (n2−1)−1 and (hυ)2, as illustrated in Fig. 15a. Table 4 shows that Eo has the same dependence as Eg, which can be determined using Tauc's relation. As indicated in the table, raising the gelatin ratio increases Eo, whereas increasing the silica ratio decreases it. This could be because increasing γ-dose causes a rise in the HOMO–LUMO gap's localized electronic states, which enhances the low energy transition and lowers the value of Eo.

The relation between the lattice dielectric constant εL and the refractive index n is given by Gadallah and El-Nahass (2013):

The carrier concentration to effective mass ratio is N/m*, c is the speed of light, and e is the electron charge. The value of εL is calculated by extrapolating n2−λ2 plots to λ2 = 0 and N/m* from the slope (Fig. 15b). Table 4 shows that increasing the silica ratio increases εL and N/m*. This means that as the silica ratio is increased, the number of free charge carriers in the polyimide/mesoporous silica hybrid nanocomposites films increases.

3.5.7 Optical conductivity

Using the provided values of α and n, the optical conductivity of polyimide/mesoporous silica hybrid nanocomposites films can be calculated (Al-Ghamdi et al. 2021):

where c is the light velocity in space.

Figure 16 shows the optical conductivity as a function of photon energy. The figure shows that as the photon energy is raised, σopt increases for all samples due to increased electron excitation. It's also worth noting that increasing the γ-dose raises the optical conductivity. Thus, increasing the number of free charge carriers in the generated polyimide/mesoporous silica hybrid nanocomposites films by increasing mesoporous silica nanoparticles causes an increase in σopt with increasing silica ratio.

Quantitative optical parameter measurements for polyimide/mesoporous silica hybrid nanocomposite films could be useful in the future.

3.5.8 Volume and surface energy loss function

The real and imaginary components 1 and 2 of the complex dielectric constant are related to the volume energy loss function (VELF) and the surface energy loss function (SELF). The SELF and VELF dropped as the incident photon energy increased, as shown in Fig. 17a, b. Furthermore, at any incident photon energies, the volume energy loss is greater than the surface energy loss, showing that the excitation of plasma oscillation in the bulk of polyimide nanocomposite films is greater than that on its surface.

The absorption coefficient, extinction coefficient, optical reflectance, dielectric constant, SELF, VELF, and refractive index of the polyimide/mesoporous silica hybrid nanocomposite films indicate that they are appropriate for the development of various photonic devices.

3.6 Surface energy properties

Due to their benefits in various applications, industrial engineering materials attract a lot of scientific and industrial interest. For optics, tribology, and corrosion/wear applications, high compactness and low porosity are the most important microstructure features. The interaction of the employed materials with water is thought to be the most important cause of the mechanical and electrical properties of industrial engineering materials becoming compromised. Because of its fundamental importance in various domains and practical value in biological and high-tech applications such as coatings, cleaning, drying, and adhesion, the wetting phenomena of a water droplet on a rough surface has been intensively investigated for a long time. At the macroscopic scale, wetting phenomena are well recognized, but they can also occur at the nanoscale. The use of oblique angle deposition (OAD) thin films incorporated into ultrasonic devices or complicated photonic structures generated by stacking thin film layers with varied refractive indices have also aided detection in liquid media. The surface tensions between the three phases (solid, liquid, and gas) could be explained in the case of three phases (solid, liquid, and gas) (see Fig. 18):

The angle at which the liquid–vapor interface meets the solid–liquid interface is known as the contact angle (θC). A drop will assume a wide range of contact angles, from the so-called advancing contact angle (θA) to the so-called receding contact angle (θR), even on a completely smooth surface. The equilibrium contact angle (θC) can be computed using the following formula (Thabet and Ebnalwaled 2017):

where,

The pH value affects the contact angle of polyimide/mesoporous silica hybrid nanocomposites films, as shown in Fig. 19a. The concentration of the utilized nanofillers also affects the contact angle of polyimide/mesoporous silica hybrid nanocomposite films. When silica nanoparticles are inserted into the polyimide matrix, the surface changes from hydrophobic to hydrophilic for all pH values.

Figure 19b shows how the concentrations of nanofillers affect the wetting energy of polyimide/mesoporous silica hybrid nanocomposites films. The wettability of polyimide/mesoporous silica hybrid nanocomposite films is improved by increasing the ratio of silica nanofillers for all pH values.

