Abstract

To research the dynamic response characteristics of the multi-link complex mechanism with lubricated clearance joint, an improved transitional lubrication model considering the roughness of the contact surface is established based on the fuzzy set model of the lubrication state. The dynamic model of a six-bar rocking feeding mechanism with lubricated clearance joint is established, and the influence of dry friction clearance and lubricated clearance on the dynamic response of the mechanism are analyzed. By comparing with the simulation results of ADAMS and Flores lubrication model, the correctness and effectiveness of the established dynamic model and the improved transition lubrication model are verified. The influence of driving speed, clearance size and number of clearances on the dynamic response of the mechanism with lubricated clearance joint is mainly studied. The simulation results show that the driving speed, clearance size and number of clearances have an impact on the dynamic characteristics of the mechanism. With the increase of driving speed and clearance value, the greater the impact on the mechanism, the increase in the number of clearances, which reduces the stability of the mechanism, and there is interaction between different clearance joints.

Similar content being viewed by others

References

Luka, S., Janko, S., Miha, B.: A review of continuous contact-force models in multibody dynamics. Int. J. Mech. Sci. 145, 171–187 (2018)

Tian, Q., Flores, P., Lankarani, H.M.: A comprehensive survey of the analytical, numerical and experimental methodologies for dynamics of multibody mechanical systems with clearance or imperfect joints. Mech. Mach. Theory 122, 1–57 (2018)

Liu, J.H., Zhang, F.K., Ding, X.Y.: Study on the evolution of real contact area between elastic-plastic rough surfaces. J. Mech. Eng. 57(7), 109–116 (2021)

Zheng, E.L., Chu, L., Jiang, S.Y., Zhu, S.Q., Kang, M., Shi, J.F.: Multi-body dynamic modeling and error analysis of planar flexible multi-link mechanism with lubricated revolute clearance joints and crankshaft-bearing structure. J. Mech. Eng. 56(3), 106–120 (2020)

Zheng, E.L., Wang, T.Y., Guo, J., Zhu, Y., Lin, X.Z., Wang, Y.J., Kang, M.: Dynamic modeling and error analysis of planar flexible multilink mechanism with clearance and spindle-bearing structure. Mech. Mach. Theory 131, 234–260 (2019)

Zheng, E.L., Zhu, R., Zhu, S.H., Lu, X.J.: A study on dynamics of flexible multi-link mechanism including joints with clearance and lubrication for ultra-precision presses. Nonlinear Dyn. 83(1–2), 137–159 (2016)

Flores, P.: A parametric study on the dynamic response of planar multibody systems with multiple clearance joints. Nonlinear Dyn. 61(4), 633–653 (2010)

Flores, P., Koshy, C.S., Lankarani, H.M., Ambrósio, J., Claro, J.C.P.: Numerical and experimental investigation on multibody systems with revolute clearance joints. Nonlinear Dyn. 65(4), 383–398 (2011)

Flores, P.: Modeling and simulation of wear in revolute clearance joints in multibody systems. Mech. Mach. Theory 44(6), 1211–1222 (2009)

Farahan, S.B., Ghazavi, M.R., Rahmanian, S.: Bifurcation in a planar four-bar mechanism with revolute clearance joint. Nonlinear Dyn. 87(2), 955–973 (2017)

Xiang, W.W.K., Yan, S.Z., Wu, J.N., Gao, R.X.: Complexity evaluation of nonlinear dynamic behavior of mechanisms with clearance joints by using the fractal method. ARCHIVE Proc. Inst. Mech Eng. Part C 228(18), 3482–3495 (2014)

Chen, Y., Wu, K., Wu, X.Z., Sun, Y., Zhong, T.S.: Kinematic accuracy and nonlinear dynamics of a flexible slider-crank mechanism with multiple clearance joints. Eur. J. Mech. /A Solids. 88, 1–20 (2021)

Wang, G., Qi, Z.H., Wang, J.: A differential approach for modeling revolute clearance joints in planar rigid multibody systems. Multibody Sys.Dyn. 39(4), 311–335 (2017)

Erkaya, S., Uzmay, I.: Effects of balancing and link flexibility on dynamics of a planar mechanism having joint clearance. Scientia Iranica. 19(3), 483–490 (2012)

Flores, P., Ambrósio, J., Claro, J.C.P., Lankarani, H.M., Koshy, C.S.: A study on dynamics of mechanical systems including joints with clearance and lubrication. Mech. Mach. Theory 41(3), 247–261 (2006)

