Abstract

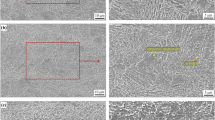

Austenite reversion in martensitic steels is known to improve fracture toughness. This research focuses on characterizing mechanical properties and the microstructure of low-carbon, high-nickel steels containing 4.5 and 10 wt pct Ni after a QLT-type austenite reversion heat treatment: first, martensite is formed by quenching (Q) from a temperature in the single-phase austenite field, then austenite is precipitated by annealing in the upper part of the intercritical region in a lamellarization step (L), followed by a tempering (T) step at lower temperatures. For the 10 wt pct Ni steel, the tensile strength after the QLT heat treatment is 910 MPa (132 ksi) at 293 K (20 °C), and the Charpy V-notch impact toughness is 144 J (106 ft-lb) at 188.8 K (−84.4 °C, −120 °F). For the 4.5 wt pct Ni steel, the tensile strength is 731 MPa (106 ksi) at 293 K (20 °C) and the impact toughness is 209 J (154 ft-lb) at 188.8 K (−84.4 °C, −120 °F). Light optical microscopy, scanning electron and transmission electron microscopies, synchrotron X-ray diffraction, and local-electrode atom-probe tomography (APT) are utilized to determine the morphologies, volume fractions, and local chemical compositions of the precipitated phases with sub-nanometer spatial resolution. The austenite lamellae are up to 200 nm in thickness, and up to several micrometers in length. In addition to the expected partitioning of Ni to austenite, APT reveals a substantial segregation of Ni at the austenite/martensite interface with concentration maxima of 10 and 23 wt pct Ni for the austenite lamellae in the 4.5 and 10 wt pct Ni steels, respectively. Copper-rich and M2C-type metal carbide precipitates were detected both at the austenite/martensite interface and within the bulk of the austenite lamellae. Thermodynamic phase stability, equilibrium compositions, and volume fractions are discussed in the context of Thermo-Calc calculations.

Similar content being viewed by others

References

H.K.D.H. Bhadeshia and R.W.K. Honeycombe: Steels – microstructure and properties. 3rd edition, Elsevier, Amsterdam, 2006, p. 183.

G. Krauss: Steels, Processing, Structure, and Performance. 3rd edition, ASM International, Metals Park, OH, 2005, p. 56.

M. Durand-Charre: Microstructure of Steels and Cast Irons. Springer-Verlag, Berlin, 2004, p. 219.

G.R. Brophy and A.J. Miller: Trans. ASM, 1949, vol. 41, pp. 1185-1203.

C.W. Marschall, R.F. Hehemann and A.R. Troiano: Trans. ASM, 1962, vol. 55, pp.135-148.

J.R. Patel, M. Cohen: Acta metall., 1953, vol. 1, pp. 531-538.

R.H. Richman, G.F. Bolling: Metall. Trans., 1971, vol. 2, pp. 2451-62.

G.R. Speich, D.S. Dabkowski, L.F. Porter: Metall. Trans., 1973, vol. 4, pp. 303-315.

S. Yano, H. Sakurai, H. Mimura, N. Watika, T. Ozawa, and K. Aoki: Trans. ISIJ, 1973, vol. 13, pp. 133-140.

J.W. Morris, Jr., J.I. Kim, and C.K. Syn: in Advances in Metal Processing, J.J. Burke, R. Mehrabian, and V. Weiss, eds., Plenum Press, New York, 1981, pp. 173–214.

J.W. Morris, Jr., C.K. Syn, J.I. Kim, and B. Fultz: Proc. Inter. Conf. Martensitic Transformations, 1979, MIT, Cambridge, MA, pp. 572–77.

J.I. Kim, C.K. Syn, J.W. Morris, Jr.: Metall. Trans. A, 1983, vol. 14A, pp. 93-103.

B. Fultz, J.I. Kim, H.J. Kim, G.O. Fior, J.W. Morris, Jr.: Metall. Trans. A, 1985, vol. 16A, pp. 2237-2249.

B. Fultz, J.W. Morris, Jr.: Metall. Trans. A, 1985, vol. 16A, pp. 2251-2256.

V.F. Zackay, E.R. Parker, D. Fahr, R. Busch: Trans. Am. Soc. Met., 1967, vol. 60, pp. 252-259.

