Abstract

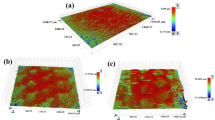

The present study concerns understanding the tribocorrosion behaviour of ultrafast laser processed Ti6Al4V processed under optimum processing conditions, leading to forming a textured surface with improved hardness and corrosion resistance. Laser periodic surfacing was conducted using Ti: sapphire laser with the pulse width of 3 ps at a 0.063 J/cm2 fluence (20 mm/sec scan speed) and 0.1 ps, at a 0.63 J/cm2 fluence (60 mm/sec scan speed) with a frequency of 10 kHz. Followed by laser processing, the tribocorrosion behaviour of the processed surface was evaluated at varied loads between 2 N and 10 N in the presence of simulated body fluid. After tribocorrosion testing, a detailed characterization of the degraded surface was carried out in terms of microstructure and composition. Tribocorrosion test showed a marginal decrease in coefficient of friction in laser surface processed samples, which increased with an increase in load as compared to as-received Ti6Al4V. A minimum coefficient of friction was observed for the samples processed with a 0.1 ps pulse width laser. The wear rate showed a significant decrease for both the samples processed with 0.1 ps and 3 ps laser pulse width as compared to as-received Ti6Al4V and increased with an increase in load. Finally, the mechanism of surface degradation was established through a detailed correlation between the characteristics and the kinetics of surface degradation.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Liu X, Chu PK, Ding C (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R Reports 47:49–121. https://doi.org/10.1016/j.mser.2004.11.001

Mathew MT, Srinivasa Pai P, Pourzal R et al (2009) Significance of tribocorrosion in biomedical applications: overview and current status. Adv Tribol. https://doi.org/10.1155/2009/250986

Sittig C, Textor M, Spencer ND et al (1999) Surface characterization of implant materials c.p. Ti, Ti-6Al-7Nb and Ti-6Al-4V with different pretreatments. J Mater Sci Mater Med 10:35–46. https://doi.org/10.1023/A:1008840026907

Lausmaa J (2001) Mechanical, thermal, chemical and electrochemical surface treatment of titanium. In: Titanium in medicine. pp 231–266

Sasikumar Y, Indira K, Rajendran N (2019) Surface modification methods for titanium and its alloys and their corrosion behavior in biological environment: a review. J Bio- Tribo-Corrosion 5:1–25. https://doi.org/10.1007/s40735-019-0229-5

Yang B, Uchida M, Kim HM et al (2004) Preparation of bioactive titanium metal via anodic oxidation treatment. Biomaterials 25:1003–1010. https://doi.org/10.1016/S0142-9612(03)00626-4

Kumari R, Majumdar JD (2017) Studies on corrosion resistance and bio-activity of plasma spray deposited hydroxylapatite (HA) based TiO 2 and ZrO 2 dispersed composite coatings on titanium alloy (Ti-6Al-4V) and the same after post spray heat treatment. Appl Surf Sci 420:935–943. https://doi.org/10.1016/j.apsusc.2017.05.208

Sathish S, Geetha M, Aruna ST et al (2011) Studies on plasma sprayed bi-layered ceramic coating on bio-medical Ti-13Nb-13Zr alloy. Ceram Int 37:1333–1339. https://doi.org/10.1016/j.ceramint.2010.12.012

Kumari R, Blawert C, Majumdar JD (2016) Microstructures and properties of plasma electrolytic oxidized Ti alloy (Ti-6Al-4V) for bio-implant application. Metall Mater Trans A Phys Metall Mater Sci 47:788–800. https://doi.org/10.1007/s11661-015-3256-y

Oh JC, Lee S, Golkovski MG (2001) Improvement of the hardness and wear resistance of (TiC, TiN)/Ti-6Al-4V surface-alloyed materials fabricated by high-energy electron-beam irradiation. Metall Mater Trans A 32:2995–3005. https://doi.org/10.1007/s11661-001-0174-y