The acquired results are because including silica nanofillers into the polyimide matrix causes the formation of many hydrophilic species, which improves the wettability of polyimide nanocomposites films. Furthermore, increasing pH values improve the wettability of polyimide/mesoporous silica hybrid nanocomposites films by forming more hydrogen bonds between the used water and the polyimide/mesoporous silica hybrid nanocomposites films, resulting in increased dipole/dipole interactions and thus improved wettability.

Figures 19 and 20 show the relationship between the spreading coefficient and work of adhesion for polyimide/mesoporous silica hybrid nanocomposites films (c, d). The silica nanofillers improved the spreading coefficient and adhesion work of polyimide/mesoporous silica hybrid nanocomposites films, as indicated in the figures. The key causes for these outcomes were surface roughness and molecular interactions.

Based on the above-mentioned results, it is possible to conclude that using nanotechnology to improve the surface energy attributes for polyimide materials is a viable option. The contact angles, energy, and attraction forces of nanocomposite surfaces were all controlled by the concentrations of mesoporous silica nanoparticles. As a result, the polyimide/mesoporous silica hybrid nanocomposite films could be beneficial for electrical plastic gloves, safety shoes, water pipelines, underground electrical cable sheathing, cable ducts, and other electrical components.

4 Conclusion

Optoelectronic properties of a set of hybrid nanocomposite films of polyimide polymer (matrix) and mesoporous silica nanoparticles (filler) that were prepared via a green sol–gel process were investigated. The films were fabricated with different ratios of mesoporous silica nanoparticle content concentrations; (0, 6, 8, 10, and 12%). Several characterization instruments were used to inspect the crystalline, morphological, spectroscopic, and surface properties of the prepared films. It was found that the prepared films exhibited photonic energy ≥ 3.1 eV in the UV region. Moreover, many optical parameters have been affected by the ratio of included mesoporous silica nanoparticles, where the band gap (Eg), transmittance, and transparency values of prepared films were decreased with increases in nano-silica ratios. On contrary, the increase of nano-silica content enhanced the refractive index, extinction coefficient dielectric, imaginary dielectric constants values, and free charge carrier concentrations for the prepared films, which subsequently resulted in improvements in their optical conductivity. Moreover, the different content of nano-silica has modified the surface structure of the prepared polyimide/mesoporous silica hybrid nanocomposite films giving the prepared films many different properties. Where the prepared films became more hydrophilic surface. Accordingly, the wettability, spreading coefficient, and adhesion work at a wide range of pH values was boosted for all the prepared polyimide/mesoporous silica hybrid nanocomposites films.

References

Abualnoun, Ajeel, S.K., Sukkar, A.N., Zedin, K.: Extraction of high purity amorphous silica from rice husk by chemical process. IOP Conf. Ser. Mater. Sci. Eng. (2020). https://doi.org/10.1088/1757-899X/881/1/012096

Afroze, T., Bhuiyan, A.: Effect of heat treatment on the structural and optical characteristics of plasma deposited 2-(diethylamino) ethyl methacrylate thin films by a capacitively coupled glow discharge plasma system. Phys. Scr. 88(4), 045502 (2013). https://doi.org/10.1088/0031-8949/88/04/045502

Al Arbash, A., Ahmad, Z., Al-Sagheer, F., Ali, A.: Microstructure and thermomechanical properties of polyimide-silica nanocomposites. J. Nanomater. (2006). https://doi.org/10.1155/JNM/2006/58648

Al-Ghamdi, H., Almuqrin, A.H., Koubisy, M., Mahmoud, K., Sayyed, M., Darwish, M., Henaish, A.: Zinc-lead-borate glasses doped with dysprosium oxide: Structure, optical, and radiation shielding features. Optik 246, 167765 (2021). https://doi.org/10.1016/j.ijleo.2021.167765

Al-Hardan, N., Abdullah, M., Aziz, A.A., Ahmad, H., Rashid, M.: The effect of oxygen ratio on the crystallography and optical emission properties of reactive RF sputtered ZnO films. Phys. B Condens. Matter 405(4), 1081–1085 (2010). https://doi.org/10.1016/j.physb.2009.11.006

Ali, N., Ali, F., Saeed, S., Said, A., Sheikh, Z.A., Salman, S.M., Bilal, M.: Synthesis and physicochemical investigation of imide-functionalized silica nanocomposites. J. Appl. Polym. Sci. 138(24), 50646 (2021). https://doi.org/10.1002/app.50646

