Abstract

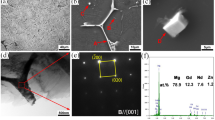

The present paper proposes an experimental study to determine the mechanical properties of an additively manufactured modified Al6061 alloy, where the addition of 2 vol.% of yttrium-stabilized zirconia (YSZ) to Al6061 base powder allows to fully remove cracks during laser beam melting processing. To this end, Vickers tests, tensile tests, Charpy tests and microstructural analyses are used. With respect to the building direction, a quasi-isotropic response is highlighted, on as-built material with properties (engineering yield and ultimate strengths) higher than the wrought 6061 alloy. This improvement can be attributed to the extra-fine microstructure, a large dislocation density and a specific precipitation/solution trapping behavior associated with the Zr addition. Besides, the alloy showed excellent tensile response reproducibility. Thereafter, effect of post-heat treatments is investigated. Classic T6 from wrought alloys practice allowed to precipitate well-known and reported nano-β″-MgxSiy phases, improving the yield and ultimate strengths, but at the expense of significant grain coarsening. The mechanical properties are further increased through an adapted heat treatment, specifically designed for this Al6061 modified alloy. Al3Zr hardening nanoprecipitates are responsible of the improved yield response observed after an annealing for 2 h at 400 °C. The competition between these different hardening precipitation phases (nano-β″/nano-Al3Zr) is finally discussed.

Similar content being viewed by others

References

C.F. Tan and M.R. Said, Effect of Hardness Test on Precipitation Hardening Aluminium Alloy 6061–T6, Chiang Mai J. Sci., 2009, 36, p 276–286.

H. Li, Characterizations of Precipitation Behavior of Al-Mg-Si Alloys Under Different Heat Treatments, China Foundry, 2018, 15, p 89–96.

A.K. Gupta, D.J. Lloyd and S.A. Court, Precipitation Hardening in Al-Mg-Si Alloys with and Without Excess Si, Mater. Sci. Eng. A., 2001, 316, p 11–17. https://doi.org/10.1016/S0921-5093(01)01247-3

S.J. Andersen, H.W. Zandbergen, J. Jansen, C. Tráholt, U. Tundal and O. Reiso, The Crystal Structure of the B’’ Phase in Al-Mg-Si Alloys, Acta Mater., 1998, 46, p 3283–3298.

S.J. Andersen, C.D. Marioara, R. Vissers, A. Frøseth and H.W. Zandbergen, The Structural Relation Between Precipitates in Al-Mg-Si alloys, the Al-Matrix and Diamond Silicon, with Emphasis on the Trigonal Phase U1-MgAl2Si2, Mater. Sci. Eng. A., 2007, 444, p 157–169. https://doi.org/10.1016/j.msea.2006.08.084

S.J. Andersen, C.D. Marioara, A. Frøseth, R. Vissers and H.W. Zandbergen, Crystal Structure of the Orthorhombic U2-Al4Mg4Si4 Precipitate in the Al-Mg-Si Alloy System and its Relation to the β′ and β″ Phases, Mater. Sci. Eng. A., 2005, 390, p 127–138. https://doi.org/10.1016/j.msea.2004.09.019

R. Vissers, M.A. van Huis, J. Jansen, H.W. Zandbergen, C.D. Marioara and S.J. Andersen, The Crystal Structure of the β′ Phase in Al-Mg-Si Alloys, Acta Mater., 2007, 55, p 3815–3823. https://doi.org/10.1016/j.actamat.2007.02.032

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck and R. Hague, 3D Printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys Using Selective Laser Melting, Prog. Mater. Sci., 2019, 106, p 100578. https://doi.org/10.1016/j.pmatsci.2019.100578

D. Jafari and W.W. Wits, The Utilization of Selective Laser Melting Technology on Heat Transfer Devices for Thermal Energy Conversion Applications: A Review, Renew. Sustain. Energy Rev., 2018, 91, p 420–442. https://doi.org/10.1016/j.rser.2018.03.109

