Abstract

We address the mechanics of an elastic ribbon subjected to twist and tensile load. Motivated by the classical work of Green (Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 154(882):430, 1936; 161(905):197, 1937) and a recent experiment (Chopin and Kudrolli in Phys. Rev. Lett. 111(17):174302, 2013) that discovered a plethora of morphological instabilities, we introduce a comprehensive theoretical framework through which we construct a 4D phase diagram of this basic system, spanned by the exerted twist and tension, as well as the thickness and length of the ribbon. Different types of instabilities appear in various “corners” of this 4D parameter space, and are addressed through distinct types of asymptotic methods. Our theory employs three instruments, whose concerted implementation is necessary to provide an exhaustive study of the various parameter regimes: (i) a covariant form of the Föppl–von Kármán (cFvK) equations to the helicoidal state—necessary to account for the large deflection of the highly-symmetric helicoidal shape from planarity, and the buckling instability of the ribbon in the transverse direction; (ii) a far from threshold (FT) analysis—which describes a state in which a longitudinally-wrinkled zone expands throughout the ribbon and allows it to retain a helicoidal shape with negligible compression; (iii) finally, we introduce an asymptotic isometry equation that characterizes the energetic competition between various types of states through which a twisted ribbon becomes strainless in the singular limit of zero thickness and no tension.

Similar content being viewed by others

Notes

Our convention in this paper is to normalize lengths by the ribbon width W, and stresses by the stretching modulus Y, which is the product of the Young modulus and the ribbon thickness (non-italicized fonts are used for dimensional parameters and italicized fonts for dimensionless parameters). Thus, the actual thickness and length of the ribbon are, respectively, t=t⋅W and L=L⋅W, the actual force that pulls on the short edges is T⋅YW, and the actual tension due to this pulling force is T=T⋅Y.

Recall that we normalize stresses by the stretching modulus Y and lengths by the ribbon width W. The dimensional bending modulus is thus: Y(Wt)2/(12(1−ν 2)).

More precisely, the NT method is an amplitude expansion of FvK equations around the compressed helicoidal state, whereas the FT theory is an asymptotic expansion of the FvK equations around the singular limit t→0, carried at a fixed confinement α. In this limit, the longitudinally wrinkled state of the ribbon approaches the compression-free stress \(\sigma_{\mathrm{FT}}^{ss}(r)\).

For simplicity, we assume that the Poisson ratio ν=0. This does not affect any of the basic results. Also, note that we neglected the contribution of the transverse stress (\({\sim} \sigma_{\mathrm{FT}}^{rr}(r)^{2}\)) since it comes with a factor O(η 4) with respect to the terms in Eq. (56).

The upper bound β j ≤1 stems from the bending modulus, and assuming that the minimal curvature of any nontrivial state is O(1).

The introduction of [44] contains a useful summary of the various approaches for linear stability analysis of elastic systems.

We just note that a non zero Poisson ratio would require another degree of freedom in the perturbative analysis, namely a transverse in-plane displacement ζu r1(r).

Recall that for a given (η,T) in the regime η 2/T>24, the FT approach in Sect. 3.3 provides a longitudinally-wrinkled state whose shape is close to the helicoid, up to deviations whose amplitude vanishes as t→0, and whose stress is given by (49), (55), up to corrections that also vanish as t→0. Therefore, the transverse linear stability analysis in this regime provides expressions for the threshold η tr(T) and the unstable mode [u s1(r),z 1[(r)]] that become accurate as t→0.

The experimental value of the length in [3] is L=20. The maximal tension in the experiment is T max=0.01; from Eq. (68), we deduce that the minimal transverse wavelength is \(\lambda_{\mathrm{min}}\sim \sqrt{Lt}T_{\mathrm{max}}^{-1/4}=1\). This explains why buckling is observed and why the infinite length approximation is in good agreement with the experiment.