G.B. Olson: in Innovations in Ultrahigh-Strength Steel Technology, Proc. 34th Sagamore Army Research Conference, G.B. Olson, M. Azrin, E.S. Wright, eds., US Government Printing Office, Washington DC, 1990, pp. 3–66.

G.N. Haidemenopoulos, G.B. Olson, and M. Cohen: in Innovations in Ultrahigh-Strength Steel Technology, Proc. 34th Sagamore Army Research Conference, G.B. Olson, M. Azrin, E.S. Wright, eds., US Government Printing Office, Washington DC, 1990, pp. 549–93.

G.N. Haidemenopoulos, G.B. Olson, M. Cohen, K. Tsuzaki: Scripta mater., 1989, vol 23, pp. 207-12.

G.B. Olson and M. Azrin: Metall. Trans. A, 1978, vol. 9A, pp. 713-721.

G.R. Speich, V.A. Demarest, and R.L. Miller: Metall. Trans. A, 1981, vol. 12A, pp. 1419–28.

Y. Sakuma, O. Matsumura, and H. Takechi: Metall. Trans. A, 1991, vol. 22A, pp. 489-498.

G.B. Olson, and C.J. Kuehmann: in Symposium on the Thermodynamics, Kinetics, Characterization and Modeling of Austenite Formation and Decomposition, Proceedings of the Materials Science and Technology (MS&T) Conference, Chicago, Il, 2003, pp. 493–504.

H.E. Lippard: PhD Thesis, Northwestern University, Evanston, IL,1999.

A. Saha, G.B. Olson: J. Computer-Aided Mater. Des., 2007, vol. 14, pp. 177-200.

A. Saha, J. Jung, G.B. Olson: J. Computer-Aided Mater. Des., 2007, vol. 14, pp. 201-33.

A. Saha: PhD Thesis, Northwestern University, Evanston, IL, 2004.

M.D. Mulholland, D.N. Seidman: Scripta mater., 2009, vol 60, pp. 992-995.

M.D. Mulholland, D.N. Seidman: Acta mater., 2011, vol 59, p. 1881-1897.

“9% Ni Steel with High Brittle Crack Arrestability”: JFE Technical Report No. 11, 2008, pp. 29–31.

A. Stormvinter, A. Borgenstam, J. Agren: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3870-3879.

B. Fultz, J.I. Kim, Y.H. Kim, J.W. Morris, Jr.: Metall. Trans. A, 1986, vol. 17A, pp. 967-972.

A. Cerezo, T.J. Godfrey, G.D.W. Smith: Rev. Sci. Instrum., 1988, vol. 59, pp. 862-866.

D. Blavette, B. Deconihout, A. Bostel, J.M. Sarrau, M. Bouet, A. Menand: Rev. Sci. Instrum., 1993, vol. 64, p. 2911-2929.

T.F. Kelly and M.K. Miller: Rev. Sci. Instrum., 2007, vol. 78, p. 031101/1-20.

D.N. Seidman: Annu. Rev. Mater. Res., 2007, vol. 37, p. 127-158.

D.N. Seidman, K. Stiller: MRS Bull., 2009, vol. 34, p. 717-721.

M.K. Miller, A. Cerezo, M.G. Hetherington, G.D.W. Smith: Atom-Probe Field-Ion Microscopy, Clarendon Press, Oxford, UK, 1996.

M.K. Miller: Atom-Probe Tomography – Analysis at the Atomic Scale, Kluwer Academic, New York, NY, 2000.

B. Gault, M.P. Moody, J.M. Cairney, S.P. Ringer: Atom-Probe Microscopy, Springer Science+Business Media, New York, NY, 2012.

B. Sundman, B. Jansson, J. Andersson: CALPHAD, 1985, vol. 9, p. 153-190.

G. Petzow: Metallographic Etching, American Society for Metals (ASM), Metals Park, OH, 1978, p. 64.

G. Thomas: Metall. Trans. A, 1978, vol. 9A, pp. 439-450.

M. Sarikaya, A.K. Jhingan:, G. Thomas: Metall. Trans. A, 1983, vol. 14A, pp. 1121-1133.

Jade 9: Materials Data Incorporated, 1224 Concannon Blvd., Livermore, California, 94550, USA.

M.M. Hall: J. Appl. Cryst., 1977,Vol. 10, pp. 66-68.

G.E. Hicho, H. Yakowitz, and R.E. Michaelis: Adv. X-ray Analysis 1971, vol. 14, p. 78.