L. Thijs, K. Kempen, J.-P. Kruth and J. Van Humbeeck, Fine-Structured Aluminium Products with Controllable Texture by Selective Laser Melting of Pre-Alloyed AlSi10Mg Powder, Acta Mater., 2013, 61, p 1809–1819. https://doi.org/10.1016/j.actamat.2012.11.052

T. Kimura and T. Nakamoto, Microstructures and Mechanical Properties of A356 (AlSi7Mg0.3) Aluminum Alloy Fabricated by Selective Laser Melting, Mater. Des., 2016, 89, p 1294–1301. https://doi.org/10.1016/j.matdes.2015.10.065

A. Aversa, G. Marchese, A. Saboori, E. Bassini, D. Manfredi, S. Biamino, D. Ugues, P. Fino and M. Lombardi, New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review, Materials, 2019, 12, p 1007. https://doi.org/10.3390/ma12071007

M.L. Montero-Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.-P. Kruth and J. Van Humbeeck, Changing the Alloy Composition of Al7075 for Better Processability Byselective Laser Melting, J. Mater. Process. Technol., 2016, 238, p 437–445.

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler and T.M. Pollock, 3D Printing of High-Strength Aluminium Alloys, Nature, 2017, 549, p 365–369.

M. Opprecht, J.-P. Garandet, G. Roux, C. Flament and M. Soulier, A Solution to the Hot Cracking Problem for Aluminium Alloys Manufactured by Laser Beam Melting, Acta Mater., 2020, 197, p 40–53. https://doi.org/10.1016/j.actamat.2020.07.015

A. Sonawane, G. Roux, J.-J. Blandin, A. Despres and G. Martin, Cracking Mechanism and its Sensitivity to Processing Conditions During Laser Powder Bed Fusion of a Structural Aluminum Alloy, Acta Mater., 2021, 15, p 100976. https://doi.org/10.1016/j.mtla.2020.100976

H. Hyer, L. Zhou, A. Mehta and Y. Sohn, Effects of Alloy Composition and Solid-State Diffusion Kinetics on Powder Bed Fusion Cracking Susceptibility, J. Phase Equilibria Diffus., 2021, 42, p 5–13. https://doi.org/10.1007/s11669-020-00844-y

H. Hyer, L. Zhou, A. Mehta, S. Park, T. Huynh, S. Song, Y. Bai, K. Cho, B. McWilliams and Y. Sohn, Composition-Dependent Solidification Cracking of Aluminum-Silicon Alloys During Laser Powder Bed Fusion, Acta Mater., 2021, 208, p 116698. https://doi.org/10.1016/j.actamat.2021.116698

A.R. Zulhishamuddin, S.N. Aqida and M. Mohd Rashidi, A Comparative Study on Wear Behaviour of Cr/Mo surface Modified Grey Cast Iron, Opt. Laser Technol., 2018, 104, p 164–169. https://doi.org/10.1016/j.optlastec.2018.02.027

S. Griffiths, M.D. Rossell, J. Croteau, N.Q. Vo, D.C. Dunand and C. Leinenbach, Effect of Laser Rescanning on the Grain Microstructure of a Selective Laser Melted Al-Mg-Zr Alloy, Mater. Charact., 2018, 143, p 34–42. https://doi.org/10.1016/j.matchar.2018.03.033

M. Awd, J. Tenkamp, M. Hirtler, S. Siddique, M. Bambach and F. Walther, Comparison of Microstructure and Mechanical Properties of Scalmalloy® Produced by Selective Laser Melting and Laser Metal Deposition, Materials, 2017, 11, p 17. https://doi.org/10.3390/ma11010017

D. Koutny, D. Palousek, L. Pantelejev, C. Hoeller, R. Pichler, L. Tesicky and J. Kaiser, Influence of Scanning Strategies on Processing of Aluminum Alloy EN AW 2618 Using Selective Laser Melting, Materials, 2018, 11, p 298. https://doi.org/10.3390/ma11020298

