Abstract

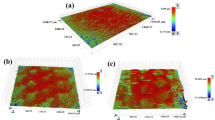

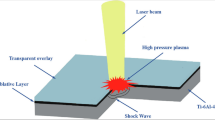

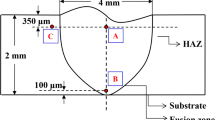

In the present study, the effect of laser intensity on the microstructure, residual stress, microhardness, and corrosion resistance property of laser shock peened Ti6Al4V using an Nd: YAG laser has been investigated. The applied laser intensity varied from 1 to 8 GW/cm2. During the processing, the pulse density was 574 pulses/cm2, and water was used as a confining layer. Due to laser shock peening, there is refinement of microstructure and presence of oxides on the surface. The residual stress on the surface was found to vary from + 130.12 to − 138.16 MPa and varied with process parameters. There is an increase in microhardness which also varied with process parameters. Due to laser surface processing, there is a significant improvement in corrosion resistance. A detailed structure–property correlation has been established.

Similar content being viewed by others

References

L. Zhang and L. Chen, A Review on Biomedical Titanium Alloys: Recent Progress and Prospect, Adv. Eng. Mater., 2019, 21(4), p 1801215. https://doi.org/10.1002/adem.201801215

M. Kaur and K. Singh, Review on Titanium and Titanium Based Alloys as Biomaterials for Orthopaedic Applications, Mater. Sci. Eng. C, 2019, 2019(102), p 844–862. https://doi.org/10.1016/j.msec.2019.04.064

T. Xue, S. Attarilar, S. Liu, J. Liu, X. Song, L. Li, B. Zhao, and Y. Tang, Surface Modification Techniques of Titanium and Its Alloys to Functionally Optimize Their Biomedical Properties: Thematic Review, Front. Bioeng. Biotechnol., 2020, 8(November), p 1–19. https://doi.org/10.3389/fbioe.2020.603072

D. Rodrigues, P. Valderrama, T. Wilson, K. Palmer, A. Thomas, S. Sridhar, A. Adapalli, M. Burbano, and C. Wadhwani, Titanium Corrosion Mechanisms in the Oral Environment: A Retrieval Study, Materials (Basel), 2013, 6(11), p 5258–5274. https://doi.org/10.3390/ma6115258

M. Noronha Oliveira, W.V.H. Schunemann, M.T. Mathew, B. Henriques, R.S. Magini, W. Teughels, and J.C.M. Souza, Can Degradation Products Released from Dental Implants Affect Peri-implant Tissues?, J. Periodontal Res., 2018, 53(1), p 1–11. https://doi.org/10.1111/jre.12479

J.C.M. Souza, M. Henriques, W. Teughels, P. Ponthiaux, J.-P. Celis, and L.A. Rocha, Wear and Corrosion Interactions on Titanium in Oral Environment: Literature Review, J. Bio- Tribo-Corrosion, 2015, 1(2), p 13. https://doi.org/10.1007/s40735-015-0013-0

T. Hanawa, Metal Ion Release from Metal Implants, Mater. Sci. Eng. C, 2004, 24(6–8), p 745–752. https://doi.org/10.1016/j.msec.2004.08.018

T.G. Wilson, P. Valderrama, M. Burbano, J. Blansett, R. Levine, H. Kessler, and D.C. Rodrigues, Foreign Bodies Associated With Peri-Implantitis Human Biopsies, J. Periodontol., 2015, 86(1), p 9–15. https://doi.org/10.1902/jop.2014.140363

J.C.M. Souza, K. Apaza-Bedoya, C.A.M. Benfatti, F.S. Silva, and B. Henriques, A Comprehensive Review on the Corrosion Pathways of Titanium Dental Implants and Their Biological Adverse Effects, Metals (Basel), 2020, 10(9), p 1272. https://doi.org/10.3390/met10091272

G.O. Alrabeah, P. Brett, J.C. Knowles, and H. Petridis, The Effect of Metal Ions Released from Different Dental Implant-Abutment Couples on Osteoblast Function and Secretion of Bone Resorbing Mediators, J. Dent., 2017, 66(March), p 91–101. https://doi.org/10.1016/j.jdent.2017.08.002

W. Pfleging, R. Kumari, H. Besser, T. Scharnweber, and J.D. Majumdar, Laser Surface Textured Titanium Alloy (Ti-6Al-4V): Part 1 - Surface Characterization, Appl. Surf. Sci., 2015, 355, p 104–111. https://doi.org/10.1016/j.apsusc.2015.06.175

R. Kumari, T. Scharnweber, W. Pfleging, H. Besser, and J.D. Majumdar, Laser Surface Textured Titanium Alloy (Ti-6Al-4V) - Part II - Studies on Bio-Compatibility, Appl. Surf. Sci., 2015, 357, p 750–758.

