Abstract

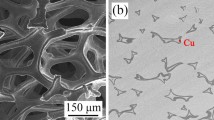

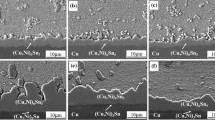

Porous Cu sheets with the pores per inch (ppi) of 110 and 500 were used as additives to improve the performances of the Sn58Bi (SnBi) solder joint. The effects of porous Cu on the microstructure, interfacial IMC, hardness, shear behavior, and thermal conductivity of the solder were investigated in this study. Experimental results indicate that there are many Cu-surrounded areas in the SnBi@110-Cu solder bulk. The Bi-rich phase and β-Sn phase in those areas show refined grain size and high hardness. The density of porous Cu in SnBi@500-Cu is higher than that in SnBi@110-Cu, and the Cu distributes uniformly in the solder bulk. Porous Cu interacts with the molten SnBi during the soldering process, resulting in an increase of the Cu concentration in the solder matrix, and then the growth of the Cu6Sn5 interfacial IMC is promoted. The addition of porous Cu has a positive effect on the improvement of the shear strength and thermal conductivity of the SnBi/Cu solder joint. In this study, the SnBi@500-Cu/Cu joint shows the highest shear strength and thermal conductivity with the average values of 83.51 MPa and 41.32 W/m K, respectively.

Similar content being viewed by others

References

M. Xiong, L. Zhang, J. Mater. Sci. 54, 1741–1768 (2019)

Y. Tian, Y. Wang, F. Guo, L. Ma, J. Han, J. Electron. Mater. 48, 2770–2779 (2019)

R. Xu, Y. Liu, F. Sun, Results. Phys. 15, 102701 (2019)

L. Gao, Z. Liu, C. Li, J. Electron. Mater. 46, 5338–5348 (2017)

X. Hu, Y. Li, Z. Min, J. Mater. Sci. Mater. Electron. 24, 2027–2034 (2013)

H. Park, C. Lee, K. Min, S. Jung, J. Electron. Mater. 48, 1746–1753 (2019)

Y. Zuo, L. Ma, S. Liu, T. Wang, F. Guo, X. Wang, J. Mater. Sci. 48, 2318–2325 (2013)

L. Shen, P. Septiwerdani, Z. Chen, Mater. Sci. Eng. A. 558, 253–258 (2012)

Y. Liu, L. Liu, R. Xu, F. Sun, D. Zhu, H. Xu, Mater. Res. Express 6, 116328 (2019)

Y. Liu, H. Fu, F. Sun, H. Zhang, X. Kong, J. Mater. Process. Tech. 238, 290–296 (2016)

C. Liu, W. Zhang, J. Electron. Mater. 44, 149–153 (2009)

O. Mokhtari, H. Nishikawa, Mater. Sci. Eng. A 651, 831–839 (2016)

N. Jiang, L. Zhang, Z. Liu, L. Sun, M. Xiong, M. Zhao, K. Xu, J. Mater. Sci. Mater. Electron. 30, 17583–17590 (2019)

Y. Liu, H. Zhang, F. Sun, J. Mater. Sci. Mater. Electron. 27, 2235–2241 (2016)

F. Wang, D. Li, Z. Zhang, M. Wu, C. Yan, J. Mater. Sci. Mater. Electron. 28, 19051–19060 (2017)

Y. Liu, S. Li, W. Song, X. Wang, H. Zhang, F. Sun, Results Phys. 13, 102256 (2019)

N. Comisso, S. Cattarin, P. Guerriero, L. Mattarozzi, M. Musiani, L. Vázquez-Gómez, E. Verlato, J. Solid. State. Electr. 20, 1139–1148 (2016)

T. Zaharinie, R. Moshwan, F. Yusof, M. Hamdi, T. Ariga, Mater. Des. 54, 375–381 (2014)

L. Wang, X. Wang, Z. Meng, H. Hou, B. Chen, J. Mater. Sci. 52, 7140–7148 (2017)

Y. Liu, Z. Li, H. Zhang, F. Sun, J. Mater. Sci. Mater. Electron. 30, 15795–15801 (2019)

Y. Xiao, S. Li, Z. Wang, Z. Song, Y. Mao, M. Li, Mater. Sci. Eng. A. 729, 241–248 (2018)

Y. Su, C. Hang, H. Chen, X. Xie, J. Ma, M. Li, Microelectron. Eng. 214, 60–67 (2019)

X. Gu, K.C. Yung, Y.C. Chan, J. Mater. Sci. Mater. Electron. 21, 1090–1098 (2010)

M. Arı, B. Saatçi, M. Gündüz, F. Meydaneri, M. Bozoklu, Mater. Charact. 59, 624–630 (2008)

Acknowledgements

This work is supported by National Natural Science Foundation of China (No. 51604090) and Natural Science Foundation of Heilongjiang Province (No. E2017050).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Ren, B., Zhou, M. et al. Microstructure, mechanical, and thermal behaviors of SnBi/Cu solder joint enhanced by porous Cu. J Mater Sci: Mater Electron 31, 8258–8267 (2020). https://doi.org/10.1007/s10854-020-03361-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03361-3