Q. Jia, P. Rometsch, S. Cao, K. Zhang and X. Wu, Towards a High Strength Aluminium Alloy Development Methodology for Selective Laser Melting, Mater. Des., 2019, 174, p 107775. https://doi.org/10.1016/j.matdes.2019.107775

Q. Jia, P. Rometsch, P. Kürnsteiner, Q. Chao, A. Huang, M. Weyland, L. Bourgeois and X. Wu, Selective Laser Melting of a High Strength Al Mn Sc Alloy: Alloy Design and Strengthening Mechanisms, Acta Mater., 2019, 171, p 108–118. https://doi.org/10.1016/j.actamat.2019.04.014

E.A. Jägle, Z. Sheng, L. Wu, L. Lu, J. Risse, A. Weisheit and D. Raabe, Precipitation Reactions in Age-Hardenable Alloys During Laser Additive Manufacturing, JOM, 2016, 68, p 943–949. https://doi.org/10.1007/s11837-015-1764-2

N.V. Dynin, V.V. Antipov, D.V. Khasikov, I. Benarieb, A.V. Zavodov and A.G. Evgenov, Structure and Mechanical Properties of an Advanced Aluminium Alloy AlSi10MgCu(Ce, Zr) Produced by Selective Laser Melting, Mater. Lett., 2021, 284, p 128898. https://doi.org/10.1016/j.matlet.2020.128898

L. Zhou, H. Hyer, J. Chang, A. Mehta, T. Huynh, Y. Yang and Y. Sohn, Microstructure, Mechanical Performance, and Corrosion Behavior of Additively Manufactured Aluminum Alloy 5083 with 0.7 and 1.0 wt% Zr Addition, Mater. Sci. Eng. A., 2021, 823, p 141679. https://doi.org/10.1016/j.msea.2021.141679

H. Hyer, L. Zhou, S. Park, T. Huynh, A. Mehta, S. Thapliyal, R.S. Mishra and Y. Sohn, Elimination of Extraordinarily High Cracking Susceptibility of Aluminum Alloy Fabricated by Laser Powder Bed Fusion, J. Mater. Sci. Technol., 2022, 103, p 50–58. https://doi.org/10.1016/j.jmst.2021.06.023

J. Zhang, J. Gao, B. Song, L. Zhang, C. Han, C. Cai, K. Zhou and Y. Shi, A Novel Crack-Free Ti-Modified Al-Cu-Mg Alloy Designed for Selective Laser Melting, Addit. Manuf., 2021, 38, p 101829. https://doi.org/10.1016/j.addma.2020.101829

Q. Tan, J. Zhang, Q. Sun, Z. Fan, G. Li, Y. Yin, Y. Liu and M.-X. Zhang, Inoculation Treatment of an Additively Manufactured 2024 Aluminium Alloy with Titanium Nanoparticles, Acta Mater., 2020, 196(2020), p 1–16. https://doi.org/10.1016/j.actamat.2020.06.026

M. Opprecht, J.-P. Garandet, G. Roux and C. Flament, An Understanding of Duplex Microstructures Encountered During High Strength Aluminium Alloy Laser Beam Melting Processing, Acta Mater., 2021, 215, p 117024. https://doi.org/10.1016/j.actamat.2021.117024

A. Mehta, L. Zhou, T. Huynh, S. Park, H. Hyer, S. Song, Y. Bai, D.D. Imholte, N.E. Woolstenhulme, D.M. Wachs and Y. Sohn, Additive Manufacturing and Mechanical Properties of the Dense and Crack Free Zr-Modified Aluminum Alloy 6061 Fabricated by the Laser-Powder Bed Fusion, Addit. Manuf., 2021, 41, p 101966. https://doi.org/10.1016/j.addma.2021.101966

F. Wang, D. Qiu, Z. Liu, J. Taylor, M. Easton and M. Zhang, Crystallographic Study of Al3Zr and Al3Nb as Grain Refiners for Al Alloys, Trans. Nonferrous Met. Soc. China, 2014, 24, p 2034–2040.

