Abstract

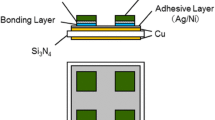

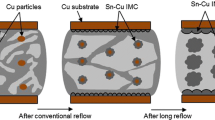

The influence of thermal cycle stress loading on hybrid bonding, which was formed by sintering a mixture of Cu nanoparticles and a eutectic Bi-Sn solder powder, has been investigated. A Si chip and a directly bonded aluminum (DBA) substrate were bonded using the hybrid bonding layer. The bonded sample was evaluated using a thermal cycle test (− 40°C and 250°C). The degradation process of the sample during the test was observed nondestructively using synchrotron radiation x-ray computed laminography. The thermal cycle stress loading had a minimal effect on the microstructure of the bonding layer, which has a high bonding strength owing to the liquid phase sintering and high decomposition melting temperature of the Cu-Sn compound formation. This property reduced the Al deformation of the DBA substrate caused by the thermal cycle loading, resulting in the suppression of the bonding layer degradation. Therefore, hybrid bonding can be instrumental in achieving the reliable operation of power modules at high temperatures.

Similar content being viewed by others

References

H. Ohashi, I. Omura, S. Matsumoto, Y. Sato, H. Tadano, and I. Ishii, IEICE Trans. Commun. E87-B, 3422 (2004).

O. Kitazawa, T. Kikuchi, M. Nakashima, Y. Tomita, H. Kosugi, T. Kaneko, and S.A.E. Int, J. Alt. Power. 5, 278 (2016).

T. Hasegawa, H. Imanishi, M. Nada and Y. Ikogi, SAE Tech. Paper 2016-01-1185 (2016).

K. Hamada, M. Nagao, M. Ajioka, and F. Kawai, IEEE Trans. Electron. Dev. 62, 278 (2015).

T. Sugiura, A. Tanida, K. Tamura, and S.A.E. Int, J. Alt. Power. 5, 294 (2016).

T. Ogawa, A. Tanida, T. Yamakawa and M. Okamura, SAE Tech. Paper 2016-01-1230 (2016).

Y. Yamada, Y. Takaku, Y. Yagi, I. Nakagawa, T. Atsumi, M. Shirai, I. Ohmura, and K. Ishida, Trans. Jpn. Inst. Electron. Packag. 79, 2 (2009).

H. Zhang, C. Chen, J. Jiu, S. Nagao, and K. Suganuma, J. Mater. Sci. Mater. Electro. Mater. Electron. 29, 8854 (2018).

H.A. Mustain, W.D. Brown, and S.S. Ang, IEEE Trans. Compon. Packag. Technol. 33, 563 (2010).

H. Ito, M. Kuwahara, H. Kadoura, and M. Usui, IET Power Electron. 12, 492 (2019).

Y. Liu, S.N. Joshi, and E.M. Dede, J. Electron. Packag. 142, 011003 (2020).

K.S. Siow and S.T. Chua, JOM 71, 3066 (2019).

W.S. Hong, M.S. Kim, C. Oh, Y. Joo, Y. Kim, and K.-K. Hong, JOM 72, 889 (2020).

R. Khazaka, L. Mendizabal, and D. Henry, J. Electron. Mater. 48, 2459 (2014).

M.-S. Kim and H. Nishikawa, Mater. Sci. Eng. A 645, 264 (2015).

S.A. Paknejad and S.H. Mannan, Microelectron. Reliab. 70, 1 (2017).

T. Ishizaki and R. Watanabe, J. Mater. Chem. 22, 25198 (2012).

O. Mokhtari and H. Nishikawa, J. Mater. Sci. Mater. Electron. 27, 4232 (2016).

Y. Liu, B. Ren, M. Zhou, X. Zeng, and F. Sun, J. Mater. Sci. Mater. Electron. 31, 8258 (2020).

T. Ishizaki, D. Miura, A. Kuno, R. Nagao, S. Aoki, Y. Ohshima, T. Kino, M. Usui, and Y. Yamada, Microelectron. Reliab. 64, 287 (2016).

T. Satoh, T. Ishizaki, and K. Akedo, J. Alloy. Comput. 691, 524 (2017).

Y. Mou, Y. Peng, Y. Zhang, H. Cheng, and M. Chen, Mater. Lett. 227, 179 (2018).

J. Xie, J. Shen, J. Deng, and X. Chen, J. Electron. Mater. 49, 2669 (2020).

M. Usui, H. Kimura, T. Satoh, T. Asada, S. Yamaguchi, and M. Kato, Microelectron. Reliab. 63, 152 (2016).

T. Satoh, T. Ishizaki, and M. Usui, Mater. Des. 124, 203 (2017).

T. Satoh, T. Ishizaki, and M. Usui, J. Mater. Sci. Mater. Electron. 29, 7161 (2018).

M. Usui, T. Satoh, H. Kimura, S. Tajima, Y. Hayashi, D. Setoyama, and M. Kato, Microelectron. Reliab. 78, 93 (2017).

L. Helfen, F. Xu, H. Suhonen, P. Cloetens, and T. Baumbach, J. Phys. Conf. Ser. 425, 192025 (2013).

J.O. Suh, K.N. Tu, and N. Tamura, JOM 58, 63 (2006).

