Abstract

In this paper, we consider the scientific, technical, and technological aspects in the field of creating new high-temperature materials for the parts of the hot section of gas turbine engines (GTEs) with operating temperatures exceeding those existing in GTEs. More refractory metallic materials for the creation of new high-melting alloys used in the manufacture of operating and nozzle blades and other parts of promising gas turbine engines based on the Co–Cr, Pt–Al, Nb–Si, and Mo–Si–B systems were studied. In alloys of the Co–Cr system, the high-temperature strength is mainly provided owing to the hardening of the Co matrix, including dispersed precipitates of the carbide phase (TaC) and the boride phase Cr2B. In alloys of the Pt–Al system, it is due to alloying with Cr, Al, Ti, Re, etc., and precipitates of the coherently embedded Pt3Al phase. In eutectic alloys of the Nb–Si system, it is due to the complex hardening of the Nb solid solution and the Nb5Si3 silicide, as well as the natural compositional structure. In Mo–Si–B alloys, high strength is achieved by alloying with α-Mo solid solution and the formation of intermetallic phases Mo3Si and Mo5SiB2 and carbides Mo2C and TiC. We selected compositions; analyzed smelting methods, including directional crystallization that provides a natural compositional structure; evaluated mechanical properties at room and high temperatures and oxidation resistance; studied structural features; and provided information on technological equipment and the possibility of obtaining parts by various methods. It is shown that, depending on the composition of the selected matrix, the operating temperature of heat-resistant alloys can increase to 1300–1500°C, which is significantly higher than the existing operating temperatures for nickel heat-resistant alloys. We conclude that the studied materials are promising for use in aircraft engine manufacture and the aerospace industry.

Similar content being viewed by others

REFERENCES

Babkin, V.N., The role of science in solving practical problems of aircraft engine building, Dvigatel’, 2013, no. 3 (87), pp. 2–6.

Kablov, E.N., Istoriya aviatsionnogo materialovedeniya. VIAM – 80 let: Gody i lyudi (The History of Aviation Materials Science. VIAM – 80 Years: Years and People), Moscow: Vseross. Inst. Aviats. Mater., 2012.

Reed, R.C., The Superalloys: Fundamentals and Applications, Cambridge: Cambridge Univ. Press, 2006.

Kablov, E.N., Innovations of VIAM as part of implementing the Strategic Directions of Development of Materials and Technologies of Their Processing for the Period up to 2030, Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Kablov, E.N., Bondarenko, Yu.A., and Echin, A.B., Development of technology of cast superalloys directional solidification with variable controlled temperature gradient, Aviats. Mater. Tekhnol., 2017, no. S, pp. 24–38. https://doi.org/10.18577/2071-9140-2017-0-S-24-38

Kablov, E.N., Petrushin, N.V., Svetlov, I.L., and Demonis, I.M., Heat-resistant foundry nickel alloys for advanced aviation gas turbine engines, Tekhnol. Legk. Splavov, 2007, no. 2, pp. 6–16.

Kablov, E.N. and Toloraiya, V.N., VIAM – founder of domestic technology for casting single-crystal turbine blades of GTE and GTS, Aviats. Mater. Tekhnol., 2012, no. S, pp. 105–117.

Walston, S., Cetel, A., MacKay, R., O’Hara, K., Duhl, D., and Dreshfield, R., Joint development of a fourth generation single crystal superalloys, Proc. 10th Int. Symp. on Superalloys, Champion, Pennsylvania, 2004, pp. 15–24.

Koizumi, Y., Kobayashi, T., Yokokawa, T., Zhang, J., Osawa, M., Harada, H., Aoki, Y., and Arai, M., Development of next-generation Ni-base single crystal superalloys, Proc. 10th Int. Symp. on Superalloys, Champion, Pennsylvania, 2004, pp. 35–43.

Kawagishi1, K., Yeh, A.-C., Yokokawa, T., Kobayashi, T., Koizumi, Y., and Harada, H., Development of an oxidationresistant high-strength sixth-generation singlecrystal superalloy TSM-238, Proc. 12th Int. Symp. on Superalloys, Champion, Pennsylvania, 2012, pp. 189–195.

Yokokawa, T., Harada, H., Mori, Y., Kawagishi, K., Koizumi, Y., Kobayashi, T., Yuyama, M., and Suzuki, S., Design of next generation Ni-base single crystal superalloys containing Ir: Towards 1150°C temperature capability, Proc. 13th Int. Symp. on Superalloys, 2016, pp. 123–130.