Flores, P.: Dynamic analysis of mechanical systems with imperfect kinematic joints. Portugal: Universidade Do Minho Ph. D thesis. (2004)

Flores, P., Lankarani, H.M., Ambrósio, J., Claro, J.C.P.: Modelling lubricated revolute joints in multibody mechanical systems. Proc. Inst. Mech. Eng. Part K 218(4), 183–190 (2004)

Flores, P., Ambrósio, J., Claro, J.C.P., Lankarani, H.M., Koshy, C.S.: Lubricated revolute joints in rigid multibody systems. Nonlinear Dyn. 56(3), 277–295 (2009)

Flores, P., Lankarani, H.M.: Spatial rigid-multibody systems with lubricated spherical clearance joints: modeling and simulation. Nonlinear Dyn. 60(1), 99–114 (2010)

Chen, X.L., Wang, T., Jiang, S.: Study on dynamic behavior of planar multibody system with multiple lubrication clearance joints. Eur. J. Mech. / A Solids 91(2022), 1–17 (2021)

Chen, X.L., Shuai, J., Yu, D., Wang, Q.: Dynamics analysis of 2-DOF complex planar mechanical system with joint clearance and flexible links. Nonlinear Dyn. 93(1), 1–26 (2018)

Tian, Q., Zhang, Y.Q., Chen, L.P., Yang, J.Z.: Simulation of planar flexible multibody systems with clearance and lubricated revolute joints. Nonlinear Dyn. 60(4), 489–511 (2010)

Tian, Q., Liu, C., Machado, M., Flores, P.: A new model for dry and lubricated cylindrical joints with clearance in spatial flexible multibody systems. Nonlinear Dyn. 64(1–2), 25–47 (2011)

Tian, Q., Sun, Y.L., Liu, C., Hu, H.Y., Flores, P.: ElastoHydroDynamic lubricated cylindrical joints for rigid-flexible multibody dynamics. Comput. Struct. 114–115, 106–120 (2013)

Zhao, B., Zhang, Z.N., Fang, C.C., Dai, X.D., Xie, Y.B.: Modeling and analysis of planar multibody system with mixed lubricated revolute joint. Tribol. Int. 98, 229–241 (2016)

Zhao, B., Zhou, K., Xie, Y.B.: A new numerical method for planar multibody system with mixed lubricated revolute joint. Int. J. Mech. Sci. 113, 105–119 (2016)

Zhao, B., Dai, X.D., Zhang, Z.N., Xie, Y.B.: A new numerical method for piston dynamics and lubrication analysis. Tribol. Int. 94, 395–408 (2016)

Zhang, T., Liu, G., Wang, X.P., Ma, S.J.: Dynamic analysis of planar multibody system with a lubricated revolute clearance joint using an improved transition force model. Adv. Mech. Eng. 9(12), 1–15 (2017)

Machado, M., Costa, J., Seabra, E., Flores, P.: The effect of the lubricated revolute joint parameters and hydrodynamic force models on the dynamic response of planar multibody systems. Nonlinear Dyn. 69(1–2), 635–654 (2012)

Reis, V.L., Daniel, G.B., Cavalca, K.L.: Dynamic analysis of a lubricated planar slider–crank mechanism considering friction and Hertz contact effects. Mech. Mach. Theory 74(6), 257–273 (2014)

Fang, C.C., Meng, X.H., Lu, Z.J., Wu, G., Tang, D.H., Zhao, B.: Modeling a lubricated full-floating pin bearing in planar multibody systems. Tribol. Int. 131, 222–237 (2019)

Li, R., Meng, X.H., Liu, R.C., Muhammad, R., Li, W.D., Dong, J.J.: Crosshead bearing analysis for low-speed marine diesel engines based on a multi-body tribo-dynamic model. Int. J. Engine Res. 22(8), 1–22 (2020)

Hori, Y.: Hydrodynamic Lubrication. Springer, Tokyo (2006)

Flores, P., Ambrósio, J., Claro, J.P.: Dynamic analysis for planar multibody mechanical systems with lubricated joints. Multibody Sys.Dyn. 12(1), 47–74 (2004)

Li, P., Chen, W., Li, D., Yu, R.F.: A novel transition model for lubricated revolute joints in planar multibody systems. Multibody Sys.Dyn. 36(3), 279–294 (2016)

Azam, A., Dorgham, A., Morina, A., Neville, A., Wilson, M.C.T.: A simple deterministic plastoelastohydrodynamic lubrication (PEHL) model in mixed lubrication. Tribol. Int. 131, 520–529 (2018)

