Abstract

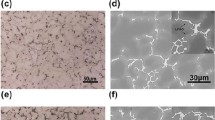

In this study, we developed a new kind of high-strength Mg–5.5Gd–3.5Nd–0.5Zn–0.4Zr (wt%) alloy. Microstructures and mechanical properties of this new kind of alloy under different heat treatment conditions have been investigated. The as-cast alloy was composed of α-Mg matrix, discontinuous α-Mg + Mg5Gd eutectic phases, needle-like Mg12Nd phases, spherical α(Zr) particles, and cuboid-shaped (Gd, Nd)H2 phases within α-Mg grains. Rod-like Zn2Zr3 phases were formed and unevenly distributed inside the α-Mg matrix after solution treatment. Thin-plate β′ phases precipitated after aging at 205 °C for 24 h. The T6-treated alloy exhibited excellent tensile properties up to 250 °C. The dislocation cross-slip was activated when tensile temperature increased to 300 °C, which resulted in the largely decreased strength and increased elongation.

Similar content being viewed by others

References

Zhang J H, Liu S J, Wu R Z, Hou L G, and Zhang M L, J. Magnesium Alloys 6 (2018) 277.

Pollock T M, Science. 328 (2010) 986.

Mordike B L, and Ebert T, Mater. Sci. Eng. A 302 (2001) 37.

Mabuchi M, Chino Y, and Iwasaki H, Mater Trans 43 (2002) 2063.

Gao L, Chen R, and Han E, J. Alloys Compd. 481 (2009) 79.

Zhang Y, Rong W, Wu Y J, and Peng L M, J Mater Sci Technol, 54 (2020) 160.

Shi L L, Huang Y D, Yang L, Feyerabend F, Mendis C, Willumeit R, Kainer K U, and Hort N, J Mech Behav Biomed Mater, 47 (2015) 38.

Li J C, He Z L, Fu P H, Peng L M, and Ding W J. Mater. Sci. Eng. A 651 (2016) 745.

Vostry P, Smola B, Stulikova I, Von B F, and Mordike B L, Phys Status Solid A, 175 (1999) 491.

Rokhlin L L, Dobatkina T V and Nikitina N I, Mater. Sci. Forum, 419 (2003) 291.

Qiang L, Wang Q D, Wang Y X, Zeng X Q, and Ding W J, J. Alloys Compd. 427 (2007) 115.

Yang J, Wang J L, and Wang L D, Mater. Sci. Eng. A 479 (2008) 339.

Negishi Y, Nishimura T, Iwasawa S, Kojima Y, and Ninomiya R, Journal of Japan Institute of Light Metals, 44 (1994)555.

Luo S F, Yang G Y, Xiao L, and Jie W Q, TMS Annual Meeting & Exhibition: Springer, 2018, 237.

Nie J F, Gao X, and Zhu S M, Scr. Mater 53 (2005) 1049.

Gao X, and Nie J F, Scr. Mater 58 (2008) 619.

Qin H, Yang G Y, Zhang L, Ouyang S X, Wang C H, and Jie W Q, Phys Status Solid A, 218 (2021) 10.

Luo S F, Yang G Y, Qin H, Xiao L, and Jie W Q, Adv. Eng. Mater. 22 (2020) 9.

Nie J F, Metall. Mater. Trans. A 43A (2012) 3891.

Wu D, Ma Y Q, Chen R S, and Ke W, J. Magnesium Alloys 2 (2014) 20.

Peng L M, Fu P H, Li Z M, Wang Y X, and Jiang H Y, J. Mater. Sci. 49 (2014) 710.

Song G L, and Stjohn D H, Journal of Light Metals 2 (2002) 1.

Qian M, Stjohn D H, and Frost M T, Scr. Mater 46 (2002) 64.

Peng Q M, Huang Y, Jian M, Li Y, and Kainer K U, Intermetallics 19 (2011) 382.

Zhu S M, Nie J F, Gibson M A, and Eastona M A, Scr. Mater. 77 (2014) 21.

Xiao L, Yang G Y, Ma J Q, Qin H, Li J H, and Jie W Q, Mater. Charact, 168 (2020) 14.

Gao X, Muddle B C, and Nie J F. Phil Mag Lett, 89 (2009) 33.

Nodooshan H R, Liu W C, Wu G H, Alizadeh R, Mahmudi R, and Ding W J, J. Alloys Compd. 619 (2015) 826.

Zheng J K, Luo R C, Zeng X Q, and Chen B, Mater. Des. 137 (2018) 316.

Gao X, He S M, Zeng X Q, Peng L M, Ding W J, and Nie J F, Mater. Sci. Eng. A 431 (2006) 322.

He S M, Zeng X Q, Peng L M, Gao X, Nie J F, and Ding W J, J. Alloys Compd. 421 (2006) 309.

Kang Y H, Wang X X, Zhang N, Yan H, and Chen R S, Mater. Sci. Eng. A 689 (2017) 435.

Luo A A, and Pekguleryuz M O, J. Mater. Sci. 29 (1994) 5259.

Tang J, Huo Q H, Zhang Z R, Zhang Y X, Zhao S L, and Hashimoto A, J. Alloys Compd. 861 (2021) 11.

Huo Q H, Ando D, Sutou Y, and Koike J, Mater. Sci. Eng. A 678 (2016) 235.

Qin H, Yang G Y, Bai T, Ouyang S X, and Jie W Q. Mater. Lett, (2021) 304.

Koike J, Kobayashi T, Mukai T, Watanabe H, Suzuki M, Maruyama K, and Higashi K, Acta Mater. 51 (2003) 205.

Smola B, Stulikova I, Pelcova J, Mordike and B L, J. Alloys Compd. 378 (2004) 196.

He S M, Zeng X Q, Peng L M, Gao X, and Nie J F, J. Alloys Compd. 427 (2007) 31.

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant No. 2018YFB2002000).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z., Zhang, D., Zhao, Z. et al. Effect of Heat Treatment on Microstructures and Mechanical Properties of Mg–5.5Gd–3.5Nd–0.5Zn–0.4Zr Alloy. Trans Indian Inst Met 75, 2883–2890 (2022). https://doi.org/10.1007/s12666-022-02646-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02646-x