Abstract

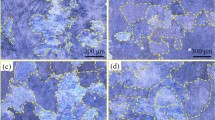

Materials for aero-engine and structural applications require the appropriate design of alloying elements that could exhibit better properties even at elevated temperatures. High entropy alloys (HEAs) have sparked worldwide attention to develop novel alloys composed of equiatomic quinary elements (Ni–Ti–Al–Li–Si) to develop lightweight material, viz. mechanical alloying (MA) technique. MA technique is applied to synthesize the newly designed composition HEA (ball-milling process carried out at 0, 1, 10, 20, 30, 40, and 50 h). The developed alloy is subjected to various characterizations such as X-ray diffraction, scanning electron microscope, transmission electron microscope, differential scanning calorimeter, and thermogravimetric analysis. The alloy confirms the face-centered cubic crystal structure with lattice parameter a = 3.5 A° at 50 h of ball milling, and elemental mapping confirms the presence of all elements. HEA in a ball-milled state confirms the nano-crystallite size of 11.5 nm with a percent lattice strain equal to 0.6089. Thermal studies clearly show the developed alloy is stable without any phase transformation. The 50 h of ball milled Ni–Ti–Al–Li–Si alloy powder is subjected to hot compaction at 850 °C for 1 h duration. The developed alloy was tested for density examination, which resulted in an average value of 3.5 ± 0.06 g/cm3, which is in good agreement with a theoretical density of 3.7 g/cm3.

Similar content being viewed by others

Data availability

Not applicable.

References

Tsai, M.H., Yeh, J.W.: High-entropy alloys: a critical review. Mater. Res. Lett. 2(3), 107–123 (2014). https://doi.org/10.1080/21663831.2014.912690

Yeh, J.W.: Overview of high-entropy alloys. In: High-entropy alloys, pp. 1–19. Springer, London (2016). https://doi.org/10.1007/978-3-319-27013-5

Smith, C.S.: Four outstanding researchers in metallurgical history. American Society for Testing and Materials, Baltimore (1963)

Abolkassem, S.A., Mohamed, L.Z., Gaber, G.A., Elkady, O.A.: Microstructure and corrosion behavior of FeNiCoCrCu and FeNiCoCrMn high entropy alloys manufactured by powder metallurgy in different acid media. J. Mater. Res. Technol. 10, 1122–1142 (2021). https://doi.org/10.1016/j.jmrt.2020.12.016

Kumar, A., Singh, A., Suhane, A.: Mechanically alloyed high entropy alloys: existing challenges and opportunities. J. Mater. Res. Technol. 17, 2431–2456 (2022). https://doi.org/10.1016/j.jmrt.2022.01.141

MacDonald, B.E., Fu, Z., Zheng, B., Chen, W., Lin, Y., Chen, F., Zhang, L., Ivanisenko, J., Zhou, Y., Hahn, H., Lavernia, E.J.: Recent progress in high entropy alloy research. JOM. 69(10), 2024–2031 (2017). https://doi.org/10.1007/s11837-017-2484-6

Sanchez, J.M., Vicario, I., Albizuri, J., Guraya, T., Garcia, J.C.: Phase prediction, microstructure and high hardness of novel light-weight high entropy alloys. J. Mater. Res. Technol. 8(1), 795–803 (2019). https://doi.org/10.1016/j.jmrt.2018.06.010

Yang, T., Zhao, Y., Liu, W., Kai, J., Liu, C.: L12-strengthened high-entropy alloys for advanced structural applications. J. Mater. Res. Technol. 33(19), 2983–2997 (2018). https://doi.org/10.1557/jmr.2018.186

Feng, R., Zhang, C., Gao, M.C., Pei, Z., Zhang, F., Chen, Y., Liaw, P.K.: High-throughput design of high-performance lightweight high-entropy alloys. Nat. Commun. 12(1), 1–10 (2021). https://doi.org/10.1038/s41467-021-24523-9

Lopes, J.G., Oliveira, J.P.: A short review on welding and joining of high entropy alloys. Metals. 10(2), 212 (2020). https://doi.org/10.3390/met10020212

Park, H.J., Kim, Y.S., Mun, S.C., Hong, S.H., Wang, W.M., Kim, K.B.: Designing of Fe-containing (Ti33Zr33Hf33)–(Ni50Cu50) high entropy alloys developed by equiatomic substitution: phase evolution and mechanical properties. J. Mater. Res. Technol. 9(4), 7732–7739 (2020). https://doi.org/10.1016/j.jmrt.2020.05.07

George, E.P., Raabe, D., Ritchie, R.O.: High-entropy alloys. Nat. Rev. Mater. 4(8), 515–534 (2019). https://doi.org/10.1038/s41578-019-0121-4