Liu, S., Cui, Y., Fu, Y., Li, B., Lv, B.L., Qian, Y.H.: Modeling of lubricated translational joints in rigid-partially flexible multibody systems and its application in two-stroke marine diesel engines. Tribol. Int. 165, 1–14 (2022)

Daniel, G.B., Machado, T.H., Cavalca, K.L.: Investigation on the influence of the cavitation boundaries on the dynamic behavior of planar mechanical systems with hydrodynamic bearings. Mech. Mach. Theory 99, 19–36 (2016)

Marques, F., Flores, P., Claro, J.C.P., Lankarani, H.M.: A survey and comparison of several friction force models for dynamic analysis of multibody mechanical systems. Nonlinear Dyn. 86(3), 1407–1443 (2016)

Phelan, R.M.: Fundamentals of Mechanical Design. Mc Graw-Hill, New York (1970)

Luo, J.B., Yan, C.N.: On the fuzzy view in the lubriction theory. Lubr. Eng. 4, 1–4 (1989)

Hamrock, B.J.: Fundamentals of fluid Film Lubrication. Mc Graw Hill, New York (1994)

Kodnir, D.S., Zhilnikov, E.P.: An investigation in the field of elastohydrodynamics. J. Tribol. 98(4), 491–499 (1976)

Podra, P., Andersson, S.: Wear simulation with the Winkler surface model. Wear 207(1), 79–85 (1997)

Conway, H.D., Lee, H.C.: The analysis of the lubrication of a flexible journal bearing. J. Tribol. 94(4), 599–604 (1975)

Acknowledgements

The authors would like to acknowledge foundation item: Innovative Research Team in University of Tianjin (No. TD13-5037), and Natural Science Foundation of China (No. 51475330, No. 52005368 and No. 52175243) for supporting the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Kinematic analysis

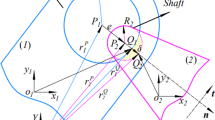

According to Fig. 5b, dynamic modeling of the mechanism

where \(x_{i}\) and \(y_{i} \left( {i = 1,2,3,4} \right)\) are the displacements in the x-direction and y-direction at the center of mass of the i-th rod respectively, \(\theta_{1}\) is the angle of crank 1, \(\theta_{2}\) is the angle of connecting rod 2, \(\theta_{3}\) is the angle of rocker 3, \(\theta_{4}\) is the angle of connecting rod 4, \(l_{CE}\) is the length from joint C to joint E, \(l_{CD}\) is the length from joint C to joint D, \(x_{5}\) is the displacement of the slider 5, \(l_{a}\) is the vertical distance from joint A to joint D, the length is 90 mm, \(l_{b}\) is the horizontal distance from joint A to joint D, the length is 170 mm.

By calculating the second derivative of Eqs. (33) to (37), the acceleration and angular acceleration of each bar parameter can be obtained

where \(\ddot{x}_{i}\) and \(\ddot{y}_{i} \left( {i = 1,2,3,4} \right)\) are the x-direction and y-direction accelerations at the center of mass of the i-th rod respectively, \(\dot{\theta }_{i}\) and \(\ddot{\theta }_{i} \left( {i = 1,2,3,4} \right)\) are the angular velocity and angular acceleration of the i-th rod respectively, \(\ddot{x}_{5}\) is the acceleration of the slider.

Appendix 2: Force analysis

The force analysis of crank 1

The force analysis of connecting rod 2

The force analysis of rocker 3

The force analysis of connecting rod 4

The force analysis of slider 5

in Eqs. (43) to (47), \(F_{{i\left( {i - 1} \right)x}}\) and \(F_{{i\left( {i - 1} \right)y}} \left( {i = 2,3,4} \right)\) are the force components of the B, C and E joints, respectively, \(F_{61}\) and \(F_{63}\) are the acting forces of the support on the crank 1 and rocker 3, respectively, \(J_{1}\), \(J_{2}\), \(J_{3}\) and \(J_{4}\) are the moments of inertia of each member to its center of mass respectively. \(m_{i} \left( {i = 1,2,3,4} \right)\) is the mass of each component respectively, \(G_{i} \left( {i = 1,2,3,4} \right)\) is the gravity of each component respectively, \(\omega_{b}\) is the crank speed, \(M_{b}\) is the crank moment.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, G., Wang, Z., Liang, D. et al. Modeling and dynamics characteristics analysis of six-bar rocking feeding mechanism with lubricated clearance joint. Arch Appl Mech 93, 2831–2854 (2023). https://doi.org/10.1007/s00419-023-02410-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-023-02410-7