Abstract

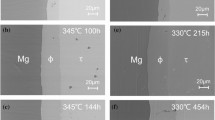

Interdiffusion and reaction between Al and Zr was investigated as functions of Zr purity, temperature, and time, using Al versus Zr solid-to-solid diffusion couple annealed in the temperature range from 425 °C to 475 °C. All diffusion couples were observed to develop two intermetallic layers, i.e., Al3Zr and Al2Zr. The Al3Zr phase grew with planar morphology, while the Al2Zr phase developed a non-planar interfacial morphology. Growth rate and integrated interdiffusion coefficients were determined using Wagner’s approach for each phase. Purity of Zr had a significant effect on the development of Al3Zr and Al2Zr phases. Diffusion couples with low-purity Zr (i.e., 99.2%) exhibited a higher growth rate for the Al3Zr, at the expense of Al2Zr growth. Couples with low purity Zr also resulted in a higher degree of non-planarity for Al2Zr phase. In general, degree of non-planarity increased with an increase in anneal time, while it decreased with an increase in temperature. Non-planar morphology was simulated based on 3-D anisotropic diffusion using diffusivity tensor (quadric), and needle-like growth, similar to that observed by experiments were simulated.

Similar content being viewed by others

References

K.E. Knipling, D.C. Dunand, and D.N. Seidman, Precipitation Evolution in Al–Zr and Al–Zr–Ti Alloys During Aging at 450–600 °C, Acta Mater., 2008, 56(6), p 1182-1195

K.E. Knipling, D.C. Dunand, and D.N. Seidman, Precipitation Evolution in Al–Zr and Al–Zr–Ti Alloys During Isothermal Aging at 375–425 °C, Acta Mater., 2008, 56(1), p 114-127

K.E. Knipling et al., Precipitation Evolution in Al–0.1 Sc, Al–0.1 Zr and Al–0.1 Sc–0.1 Zr (at.%) Alloys During Isochronal Aging, Acta Mater., 2010, 58(15), p 5184-5195

P.H.L. Souza, C.A.S. de Oliveira, and J.M. do Vale Quaresma, Precipitation Hardening in Dilute Al–Zr Alloys, J. Mater. Res. Technol., 2018, 7(1), p 66-72

A. Mehta et al., Microstructural Characterization of AA6061 Versus AA6061 HIP Bonded Cladding-Cladding Interface, J. Phase Equilib. Diffus., 2018, 39(2), p 246-254

R. Newell et al., Interdiffusion, reactions, and phase transformations observed during fabrication of low enriched uranium monolithic fuel system for research and test reactors. in Defect and Diffusion Forum (2018). Trans Tech Publ

R. Newell et al., Relating diffusion couple experiment results to observed as-fabricated microstructures in low-enriched U-10wt.% Mo monolithic fuel plates. in Defect and Diffusion Forum (2017). Trans Tech Publ

D.D. Keiser et al., High-Density, Low-Enriched Uranium Fuel for Nuclear Research Reactors, JOM, 2003, 55(9), p 55-58

R. Newell et al., Mechanical Properties Examined by Nanoindentation for Selected Phases Relevant to the Development of Monolithic Uranium-Molybdenum Metallic Fuels, J. Nucl. Mater., 2017, 487, p 443-452

A. Mehta et al., Phase Transformations and Microstructural Development in the U-10 Wt Pct Mo Alloy with Varying Zr Contents After Heat Treatments Relevant to the Monolithic Fuel Plate Fabrication Process, Metall. Mater. Trans. A, 2019, 50, p 72-96

J. Dickson et al., Interdiffusion and Reaction Between Zr and Al Alloys from 425° to 625 °C, Intermetallics, 2014, 49, p 154-162

G. Kidson and G. Miller, A Study of the Interdiffusion of Aluminum and Zirconium, J. Nucl. Mater., 1964, 12(1), p 61-69

A. Laik, K. Bhanumurthy, and G. Kale, Intermetallics in the Zr–Al Diffusion Zone, Intermetallics, 2004, 12(1), p 69-74

J. Morral et al., Three Types of Planar Boundaries in Multiphase Diffusion Couples, Scr. Mater., 1996, 34(11), p 1661-1666

J. Morral, X. Qiao, and C. Jin, Microstructure in diffusion couples. Understanding Microstructure: Key to Advances in Materials (1996), pp. 37–40

W.C. Johnson, On the Inapplicability of Gibbs Phase Rule to Coherent Solids, Metall. Trans. A, 1987, 18(6), p 1093-1097

D. Borivent, B. Billia, and J. Paret, Anomalous Growth of Ni3Si2 in Bulk Ni/Si Interdiffusion, J. Appl. Phys., 2008, 104(1), p 013523

P. Tortorici and M. Dayananda, Diffusion Structures in Mo vs Si Solid-Solid Diffusion Couples, Scr. Mater., 1998, 38(12), p 1863-1869

A. Mostafa and M. Medraj, On the Atomic Interdiffusion in Mg–{Ce, Nd, Zn} and Zn–{Ce, Nd} Binary Systems, J. Mater. Res., 2014, 29(13), p 1463-1479

S. Bhagavantam and P. Pantulu. Generalized symmetry and Neumann’s principle. in Proceedings of the Indian Academy of Sciences-Section A (Springer, 1967)

K. Bouche, F. Barbier, and A. Coulet, Intermetallic Compound Layer Growth Between Solid Iron and Molten Aluminium, Mater. Sci. Eng. A, 1998, 249(1–2), p 167-175

P. Tortorici and M. Dayananda, Growth of Silicides and Interdiffusion in the Mo–Si System, Metall. Mater. Trans. A, 1999, 30(3), p 545-550

