Abstract

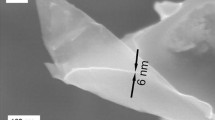

Aluminum matrix composites (AMCs) reinforced with graphene nanoplatelets (GNPs) were fabricated by using an accumulative roll-compositing (ARC) process. Microstructure, mechanical and electrical properties of the nanostructured AMCs were characterized. The results showed that small addition (0.2 vol% and 0.5 vol%) of GNPs can lead to a simultaneous increase in the tensile strength and ductility of the GNPs/Al nanocomposites, as compared with the same processed pure Al. With increasing GNPs content, the tensile strength of the GNPs/Al nanocomposites can be enhanced to 387 MPa with retained elongation of 15%. Meanwhile, the GNPs/Al nanocomposites exhibited a good electrical conductivity of 77.8%–86.1% that of annealed pure Al. The excellent properties (high strength, high ductility and high conductivity) of the GNPs/Al are associated with the particular ARC process, which facilitates the uniform dispersion of GNPs in the matrix and formation of ultrafine-grained Al matrix. The strengthening and toughening of the GNPs/Al nanocomposites were discussed considering different mechanisms and the unique effect of GNPs.

Graphic abstract

Similar content being viewed by others

References

Ma ZY, Tjong SC. In situ ceramic particle-reinforced aluminum matrix composites fabricated by reaction pressing in the TiO2 (Ti)-Al-B (B2O3) systems. Metall Mater Trans A. 1997;28(9):1931.

Liu YQ, Fan JZ, Hao XX, Wei SH, Nie JH, Ma ZL, Liu MK, Wang YB. Advanced hermetic electronic packaging based on lightweight silicon/aluminum composite produced by powder metallurgy technique. Rare Met. 2020;39(11):1307.

Feng SY, Li QL, Liu W, Shu GG, Wang X. Microstructure and mechanical properties of Al-B4C composite at elevated temperature strengthened with in situ Al2O3 network. Rare Met. 2020;39(6):671.

Gao HD, Wang ZH, Shao J. Manufacture and characteristics of Al2O3 composite coating on steel substrate by SHS process. Rare Met. 2019;38(7):704.

Bi GL, Han YX, Jiang J, Jiang CH, Li YD, Ma Y. Microstructural evolution and age-hardening behavior of quasicrystal-reinforced Mg-Dy-Zn alloy. Rare Met. 2019;38(8):739.

Baig Z, Mamat O, Mustapha M. Recent progress on the dispersion and the strengthening effect of carbon nanotubes and graphene-reinforced metal nanocomposites: a review. Crit Rev Solid State Mater Sci. 2018;43(1):1.

Tjong SC. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater Sci Eng R Reports. 2013;74(10):281.

Kuzumaki T, Miyazawa K, Ichinose H, Ito K. Processing of carbon nanotube reinforced aluminum composite. J Mater Res. 1998;13(09):2445.

Izadi H, Gerlich AP. Distribution and stability of carbon nanotubes during multi-pass friction stir processing of carbon nanotube/aluminum composites. Carbon. 2012;50(12):4744.

Li PB, Tan WT, Gao MM, Liu KG. Semisolid microstructural evolution of (CNTs + Sip)/AZ91D powder compacts prepared from powders by cold pressing and remelting. Rare Met. 2020;39(6):733.

Kim KT, Eckert J, Menzel SB, Gemming T, Hong SH. Grain refinement assisted strengthening of carbon nanotube reinforced copper matrix nanocomposites. Appl Phys Lett. 2008;92(12):121901.

Honma T, Nagai K, Katou A, Arai K, Suganuma M, Kamado S. Synthesis of high-strength magnesium alloy composites reinforced with Si-coated carbon nanofibres. Scr Mater. 2009;60(6):451.

Shimizu Y, Miki S, Soga T, Itoh I, Todoroki H, Hosono T, Sakaki K, Hayashi T, Kim KA, Endo M, Morimoto S, Koide A. Multi-walled carbon nanotube-reinforced magnesium alloy composites. Scr Mater. 2008;58(4):267.

Kwon H, Estili M, Takagi K, Miyazaki T, Kawasaki A. Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites. Carbon. 2009;47(3):570.

Morovvati MR, Mollaei-Dariani B. The formability investigation of CNT-reinforced aluminum nano-composite sheets manufactured by accumulative roll bonding. Int J Adv Manuf Technol. 2018;95(9–12):3523.

Tokutomi J, Uemura T, Sugiyama S, Shiomi J, Yanagimoto J. Hot extrusion to manufacture the metal matrix composite of carbon nanotube and aluminum with excellent electrical conductivities and mechanical properties. CIRP Ann. 2015;64(1):257.