If the ribbon becomes even shorter, it is possible that the boundary effect is sufficiently strong and the assumed mode structure Eq. (71) is not valid. In Sect. 6 we discuss the possibility that this might happen even in the ribbon limit (i.e., L≫1) provided t is small enough.

The well-known work of Cerda and Mahadevan [8] addressed this problem in the far-from-threshold regime, where wrinkles are fully developed and the transverse compression cannot be approximated by its value at threshold. The planar (unbuckled) state that underlies the wrinkling instability due to clamped boundaries was studied numerically in some recent works [47, 48]. However, these works did not address the ribbon limit L≫1 that we study here. A couple of papers [49] attempted to extend the far-from-threshold approach of [8] to the near-threshold regime (by invoking effective “inextensibility” constraints), but the justification of this approach has yet to be established.

The exact boundary conditions at s=±L/2 may depend on the specific set-up used to apply simultaneously tension and twist. These may include, for instance, complete clamping (i.e.,u=z=0) or partial clamping (i.e., only z=0).

Abbreviations

- ssFvK equations:

-

“small-slope” (standard) Föppl–von Kármán equations

- cFvK equations:

-

covariant Föppl–von Kármán equations

- t, W, L:

-

thickness, width and length of the ribbon (non-italicized quantities are dimensional)

- t, W=1, L :

-

thickness, width and length normalized by the width

- ν :

-

Poisson ratio

- \(\mathrm{E}, \mathrm {Y},\mathrm {B}=\frac{\mathrm {Y}\mathrm {t}^{2}}{12(1-\nu^{2})}\) :

-

Young, stretching and bending modulus

- Y=1, \(B=\frac{t^{2}}{12(1-\nu^{2})}\) :

-

stretching and bending modulus, normalized by the stretching modulus

- T=T/Y:

-

tensile strain (tensile load normalized by stretching modulus)

- θ, η=θ/L :

-

twist angle and normalized twist

- \((\hat{\boldsymbol {x}},\hat{\boldsymbol {y}},\hat{\boldsymbol {z}})\) :

-

Cartesian basis

- s, r :

-

material coordinates (longitudinal and transverse)

- z(s,r):

-

out of plane displacement (of the helicoid) in the small-slope approximation

- X(s,r):

-

surface vector

- \(\hat{\boldsymbol {n}}\) :

-

unit normal to the surface

- σ αβ :

-

stress tensor

- ε αβ :

-

strain tensor

- g αβ :

-

metric tensor

- c αβ :

-

curvature tensor

- \(\mathcal{A}^{\alpha\beta\gamma\delta}\) :

-

elastic tensor

- ∂ α , D α :

-

partial and covariant derivatives

- H, K :

-

mean and Gaussian curvatures

- ζ :

-

infinitesimal amplitude of the perturbation in linear stability analysis

- z 1(s,r):

-

normal component of an infinitesimal perturbation to the helicoidal shape

- η lon, λ lon :

-

longitudinal instability threshold and wavelength

- η tr, λ tr :

-

transverse instability threshold and wavelength

- α=η 2/T :

-

confinement parameter

- α lon :

-

threshold confinement for the longitudinal instability

- r wr :

-

(half the) width of the longitudinally wrinkled zone

- Δα=α−24:

-

distance to the threshold confinement

- f(r):

-

amplitude of the longitudinal wrinkles

- U hel, U FT :

-

elastic energies (per length) of the helicoid and the far from threshold longitudinally wrinkled state

- U dom, U sub :

-

dominant and subdominant (with respect to t) parts of U FT

- X cl(s):

-

ribbon centerline

- \(\hat{t} = d\boldsymbol {X}_{\mathrm{cl}}(s)/ds\) :

-

tangent vector in the ribbon midplane

- \(\hat{\boldsymbol {r}}(s)\) :

-

normal to the tangent vector

- \(\hat{\boldsymbol{b}}(s)\) :

-

Frenet binormal to the curve X cl(s)

- τ(s),κ(s):

-

torsion and curvature of X cl(s)

References

Green, A.E.: Proc. R. Soc. Lond. Ser. A, Math. Phys. Sci. 154(882), 430 (1936)