R. Kumari and J.D. Majumdar, Studies on Corrosion Resistance and Bio-Activity of Plasma Spray Deposited Hydroxylapatite (HA) Based TiO2 and ZrO2 Dispersed Composite Coatings on Titanium Alloy (Ti-6Al-4V) and the Same after Post Spray Heat Treatment, Appl. Surf. Sci., 2017, 420, p 935–943. https://doi.org/10.1016/j.apsusc.2017.05.208

M. Dileep, R. Bathe, I. Manna, G. Padmanabham, and J. Dutta Majumdar, Ultrafast Laser-Induced Periodic Structuring of Titanium Alloy (Ti-6Al-4V), J. Mater. Eng. Perform., 2021, 30(6), p 4000–4011. https://doi.org/10.1007/s11665-021-05779-0

S.B. Patel, A. Hamlekhan, D. Royhman, A. Butt, J. Yuan, T. Shokuhfar, C. Sukotjo, M.T. Mathew, G. Jursich, and C.G. Takoudis, Enhancing Surface Characteristics of Ti-6Al-4V for Bio-Implants Using Integrated Anodization and Thermal Oxidation, J. Mater. Chem. B, 2014, 2(23), p 3597. https://doi.org/10.1039/c3tb21731k

X. Liu, P.K. Chu, and C. Ding, Surface Modification of Titanium, Titanium Alloys, and Related Materials for Biomedical Applications, Mater. Sci. Eng. R Rep., 2004, 47(3–4), p 49–121.

B. Dhakal and S. Swaroop, Review: Laser Shock Peening as Post Welding Treatment Technique, J. Manuf. Process., 2018, 2018(32), p 721–733. https://doi.org/10.1016/j.jmapro.2018.04.006

C. Zhang, Y. Dong, and C. Ye, Recent Developments and Novel Applications of Laser Shock Peening: A Review, Adv. Eng. Mater., 2021, 23(7), p 2001216. https://doi.org/10.1002/adem.202001216

R.K. Gupta, B.K. Pant, V. Kain, R. Kaul, and K.S. Bindra, 2019 Laser Shock Peening and Its Applications: A Review, Lasers Manuf. Mater. Process., 2019, 6(4), p 424–463. https://doi.org/10.1007/s40516-019-00098-8

J.L. Hu, J. Lou, H.C. Sheng, S.H. Wu, G.X. Chen, K.F. Huang, L. Ye, Z.K. Liu, Y.L. Shi, and S. Yin, The Effects of Laser Shock Peening on Microstructure and Properties of Metals and Alloys: A Review, Adv. Mater. Res., 2011, 347–353, p 1596–1604. https://doi.org/10.4028/www.scientific.net/AMR.347-353.1596

K. Praveenkumar, P. Mylavarapu, and S. Swaroop, Surface Oxidation and Subsurface Deformation in a Laser-Peened Ti-6Al-4V, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07639-x

S. Prabhakaran, A. Kulkarni, G. Vasanth, S. Kalainathan, P. Shukla, and V.K. Vasudevan, Laser Shock Peening without Coating Induced Residual Stress Distribution, Wettability Characteristics and Enhanced Pitting Corrosion Resistance of Austenitic Stainless Steel, Appl. Surf. Sci., 2018, 428, p 17–30. https://doi.org/10.1016/j.apsusc.2017.09.138

S. Petronić, K. Čolić, B. Đorđević, D. Milovanović, M. Burzić, and F. Vučetić, Effect of Laser Shock Peening with and without Protective Coating on the Microstructure and Mechanical Properties of Ti-Alloy, Opt. Lasers Eng., 2020, 129, p 106052.

B. Jose, T. Patil, S. Sudhagara Rajan, K. Praveenkumar, G. Manivasagam, and S. Swaroop, Effect of Laser Shock Peening without Coating (LPwC) on a Surface and Sub-Surface Characteristics of Aged Ti 15V-3Al-3Cr-3Sn Alloy, Mater. Today Proc., 2021, 46, p 578–582. https://doi.org/10.1016/j.matpr.2020.11.289

Y. Sano, M. Obata, T. Kubo, N. Mukai, M. Yoda, K. Masaki, and Y. Ochi, Retardation of Crack Initiation and Growth in Austenitic Stainless Steels by Laser Peening without Protective Coating, Mater. Sci. Eng. A, 2006, 417(1–2), p 334–340. https://doi.org/10.1016/j.msea.2005.11.017

S. Kalainathan, S. Sathyajith, and S. Swaroop, Effect of Laser Shot Peening without Coating on the Surface Properties and Corrosion Behavior of 316L Steel, Opt. Lasers Eng., 2012, 50(12), p 1740–1745. https://doi.org/10.1016/j.optlaseng.2012.07.007