Biswas A, Li L, Chatterjee UK et al (2009) Diode laser assisted surface nitriding of Ti-6Al-4V: properties of the nitrided surface. Metall Mater Trans A Phys Metall Mater Sci 40:3031–3037. https://doi.org/10.1007/s11661-009-0021-0

Kurella A, Dahotre NB (2005) Review paper: surface modification for bioimplants: the role of laser surface engineering. J Biomater Appl 20:5–50. https://doi.org/10.1177/0885328205052974

Kumari R, Scharnweber T, Pfleging W et al (2015) Laser surface textured titanium alloy (Ti-6Al-4V)—Part II—studies on bio-compatibility. Appl Surf Sci 357:750–758. https://doi.org/10.1016/j.apsusc.2015.08.255

Kumari R, Pfleging W, Besser H, Majumdar JD (2019) Microstructure and corrosion behavior of laser induced periodic patterned titanium based alloy. Opt Laser Technol 116:196–213. https://doi.org/10.1016/j.optlastec.2019.03.017

Biswas A, Maity TK, Chatterjee UK et al (2006) Laser surface nitriding of Ti-6Al-4V for bio-implant application. Trends Biomater Artif Organs 20:68–71

Biswas A, Li L, Chatterjee UK et al (2008) Mechanical and electrochemical properties of laser surface nitrided Ti-6Al-4V. Scr Mater 59:239–242. https://doi.org/10.1016/j.scriptamat.2008.03.020

Dutta Majumdar J, Manna I (2011) Laser material processing. Int Mater Rev 56:341–388. https://doi.org/10.1179/1743280411Y.0000000003

Shaikh S, Kedia S, Singh D et al (2019) Surface texturing of Ti6Al4V alloy using femtosecond laser for superior antibacterial performance. J Laser Appl 31:022011. https://doi.org/10.2351/1.5081106

Shivakoti I, Kibria G, Cep R et al (2021) Laser surface texturing for biomedical applications: A review. Coatings 11:1–15. https://doi.org/10.3390/coatings11020124

Schnell G, Staehlke S, Duenow U et al (2019) Femtosecond laser nano/micro textured Ti6Al4V surfaces—effect on wetting and MG-63 cell adhesion. Materials (Basel) 12:2210. https://doi.org/10.3390/ma12132210

Rapoport L, Moshkovich A, Perfilyev V et al (2008) Friction and wear of MoS2 films on laser textured steel surfaces. Surf Coatings Technol 202:3332–3340. https://doi.org/10.1016/j.surfcoat.2007.12.009

Cao L, Chen Y, Cui J et al (2020) Corrosion wear performance of pure titanium laser texturing surface by nitrogen ion implantation. Metals (Basel) 10:1–10. https://doi.org/10.3390/met10080990

Pfleging W, Kumari R, Besser H et al (2015) Laser surface textured titanium alloy (Ti–6Al–4V): Part 1—surface characterization. Appl Surf Sci 355:104–111. https://doi.org/10.1016/j.apsusc.2015.06.175

Šugár P, Kováčik J, Šugárová J, Ludrovcová B (2019) A study of laser micromachining of PM processed Ti compact for dental implants applications. Materials (Basel) 12:2246. https://doi.org/10.3390/ma12142246

Uhlmann E, Schweitzer L, Kieburg H et al (2018) The effects of laser microtexturing of biomedical grade 5 Ti-6Al-4V dental implants (abutment) on biofilm formation. Procedia CIRP 68:184–189. https://doi.org/10.1016/j.procir.2017.12.044

Li CL, Fisher CJ, Burke R, Andersson-Engels S (2022) Orthopedics-related applications of ultrafast laser and its recent advances. Appl Sci 12:3957. https://doi.org/10.3390/app12083957

Ripoll MR, Simič R, Brenner J, Podgornik B (2013) Friction and lifetime of laser surface-textured and mos2-coated Ti6Al4V under dry reciprocating sliding. Tribol Lett 51:261–271. https://doi.org/10.1007/s11249-013-0170-6