B.L. Averbach and M. Cohen: Trans AIME, 1948, vol 176, p. 401-15.

M.K. Miller, K.F. Russell, G. Thompson: Ultramicroscopy, 2005, vol. 102, p. 287-298.

K. Thompson, D.J. Lawrence, D.J. Larson, J.D. Olson, T.F. Kelly, B.P. Gorman: Ultramicroscopy, 2007, vol. 107, p. 131-139.

L. Kaufman and M. Hillert: Thermodynamics of Martensitic Transformations, in Martensite, eds. G.B. Olson and W.S. Owen, ASM International, 1992, p. 51.

H.K.D.H. Bhadeshia and R.W.K. Honeycombe: Steels – microstructure and properties. 3rd edition, Elsevier, Amsterdam, 2006, p. 74.

O.C. Hellman, J.A. Vandenbroucke, J. Rüsing, D. Isheim, D.N. Seidman: Microsc. Microanal., 2000, vol. 6, p. 437-444.

B.D. Cullity, S.R. Stock: Elements of X-Ray Diffraction, 3rd edition, Prentice Hall, Upper Saddle River, NJ, 2001, p. 355.

G. Krauss: Steels, Processing, Structure, and Performance. 3rd edition, ASM International, Metals Park, OH, 2005, p. 34.

B.W. Krakauer and D.N. Seidman: Phys. Rev. B, 1993, vol. 48, pp. 6724-6727.

B.W. Krakauer and D.N. Seidman: Acta mater., 1998, vol. 46, pp. 6145-6161.

M. Tetsuya, J. Shimomura, K. Seto: Mater. Trans. JIM, 1996, vol. 37, pp. 323-329.

C.M. Liu, N.K. Abiko, H. Kimura: Metall. Trans. A, 1992, vol. 23A, pp. 263-269.

E. Yasyhara, K. Sakata, T. Kata, O. Hashimoto: ISIJ Int., 1994, vol. 34, pp. 99-107.

R. Defay, I. Prigogine, A. Bellemans, D.H. Everett: Surface tension and adsorption, Wiley, New York, NY, 1966, p. 85.

S.A. Dregia, P. Wynblatt: Acta metall. mater., 1991, vol. 39, pp. 771-778.

E.A. Marquis, D.N. Seidman, M. Asta, C.M. Woodward, and V. Ozolins: Phys. Rev. Lett., 2003, vol. 91, pp. 036101, 1-4.

D. Isheim, M.S. Gagliano, M.E. Fine, D.N. Seidman: Acta mater., 2006, vol 54, pp. 841-849.

M. Perez, F. Perrard, V. Massardier, X. Kleber, A. Deschamps, H. de Monestrol, P. Pareige, G. Covarel: Phil. Mag., 2005, vol. 85, pp. 2197-2210.

K.I. Hirano, M. Cohen, D.L. Averbach: Acta metall., 1961, vol 9, p. 440-445.

Acknowledgments

This research was sponsored by the Office for Naval Research (ONR) under grant N00014-09-1-0361, thanks to Dr. W. W. Mullins, grant officer. The atom-probe tomographic measurements were performed at the Northwestern University Center for Atom-Probe Tomography (NUCAPT). The local-electrode atom-probe tomograph was purchased and upgraded with funding from NSF-MRI (DMR-0420532) and ONR-DURIP (N00014-0400798, N00014-0610539, N00014-0910781) grants. The current study made use of the Shared Facilities at the Materials Research Center of Northwestern University, supported by the National Science Foundation’s MRSEC program (DMR-1121262). Additional instrumentation at NUCAPT was supported by the Initiative for Sustainability and Energy at Northwestern (ISEN). The authors thank Dr. Denis Keane for his help with the synchrotron experiments at the DuPont-Northwestern-Dow Collaborative Access Team (DND-CAT) of the Advanced Photon Source (APS). DND-CAT is supported by E.I. DuPont de Nemours & Co., The Dow Chemical Company, and Northwestern University. Use of the APS, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Argonne National Laboratory, was supported by the U.S. DOE, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 12, 2011.

Rights and permissions

About this article

Cite this article

Isheim, D., Hunter, A.H., Zhang, X.J. et al. Nanoscale Analyses of High-Nickel Concentration Martensitic High-Strength Steels. Metall Mater Trans A 44, 3046–3059 (2013). https://doi.org/10.1007/s11661-013-1670-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1670-6