Al-Kandary, S., Ali, A., Ahmad, Z.: Morphology and thermo-mechanical properties of compatibilized polyimide-silica nanocomposites. J. Appl. Polym. Sci. 98(6), 2521–2531 (2005). https://doi.org/10.1002/app.22233

Al-Kandary, S., Ali, A., Ahmad, Z.: New polyimide-silica nano-composites from the sol-gel process using organically-modified silica network structure. J. Mater. Sci. 41(10), 2907–2914 (2006). https://doi.org/10.1007/s10853-005-5123-5

Alsaad, A.A., Ahmad, A.R., Al Dairy, A.S., Al-anbar, Q.M., Al-Bataineh: Spectroscopic characterization of optical and thermal properties of (PMMA-PVA) hybrid thin films doped with SiO2 nanoparticles. Res. Phys. 19, 103463 (2020). https://doi.org/10.1016/j.rinp.2020.103463

Aziz, S.B., Omed, G., Abdullah, A.M., Hussein, R.T., Abdulwahid, M.A., Rasheed, H.M., Ahmed, S.W., Abdalqadir, A., Mohammed, R.: Optical properties of pure and doped PVA: PEO based solid polymer blend electrolytes: two methods for band gap study. J. Mater. Sci. Mater. Electron. 28(10), 7473–7479 (2017). https://doi.org/10.1007/s10854-017-6437-1

Chang, C.-C., Chen, W.-C.: Synthesis and optical properties of polyimide-silica hybrid thin films. Chem. Mater. 14(10), 4242–4248 (2002). https://doi.org/10.1021/cm0202310

Cho, J., Joshi, M., Sun, C.: Effect of inclusion size on mechanical properties of polymeric composites with micro and nano particles. Compos. Sci. Technol. 66(13), 1941–1952 (2006). https://doi.org/10.1016/j.compscitech.2005.12.028

Chruściel, J., Ślusarski, L.: Synthesis of nanosilica by the sol-gel method and its activity toward polymers. Mater. Sci. 21(4), 461–469 (2003)

Deng, B., Zhang, S., Liu, C., Li, W., Zhang, X., Wei, H., Gong, C.: Synthesis and properties of soluble aromatic polyimides from novel 4, 5-diazafluorene-containing dianhydride. Rsc Adv. 8(1), 194–205 (2018). https://doi.org/10.1039/C7RA12101F

Dhakshnamoorthy, M., Vikram, S., Vasanthakumari, R.: Development of flexible low dielectric constant polyimide films based on iso-propylidene, aryl-ether linked dianhydride/diamine. Int. J. Sci. Eng. Res 3, 2229–2234 (2012)

Ding, Y., Chen, Y., Zheng, J.: Dispersion of nanoparticles in polymer matrices with well-designed ligands as dispersant/emulsifier/comonomer. Compos. Sci. Technol. 156, 215–222 (2018). https://doi.org/10.1016/j.compscitech.2018.01.011

Elawwad, A., Ragab, M., Hamdy, A., Husein, D.Z.: Enhancing the performance of microbial desalination cells using δMnO2/graphene nanocomposite as a cathode catalyst. J. Water Reuse Desalinat. 10(3), 214–226 (2020). https://doi.org/10.2166/wrd.2020.011

Feng, X., Liu, J.: Thermoplastic Polyimide (TPI). High Perform. Polym. Their Nanocompos. (2018). https://doi.org/10.1002/9781119363910.ch6

Fu, S., Sun, Z., Huang, P., Li, Y., Hu, N.: Some basic aspects of polymer nanocomposites: a critical review. Nano Mater. Sci. 1(1), 2–30 (2019). https://doi.org/10.1016/j.nanoms.2019.02.006

Fu, S.-Y., Feng, X.-Q., Lauke, B., Mai, Y.-W.: Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. B Eng. 39(6), 933–961 (2008). https://doi.org/10.1016/j.compositesb.2008.01.002

Gaabour, L.H.: Influence of silica nanoparticles incorporated with chitosan/polyacrylamide polymer nanocomposites. J. Mater. Res. Technol. 8(2), 2157–2163 (2019). https://doi.org/10.1016/j.jmrt.2019.02.003

Gadallah, A.-S., El-Nahass, M.: Structural, optical constants and photoluminescence of ZnO thin films grown by sol-gel spin coating. Adv. Condens. Matter Phys. (2013). https://doi.org/10.1155/2013/234546