Zhang, Y.: High-entropy materials, vol. 2, pp. 215–232. Springer Nature Singapore Pte Ltd (2019). https://doi.org/10.1007/978-981-13-8526-1

Tokarewicz, M., Grądzka-Dahlke, M.: Review of recent research on AlCoCrFeNi high-entropy alloy. Metals. 11(8), 1302 (2021). https://doi.org/10.3390/met11081302

Jo, Y.H., Choi, W.M., Kim, D.G., Zargaran, A., Sohn, S.S., Kim, H.S., Lee, B.J., Kim, N.J., Lee, S.: FCC to BCC transformation-induced plasticity based on thermodynamic phase stability in novel V10Cr10Fe45CoxNi35−x medium-entropy alloys. Sci. Rep. 9(1), 1–14 (2019). https://doi.org/10.1038/s41598-019-39570-y

Cantor, B., Chang, I.T.H., Knight, P., Vincent, A.J.B.: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375, 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

Klimova, M.V., Semenyuk, A.O., Shaysultanov, D.G., Salishchev, G.A., Zherebtsov, S.V., Stepanov, N.D.: Effect of carbon on cryogenic tensile behavior of CoCrFeMnNi-type high entropy alloys. J. Alloys Compd. 811, 152000 (2019). https://doi.org/10.1016/j.jallcom.2019.152000

Hu, Y.L., Bai, L.H., Tong, Y.G., Deng, D.Y., Liang, X.B., Zhang, J., Li, Y.J., Chen, Y.X.: First-principle calculation investigation of NbMoTaW based refractory high entropy alloys. J. Alloys Compd. 827, 153963 (2020). https://doi.org/10.1016/j.jallcom.2020.153963

Wei, S., He, F., Tasan, C.C.: Metastability in high-entropy alloys: a review. J. Mater. Res. 33(19), 2924–2937 (2018). https://doi.org/10.1557/jmr.2018.306

Niu, C., LaRosa, C.R., Miao, J., Mills, M.J., Ghazisaeidi, M.: Magnetically-driven phase transformation strengthening in high entropy alloys. Nat. Commun. 9(1), 1–9 (2018). https://doi.org/10.1038/s41467-018-03846-0

Fu, Y., Li, J., Luo, H., Du, C., Li, X.: Recent advances on environmental corrosion behavior and mechanism of high-entropy alloys. J. Mater. Sci. Technol. 80, 217–233 (2021). https://doi.org/10.1016/j.jmst.2020.11.044

Ni, X., Dai, T., Lu, T., Pan, J., Li, M., Dai, J.: Microstructure and properties of CrMnFeCoNi high-entropy alloy prepared by mechanical alloying and spark plasma sintering. Powder Metall. 62(1), 38–43 (2019). https://doi.org/10.1080/00325899.2018.1554834

Kang, B., Lee, J., Ryu, H.J., Hong, S.H.: Ultra-high strength WNbMoTaV high-entropy alloys with fine grain structure fabricated by powder metallurgical process. Mater. Sci. Eng. A 712, 616–624 (2018). https://doi.org/10.1016/j.msea.2017.12.021

Zhang, W., Liaw, P.K., Zhang, Y.: Science and technology in high-entropy alloys. Sci. China Mater. 61(1), 2–22 (2018). https://doi.org/10.1007/s40843-017-9195-8

Zhang, Y., Zuo, T.T., Tang, Z., Gao, M.C., Dahmen, K.A., Liaw, P.K., Lu, Z.P.: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

Ganesh, U.L., Raghavendra, H.: Review on the transition from conventional to multi-component-based nano-high-entropy alloys—NHEAs. J. Therm. Anal. Calorim. 139(1), 207–216 (2020). https://doi.org/10.1007/s10973-019-08360-z

Huang, B.L., Perez, R.J., Lavernia, E.J., Luton, M.J.: Formation of supersaturated solid solutions by mechanical alloying. Nanostruct. Mater. 7(1–2), 67–79 (1996). https://doi.org/10.1016/0965-9773(95)00299-5

Nová, K., Novák, P., Průša, F., Kopeček, J., Čech, J.: Synthesis of intermetallics in Fe–Al–Si system by mechanical alloying. Metals. 9(1), 20 (2019). https://doi.org/10.3390/met9010020

Shuai, C., He, C., Peng, S., Qi, F., Wang, G., Min, A., Wang, W.: Mechanical alloying of immiscible metallic systems: process, microstructure, and mechanism. Adv. Eng. Mater. 23(4), 2001098 (2021). https://doi.org/10.1002/adem.202001098