Khan, T., Further assessment and improvement of high strength γ/γ'-NbC composites for advanced turbine blades, Proc. Conf. on In-Situ Composites 111, Lexington: Ginn Custom, 1978, pp. 378–389.

Damerval, C., Contributions a l’étude du comportement mécanique des composites COTAS γ/γ'-NbC a moyennc et naute temperature, Note Techniq. ONERA, 1986.

Stohr, J.F., Stubilite thermique de composites de solidification metal-carbure, Ann. Chim., 1980, vol. 5, nos. 2–3, pp. 226–241.

Woodford, D.A., Creep and rupture of an advanced fiber strengthened eutectic composite superalloy, Metall. Trans. A, 1977, vol. 8, no. 4, pp. 639–650.

Meetnam, G.W., Superalloys in gas turbine engines, Metall. Mater. Technol., 1982, vol. 14, no. 9, pp. 387–392.

Kachanov, E.B., Petrushin, N.V., and Svetlov, I.L., Heat-resistant eutectic alloys with carbide-intermetallic strengthening, Met. Sci. Heat Treat., 1995, vol. 37, no. 4, pp. 154–159. https://doi.org/10.1007/BF01189472

Bondarenko, Yu.A., Kablov, E.N., and Pankratov, V.A., Features of obtaining working blades of small-sized gas turbine engines from VKLS-20 alloy, Aviats. Prom-st., 1993, no. 2, pp. 9–10.

Bondarenko, Yu.A., Trends in the development of high-temperature metal materials and technologies in the production of modern aircraft gas turbine engines, Aviats. Mater. Tekhnol., 2019, no 2 (55), pp. 3–11. https://doi.org/10.18577/2071-9140-2019-0-2-3-11

Gorr, B., Burk, S., Trindade, V.B., and Christ, H.-J., The effect of pre-oxidation treatment on the high-temperature oxidation of Co–Re–Cr model alloys, Oxid. Met., 2010, vol. 74, nos. 5–6, pp. 239–253.

Mukherjl, D., Rosler, J., Wehrs, J., Strunz, P., Beran, P., Gilles, R., Hofmann, M., Hoelzel, M., Eckerlebe, H., Szentmiklosi, L., and Macsik, Z., Application of in situ neutron and X-ray measurements at high temperatures in the development of Co–Re-based alloys for gas turbines, Metall. Mater. Trans. A, 2013, vol. 44, pp. 22–30.

Strunz, P., Mukherji, D., Beran, P., Gilles, R., Karge, L., Hofmann, M., Hoelzel, M., Rosler, J., and Farkas, G., Matrix transformation in boron containing high-temperature Co–Re–Cr alloys, Met. Mater. Int., 2018, vol. 24, no. 5, pp. 934–944.

Wolff, I.M. and Hill, P.J., Platinum metals-based intermetallics for high-temperature service, Platinum Met. Rev., 2000, vol. 44, no. 4, pp. 158–166.

Hill, P.J., Biggs, T., Ellis, P., Hohls, J., Taylor, S.S., and Wolff, I.M., An assessment of ternary precipitation strengthened Pt alloys for ultra-high temperature applications, Mater. Sci. Eng., A, 2001, vol. 301, no. 2, pp. 167–179.

Odusote, J.K., Cornish, L.A., and Papo, J.M., Assessment of the oxidation behavior of a Pt-based alloy for high temperature applications, J. Mater. Eng. Perform., 2013, vol. 22, no. 11, pp. 3466–3475.

Vorberg, S., Wenderoth, M., Fischer, B., Glatzel, U., and Volkl, R., A TEM investigation of the γ/γ' phase boundary in Pt-based superalloys, JOM, 2005, vol. 57, pp. 49–51.

Huller, M., Wenderoth, S., Vorberg, S., Fischer, B., Glatzel, U., and Volkl, R., Optimization of composition and heat treatment of age-hardened Pt–Al–Cr–Ni alloys, Metall. Mater. Trans. A, 2005, vol. 36, no. 13, pp. 681–689.

Wenderoth, M., Volkl, R., Vorberg, S., Yamabe-Mitarai, Y., Harada, H., and Glatzel, U., Microstructure, oxidation resistance and high-temperature strength of gamma prime hardened Pt-base alloy, Int. J. Mater. Res., 2007, vol. 98, no. 6, pp. 463–467.

Fairbank, G.B., Humphreys, C.J., Kelly, A., and Jones, C.N., Ultra-high temperature intermetallic for the third millennium, Intermetallics, 2000, vol. 8, pp. 1091–1100.