Gao, S., A., S., Holmes.: Surface enhanced Raman spectroscopy for non-destructive analysis of surfaces following excimer laser removal of polyimide. 2004 IEEE/SEMI Advanced Semiconductor Manufacturing Conference and Workshop (IEEE Cat. No. 04CH37530), IEEE (2004). https://doi.org/10.1109/ASMC.2004.1309620

Glogowski, E., Tangirala, R., Russell, T.P., Emrick, T.: Functionalization of nanoparticles for dispersion in polymers and assembly in fluids. J. Polym. Sci. Part A Polym. Chem. 44(17), 5076–5086 (2006). https://doi.org/10.1002/pola

Ha, C.-S., Mathews, A.S.: Polyimides and High Performance Organic Polymers. In: Advanced Functional Materials. Springer, pp 1–36 (2011). https://doi.org/10.1007/978-3-642-19077-3_1

Ha, T.-J., Im, S.-J., Yoon, H.W., Jang, H.-H., Park: Pore structure control of ordered mesoporous silica film using mixed surfactants. J. Nanomater. (2011). https://doi.org/10.1155/2011/326472

Hamdy, A., Ismail, S.H., Ebnalwaled, A., Mohamed, G.G.: Characterization of superparamagnetic/monodisperse PEG-coated magnetite nanoparticles sonochemically prepared from the hematite Ore for Cd(II) removal from aqueous solutions. J. Inorg. Organomet. Polym Mater. 31(1), 397–414 (2021). https://doi.org/10.1007/s10904-020-01741-0

Hariharan, A., Kumar, S., Alagar, M., Dinakaran, K., Subramanian, K.: Synthesis, photophysical and electrochemical properties of polyimides of tetraaryl imidazole. Polym. Bull. 75(1), 93–107 (2018). https://doi.org/10.1007/s00289-017-2015-1

Haque, S., Ardila-Rey, J.A., Umar, Y., Masud, A.A., Muhammad-Sukki, F., Jume, B.H., Rahman, H., Bani, N.A.: Application and suitability of polymeric materials as insulators in electrical equipment. Energies 14(10), 2758 (2021). https://doi.org/10.3390/en14102758

Hassanien, A.S., Akl, A.A.: Optical characteristics of iron oxide thin films prepared by spray pyrolysis technique at different substrate temperatures. Appl. Phys. A 124(11), 1–16 (2018). https://doi.org/10.1007/s00339-018-2180-6

Hicyilmaz, A.S., Bedeloglu, A.C.: Applications of polyimide coatings: a review. SN Appl. Sci. 3(3), 1–22 (2021). https://doi.org/10.1007/s42452-021-04362-5

Ju, C., Kim, T., Kang, H.: Liquid crystal alignment behaviors on capsaicin substituted polystyrene films. RSC Adv. 7(66), 41376–41383 (2017). https://doi.org/10.1039/C7RA08321A

Knežević, N.Z., Ilić, N., Dokić, V., Petrović, R., Janaćković, D. (2018). Mesoporous silica and organosilica nanomaterials as UV-blocking agents. ACS Appl. Mater. Interfaces 10(24), 20231–20236. https://doi.org/10.1021/acsami.8b04635

Hore, M.J.: Polymers on nanoparticles: structure & dynamics. Soft Matter 15(6), 1120–1134 (2019). https://doi.org/10.1039/c8sm02110d

Huang, B., Li, K., Peng, M., Cheng, J.: Polyimide/fluorinated silica composite films with low dielectric constant and low water absorption. High Perform. Polym. 34(4), 434–443 (2022). https://doi.org/10.1177/09540083211073657

Huang, J., Zhang, G., Dong, B., Liu, J.: Synthesis and properties of polyimide silica nanocomposite film with high transparent and radiation resistance. Nanomaterials 11(3), 562 (2021). https://doi.org/10.3390/nano11030562

Issa, A.A., Luyt, A.S.: Kinetics of alkoxysilanes and organoalkoxysilanes polymerization: a review. Polymers 11(3), 537 (2019). https://doi.org/10.3390/polym11030537

Jeevanandam, J., Barhoum, A., Chan, Y.S., Dufresne, A., Danquah, M.K.: Review on nanoparticles and nanostructured materials: history, sources, toxicity and regulations. Beilstein J. Nanotechnol. 9(1), 1050–1074 (2018). https://doi.org/10.3762/bjnano.9.98