Sokkalingam, R., Tarraste, M., Surreddi, K.B., Mikli, V., Muthupandi, V., Sivaprasad, K., Prashanth, K.G.: Powder metallurgy of Al0.1CoCrFeNi high-entropy alloy. J. Mater. Res. 35, 2835–2847 (2020). https://doi.org/10.1557/jmr.2020.272

Zaara, K., Chemingui, M., Le Gallet, S., Gaillard, Y., Escoda, L., Saurina, J., Suñol, J.J., Bernard, F., Khitouni, M., Optasanu, V.: High-entropy FeCoNiB0.5Si0.5 alloy synthesized by mechanical alloying and spark plasma sintering. Curr. Comput.-Aided Drug Des. 10(10), 929 (2020)

Rogachev, A.S., Kochetov, N.A., Panteleeva, A.V., Kuskov, K.V., Kovalev, D.Y., Shchukin, A.S., Vadchenko, S.G., Scheck, Y.B.: High-energy ball milling and spark plasma sintering of the CoCrFeNiAl high-entropy alloy. Metals. 10(11), 1489 (2020). https://doi.org/10.3390/met10111489

Rameshbabu, A.M., Parameswaran, P., Vijayan, V., Panneer, R.: Diffraction, microstructure and thermal stability analysis in a double phase nanocrystalline Al20Mg20Ni20Cr20Ti20 high entropy alloy. J. Mech. Behav. Mater. 26(3–4), 127–132 (2017). https://doi.org/10.1515/jmbm-2017-0021

Fu, Z., Chen, W., Jiang, Z., MacDonald, B.E., Lin, Y., Chen, F., Zhang, L., Lavernia, E.J.: Influence of Cr removal on the microstructure and mechanical behaviour of a high-entropy Al0.8Ti0.2CoNiFeCr alloy fabricated by powder metallurgy. Powder Metall. 61(2), 106–114 (2018)

Zhang, M., Zhang, W., Liu, Y., Liu, B., Wang, J.: FeCoCrNiMo high-entropy alloys prepared by powder metallurgy processing for diamond tool applications. Powder Metall. 61(2), 123–130 (2018). https://doi.org/10.1080/00325899.2018.1429044

Tian, L., Fu, M., Xiong, W.: Microstructural evolution of AlCoCrFeNiSi high-entropy alloy powder during mechanical alloying and its coating performance. Materials. 11(2), 320 (2018). https://doi.org/10.3390/ma11020320

Ge, W., Wang, Y., Shang, C., Zhang, Z., Wang, Y.: Microstructures and properties of equiatomic CuZr and CuZrAlTiNi bulk alloys fabricated by mechanical alloying and spark plasma sintering. J. Mater. Sci. 52(10), 5726–5737 (2017). https://doi.org/10.1007/s10853-017-0808-0

Novák, P., Barták, Z., Nová, K., Průša, F.: Effect of nickel and titanium on properties of Fe–Al–Si alloy prepared by mechanical alloying and spark plasma sintering. Materials. 13(3), 800 (2020). https://doi.org/10.3390/ma13030800

Zhang, C., Yang, F., Guo, Z., Wang, H., Lu, B.: Oxygen scavenging, grain refinement and mechanical properties improvement in powder metallurgy titanium and titanium alloys with CaB6. Powder Technol. 340, 362–369 (2018). https://doi.org/10.1016/j.powtec.2018.09.054

Suryanarayana, C., Al-Joubori, A.A., Wang, Z.: Nanostructured materials and nanocomposites by mechanical alloying: an overview. Metal. Mater. Int. (2021). https://doi.org/10.1007/s12540-021-00998-5

El-Eskandarany, M.S., Ali, N., Al-Ajmi, F., Banyan, M.: Phase Transformations from Nanocrystalline to Amorphous (Zr70Ni25Al5) 100-xWx (x; 0, 2, 10, 20, 35 at. %) and Subsequent Consolidation. Nanomaterials 11(11), 2952 (2021). https://doi.org/10.3390/nano11112952

Bindu, P., Thomas, S.: Estimation of lattice strain in ZnO nanoparticles: X-ray peak profile analysis. J. Theor. Appl. Phys. 8(4), 123–134 (2014). https://doi.org/10.1007/s40094-014-0141-9

Maulik, O., Kumar, D., Kumar, S., Dewangan, S.K., Kumar, V.: Structure and properties of lightweight high entropy alloys: a brief review. Mater. Res. Express 5(5), 052001 (2018). https://doi.org/10.1088/2053-1591/aabbca

