Abstract

GNPs-A380 composites with different GNPs contents (0.0 wt%, 0.5 wt%, 1.0 wt%, 1.5 wt%) are prepared by ultrasonic casting method. Using magnetic stirring for GNPs pre-dispersion treatment can effectively disperse GNPs and damage to GNPs is less. The distribution of GNPs in GNPs-A380 composites is optimal when the GNPs content is 1.0 wt%, and the microstructure is also optimal. The good dispersion of GNPs also results in the best refinement of the second phase. GNPs refine the second-phase GNPs-A380 composites by hindering the growth of the second phase. The refinement of the second phase reduces the stress concentration and crack spread in GNPs-A380 composites when loaded. The improvement of mechanical properties of GNPs-A380 composites is due to the dislocation strengthening and load transfer strengthening of GNPs.

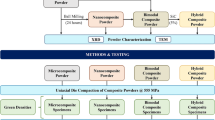

Graphical Abstract

Similar content being viewed by others

References

K. Mostafa, A. Mortaza, E. Masoud, A. Mohammad, Microstructure, hardness and tensile properties of A380 aluminum alloy with and without Li additions. Mater. Sci. Eng. A 582, 409–414 (2013). https://doi.org/10.1016/j.msea.2013.05.088

Q.J. Wu, H. Yan, P.X. Zhang, X.Q. Zhu, Q. Nie, Enhancing wear resistance of A356 alloy by adding CNFs based on ultrasonic vibration casting. Acta Metall. Sin. (Engl. Lett.) 31, 523–532 (2018). https://doi.org/10.1007/s40195-017-0680-6

B. Chen, K. Kondoh, H. Imai, J. Umeda, M. Takahashi, Takahashi, Simultaneously enhancing strength and ductility of carbon nanotube/aluminum composites by improving bonding conditions. Scr. Mater. 113, 158–162 (2016). https://doi.org/10.1016/j.scriptamat.2015.11.011

P. Ajay Kumar, P. Rohatgi, D. Weiss, 50 years of foundry-produced metal matrix composites and future opportunities. Inter. Metalcast. 14, 291–317 (2020). https://doi.org/10.1007/s40962-019-00375-4

L. Jiao, B. Wang, Y. Zhao et al., Microstructure and mechanical properties of in situ AlB2/A356 composites under T6 treatment. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00828-3

M. Alipour, R. Keshavamurthy, P.G. Koppad, A. Shakiba, N.C. Reddy, Investigation of microstructure and mechanical properties of cast Al–10Zn–3.5Mg–2.5Cu nanocomposite reinforced with graphene nano sheets produced by ultrasonic assisted stir casting. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00826-5

F. Lin, F. Jia, M. Ren, J. Wang, M. Yang, Z. Chen, Z. Jiang, Microstructure, mechanical and thermal properties of ultrafine-grained Al2024–TiC-GNPs nanocomposite. Mater. Sci. Eng. A 841, 142855 (2022). https://doi.org/10.1016/j.msea.2022.142855

M.K. Hullur, D.M. Goudar, K. Venkateshwaralu et al., Sliding wear behaviour of in situ TiB2 reinforced hypoeutectic Al-Si Alloy composites. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00847-0

G. Kumaresan, B.A. Kumar, Investigations on mechanical and wear properties of Al matrix composites reinforced with hybrid SiC and Al2O3 micro-particles. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00817-6

Yadav, A.K. Kumar, V. Ankit et al., Microstructure and mechanical properties of an in situ Al 356-Mg2Si-TiB2 hybrid composite prepared by stir and cooling slope casting. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00804-x

C. Panthglin, S. Boontein, J. Kajornchaiyakul et al., Microstructure and impression creep characteristics of A356–SiC composites containing Zr. Inter. Metalcast. 16, 783–797 (2022). https://doi.org/10.1007/s40962-021-00620-9

R. Soundararajan, A. Sathishkumar, S. Sivasankaran et al., Evaluation of microstructures, mechanical and dry-sliding wear performance of A356-(Fly Ash/SiCp) hybrid composites. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-021-00731-3

U. Aybarç, O. Ertuğrul, M.Ö. Seydibeyoğlu, Effect of Al2O3 particle size on mechanical properties of ultrasonic-assisted stir-casted Al A356 matrix composites. Inter. Metalcast. 15, 638–649 (2021). https://doi.org/10.1007/s40962-020-00490-7

A.A. Balandin, S. Ghosh, W. Bao et al., Superior thermal conductivity of single-layer graphene. Nano Lett. 8, 902–907 (2018). https://doi.org/10.1021/nl0731872

X. Gao, H. Yue, E. Guo et al., Preparation and tribological properties of homogeneously dispersed graphene-reinforced aluminium matrix composites. Mater. Sci. Technol. 34, 1316–1322 (2018). https://doi.org/10.1080/02670836.2018.1446869

A. Bhadauria, L.K. Singh, T. Laha, Effect of physio-chemically functionalized graphene nanoplatelet reinforcement on tensile properties of aluminum nanocomposite synthesized via spark plasma sintering. J. Alloys Compd. 748, 783–793 (2018). https://doi.org/10.1016/j.jallcom.2018.03.186

S. Liu, S.F. GAO, Q. ZHANG et al., Fabrication of carbon nanotubes reinforced AZ91D composites by ultrasonic processing. Trans. Nonferrous Met. Soc. China 20, 1222–1227 (2010). https://doi.org/10.1016/S1003-6326(09)60282-X