U. Trdan and J. Grum, SEM/EDS Characterization of Laser Shock Peening Effect on Localized Corrosion of Al Alloy in a near Natural Chloride Environment, Corros. Sci., 2014, 82, p 328–338. https://doi.org/10.1016/j.corsci.2014.01.032

G. Ranjith Kumar, G. Rajyalakshmi, S. Swaroop, S. ArulXavierStango, and U. Vijayalakshmi, Laser Shock Peening Wavelength Conditions for Enhancing Corrosion Behaviour of Titanium Alloy in Chloride Environment, J. Brazil. Soc. Mech. Sci. Eng., 2019, 41(3), p 129. https://doi.org/10.1007/s40430-019-1633-y

G. Ranjith Kumar and G. Rajyalakshmi, Role of Nano Second Laser Wavelength Embedded Recast Layer and Residual Stress on Electrochemical Corrosion of Titanium Alloy, Mater. Res. Express, 2019, 6(8), p 086583. https://doi.org/10.1088/2053-1591/ab1fb2

A. Chattopadhyay, G. Muvvala, S. Sarkar, V. Racherla, and A.K. Nath, Effect of Laser Shock Peening on Microstructural, Mechanical and Corrosion Properties of Laser Beam Welded Commercially Pure Titanium, Opt. Laser Technol., 2021, 2021(133), p 106527. https://doi.org/10.1016/j.optlastec.2020.106527

C.A. Reynoso-Garcia, G. Gomez-Rosas, O. Blanco, C. Rubio-Gonzalez, A.C. Chavez, E. Castañeda, and J.L. Ocaña, Improving the Surface Properties of Ti6Al4V with Laser Shock Processing, Int. J. Peen. Sci. Technol., 2018, 1, p 119–136.

S. Varin, Y. Jain, S. Prabhakaran, and S. Kalainathan, Influence of Multiple Laser Shock Peening without Coating on Ti-6Al-4V Alloy for Aircraft Applications, Mech. Mater. Sci. Eng., 2017, p 363–367.

D. Madapana, H. Ramadas, A.K. Nath, and J. Dutta Majumdar, Studies on Laser Shock Peening on Nanomechanical and Mechano-Chemical Properties of Titanium Alloy (Ti6Al4V), JOM, 2022, 75, p 109–119. https://doi.org/10.1007/s11837-022-05504-9

X. Shen, P. Shukla, S. Nayak, V. Gopal, P. Subramanian, A. Sarah Benjamin, and S. Kalainathan, Biological and Mechanical Response of Laser Shock Peening Orthopaedic Titanium Alloy (Ti-6Al-7Nb), Proc. Inst. Mech. Eng. Part H J. Eng. Med., 2022, 236(8), p 1169–1187.

M. Dileep and J.D. Majumdar, Corrosion and Tribocorrosion Behaviour of Laser Shock Peened Ti6Al4V, (under submission), 2022.

Acknowledgment

Partial financial supports from the Science and Engineering Research Board, N. Delhi (POWER Fellowship, SPF/2021/000073, Dt. 11-03-2021), Ministry of Human Resource Development (MHRD), Government of India (under IMPRINT-2, sanction letter IMP/2018/001162, Dt. 02-01-2019), Department of Science and Technology (DST), N. Delhi (DST/TSG/AMT/2015/636/G, Dt. 18-06-2018, DST/TDT/AMT/2017/074 (G), Dt. 12-09-2018), and Alexander von Humboldt Foundation (Friedrich Wilhelm Bessel Award), Bonn, Germany, are gratefully acknowledged. Experimental supports from Indian Institute of Technology Kharagpur (Pulsed Laser Lab and Central Research Facility) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the 4th International Conference on Processing & Characterization of Materials (ICPCM 2022) held December 9–11, 2022, at the National Institute of Technology, Rourkela, Odisha, India. It has been expanded from the original presentation. The issue was organized by Prof. Joao Pedro Oliveira, Universidade NOVA de Lisboa, Portugal; Prof. B. Venkata Manoj Kumar, Indian Institute of Technology Roorkee, India; Dr. D. Arvindha Babu, DMRL, DRDO, Hyderabad, India; Prof. Kumud Kant Mehta and Prof. Anshuman Patra, National Institute of Technology Rourkela, Odisha, India; and Prof. Manab Mallik, National Institute of Technology Durgapur, India.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Madapana, D., Ramadas, H., Nath, A.K. et al. Structure-Property-Process Parameters Correlation of Laser Shock-Peened Titanium Alloy (Ti6Al4V) Without Protective Layer. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08900-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08900-7