Etsion I (2004) Improving tribological performance of mechanical components by laser surface texturing. Tribol Lett 17:733–737. https://doi.org/10.1007/s11249-004-8081-1

Mukherjee S, Dhara S, Saha P (2021) Enhanced corrosion, tribocorrosion resistance and controllable osteogenic potential of stem cells on micro-rippled Ti6Al4V surfaces produced by pulsed laser remelting. J Manuf Process 65:119–133. https://doi.org/10.1016/j.jmapro.2021.03.023

Vilhena LM, Shumayal A, Ramalho A, Ferreira JAM (2020) Tribocorrosion behaviour of Ti6Al4V produced by selective laser melting for dental implants. Lubricants 8:22. https://doi.org/10.3390/lubricants8020022

Feyzi M, Fallahnezhad K, Taylor M, Hashemi R (2022) The tribocorrosion behaviour of Ti-6Al-4 V alloy: the role of both normal force and electrochemical potential. Tribol Lett 70:83. https://doi.org/10.1007/s11249-022-01624-0

Namus R, Nutter J, Qi J, Rainforth WM (2021) Sliding speed influence on the tribo-corrosion behaviour of Ti6Al4V alloy in simulated body fluid. Tribol Int 160:107023. https://doi.org/10.1016/j.triboint.2021.107023

Dileep M, Bathe R, Manna I et al (2021) Ultrafast laser-induced periodic structuring of titanium alloy (Ti-6Al-4V). J Mater Eng Perform 30:4000–4011. https://doi.org/10.1007/s11665-021-05779-0

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. https://doi.org/10.1557/JMR.1992.1564

Conradi M, Kosec T, Podgornik B et al (2021) Effect of laser texturing pattern on Ti6Al4V tribocorrosion in a physiological solution. Surf Innov. https://doi.org/10.1680/jsuin.21.00048

Siddaiah A, Mao B, Liao Y, Menezes PL (2020) Effect of laser shock peening on the wear-corrosion synergistic behavior of an AZ31B magnesium alloy. J Tribol 142:1–11. https://doi.org/10.1115/1.4045500

Mischler S (2013) Sliding tribo-corrosion of passive metals: mechanisms and modeling. In: Tribo-corrosion: research, testing, and applications. ASTM International, West Conshohocken, pp 1–18

ASTM G119–93 (1994) Standard guide for determining synergism between wear and corrosion. Wear Erosion, Met Corros 93:1–7. https://doi.org/10.1520/G0119-09R21.2

Klaffke D (1989) Fretting wear of ceramics. Tribol Int 22:89–101. https://doi.org/10.1016/0301-679X(89)90169-2

Mahmud DNF, Bin AMF, Bin MNA et al (2019) Influence of contact pressure and sliding speed dependence on the tribological characteristics of an activated carbon-epoxy composite derived from palm kernel under dry sliding conditions. Friction 7:227–236. https://doi.org/10.1007/s40544-018-0205-y

Dai FZ, Geng J, Tan WS et al (2018) Friction and wear on laser textured Ti6Al4V surface subjected to laser shock peening with contacting foil. Opt Laser Technol 103:142–150. https://doi.org/10.1016/j.optlastec.2017.12.044

Emmony DC, Howson RP, Willis LJ (1973) Laser mirror damage in germanium at 10.6 μm. Appl Phys Lett 23:598–600. https://doi.org/10.1063/1.1654761

Clark SE, Emmony DC (1989) Ultraviolet-laser-induced periodic surface structures. Phys Rev B 40:2031–2041. https://doi.org/10.1103/PhysRevB.40.2031

Dileep M, Majumdar JD (2022) Short and ultrashort laser surface processing of alpha + beta titanium alloy (Ti6Al4V): present status. Trans Indian Natl Acad Eng. https://doi.org/10.1007/s41403-022-00333-3

Phillips KC, Gandhi HH, Mazur E, Sundaram SK (2015) Ultrafast laser processing of materials: a review. Adv Opt Photonics 7:684. https://doi.org/10.1364/aop.7.000684