X. Milhet, A. Nait-Ali, D. Tandiang, Y.-J. Liu, D. Van Campen, V. Caccuri, and M. Legros, Acta Mater. 156, 310 (2018).

D.T. Chu, Y.-C. Chu, J.-A. Lin, Y.-T. Chen, C.-C. Wang, Y.-F. Song, C.-C. Chiang, C. Chen, and K.N. Tu, Microelectron. Reliab. 79, 32 (2017).

H. Tsuritani, T. Sayama, Y. Okamoto, T. Takayanagi, M. Hoshino, K. Uesugi, J. Ooi and T. Mori, Proc. ASME 2017 IPACK 2017-74177 (2017) V001T01A015.

M. Hoshino, K. Uesugi, A. Takeuchi, Y. Suzuki, and N. Yagi, Rev. Sci. Instrum. 82, 073706 (2011).

T. Asada, H. Kimura, S. Yamaguchi, S. Hayashi and Y. Uyama, Proc. Int. Conf. Adv. Technol. Exp. Mech. 48 (2015).

H. Kimura, M. Usui, M. Kamiyama, T. Asada, S. Yamaguchi, D. Setoyama, and T. Satoh, R&D Rev. Toyota CRDL 50–1, 39 (2019).

T. Nonaka, K. Dohmae, Y. Hayashi, T. Araki, S. Yamaguchi, Y. Nagai, Y. Hirose, T. Tanaka, H. Kitamura, T. Uruga, H. Yamazaki, H. Yumoto, H. Ohashi, S. Goto, and A.I.P. Conf, Proc. 1741, 030043 (2016).

Y. Hirose, SPring-8 Research Frontiers 2009, 170 (2009).

L. Wang, M. Li, J. Almer, T. Bieler, and R. Barabash, Front. Mater. Sci. 7, 156 (2013).

J.J. Williams, Z. Flom, A.A. Amell, N. Chawla, X. Xiao, and F. De Carlo, Acta Mater. 102, 220 (2016).

Y. Hayashi, Y. Hirose, and Y. Seno, J. Appl. Crystallogr. 48, 1094 (2015).

D. Setoyama, Y. Hayashi, and N. Iwata, Mater. Sci. Forum 777, 142 (2014).

Y. Hayashi, D. Setoyama, Y. Hirose, T. Yoshida, and H. Kimura, Science 366, 1492 (2020).

K. Tanaka, Y. Akiniwa, JSME Int. J., 47-3, 252 (2004).

T. Satoh and M. Usui, J. Mater. Sci. Mater. Electron. 31, 6547 (2020).

Y. Yanaka, Y. Kariya, H. Watanabe, and H. Hokazono, Mater. Trans. 57, 819 (2016).

W.H. Tao, C. Chen, C.E. Ho, W.T. Chen, and C.R. Kao, Chem. Mater. 13, 1051 (2001).

Y. Nagatomo, T. Kitahara, T. Nagase, Y. Kuromitsu, H. Sosiati, and N. Kuwano, Mater. Trans. 49, 2808 (2008).

T. Gua. Lei, J. N. Calata, K. D. T. Ngo and G.-Q. Lu, IEEE Trans. Dev. Mater. Reliab. https://doi.org/10.1109/tdmr.2009.2033668.

C. Pei, C. Chen, K. Suganuma, and G. Fu, J. Electron. Mater. 47, 811 (2018).

S. Nishimoto, S.A. Moeini, T. Ohashi, Y. Nagatomo, and P. McCluskey, Microelectron. Reliab. 87, 232 (2018).

D. Kim, C. Chen, S.-J. Lee, S. Nagao, and K. Suganuma, J. Mater. Sci. Mater. Electron. 31, 3715 (2020).

Acknowledgements

The synchrotron radiation x-ray experiments were performed at the BL33XU (Toyota beamline) of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal Nos. 2017A7012, 2017B7012, and 2018B7012). The authors would like to thank Mr. Kuwahara for the technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors claim no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Usui, M., Satoh, T., Kamiyama, M. et al. Reliability of Cu Nanoparticles/Bi-Sn Solder Hybrid Bonding Under Cyclic Thermal Stresses. JOM 73, 600–608 (2021). https://doi.org/10.1007/s11837-020-04521-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04521-w