L.-P. Lapierre-Boire, C. Blais, S. Pelletier and F. Chagnon, Improvement of Flow of an Iron-Copper-Graphite Powder Mix Through Additions of Nanoparticles, Powder Technol., 2016, 299, p 156–167. https://doi.org/10.1016/j.powtec.2016.05.046

J. Yang, A. Sliva, A. Banerjee, R.N. Dave and R. Pfeffer, Dry Particle Coating for Improving the Flowability of Cohesive Powders, Powder Technol., 2005, 158, p 21–33.

C. Weingarten, D. Buchbinder, N. Pirch, W. Meiners, K. Wissenbach and R. Poprawe, Formation and Reduction of Hydrogen Porosity During Selective Laser Melting of AlSi10Mg, J. Mater. Process. Technol., 2015, 221, p 112–120. https://doi.org/10.1016/j.jmatprotec.2015.02.013

C. Fressengeas, B. Beausir, C. Kerisit, A.-L. Helbert, T. Baudin, F. Brisset, M.-H. Mathon, R. Besnard and N. Bozzolo, On the Evaluation of Dislocation Densities in Pure Tantalum from EBSD Orientation Data, Matér. Tech., 2018, 106, p 604. https://doi.org/10.1051/mattech/2018058

F. Peyrouzet, D. Hachet, R. Soulas, C. Navone, S. Godet and S. Gorsse, Selective Laser Melting of Al0.3CoCrFeNi High-Entropy Alloy: Printability, Microstructure, and Mechanical Properties, JOM, 2019, 71, p 3443–3451. https://doi.org/10.1007/s11837-019-03715-1

Y.J. Yin, J.Q. Sun, J. Guo, X.F. Kan and D.C. Yang, Mechanism of High Yield Strength and Yield Ratio of 316 L Stainless Steel by Additive Manufacturing, Mater. Sci. Eng. A., 2019, 744, p 773–777. https://doi.org/10.1016/j.msea.2018.12.092

ASM Handbook, 10th ed., 1995

L. Zhou, H. Hyer, S. Park, H. Pan, Y. Bai, K.P. Rice and Y. Sohn, Microstructure and Mechanical Properties of Zr-Modified Aluminum Alloy 5083 Manufactured by Laser Powder Bed Fusion, Addit. Manuf., 2019, 28, p 485–496. https://doi.org/10.1016/j.addma.2019.05.027

B. Reyne, P.-Y. Manach and N. Moës, Macroscopic Consequences of Piobert-Lüders and Portevin–Le Chatelier Bands During Tensile Deformation in Al-Mg Alloys, Mater. Sci. Eng. A., 2019, 746, p 187–196. https://doi.org/10.1016/j.msea.2019.01.009

T.V. Kumar, M. Indu, A.S. Gopal, A.V. Krishna and D.V. Reddy, Microstructure Study and Mechanical Testing of Al 6061-Si3n4 Metal Matrix Composites, Met. Matrix Compos., 2019, 8, p 5.

H. Mohammadi, A.R. Eivani, S.H. Seyedein and M. Ghosh, Modified Monte Carlo Approach for Simulation of Grain Growth and Ostwald Ripening in two-Phase Zn–22Al Alloy, J. Mater. Res. Technol., 2020, 9, p 9620–9631. https://doi.org/10.1016/j.jmrt.2020.06.017

H. Mehrer, M. Luckabauer and W. Sprengel, Self- and Solute Diffusion, Interdiffusion and Thermal Vacancies in the System Iron-Aluminium, Defect Diffus. Forum, 2013, 333, p 1–25. https://doi.org/10.4028/www.scientific.net/DDF.333.1

S.G. Fries and T. Jantzen, Compilation of `CALPHAD’ Formation Enthalpy Data Binary Intermetallic Compounds in the COST 507 Gibbsian database, Thermochim. Acta., 1998, 314, p 23–33.