Philip, J.T., Mathew, J., Kuriachen, B.: Tribology of Ti6Al4V: a review. Friction. 7(6), 497–536 (2019). https://doi.org/10.1007/s40544-019-0338-7

Gupta, M.K., Mia, M., Pruncu, C.I., Kapłonek, W., Nadolny, K., Patra, K., Mikolajczyk, T., Pimenov, D.Y., Sarikaya, M., Sharma, V.S.: Parametric optimization and process capability analysis for machining of nickel-based superalloy. Int. J. Adv. Manuf. Technol. 102(9), 3995–4009 (2019). https://doi.org/10.1007/s00170-019-03453-3

Akbarpour, M.R., Alipour, S., Najafi, M., Ebadzadeh, T., Kim, H.S.: Microstructural characterization and enhanced hardness of nanostructured Ni3Ti–NiTi (B2) intermetallic alloy produced by mechanical alloying and fast microwave-assisted sintering process. Intermetallics 131, 107119 (2021). https://doi.org/10.1016/j.intermet.2021.107119

Močnik, P., Kosec, T.: A critical appraisal of the use and properties of nickel-titanium dental alloys. Materials. 14(24), 7859 (2021). https://doi.org/10.3390/ma14247859

Asadikiya, M., Yang, S., Zhang, Y., Lemay, C., Apelian, D., Zhong, Y.: A review of the design of high-entropy aluminum alloys: a pathway for novel Al alloys. J. Mater. Sci. 56, 1–18 (2021). https://doi.org/10.1007/s10853-021-06042-6

Wanhill, R.J.H.: Aerospace applications of aluminum–lithium alloys. In: Gokhale, A.A., Wanhill, R.J.H. (eds.) Aluminum–lithium alloys, pp. 503–535. Butterworth-Heinemann (2014)

Kablov, E.N., Antipov, V.V., Oglodkova, J.S., Oglodkov, M.S.: Development and application prospects of aluminium–lithium alloys in aircraft and space technology. Metallurgist 65(1), 72–81 (2021). https://doi.org/10.1007/s11015-021-01134-9

Knaislová, A., Novák, P., Průša, F., Cabibbo, M., Jaworska, L., Vojtěch, D.: High-temperature oxidation of Ti–Al–Si alloys prepared by powder metallurgy. J. Alloys Compd. 810, 151895 (2019). https://doi.org/10.1016/j.jallcom.2019.151895

Liu, J., Wang, X., Chen, J., Liu, J.: The effect of cold rolling on age hardening of Cu-3Ti-3Ni-0.5 Si alloy. J. Alloys Compd. 797, 370–379 (2019). https://doi.org/10.1016/j.jallcom.2019.05.091

Ji, C., Ma, A., Jiang, J.: Mechanical properties and corrosion behavior of novel Al–Mg–Zn–Cu–Si lightweight high entropy alloys. J. Alloys Compd. 900, 163508 (2021). https://doi.org/10.1016/j.jallcom.2021.163508

Ahssi, M.A.M., Erden, M.A., Acarer, M., Çuğ, H.: The effect of nickel on the microstructure, mechanical properties and corrosion properties of niobium–vanadium microalloyed powder metallurgy steels. Materials. 13(18), 4021 (2020). https://doi.org/10.3390/ma13184021

Suryanarayana, C.: Mechanical alloying: a novel technique to synthesize advanced materials. Research (2019). https://doi.org/10.34133/2019/4219812

Jia, Y., Jia, Y., Wu, S., Ma, X., Wang, G.: Novel ultralight-weight complex concentrated alloys with high strength. Materials. 12(7), 1136 (2019). https://doi.org/10.3390/ma12071136

Li, Y., Zhang, Y.: Light-weight and flexible high-entropy alloys. In engineering steels and high entropy-alloys. IntechOpen. (2019). https://doi.org/10.5772/intechopen.88332

Gali, A., George, E.P.: Tensile properties of high-and medium-entropy alloys. Intermetallics 39, 74–78 (2013). https://doi.org/10.1016/j.intermet.2013.03.018

Vaidya, M., Guruvidyathri, K., Murty, B.S.: Phase formation and thermal stability of CoCrFeNi and CoCrFeMnNi equiatomic high entropy alloys. J. Alloys Compd. 774, 856–864 (2019). https://doi.org/10.1016/j.jallcom.2018.09.342

Hayakawa, S., Xu, H.: Temperature-dependent mechanisms of dislocation–twin boundary interactions in Ni-based equiatomic alloys. Acta Mater. 211, 116886 (2021). https://doi.org/10.1016/j.actamat.2021.116886