Jeon, I.-Y., Baek, J.-B.: Nanocomposites derived from polymers and inorganic nanoparticles. Materials. 3(6), 3654–3674 (2010). https://doi.org/10.3390/ma3063654

Joly, C., Smaihi, M., Porcar, L., Noble, R.: Polyimide-Silica composite materials: how does silica influence their microstructure and gas permeation properties? Chem. Mater. 11(9), 2331–2338 (1999). https://doi.org/10.1021/cm9805018

Kadhim, F., Chiad, J.B.T., Ali, N.A., Odah, J.F.: Synthesis and spectroscopic properties of silica nanoparticles as scatter centers in random gain porous media. J. Sol-Gel Sci. Technol. 75(2), 247–254 (2015). https://doi.org/10.1007/s10971-015-3740-2

Kalia, S., Haldorai, Y.: Organic-inorganic hybrid nanomaterials, vol. 267. Springer, Berlin (2015). https://doi.org/10.1007/978-3-319-13593-9

Kim, Y., Lee, S., Yoon, H.: Fire-safe polymer composites: flame-retardant effect of nanofillers. Polymers 13(4), 540 (2021). https://doi.org/10.3390/polym13040540

Lee, T., Park, S.S., Jung, Y., Han, S., Han, D., Kim, I., Ha, C.-S.: Preparation and characterization of polyimide/mesoporous silica hybrid nanocomposites based on water-soluble poly (amic acid) ammonium salt. Eur. Polym. J. 45(1), 19–29 (2009). https://doi.org/10.1016/j.eurpolymj.2008.09.022

Li, S., Meng Lin, M., Toprak, M.S., Kim, D.K., Muhammed, M.: Nanocomposites of polymer and inorganic nanoparticles for optical and magnetic applications. Nano Rev. 1(1), 5214 (2010). https://doi.org/10.3402/nano.v1i0.5214

Li, X., Zou, H., Liu, P.: Structure and dielectric properties of polyimide/silica nanocomposite nanofoam prepared by solid-state foaming. J. Appl. Polym. Sci. (2015). https://doi.org/10.1002/app.42355

Lü, C., Yang, B.: High refractive index organic–inorganic nanocomposites: design, synthesis and application. J. Mater. Chem. 19(19), 2884–2901 (2009). https://doi.org/10.1039/b816254a

Ma, J., Qi, X., Zhao, Y., Dong, Y., Song, L., Zhang, Q., Yang, Y.: Polyimide/mesoporous silica nanocomposites: characterization of mechanical and thermal properties and tribochemistry in dry sliding condition. Mater. Des. 108, 538–550 (2016). https://doi.org/10.1016/j.matdes.2016.07.036

Máková, V., Holubová, B., Krabicová, I., Kulhánková, J., Řezanka, M.: Hybrid organosilane fibrous materials and their contribution to modern science. Polymer (2021). https://doi.org/10.1016/j.polymer.2021.123862

Matĕjka, L., Merhari, L.: Hybrid nanocomposites for nanotechnology: electronic. Opt. Magn. Biomed. Appl. (2009). https://doi.org/10.1007/978-0-387-30428-1

Matĕjka, L., Merhari, L.: Hybrid nanocomposites for nanotechnology: electronic. Opt. Magn. Biomed. Appl. (2009). https://doi.org/10.1007/978-0-387-30428-1

Mehdipour-Ataei, S., Tabatabaei-Yazdi, Z.: Heat Resistant polymers. Encycl. Polym. Sci. Technol (2002). https://doi.org/10.1002/0471440264.pst636

Mir, F.A., Rehman, U., Asokan, S., Khan, K., Bhat, G.S.: Optical, DC and AC electrical investigations of 4-hydroxy coumarin molecule as an organic Schottky diode. J. Mater. Sci. Mater. Electron. 25(3), 1258–1263 (2014). https://doi.org/10.1007/s10854-014-1718-4

Mistrik, J., Kasap, S., Ruda, H.E., Koughia, C., Singh, J.: Optical properties of electronic materials: fundamentals and characterization. In: Springer Handbook of Electronic and Photonic Materials. Springer, pp 1–1 (2017). https://doi.org/10.1007/978-3-319-48933-9_3

Moon, K.H., Chae, B., Kim, K.S., Lee, S.W., Jung, Y.M.: Preparation and characterization of transparent polyimide-silica composite films using Polyimide with Carboxylic Acid Groups. Polymers 11(3), 489 (2019). https://doi.org/10.3390/polym11030489