Green, A.E.: Proc. R. Soc. Lond. Ser. A, Math. Phys. Sci. 161(905), 197 (1937). http://www.jstor.org/stable/96910

Chopin, J., Kudrolli, A.: Phys. Rev. Lett. 111(17), 174302 (2013). doi:10.1103/PhysRevLett.111.174302

Mockensturm, E.M.: J. Appl. Mech. 68(4), 561 (2000). doi:10.1115/1.1357517

Coman, C.D., Bassom, A.P.: Acta Mechanica 200(1–2), 59 (2008). doi:10.1007/s00707-007-0572-3

Sadowsky, M.: Teil II. Verhandl. des 3. Intern. Kongr. f. Techn. Mechanik, 444–451 (1930)

Korte, A.P., Starostin, E.L., van der Heijden, G.H.M.: Proc. R. Soc. A, Math. Phys. Eng. Sci. 467(2125), 285 (2011). doi:10.1098/rspa.2010.0200

Cerda, E., Mahadevan, L.: Phys. Rev. Lett. 90(7), 074302 (2003). doi:10.1103/PhysRevLett.90.074302

Goriely, A., Nizette, M., Tabor, M.: J. Nonlinear Sci. 11(1), 3 (2001). doi:10.1007/s003320010009

Champneys, A.R., Thompson, J.M.T.: Proc. R. Soc. Lond. Ser. A, Math. Phys. Eng. Sci. 452(1954), 2467 (1996). doi:10.1098/rspa.1996.0132

van der Heijden, G., Thompson, J.: Phys. D: Nonlinear Phenom. 112(1–2), 201 (1998). Proceedings of the Workshop on Time-Reversal Symmetry in Dynamical Systems. doi:10.1016/S0167-2789(97)00211-X

van der Heijden, G.H.M., Thompson, J.M.T.: Nonlinear Dyn. 21(1), 71 (2000). doi:10.1023/A:1008310425967

Santangelo, C.: Geometric frustration in twisted strips. J. Club Condens. Matter Phys. (2014). http://www.condmatjournalclub.org/?p=2330

Davidovitch, B., Schroll, R.D., Vella, D., Adda-Bedia, M., Cerda, E.A.: Proc. Natl. Acad. Sci. 108(45), 18227 (2011). doi:10.1073/pnas.1108553108

King, H., Schroll, R.D., Davidovitch, B., Menon, N.: Proc. Natl. Acad. Sci. 109(25), 9716 (2012). doi:10.1073/pnas.1201201109

Grason, G.M., Davidovitch, B.: Proc. Natl. Acad. Sci. 110(32), 12893 (2013). doi:10.1073/pnas.1301695110

Landau, L.D., Lifchitz, E.M., Kosevitch, A.M., Pitaevski, L.P., Sykes, J.B., Reid, W.: Course of Theoretical Physics: Theory of Elasticity. Butterworth-Heinemann, Stoneham (1986)

Cranford, S., Buehler, M.J.: Model. Simul. Mater. Sci. Eng. 19(5), 054003 (2011). http://stacks.iop.org/0965-0393/19/i=5/a=054003

Kit, O.O., Tallinen, T., Mahadevan, L., Timonen, J., Koskinen, P.: Phys. Rev. B 85(8), 085428 (2012). doi:10.1103/PhysRevB.85.085428

Ogden, R.W.: Non-linear Elastic Deformations. Courier Dover Publications, New York (1997)

Efrati, E., Sharon, E., Kupferman, R.: J. Mech. Phys. Solids 57(4), 762 (2009). doi:10.1016/j.jmps.2008.12.004

Dias, M.A., Hanna, J.A., Santangelo, C.D.: Phys. Rev. E 84(3), 036603 (2011). doi:10.1103/PhysRevE.84.036603

Hohlfeld, E., Davidovitch, B.: (2014, submitted)