Xiang, T., Du, P., Cai, Z., Li, K., Bao, W., Yang, X., Xie, G.: Phase-tunable equiatomic and non-equiatomic Ti–Zr–Nb–Ta high-entropy alloys with ultrahigh strength for metallic biomaterials. J. Mat. Sci. Technol. 117, 196–206 (2022). https://doi.org/10.1016/j.jmst.2021.12.014

Zhang, B., Duan, Y., Cui, Y., Ma, G., Wang, T., Dong, X.: Improving electromagnetic properties of FeCoNiSi0.4Al0.4 high entropy alloy powders via their tunable aspect ratio and elemental uniformity. Mater. Des. 149, 173–183 (2018). https://doi.org/10.1016/j.matdes.2018.04.018

Pradeep, N.B., Hegde, M.R., Patel, G.C.M., Giasin, K., Pimenov, D.Y., Wojciechowski, S.: Synthesis and characterization of mechanically alloyed nanostructured ternary titanium based alloy for bio-medical applications. J. Mater. Res. Technol. 16, 88–101 (2022). https://doi.org/10.1016/j.jmrt.2021.11.101

Kumar, C.M.P., Lakshmikanthan, A., Chandrashekarappa, M.P.G., Pimenov, D.Y., Giasin, K.: Electrodeposition based preparation of Zn–Ni alloy and Zn–Ni–WC nano-composite coatings for corrosion-resistant applications. Coatings 11(6), 712 (2021). https://doi.org/10.3390/coatings11060712

Kumar, C.M.P., Chandrashekarappa, M.P.G., Kulkarni, R.M., Pimenov, D.Y., Giasin, K.: The effect of Zn and Zn–WO3 composites nano-coatings deposition on hardness and corrosion resistance in steel substrate. Materials 14(9), 2253 (2021). https://doi.org/10.3390/ma14092253

Alshataif, Y.A., Sivasankaran, S., Al-Mufadi, F.A., Alaboodi, A.S., Ammar, H.R.: Synthesis, structure, and mechanical response of Cr0.26Fe0.24Al0.5 and Cr0.15Fe0.14Al0.30Cu0.13Si0.28 nanocrystallite entropy alloys. Adv. Powder Technol. 31, 2161–2177 (2020). https://doi.org/10.1016/j.apt.2020.03.012

Sivasankaran, S., Al-Mufadi, F.A., Ammar, H.R.: Influence of V and Zn in FeCrCuMnTi high-entropy alloys on microstructures and uniaxial compaction behavior prepared by mechanical alloying. Curr. Comput. Aided Drug Des. 11, 1413 (2021). https://doi.org/10.3390/cryst11111413

Louidi, S., Bentayeb, F.-Z., Suñol, J.-J., Escoda, L.: Formation study of the ball-milled Cr20Co80 alloy. J. Alloys Compd. 493, 110–115 (2010). https://doi.org/10.1016/j.jallcom.2009.12.077

Zerniz, N., Azzaza, S., Chater, R., Abbas, H., Bououdina, M., Bouchelaghem, W.: Magnetic and structural properties of nanostructured Fe–20Al–2Cr powder mixtures. Mater. Charact. 100, 21–30 (2015). https://doi.org/10.1016/j.matchar.2014.12.010

Lakshmikanthan, A., Udayagiri, S.B., Koppad, P.G., Gupta, M., Munishamaiah, K., Bontha, S.: The effect of heat treatment on the mechanical and tribological properties of dual size SiC reinforced A357 matrix composites. J. Mater. Res. Technol. 9(3), 6434–6452 (2020). https://doi.org/10.1016/j.jmrt.2020.04.027

Lakshmikanthan, A., Bontha, S., Krishna, M., Koppad, P.G., Ramprabhu, T.: Microstructure, mechanical and wear properties of the A357 composites reinforced with dual sized SiC particles. J. Alloys Compd. 786, 570–580 (2019). https://doi.org/10.1016/j.jallcom.2019.01.382

Senkov, O.N., Senkova, S.V., Woodward, C., Miracle, D.B.: Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 61(5), 1545–1557 (2012). https://doi.org/10.1016/j.actamat.2012.11.032

Varalakshmi, S., Kamaraj, M., Murty, B.S.: Synthesis and characterization of Nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J. Alloys Compd. 460, 253–257 (2008). https://doi.org/10.1016/j.jallcom.2007.05.104

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ganesh, U.L., Raghavendra, H., Patel, G.C.M. et al. Design and Development of Low Density and Refractory Based on Ni-Ti-Al-Li-Si Pentanary Equiatomic High Entropy Alloys: Microstructure and Phase Analysis. Int J Interact Des Manuf (2022). https://doi.org/10.1007/s12008-022-01070-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-022-01070-1