Müller, K., Bugnicourt, E., Latorre, M., Jorda, M., Echegoyen Sanz, Y., Lagaron, J.M., Miesbauer, O., Bianchin, A., Hankin, S., Bölz, U.: Review on the processing and properties of polymer nanocomposites and nanocoatings and their applications in the packaging, automotive and solar energy fields. Nanomaterials 7(4), 74 (2017). https://doi.org/10.3390/nano7040074

Musto, P., Ragosta, G., Scarinzi, G., Mascia, L.: Polyimide-silica nanocomposites: spectroscopic, morphological and mechanical investigations. Polymer 45(5), 1697–1706 (2004). https://doi.org/10.1016/j.polymer.2003.12.044

Nofal, M.M., Aziz, S.B., Hadi, J.M., Karim, W.O., Dannoun, E., Hussein, M., Hussen, A.: Polymer composites with 0.98 transparencies and small optical energy band gap using a promising green methodology: structural and optical properties. Polymers 13(10), 1648 (2021). https://doi.org/10.3390/polym13101648

Nouh, S., Tommalieh, M., El-Shamy, N.: Structural and optical modifications in gamma-irradiated polyimide/silica nanocomposite. Radiat. Eff. Defects Solids 170(6), 548–555 (2015). https://doi.org/10.1080/10420150.2015.1052438

Rahman, I.A., Padavettan, V.: Synthesis of silica nanoparticles by sol-gel: size-dependent properties, surface modification, and applications in silica-polymer nanocomposites-a review. J. Nanomater. (2012). https://doi.org/10.1155/2012/132424

Ragosta, G., Musto, P.: Polyimide/silica hybrids via the sol-gel route: high performance materials for the new technological challenges. Express Polym. Lett. 3(413), 428 (2009). https://doi.org/10.3144/expresspolymlett.2009.51

Rahman, I.A., Padavettan, V.: Synthesis of silica nanoparticles by sol-gel: size-dependent properties, surface modification, and applications in silica-polymer nanocomposites-a review. J. Nanomater. (2012). https://doi.org/10.1155/2012/132424

Raman, N., Sudharsan, S., Pothiraj, K.: Synthesis and structural reactivity of inorganic–organic hybrid nanocomposites–a review. J. Saudi Chem. Soc. 16(4), 339–352 (2012). https://doi.org/10.1016/j.jscs.2011.01.012

Rehman, H.U., Schmidt, H., Ahmad, Z.: Synthesis and characterization of polyimide-silica hybrids: effect of matrix polarity on the mechanical and thermal properties. J. Macromol. Sci. Part A Pure Appl. Chem. 43(4–5), 703–717 (2006). https://doi.org/10.1080/10601320600602613

Ren, Q., Ma, C., Xu, D., Guo, S., Zhang, G., Meng, F., Trivedi, S.: Determination of the optical constants and their dispersion of DMACB/PEK-c polymer films. J. Mater. Sci. Lett. 19(1), 7–10 (2000). https://doi.org/10.1023/A:1006727109684

Sanchez, C., Julián, B., Belleville, P., Popall, M.: Applications of hybrid organic–inorganic nanocomposites. J. Mater. Chem. 15(35–36), 3559–3592 (2005). https://doi.org/10.1039/B509097K

Seo, K., Nam, K.-H., Lee, S., Han, H.: Low stress polyimide/silica nanocomposites as dielectrics for wafer level chip scale packaging. Mater. Lett. 263, 127204 (2020). https://doi.org/10.1016/j.matlet.2019.127204

Subramani, N., Kasargod Nagaraj, K.S., Shivanna, S., Siddaramaiah, H.: Highly flexible and visibly transparent poly (vinyl alcohol)/calcium zincate nanocomposite films for UVA shielding applications as assessed by novel ultraviolet photon induced fluorescence quenching. Macromolecules 49(7), 2791–2801 (2016). https://doi.org/10.1021/acs.macromol.5b02282

Sun, J., Xu, Z., Li, W., Shen, X.: Effect of nano-SiO2 on the early hydration of alite-sulphoaluminate cement. Nanomaterials 7(5), 102 (2017). https://doi.org/10.3390/nano7050102