Cornish, L.A., Fischer, B., and Volkl, R., Development of platinum-group-metal superalloys for high-temperature use, MRS Bull., 2003, vol. 28, no. 9, pp. 632–638.

Ospennikova, O.G., Podjyachev, V.N., and Stolyankov, Yu.V., Refractory alloys for innovative equipment, Tr. VIAM, 2016, no. 10 (46), art. ID 5. https://doi.org/10.18577/2307-6046-2016-0-10-5-5. http://www.viam-works.ru

Bewlay, B.P., Jackson, M.R., Sutliffe, J.A., et al., Solidification processing of high temperature intermetallic eutectic-based alloys, Mater. Sci. Eng., A, 1995, vols. 192–193, part 2, pp. 534–543.

Bewlay, B.P., Jackson, M.R., and Lipsitt, H.A., The balance of mechanical and environmental properties of a multielement niobium-niobium silicide-based in situ composite, Metall. Mater. Trans. A, 1996, vol. 27, no. 12, pp. 3801–3808.

Bewlay, B.P., Jackson, M.R., and Subramanian, P.R., Processing high-temperature refractory-metal silicide in-situ composites, JOM, 1999, vol. 51, no. 4, pp. 32–36.

Tanaka, R., Kasama, A., Fujikura, M., Iwanaga, I., Tanaka, H., and Motsumuro, Y., Research and development of niobium-based superalloys for hot components of gas turbines, Proc. Int. Gas Turbine Congress, 2003, pp. 1–5.

Guo, X.P., Guan, P., Ding, X., Zhang, J., Kusabiraki, K., and Fu, H.Z., Unidirectional solidification of a Nbss/Nb5Si3 in-situ composite, Mater. Sci. Forum, 2005, vols. 475–479, pp. 745–748.

Bewlay, B.P., Jackson, M.R., Zhao, J.C., Subramanian, P.R., Mendiratta, M.G., and Lewandowski, J., Ultrahigh-temperature Nb-silicide-based composites, MRS Bull., 2003, vol. 28, no. 9, pp. 646–653.

Bewlay, B.P., Jackson, M.R., Zhao, J.C., and Subramanian, P.R., A review of very high-temperature Nb-silicide based composites, Metall. Mater. Trans. A, 2003, vol. 34, no. 10, pp. 2043–2052.

Soviet, N., Zhang, J., Yang, X., Liu, L., and Fu, H.-C., CN Patent no. 102703971 (Claimed 06.01.2012, publ. 10.03.2012).

Huang, S.-C., Elliott, A.J., Gigliotti, M.F.X., Jr., Petterson, R.J., and Rutkowski, S.F., US Patent no. 8307881 (Claimed 01.06.2009, publ. 11.13.2012).

Zhang, J., Liu, L., Song, F., Soviet, N., and Fu, H.-C., CN Patent no. 102051669 (Claimed 11.04.2010, publ. 07.25.2012).

Bewlay, B., Cretegny, L., Gigliotti, M., Petterson, R., Ritter, A., and Rutkowski, S., US Patent no. 2006130996 (Claimed 12.22.2004, publ. 06.22.2006).

Bewlay, B.P. and Klug, F.J., US Patent no. 7610945 (Claimed 09.29.2006, publ. 11.03.2009).

Bewlay, B.P., Subramanian, P.R., Rigney, J.D., Dido-mizio, R., and Dheeradhada, V.S., EP Patent no. 2322684 (Claimed 10.16.2009, publ. 05.18.2011).

Bewlay, B.P., Cretegny, L., Young, C.D., Azer, M.N., and Ritter, A.M., EP Patent no. 1743729 (Claimed 06.29.2006, publ. 04.18.2007).

Svetlov, I.L., High-temperature Nb–Si composites – replacement with monocrystalline nickel heat-resistant alloys, Dvigatel’, 2010, no. 5 (71), pp. 36–37.

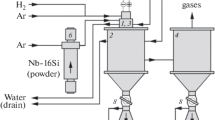

Min, P.G. and Vadeev, V.E., Vacuum induction furnace melting technology for high-temperature composite material based on Nb–Si system, Metallurgist, 2019, vol. 63, pp. 878–884. https://doi.org/10.1007/s11015-019-00902-y

Bondarenko, Yu.A., Echin, A.B., Kolodyazhnyi, M.Yu., and Surova, V.A., Formation of the structure of a eutectic alloy of the Nb–Si system during directed crystallization with liquid-metal coolant, Met. Sci. Heat Treat., 2017, vol. 59, pp. 513–517. https://doi.org/10.1007/s11041-017-0181-2

Bondarenko, Yu.A., Kolodyazhny, M.Yu., Echin, A.B., and Raevskikh, A.N., On microstructure and properties of niobium-silicon composite obtained by directional solidification in liquid metal, Vopr. Materialoved., 2017, no. 2 (90), pp. 68–76.