Bartolucci SF, Paras J, Rafiee MA, Rafiee J, Lee S, Kapoor D, Koratkar N. Graphene–aluminum nanocomposites. Mater Sci Eng, A. 2011;528(27):7933.

Wang J, Li Z, Fan G, Pan H, Chen Z, Zhang D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr Mater. 2012;66(8):594.

Li JL, Xiong YC, Wang XD, Yan SJ, Yang C, He WW, Chen JZ, Wang SQ, Zhang XY, Dai SL. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater Sci Eng, A. 2015;626:400.

Gao X, Yue H, Guo E, Zhang H, Lin X, Yao L, Wang B. Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites. Mater Des. 2016;94:54.

Shin SE, Choi HJ, Shin JH, Bae DH. Strengthening behavior of few-layered graphene/aluminum composites. Carbon. 2015;82:143.

Li M, Gao H, Liang J, Gu S, You W, Shu D, Wang J, Sun B. Microstructure evolution and properties of graphene nanoplatelets reinforced aluminum matrix composites. Mater Charact. 2018;140:172.

Singhal SK, Pasricha R, Teotia S, Kumar G, Mathur RB. Fabrication and characterization of Al-matrix composites reinforced with amino-functionalized carbon nanotubes. Compos Sci Technol. 2011;72(1):103.

Liu ZY, Xu SJ, Xiao BL, Xue P, Wang WG, Ma ZY. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Compos Part A Appl Sci Manuf. 2012;43(12):2161.

Li CL, Mei QS, Li JY, Chen F, Ma Y, Mei XM. Hall-Petch relations and strengthening of Al–ZnO composites in view of grain size relative to interparticle spacing. Scr Mater. 2018;153:27.

Zhang GP, Mei QS, Chen F, Ma Y, Mei XM, Li JY, Ruan XF, Wan L. Production of a high strength Al/(TiAl3 + Al2O3) composite from an Al-TiO2 system by accumulative roll-bonding and spark plasma sintering. Mater Sci Eng, A. 2019;752:192.

Bisht A, Srivastava M, Kumar RM, Lahiri I, Lahiri D. Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering. Mater Sci Eng, A. 2017;695:20.

Zhao L, Lu H, Gao Z. Microstructure and mechanical properties of Al/graphene composite produced by high-pressure torsion. Adv Eng Mater. 2015;17(7):976.

Rashad M, Pan F, Tang A, Asif M. Effect of graphene nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog Nat Sci Mater Int. 2014;24(2):101.

Liu SX. Practical Metal Materials Handbook. Beijing: China Machine Press; 2017. 701.

Shen NF. New Handbook of Metallic Materials. Beijing: Science Press; 2003. 275.

Zhang JY, Gao YH, Yang C, Zhang P, Kuang J, Liu G, Sun J. Microalloying Al alloys with Sc: a review. Rare Met. 2020;39(6):636.

Liu CY, Teng GB, Ma ZY, Wei LL, Zhou WB, Huang HF, Qi HQ. Mechanical properties and thermal stability of 7055 Al alloy by minor Sc addition. Rare Met. 2020;39(6):725.

Nie JF, Muddle BC. Microstructural design of high-strength aluminum alloys. J Phase Equilibria. 1998;19(6):543.

Yun C, Feng Y, Qiu T, Yang J, Li X, Yu L. Mechanical, electrical, and thermal properties of graphene nanosheet/aluminum nitride composites. Ceram Int. 2015;41(7):8643.

Walker LS, Marotto VR, Rafiee MA, Koratkar N, Corral EL. Toughening in graphene ceramic composites. ACS Nano. 2011;5(4):3182.

Lee B, Koo MY, Jin SH, Kim KT, Hong SH. Simultaneous strengthening and toughening of reduced graphene oxide/alumina composites fabricated by molecular-level mixing process. Carbon. 2014;78:212.

Yan SY, Dai SL, Zhang XY, Yang C, Hong QH, Chen JZ, Lin ZM. Investigating aluminum alloy reinforced by graphene nanoflakes. Mater Sci Eng, A. 2014;612:440.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51371128) and the Fundamental Research Funds for the Central Universities of China (No. 2042017KF0190).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, ZH., Hui, HY., Li, CL. et al. GNPs/Al nanocomposites with high strength and ductility and electrical conductivity fabricated by accumulative roll-compositing. Rare Met. 40, 2593–2601 (2021). https://doi.org/10.1007/s12598-020-01695-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01695-9