Bonse J, Hohm S, Kirner SV et al (2017) Laser-induced periodic surface structures—a scientific evergreen. IEEE J Sel Top Quantum Electron 23:1–59. https://doi.org/10.1109/JSTQE.2016.2614183

Ageev EI, Kudryashov SI, Nikonorov NV et al (2016) Non-contact ultrasonic acquisition of femtosecond laser-driven ablative Mbar-level shock waves on Ti alloy surface. Appl Phys Lett 108:084106. https://doi.org/10.1063/1.4942833

Tsujino M, Sano T, Ogura T et al (2012) Formation of high-density dislocations and hardening in femtosecond-laser-shocked silicon. Appl Phys Express 5:022703. https://doi.org/10.1143/APEX.5.022703

Matsuda T, Sano T, Arakawa K, Hirose A (2014) Dislocation structure produced by an ultrashort shock pulse. J Appl Phys 116:183506. https://doi.org/10.1063/1.4901928

Chichkov BN, Momma C, Nolte S et al (1996) Femtosecond, picosecond and nanosecond laser ablation of solids. Appl Phys A Mater Sci Process 63:109–115. https://doi.org/10.1007/BF01567637

Le Harzic R, Huot N, Audouard E et al (2002) Comparison of heat-affected zones due to nanosecond and femtosecond laser pulses using transmission electronic microscopy. Appl Phys Lett 80:3886–3888. https://doi.org/10.1063/1.1481195

Sun R, He G, Bai H et al (2021) Laser shock peening of Ti6Al4V alloy with combined nanosecond and femtosecond laser pulses. Metals (Basel) 12:26. https://doi.org/10.3390/met12010026

Krawiec H, Vignal V, Heintz O et al (2008) Local electrochemical studies and surface analysis on worn surfaces. J Electrochem Soc 155:C127. https://doi.org/10.1149/1.2830954

Yu Y, Zhou L, Cai Z et al (2022) Research on the mechanism of DD6 single crystal superalloy wear resistance improvement by femtosecond laser modification. Appl Surf Sci 577:151691. https://doi.org/10.1016/j.apsusc.2021.151691

Acknowledgements

Partial financial supports from the Science and Engineering Research Board, N. Delhi (POWER Fellowship, SPF/2021/000073, Dt. 11-03-2021), Ministry of Human Resource Development (MHRD), Government of India (under IMPRINT-2, sanction letter IMP/2018/001162, Dt. 02-01-2019) Department of Science and Technology (DST), N. Delhi (DST/TSG/AMT/2015/636/G, Dt. 18-06-2018, DST/TDT/AMT/2017/074 (G), Dt. 12-09-2018), and Alexander von Humboldt Foundation (Friedrich Wilhelm Bessel Award), Bonn, Germany are gratefully acknowledged. Experimental supports from ARCI, Hyderabad Central Research Facility, Indian Institute of Technology Kharagpur, India are gratefully acknowledged.

Funding

Partial financial supports from the Science and Engineering Research Board, N. Delhi (POWER Fellowship, SPF/2021/000073, Dt. 11-03-2021), Ministry of Human Resource Development (MHRD), Government of India (under IMPRINT-2, sanction letter IMP/2018/001162, Dt. 02-01-2019) Department of Science and Technology (DST), N. Delhi (DST/TSG/AMT/2015/636/G, Dt. 18-06-2018, DST/TDT/AMT/2017/074 (G), Dt. 12-09-2018), and Alexander von Humboldt Foundation (Friedrich Wilhelm Bessel Award), Bonn, Germany are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Conceptualization was performed by JDM, RB, IM, and DM; methodology by JDM, RB, IM, and DM; writing—original draft preparation—by JDM and DM; review and editing by JDM, RB, IM, and DM; supervision by JDM

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Madapana, D., Bathe, R., Manna, I. et al. Tribocorrosion Behaviour of Laser-Induced Periodic Surface Structured Ti6Al4V. J Bio Tribo Corros 9, 9 (2023). https://doi.org/10.1007/s40735-022-00724-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-022-00724-7