G. Liu, N. Zhao, C. Shi et al., In-situ synthesis of graphene decorated with nickel nanoparticles for fabricating reinforced 6061Al matrix composites. Mater. Sci. Eng. A 699, 185–193 (2017). https://doi.org/10.1016/j.msea.2017.05.084

B. Mina, G.Y. Kim, Z. Can, Z. Kun, W. Shiren, T. Xiaoduan, W. Xinwei, Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. Part B 60, 111–118 (2014). https://doi.org/10.1016/j.compositesb.2013.12.043

R. Pérez-Bustamante, F. Pérez-Bustamante, I. Estrada-Guel, L. Licea-Jiménez, M. Miki-Yoshida, R. Martínez-Sánchez, Effect of milling time and CNT concentration on hardness of CNT/Al2024 composites produced by mechanical alloying. Mater. Charact. 75, 13–19 (2013). https://doi.org/10.1016/j.matchar.2012.09.005

S.J. Yan, S.L. Dai, X.Y. Zhang, C. Yang, Q.H. Hong, J.Z. Chen et al., Investigating aluminum alloy reinforced by graphene nanoflakes. Mater. Sci. Eng. A 612, 440 (2014). https://doi.org/10.1016/j.msea.2014.06.077

S.E. Shin, H.J. Choi, J.H. Shin, D.H. Bae, Strengthening behavior of few-layered graphene/aluminum composites. Carbon 82, 143–151 (2015). https://doi.org/10.1016/j.carbon.2014.10.044

D. Yuan, X. Yang, S. Wu, Development of high strength and toughness nano-SiCp/A356 composites with ultrasonic vibration and squeeze casting. J. Manuf. Process. Tech. 69, 1–9 (2019). https://doi.org/10.1016/j.jmatprotec.2019.01.021

Z.W. Huang, H. Yan, J.J. Xiong, Analysis of microstructure and mechanical properties of graphene nanoplatelet reinforced 2024Al alloy. Mater. Sci. Eng. A 832, 142466 (2022). https://doi.org/10.1016/j.msea.2021.142466

A. Fadavi Boostani, S. Yazdani, R. Taherzadeh Mousavian, S. Tahamtan, R. Azari Khosroshahi, D. Wei, D. Brabazon, J.Z. Xu, X.M. Zhang, Z.Y. Jiang, Strengthening mechanisms of graphene sheets in aluminium matrix nanocomposites. Mater. Des. 88, 983–989 (2015). https://doi.org/10.1016/j.matdes.2015.09.063

M. Zeng, H. Yan, K. Li, Y. Lei, Microstructure, wettability, and mechanical properties of ADC12 alloy reinforced with TiO2-coated carbon nanotubes. J. Alloys. Compd. 897, 163181 (2022). https://doi.org/10.1016/j.jallcom.2021.163181

Z. Haiping, X. Cong, X. Wenlong, K. Ameyama, C. Ma, Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion. Mater. Sci. Eng. A 658, 8–15 (2016). https://doi.org/10.1016/j.msea.2016.01.076

H. Kwon, J. Mondal, K.A. AlOgab, V. Sammelselg, M. Takamichi, A. Kawaski et al., Graphene oxide-reinforced aluminum alloy matrix composite materials fabricated by powder metallurgy. J. Alloys Compd. 698, 807–813 (2017). https://doi.org/10.1016/j.jallcom.2016.12.179

M.J. Bucknum, E.A. Castro, The carbon allotrope hexagonite and its potential synthesis from cold compression of carbon nanotubes. J. Chem. Theory Comput. 2, 775 (2006). https://doi.org/10.1021/ct060003n

B.S. Guo, Y.Q. Chen, Z.G. Wang, J.H. Yi, S. Ni, Y. Du, W. Li, M. Song, Enhancement of strength and ductility by interfacial nano-decoration in carbon nanotube/aluminum matrix composites. Carbon 159, 201–212 (2020). https://doi.org/10.1016/j.carbon.2019.12.038

W.S. Yang, G.Q. Chen, J. Qiao, S.F. Liu, R. Xiao, R.H. Dong, M. Hussain, G.H. Wu, Graphene nanoflakes reinforced Al-20Si matrix composites prepared by pressure infiltration method. Mater. Sci. Eng. A 700, 351–357 (2017). https://doi.org/10.1016/j.msea.2017.06.027

L.A. Yolshina, R.V. Muradymov, I.V. Korsun, G.A. Yakovlev, S.V. Smirnov, Novel aluminum-graphene and aluminum-graphite metallic composite materials: synthesis and properties. J. Alloys. Compd. 663, 449–459 (2016). https://doi.org/10.1016/j.jallcom.2015.12.084

K.K. Ma, H.M. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 62, 141–155 (2014). https://doi.org/10.1016/j.actamat.2013.09.042

A. Patil, M.S. Kiran Kumar Yadav Nartu, F. Ozdemir, R. Banerjee, R.K. Gupta, T. Borkar, Enhancement of the mechanical properties of graphene nanoplatelet (GNP) reinforced nickel matrix nanocomposites. Mater. Sci. Eng. 817, 141324 (2021). https://doi.org/10.1016/j.msea.2021.141324

Acknowledgments

This study was supported by the national natural science foundation of China (Grant No. 51965040); and the Jiangxi Province Innovation Special Fund Project Foundation (Grant No. YC2021-S136).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Z., Yan, H. Effect of Graphene on the Microstructure Evolution and Mechanical Properties of Al–10Si–2Cu–1.5Fe Aluminum Matrix Composites. Inter Metalcast 17, 2808–2817 (2023). https://doi.org/10.1007/s40962-022-00952-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00952-0