Stein, M., Hedgepeth, J.M.: Analysis of Partly Wrinkled Membranes. National Aeronautics and Space Administration, Washington (1961)

Pipkin, A.C.: IMA J. Appl. Math. 36(1), 85 (1986). doi:10.1093/imamat/36.1.85

Mansfield, E.H.: The Bending and Stretching of Plates. Cambridge University Press, Cambridge (2005)

Davidovitch, B., Schroll, R.D., Cerda, E.: Phys. Rev. E 85(6), 066115 (2012). doi:10.1103/PhysRevE.85.066115

Bella, P., Kohn, R.V.: Commun. Pure Appl. Math. (2013)

Audoly, B., Pomeau, Y.: Elasticity and Geometry: From Hair Curls to the Non-linear Response of Shells. Oxford University Press, Oxford (2010)

Huang, J., Davidovitch, B., Santangelo, C.D., Russell, T.P., Menon, N.: Phys. Rev. Lett. 105(3), 038302 (2010). doi:10.1103/PhysRevLett.105.038302

Vandeparre, H., Piñeirua, M., Brau, F., Roman, B., Bico, J., Gay, C., Bao, W., Lau, C.N., Reis, P.M., Damman, P.: Phys. Rev. Lett. 106, 224301 (2011). doi:10.1103/PhysRevLett.106.224301

Schroll, R.D., Adda-Bedia, M., Cerda, E., Huang, J., Menon, N., Russell, T.P., Toga, K.B., Vella, D., Davidovitch, B.: Phys. Rev. Lett. 111(1), 014301 (2013). doi:10.1103/PhysRevLett.111.014301

Pogorelov, A.: Extrinsic Geometry of Convex Surfaces

Witten, T.A.: Rev. Mod. Phys. 79, 643 (2007). doi:10.1103/RevModPhys.79.643

Sharon, E., Roman, B., Marder, M., Shin, G.S., Swinney, H.L.: Nature 419(6907), 579 (2002). doi:10.1038/419579a

Audoly, B., Boudaoud, A.: Phys. Rev. Lett. 91, 086105 (2003). doi:10.1103/PhysRevLett.91.086105

Klein, Y., Venkataramani, S., Sharon, E.: Phys. Rev. Lett. 106, 118303 (2011). doi:10.1103/PhysRevLett.106.118303

Gemmer, J.A., Venkataramani, S.C.: Nonlinearity 25(12), 3553 (2012). http://stacks.iop.org/0951-7715/25/i=12/a=3553

Giomi, L., Mahadevan, L.: Phys. Rev. Lett. 104, 238104 (2010). doi:10.1103/PhysRevLett.104.238104

Kohn, R.V., Nguyen, H.M.: J. Nonlinear Sci. 23(3), 343 (2013). doi:10.1007/s00332-012-9154-1

Audoly, B., Boudaoud, A.: J. Mech. Phys. Solids 56(7), 2444 (2008). doi:10.1016/j.jmps.2008.03.001

Michell, J.: Messenger of Math. 11, 181 (1889–1890)

Goriely, A.: J. Elast. 84(3), 281 (2006). doi:10.1007/s10659-006-9055-3

Majumdar, A., Prior, C., Goriely, A.: J. Elast. 109(1), 75 (2012). doi:10.1007/s10659-012-9371-8

Love, A.E.H.: A Treatise on the Mathematical Theory of Elasticity. Cambridge University Press, Cambridge (2013)

Ashwell, D.G.: Q. J. Mech. Appl. Math. 15(1), 91 (1962). doi:10.1093/qjmam/15.1.91

Nayyar, V., Ravi-Chandar, K., Huang, R.: Int. J. Solids Struct. 48(25–26), 3471 (2011). doi:10.1016/j.ijsolstr.2011.09.004

Healey, T., Li, Q., Cheng, R.B.: J. Nonlinear Sci. 23(5), 777 (2013). doi:10.1007/s00332-013-9168-3

Kim, T.Y., Puntel, E., Fried, E.: Int. J. Solids Struct. 49(5), 771 (2012). doi:10.1016/j.ijsolstr.2011.11.018