S. Prasad and A. Paul, Growth Mechanism of Phases by Interdiffusion and Atomic Mechanism of Diffusion in the Molybdenum–Silicon System, Intermetallics, 2011, 19(8), p 1191-1200

W.-J. Cheng and C.-J. Wang, Growth of Intermetallic Layer in the Aluminide Mild Steel During Hot-Dipping, Surf. Coat. Technol., 2009, 204(6–7), p 824-828

T. Heumann and N. Dittrich, Structure Character of the Fe2Al5 Intermetallics Compound in Hot Dip Aluminizing Process, Z. Metallk., 1959, 50, p 617-623

A. Bouayad et al., Kinetic Interactions Between Solid Iron and Molten Aluminium, Mater. Sci. Eng., A, 2003, 363(1–2), p 53-61

S. Chen et al., Nanoscale Structures of the Interfacial Reaction Layers Between Molten Aluminium and Solid Steel Based on Thermophysical Simulations, J. Alloy. Compd., 2018, 739, p 184-189

W.-J. Cheng and C.-J. Wang, Study of Microstructure and Phase Evolution of Hot-Dipped Aluminide Mild Steel During High-Temperature Diffusion Using Electron Backscatter Diffraction, Appl. Surf. Sci., 2011, 257(10), p 4663-4668

V. Yeremenko, Y.V. Natanzon, and V.I. Dybkov, The Effect of Dissolution on the Growth of the Fe2Al5 Interlayer in the Solid Iron-Liquid Aluminium System, J. Mater. Sci., 1981, 16(7), p 1748-1756

J.H. Gülpen, Reactive Phase Formation in the Ni-Si System, Eindhoven University of Technology, Eindhoven, 1995

K. Tu et al., Intermetallic Compound Formation in Thin-Film and in Bulk Samples of the Ni–Si Binary System, J. Appl. Phys., 1983, 54(2), p 758-763

D. Borivent, J. Paret, and B. Billia, Reactive Interdiffusion in the Binary System Ni–Si: Morphology of the Ni3Si2 Phase, J. Phase Equilib. Diffus., 2006, 27(6), p 561-565

J.H. Gülpen, A.A. Kodentsov, and F.J. van Loo, Growth of Silicides in Ni-Si and Ni-SiC Bulk Diffusion Couples, Z. Metallkd., 1995, 86(8), p 530-539

J. Gülpen, A. Kodentsov, and F. Van Loo. The Growth of Silicides in Ni-Si and Ni-SiC Diffusion Couples, in Materials Science Forum (1994). Trans Tech Publ

C. Wagner, The Evaluation of Data Obtained with Diffusion Couples of Binary Single-Phase and Multiphase Systems, Acta Metall., 1969, 17(2), p 99-107

M.A. Dayananda, Average Effective Interdiffusion Coefficients in Binary and Multicomponent Alloys. in Defect and Diffusion Forum (1993). Trans Tech Publ.

M. Dayananda and C. Kim, Zero-Flux Planes and Flux Reversals in Cu–Ni–Zn Diffusion Couples, Metall. Mater. Trans. A, 1979, 10(9), p 1333-1339

C. Matano, On the Relation Between the Diffusion-Coefficients and Concentrations of Solid Metals (The Nickel–Copper System), Jpn. J. Phys., 1933, 8(3), p 109-113

J.F. Nye, Physical Properties of Crystals: Their Representation by Tensors and Matrices, Oxford University Press, Oxford, 1987

D.K. Jones, Chapter 3—Gaussian Modeling of the Diffusion Signal, in Diffusion MRI, ed. by H. Johansen-Berg, and T.E.J. Behrens. (Academic Press, London, 2009), pp. 37–54.

S.K. Das et al., Investigation of Anisotropic Diffusion Behavior of Zn in hcp Mg and Interdiffusion Coefficients of Intermediate Phases in the Mg–Zn System, Calphad, 2013, 42, p 51-58

C. Alcock, V. Itkin, and M. Horrigan, Vapour Pressure Equations for the Metallic Elements: 298–2500K, Can. Metall. Q., 1984, 23(3), p 309-313

W.-C. Hu et al., First-Principles Study of Structural and Electronic Properties of C14-type Laves Phase Al2Zr and Al2Hf, Comput. Mater. Sci., 2014, 83, p 27-34

G. Ghosh and M. Asta, First-Principles Calculation of Structural Energetics of Al-TM (TM = Ti, Zr, Hf) Intermetallics, Acta Mater., 2005, 53(11), p 3225-3252

H. Hu et al., The Structural Stability, Mechanical Properties and Stacking Fault Energy of Al3Zr Precipitates in Al-Cu-Zr Alloys: HRTEM Observations and First-Principles Calculations, J. Alloy. Compd., 2016, 681, p 96-108

M. Karpets et al., The Influence of Zr Alloying on the Structure and Properties of Al3Ti, Intermetallics, 2003, 11(3), p 241-249

H. Mehrer, Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-Controlled Processes, Vol 155, Springer, Berlin, 2007

Acknowledgment

This work was supported by the U.S. Department of Energy, Office of Nuclear Materials Threat Reduction (NA-212), National Nuclear Security Administration, under DOE-NE Idaho Operations Office Contract DE-AC07-05ID14517. Accordingly, the U.S. Government retains a non-exclusive, royalty-free license to publish or reproduce the published form of this contribution, or allow others to do so, for U.S. Government purposes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehta, A., Dickson, J., Newell, R. et al. Interdiffusion and Reaction Between Al and Zr in the Temperature Range of 425 to 475 °C. J. Phase Equilib. Diffus. 40, 482–494 (2019). https://doi.org/10.1007/s11669-019-00729-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-019-00729-9