Bondarenko, Yu.A., Echin, A.B., Kolodyazhnyi, M.Yu., and Narskii, A.R., Directional solidification, structure, and mechanical properties of a eutectic Nb–Si alloy with a natural composite structure for GTE blades, Russ. Metall. (Metally), 2017, vol. 2017, pp. 1012–1017. https://doi.org/10.1134/S0036029517120047

Bondarenko, Yu.A., Kolodyazhny, M.Yu., Echin, A.B., and Narskiy, A.R., Directional solidification, structure and properties of natural composite based on eutectic Nb–Si at working temperatures up to 1350°C degrees for the blades of gas turbine engine, Tr. VIAM, 2018, no. 1 (61), pp. 1–9. https://doi.org/10.18577/2307-6046-2018-0-1-1-1-1. http://www.viam-works.ru

Schneibel, J.H., Tortorelli, P.F., Ritchie, R.O., and Kruzic, J.J., Optimization of Mo–Si–B intermetallic alloys, Metall. Mater. Trans. A, 2005, vol. 36, pp. 525–531.

Ha, S.-H., Yoshimi, K., Maruyama, K., Tu, R., and Goto, T., Phase formation and solidification routes near Mo–Mo5SiB2 eutectic point in Mo–Si–B system, Mater. Trans., 2010, vol. 51, no. 9, pp. 1699–1704. https://www.jim.or.jp/journal/e/pdf3/51/09/1699.pdf

Kamata, S.Y., Kanekon, D., Lu, Y., Sekido, N., Maruyama, K., Eggeler, G., and Yoshimi, K., Ultrahigh-temperature tensile creep of TiC-reinforced Mo–Si–B-based alloy, Sci. Rep., 2018, vol. 8, no. 1, art. ID 10487. https://doi.org/10.1038/s41598-018-28379-w

Jain, P. and Kumar, K.S., Tensile creep of Mo–Si–B alloys, Acta Mater., 2010, vol. 58, pp. 2124–2142.

Uemura, S., Yamamuro, T., Kim, J.W., Morizono, Y., Tsurekawa, S., and Yoshimi, K., Quantitative evaluation of microstructure in Mo–Si–B–TiC alloy produced by melting and tilt casting methods, Mater. Trans., 2018, vol. 59, no. 1, pp. 136–145.

Takata, N., Sekido, N., Takeyama, M., and Perepezko, J.H., Crystallography of Bcc/T1/T2 three-phase microstructure in the directionally solidified Mo–Nb–Si–B alloy, MRS Online Proc. Libr., 2015, vol. 1760. https://doi.org/10.1557/opl.2015.53

Matsunoshita, H., Sasai, Y., Fujiwara, K., Kishida, K., and Inui, H., Plastic deformation of directionally solidified ingots of binary and some ternary MoSi2/Mo5Si3 eutectic composites, Sci. Technol. Adv. Mater., 2016, vol. 17, no. 1, pp. 517–529.

Jehanno, P., Heilmaier, M., and Kestler, H., Characterization of an industrially processed Mo-based silicide alloy, Intermetallics, 2004, vol. 12, pp. 1005–1009.

Kamata, S.Y., Kanekon, D., Lu, Y., Sekido, N., Maruyama, K., Eggeler, G., and Yoshimi, K., Ultrahigh-temperature tensile creep of TiC-reinforced Mo–Si–B-based alloy, Sci. Rep., 2018, vol. 8, no. 1, art. ID 10487. https://doi.org/10.1038/s41598-018-28379-w

Perepezko, J.H., Sossaman, T.A., and Taylor, M., Environmentally resistant Mo–Si–B-based coating, J. Therm. Spray Technol., 2017, vol. 26, pp. 929–940.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Ivanov

Rights and permissions

About this article

Cite this article

Bondarenko, Y.A., Kolodyazhnyy, M.Y. & Surova, V.A. Creation of High-Temperature Heat-Resistant Alloys Based on Refractory Matrices and Natural Composites. Inorg. Mater. Appl. Res. 12, 1157–1163 (2021). https://doi.org/10.1134/S2075113321050063

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321050063