Lee, C., Wei, X., Kysar, J.W., Hone, J.: Science 321(5887), 385 (2008)

Novoselov, K.S., Fal[prime]ko, V.I., Colombo, L., Gellert, P.R., Schwab, M.G., Kim, K.: Nature 490(7419), 192 (2012). doi:10.1038/nature11458

Mahadevan, L., Vaziri, A., Das, M.: Europhys. Lett. 77(4), 40003 (2007). http://stacks.iop.org/0295-5075/77/i=4/a=40003

Schroll, R.D., Katifori, E., Davidovitch, B.: Phys. Rev. Lett. 106, 074301 (2011). doi:10.1103/PhysRevLett.106.074301

Klein, Y., Efrati, E., Sharon, E.: Science 315(5815), 1116 (2007). doi:10.1126/science.1135994

Kim, J., Hanna, J.A., Byun, M., Santangelo, C.D., Hayward, R.C.: Science 335(6073), 1201 (2012). doi:10.1126/science.1215309

Acknowledgements

The authors would like to thank C. Santangelo for many enlightening discussions and particularly for educating us on the covariant FvK equations; and to A. Romaguera, F. Brau, B. Audoly, and two anonymous referees, for their critical reading and useful comments on the manuscript. B.D. would like to thank E. Hohlfeld for many inspiring discussions on asymptotic isometries and their use for elastic sheets subjected to geometric constraints and tensile loads. The authors acknowledge financial support by CNPq-Ciência sem fronteiras program, Brazil (J.C.), the KECK foundation Award 37086 (V.D.), and NSF CAREER Award DMR-11-51780 (B.D.).

Author information

Authors and Affiliations

Corresponding author

Additional information

J.C. and V.D. have contributed equally to this work.

Appendices

Appendix A: Hookean Elasticity and Leading Order Stresses and Strains

Our theory addresses the “corner” in the 4d parameter space, defined by Eqs. (1), (2), and therefore most of the analysis in this paper employs expansions in these parameters. Why do we assume these parameters are small?

First,t≪1 and L −1≪1 stem from the definition of a ribbon. Second, we focus our discussion on the universal, material-independent behavior of elastic ribbons and therefore we consider a Hookean response, whereby the stress-strain relationship is linear. Since Hookean response is valid only for small strains, and since the exerted tension T necessarily induces strain, we must require T≪1. Finally, the assumption η≪1 is more subtle. For the unwrinkled helicoidal state, we showed in Sect. 2.3 that the components of the strain and stress tensors are proportional to positive powers of η, and therefore Hookean response is valid only for sufficiently small values of η. In contrast, for the longitudinally-wrinkled helicoidal state (i.e.\(,\eta > \sqrt{24 T}\)), we showed in Sect. 3.3 that the ribbon may become nearly strainless (i.e., asymptotically isometric to the undeformed ribbon) even under finite η, therefore the Hookean response for the wrinkled state is not limited to small values of η. However, even for the wrinkled state the assumption η≪1 is very useful, since it enables an easy way to compute the various components of the stress tensor and allows us to characterize the wrinkled state as a sinusoidal undulation (Eq. (54) and Appendix C). Importantly, our finding that the threshold values η lon,η tr vanish in the asymptotic limit t→0 (see Sect. 4.1 and Fig. 8), proves in a self-consistent manner that the basic morphological instabilities of a stretched-twisted ribbon are well described by assuming η≪1.