C. Flament, Etude des évolutions microstructurales sous irradiation de l’alliage d’aluminium 6061-T6, Université Grenoble Alpes, 2015

S. Fang and Du. Li, Precipitation Sequence of an aged Al-Mg-Si Alloy, J Min. Metall. Sect. B-Met., 2010, 46, p 171–180.

E. Clouet, A. Barbu, L. Lae and G. Martin, Precipitation Kinetics of AlZr and AlSc in Aluminum Alloys Modeled with Cluster Dynamics, Acta Mater., 2005, 53, p 2313–2325. https://doi.org/10.1016/j.actamat.2005.01.038

J.R. Croteau, S. Griffiths, M.D. Rossell, C. Leinenbach, C. Kenel, V. Jansen, D.N. Seidman, D.C. Dunand and N.Q. Vo, Microstructure and Mechanical Properties of Al-Mg-Zr Alloys Processed by Selective Laser Melting, Acta Mater., 2018, 153, p 35–44. https://doi.org/10.1016/j.actamat.2018.04.053

K.E. Knipling, D.C. Dunand and D.N. Seidman, Nucleation and Precipitation Strengthening in Dilute Al-Ti and Al-Zr Alloys, Metall. Mater. Trans. A., 2007, 38, p 2552–2563. https://doi.org/10.1007/s11661-007-9283-6

K.E. Knipling, D.C. Dunand and D.N. Seidman, Precipitation Evolution in Al–Zr and Al–Zr–Ti Alloys During Isothermal Aging at 375-425 °C, Acta Mater., 2008, 56, p 114–127. https://doi.org/10.1016/j.actamat.2007.09.004

A.V. Mikhaylovskaya, A.G. Mochugovskiy, V.S. Levchenko, NYu. Tabachkova, W. Mufalo and V.K. Portnoy, Precipitation Behavior of L12 Al3Zr Phase in Al-Mg-Zr Alloy, Mater. Charact., 2018, 139, p 30–37. https://doi.org/10.1016/j.matchar.2018.02.030

A. Mehta, J. Dickson, R. Newell, D.D. Keiser and Y. Sohn, Interdiffusion and Reaction Between Al and Zr in the Temperature Range of 425 to 475 °C, J. Phase Equilibria Diffus., 2019, 40, p 482–494. https://doi.org/10.1007/s11669-019-00729-9

Y. Du, Y.A. Chang, B. Huang, W. Gong, Z. Jin, H. Xu, Z. Yuan, Y. Liu, Y. He and F.-Y. Xie, Diffusion Coefficients of Some Solutes in Fcc and Liquid Al: Critical Evaluation and Correlation, Mater. Sci. Eng. A., 2003, 363, p 140–151. https://doi.org/10.1016/S0921-5093(03)00624-5

K.E. Knipling, D.N. Seidman and D.C. Dunand, Ambient- and high-temperature mechanical properties of isochronally aged Al–0.06Sc, Al–0.06Zr and Al–0.06Sc–0.06Zr (at.%) alloys, Acta Mater., 2011, 59, p 943–954. https://doi.org/10.1016/j.actamat.2010.10.017

Z. Jia, J. Røyset, J.K. Solberg and Q. Liu, Formation of Precipitates and Recrystallization Resistance in Al-Sc-Zr Alloys, Trans. Nonferrous Met. Soc. China, 2012, 22, p 1866–1871. https://doi.org/10.1016/S1003-6326(11)61399-X

M.J. Jones and F.J. Humphreys, Interaction of Recrystallization and Precipitation: The Effect of Al3Sc on the Recrystallization Behaviour of Deformed Aluminium, Acta Mater., 2003, 51, p 2149–2159. https://doi.org/10.1016/S1359-6454(03)00002-8

A. Deschamps and Y. Brechet, Influence of Predeformation and Ageing of an Al-Zn-Mg Alloy II: MODELING of Precipitation Kinetics and Yield Stress, Acta Mater., 1999, 47, p 293–305.

M.J. Starink and S.C. Wang, A Model for the Yield Strength of Overaged Al-Zn-Mg-Cu Alloys, Acta Mater., 2003, 51, p 31–50.