Thabet, A., Ebnalwaled, A.: Improvement of surface energy properties of PVC nanocomposites for enhancing electrical applications. Measurement 110, 78–83 (2017). https://doi.org/10.1016/j.measurement.2017.06.023

Tommalieh, M., Zihlif, A., Ragosta, G.: Electrical and thermal properties of polyimide/silica nanocomposite. J. Exp. Nanosci. 6(6), 652–664 (2011). https://doi.org/10.1080/17458080.2010.547950

Tommalieh, M., Zihlif, A.: Optical properties of polyimide/silica nanocomposite. Physica B 405(23), 4750–4754 (2010). https://doi.org/10.1016/j.physb.2010.08.070

Tripathy, D.K., Sahoo, B.P.: Properties and Applications of Polymer Nanocomposites. Springer, Berlin (2017). https://doi.org/10.1007/978-3-662-53517-2

Tsai, C.-L., Yen, H.-J., Liou, G.-S.: Highly transparent polyimide hybrids for optoelectronic applications. React. Funct. Polym. 108, 2–30 (2016). https://doi.org/10.1016/j.reactfunctpolym.2016.04.021

Virk, H., Chandi, P., Srivastava, A.: Physical and chemical response of 70 MeV carbon ion irradiated Kapton-H polymer. Bull. Mater. Sci. 24(5), 529–534 (2001). https://doi.org/10.1007/BF02706726

Wahab, M.A., Kim, I., Ha, C.-S.: Microstructure and properties of polyimide/poly (vinylsilsesquioxane) hybrid composite films. Polymer 44(16), 4705–4713 (2003). https://doi.org/10.1016/S0032-3861(03)00429-4

Wu, G., Li, J., Wang, K., Wang, Y., Pan, C., Feng, A.: In situ synthesis and preparation of TiO2/polyimide composite containing phenolphthalein functional group. J. Mater. Sci. Mater. Electron. 28(9), 6544–6551 (2017). https://doi.org/10.1007/s10854-017-6343-6

Yakuphanoglu, F., Cukurovali, A., Yilmaz, I.: Single-oscillator model and determination of optical constants of some optical thin film materials. Phys. B 353(3–4), 210–216 (2004). https://doi.org/10.1016/j.physb.2004.09.097

Yang, Y., Yin, D., Zhong, C., Xiong, R., Shi, J., Liu, Z., Wang, X., Lei, Q.: Surface morphology and raman analysis of the polyimide film aged under bipolar pulse voltage. Polym. Eng. Sci. 53(7), 1536–1541 (2013). https://doi.org/10.1002/pen.23384

Yu, H.-C., Kumar, S.V., Lee, J.H., Oh, S.Y., Chung, C.-M.: Preparation of robust, flexible, transparent films from partially aliphatic copolyimides. Macromol. Res. 23(6), 566–573 (2015). https://doi.org/10.1007/s13233-015-3073-6

Zha, J.-W., Liu, X.-J., Tian, Y., Dang, Z.-M., Chen, G.: High-temperature polyimide dielectric materials for energy storage. In: Polyimide for Electronic and Electrical Engineering Applications. IntechOpen (2020). https://doi.org/10.5772/intechopen.92260

Zhao, F., Yao, D., Guo, R., Deng, L., Dong, A., Zhang, J.: Composites of polymer hydrogels and nanoparticulate systems for biomedical and pharmaceutical applications. Nanomaterials 5(4), 2054–2130 (2015). https://doi.org/10.3390/nano5042054

Zou, H., Wu, S., Shen, J.: Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem. Rev. 108(9), 3893–3957 (2008). https://doi.org/10.1021/cr068035q

Acknowledgements

This research was supported by the Egypt Nanotechnology Center – Cairo University (EGNC-CU).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

A.A. Ebnalwaled performed the formal analysis; Conceptualization; Methodology; Software; and Writing original draft. Ahmed H. Sadek performed Data curation; Investigation; Resources; Writing—review &editing. Sameh H. Ismail performed Formal analysis; Resources; research; Software. Gehad G. Mohamed performed Validation; Visualization; Reviewed and edited the paper; Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ebnalwaled, A.A., Sadek, A.H., Ismail, S.H. et al. Structural, optical, dielectric, and surface properties of polyimide hybrid nanocomposites films embedded mesoporous silica nanoparticles synthesized from rice husk ash for optoelectronic applications. Opt Quant Electron 54, 690 (2022). https://doi.org/10.1007/s11082-022-03976-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-022-03976-2