Our theory is thus valid at the leading order in t,L −1, η and T, and any higher order terms are ruled out from the derivations. Leading terms should be understood with respect to these expansion parameters. Namely, denoting by A a scalar, or a component of a vector or tensor (e.g., longitudinal contraction, transverse or longitudinal stress or strain), then A is expanded as

and the order of A is given by the four positive integers (a i ). Saying that the order \((a_{i}')\) is higher than the order (a i ) means that

The leading terms of A are the minimal orders for the relation (95) with non-zero coefficient. For example, the leading terms of the longitudinal stress in the helicoidal state are given in Eq. (3)\(,\sigma^{ss}_{\mathrm{hel}}=T+\frac{\eta^{2}}{2} (r^{2}-\frac{1}{12} )\), they correspond to the orders (1,0,0,0) and (0,2,0,0). These two orders are minimal and cannot be compared. The transverse stress given in Eq. (4) has vanishing coefficients for these orders, and the minimal orders with non zero coefficients are (1,2,0,0) and (0,4,0,0) (i.e.,Tη 2 and η 4). The s-independent transverse buckling equation (79) contains terms of order (1,2,0,0), (0,4,0,0) and (0,0,2,0) (respectively,Tη 2, η 4 and t 2).

In a given equation, several orders may appear; in this case only the minimal ones should be considered. This happens in the computation of the stress in the helicoidal state. Equation (33) shows that σ rr is of higher order than σ ss; besides, one of the two terms in the r.h.s. of Eq. (37) has obviously the same order (0,2,0,0) as σ ss in Eq. (36). Thus, consistency of Eqs. (33), (36), (37) implies that the leading terms in the r.h.s. mutually cancel each other (which we call a “solvability condition”), leading to Eq. (38) for \(u_{r}'(r)\). This last equation allows to compute the longitudinal stress, Eq. (39), from which we deduce the transverse stress, Eq. (40), using again Eq. (33).

Appendix B: Covariant Derivative: Definition and Application to the Helicoid

For an arbitrary surface with metric g αβ , the covariant derivative is defined with the Christoffel symbols, that are given by

The covariant derivative of a vector u α is then defined as

The strain tensor has two indices, so that its covariant derivative is

For the helicoid with metric (30)

the non-zero Christoffel symbols are (to the leading order):

Appendix C: Shape of the Longitudinally Wrinkled Helicoid Far from Threshold

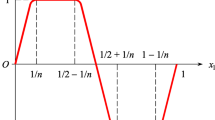

Far from threshold, longitudinal wrinkles relax the longitudinal compression. In the main text, we propose the following form for the wrinkles:

where the longitudinal contraction is given by  . The longitudinal strain in this configuration is

. The longitudinal strain in this configuration is

Setting \(k^{2}f(r)^{2}=2\eta^{2} (r^{2}-r_{\mathrm{wr}}^{2} )\) (Eq. (54)) allows to cancel the s-independent part. However, since this equation implies that the product kf does not vanish in the limit t→0, we find that the s-dependent terms in the above expression for ε ss remain finite as t→0, in apparent contradiction to our assumption that the wrinkled state becomes asymptotically strainless in the limit t,T→0. This shortcoming can be fixed, however, by adding to the deformation (104) a longitudinal displacement term,u s (s,r),

leading to the longitudinal strain

Setting

we find that both s-dependent and s-independent terms of the longitudinal strain ε ss in the wrinkled zone vanish for t→0 (up to higher order terms in η).

The configuration given by Eqs. (106), (108) has also transverse and shear strains, given by

However, in contrast to the individual terms in Eq. (105), which are proportional to the product kf (that remains finite as t→0), all terms on the r.h.s. of Eqs. (109), (110) vanish in the limit of small thickness (since, while kf(r) is finite, the amplitude f(r)→0 in this limit).

Appendix D: The Stability Analysis of Kirchoff Rod Equations

Here we translate the relevant results of [9], which addressed the stability analysis of a Kirchoff rod with non-symmetric cross section to the terminology of our paper.

The relevant results for us pertain to the linear stability analysis of the helicoidal (“straight”) state of the ribbon. This is summarized in Eqs. (58) and (59) that provide the threshold for the two types of instabilities of the centerline (“tapelike” = TL, and “thick” = th). We explain the meaning of the parameters a,b and ρ.