S. Thangaraju, M. Heilmaier, B.S. Murty and S.S. Vadlamani, On the Estimation of True Hall-Petch Constants and Their Role on the Superposition Law Exponent in Al Alloys, Adv. Eng. Mater., 2012, 14, p 892–897. https://doi.org/10.1002/adem.201200114

E.O. Hall, The Deformation and Ageing of Mild Steel: III Discussion of Results, Proc. Phys. Soc. Sect. B., 1951, 64, p 747–753. https://doi.org/10.1088/0370-1301/64/9/303

N.J. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, 174, p 25–28.

Y. Bréchet, J. Philibert, A. Vignes, and P. Combrade, Métallurgie du minerai au matériau, Dunod, 2013

M.S.K.K.Y. Nartu, T. Alam, S. Dasari, S.A. Mantri, S. Gorsse, H. Siller, N. Dahotre and R. Banerjee, Enhanced Tensile Yield Strength in Laser Additively Manufactured Al0.3CoCrFeNi High Entropy Alloy, Materialia., 2020, 9, p 100522. https://doi.org/10.1016/j.mtla.2019.100522

S. Zhang, H. Zhu, L. Zhang, W. Zhang, H. Yang and X. Zeng, Microstructure and properties in QCr0.8 alloy produced by selective laser melting with different heat treatment, J. Alloys Compd., 2019, 800, p 286–293. https://doi.org/10.1016/j.jallcom.2019.06.018

B. Selva Babu, S. Sathiyaraj, A.K.P. Ramesh, B.A. Afridi and K. Kristo Varghese, Investigation of Machining Characteristics of Aluminium 6061 by Wire Cut EDM Process, Mater. Today Proc., 2020, 45, p 6247–6252. https://doi.org/10.1016/j.matpr.2020.10.698

P. Cao, M. Qian and D.H. StJohn, Effect of Iron on Grain Refinement of High-Purity Mg-Al Alloys, Scr. Mater., 2004, 51, p 125–129. https://doi.org/10.1016/j.scriptamat.2004.03.039

W. Lefebvre, N. Masquelier, J. Houard, R. Patte and H. Zapolsky, Tracking the Path of Dislocations Across Ordered Al3Zr Nano-Precipitates in Three Dimensions, Scr. Mater., 2014, 70, p 43–46. https://doi.org/10.1016/j.scriptamat.2013.09.014

A.J. Ardell, Precipitation Hardening, Metall. Trans. A, 1985, 16, p 2131–2165.

S. Gorsse, C. Hutchinson, M. Gouné and R. Banerjee, Additive Manufacturing of Metals: A Brief Review of the Characteristic Microstructures and Properties of Steels, Ti-6Al-4V and High-Entropy Alloys, Sci. Technol. Adv. Mater., 2017, 18, p 584–610. https://doi.org/10.1080/14686996.2017.1361305

P.A. Hooper, Melt Pool Temperature and Cooling Rates in Laser Powder Bed Fusion, Addit. Manuf., 2018, 22, p 548–559. https://doi.org/10.1016/j.addma.2018.05.032

L.-E. Loh, C.-K. Chua, W.-Y. Yeong, J. Song, M. Mapar, S.-L. Sing, Z.-H. Liu and D.-Q. Zhang, Numerical Investigation and an Effective Modelling on the Selective Laser Melting (SLM) Process with Aluminium Alloy 6061, Int. J. Heat Mass Transf., 2015, 80, p 288–300. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.014

Acknowledgments

The TEM pictures were acquired at the CEA NanoCharacterization Platform (PFNC)—Minatec, thanks to the French RTB (IRT Nanoelec) and the equipex NanoID. The authors thanks Nathalie LADRAT for FIB lamella preparation. Céline RIBIERE is also acknowledged for her 3D printing technical assistance. M.O thanks Florian PEYROUZET for fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Opprecht, M., Roux, G., Garandet, JP. et al. A Study of the Mechanical Properties of Al6061-Zr1,2 Alloy Processed by Laser Beam Melting. J. of Materi Eng and Perform 32, 1840–1855 (2023). https://doi.org/10.1007/s11665-022-07218-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07218-0