The parameter a (Eq. (9) of [9]) is the ratio between the two principal moments of inertia of the rod (I 1<I 2). The parameter b (also Eq. (9) of [9]) involves also the Poisson ratio (denoted σ in [9], and ν in our manuscript), and the “mixed” moment of inertia J. In the limit t≪1: I 1∼Wt 3,I 2∼tW3 and J∼tW3, with some numerical coefficients that depend on the exact shape of the cross section. In Eq. (12), both a and b are evaluated for an ellipsoidal cross section, but we assume that the same expressions (i.e., the exact respective ratios between J,I 1,I 2) hold also for a rectangular cross section, from which we can translate to our terminology:

where we assume already the limit t≪1 and expanded b to lowest order in t.

Now, let us consider the parameter \(\rho=F_{3}^{(0)}/{\kappa_{3}^{(0)}}^{2}\) (Eq. (35) of [9]), where \(F_{3}^{(0)}\) is the normalized force exerted along the centerline and \(\kappa_{3}^{(0)}\) is the exerted “torsion” of the centerline. We will show that the translation to our terminology is:

To see this, first note that \(F_{3}^{(0)}\) and \(\kappa_{3}^{(0)}\) are defined as the tension and the twist density in the sentence after Eq. (14) of [9]. In order to understand the normalization, we need the normalization of lengths and forces, given, respectively in Eqs. (6) and (7b). Note that lengths are measured in units of t (since I 1∼t 3 W and A∼tW). The expressions of κ 3 and F 3 in our parameters is therefore\(:\kappa_{3}^{(0)} = (\theta/L)/t = \eta/ t\), and \(F_{3}^{(0)} = \mathrm{force}/(E tW) = \mathrm{force}/(Y W) = T\). Substituting this expression for \(F_{3}^{(0)}\) and \(\kappa_{3}^{(0)}\) in Eq. (35) of [9], we find the above transformation of the parameter ρ to our parameters. Importantly,ρ of [9] is inversely proportional to the ratio η 2/T, and hence the unstable range of the helicoidal state (gray zones in Fig. 4 of [9]) corresponds to large value of twist/tension (namely η 2/T above some threshold).

Let us turn now to Eqs. (58), (59), and express them in our terminology. From Eq. (58) we obtain the threshold for the “tapelike” mode to be:

in the limit t≪1, which ranges from 1 to 3 as ν ranges from 0 to 1/2. Equation (59) leads the threshold for the “thick” mode,

in the limit t≪1. This expression ranges from 1/2 to 2.8 as ν ranges from 0 to 1/2 and it is smaller than the first threshold for any value of ν.

Appendix E: Estimating the Clamping-Induced Energy

The transverse displacement u r must vanish near the clamped edges (s=±L/2), and is expected to approach u r ≈−νTr/2 beyond a characteristic length ℓ from the clamped edges. In the region s∈(−L/2+ℓ,L/2−ℓ) the Poisson contraction applies, such that the strain can be approximated as:

and the corresponding energy per length is:

In the near-boundary zones s∈±(L/2−ℓ,L/2), where u r is not determined by the Poisson effect, we may express the strain field as:

where f i (s/ℓ,r) are O(1) functions that characterize the variation of the displacement field from the clamped edge to its bulk value. Note that the ℓ-independent component of ε ss is derived from the Hookean stress-strain relationship by assuming σ ss≈T and ε rr ≈0. Integrating over the boundary zones s∈±(L/2−ℓ,L/2), the energy per length associated with the strain field is estimated as:

(where some unknown numerical constants, which are independent on ℓ and ν, multiply each of the two terms in the above expression). Combining the two energies, Eqs. (116), (118), and minimizing over ℓ, we obtain:

where F(ν) is some smooth function of ν that satisfies F(ν)→cst for ν→0.

Rights and permissions

About this article

Cite this article

Chopin, J., Démery, V. & Davidovitch, B. Roadmap to the Morphological Instabilities of a Stretched Twisted Ribbon. J Elast 119, 137–189 (2015). https://doi.org/10.1007/s10659-014-9498-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10659-014-9498-x