Abstract

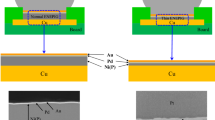

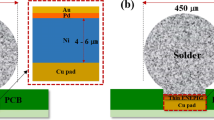

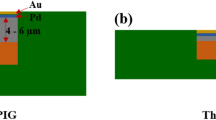

The microelectronics packaging industry, although rapidly growing, faces several challenges including 3-D integration, issues with multifunctional capability, and fluctuating input/output (I/O) density, among others. Better-performing microelectronics assemblies for mitigating these challenges require alloys with superior solderability and minimal metallization layer thickness. To this end, in this study, we investigated two kinds of electroless-nickel electroless-palladium immersion gold (ENEPIG) with 0.3 μm Ni, 0.1 μm pure Pd or Pd-phosphorous (Pd(P)), and 0.1 μm Au layers plated on a printed circuit board (PCB) substrate. To analyze the effects of the pure Pd and Pd(P) layers in the thin ENEPIG, we evaluated the interfacial reactions and mechanical properties of the SAC305 solder with a pure Pd or Pd(P) layer in the thin ENEPIG joints after aging at 150 °C. Needle-type and chunky-type (Cu,Ni)6Sn5 IMCs were formed at the interfaces of the pure Pd and Pd(P) joints, respectively. The (Cu,Ni)6Sn5 IMC of the pure Pd joint was thinner than that of the Pd(P) joint after reflowing and aging for 100 h. However, the total IMC of the Pd(P) joint was thinner than that of the pure Pd joint from 250 to 1000 h. In a low-speed shear test, the shear strength of the Pd(P) joint was higher than that of the pure Pd joint for the entire aging time. Most fractures occurred at the Sn-rich surface with a ductile mode, regardless of the different substrates and aging times. After high-speed shear testing, the shear strength of the pure Pd joint was higher than that of the Pd(P) joint until aging for 100 h. After aging for 250 h, the shear strength of the Pd(P) joint was higher than that of the pure Pd joint. The results for brittle fracture rate were similar to those for high-speed shear strength. Hence, Pd(P) joints are expected to demonstrate higher reliabilities than pure Pd joints after long aging treatment.

Similar content being viewed by others

References

Y.C. Chan, D. Yang, Pro. Mater. Sci. 55, 428 (2010). https://doi.org/10.1016/j.pmatsci.2010.01.001

W.H. Chen, C.F. Yu, H.C. Cheng, Y.M. Tsai, S.T. Lu, Microelectron. Eng. 53, 30 (2013). https://doi.org/10.1016/j.microrel.2012.06.146

T.K. Lee, H. Ma, K.C. Liu, J. Xue, J. Electron. Mater. 39, 2564 (2010). https://doi.org/10.1007/s11664-010-1352-8

C.T. Peng, C.M. Liu, J.C. Lin, H.C. Cheng, I.E.E.E. Trans, Electron. Packag. Manuf. 27, 684 (2004). https://doi.org/10.1109/TCAPT.2004.838867

J. Zhang, Z. Hai, S. Thirugnanansambandam, J.L. Evans, M.J. Bozack, Y. Zhang, J.C. Suhling, I.E.E.E. Trans, Electron. Packag. Manuf. 3, 1348 (2013). https://doi.org/10.1109/TCPMT.2013.2251932

A.K. Gain, L. Zhang, J. Alloys. Compd. 617, 779 (2014). https://doi.org/10.1016/j.jallcom.2014.08.076

W.R. Myung, Y. Kim, S.B. Jung, J. Alloys. Compd. 615, s411 (2014). https://doi.org/10.1016/j.jallcom.2014.01.078

J. Glazer, J. Electron. Mater. 23, 693 (1994). https://doi.org/10.1007/BF02651361

K. Chu, Y. Sohn, C. Moon, Scr. Mater. 109, 113 (2015). https://doi.org/10.1016/j.scriptamat.2015.07.032

L. Yang, W. Zhou, Y. Ma, X. Li, Y. Liang, W. Cui, P. Wu, Mater. Sci. Eng. A 667, 368 (2016). https://doi.org/10.1016/j.msea.2016.05.015

H.F. Zou, Q.K. Zhang, Z.F. Zhang, Mater. Sci. Eng. A 532, 167 (2012). https://doi.org/10.1016/j.msea.2011.10.078

S. Ahat, M. Sheng, L. Luo, J. Electron. Mater. 30, 1317 (2001). https://doi.org/10.1007/s11664-001-0118-8

X. Deng, G. Piotrowski, J.J. Williams, N. Chawla, J. Electron. Mater. 32, 1403 (2003). https://doi.org/10.1007/s11664-003-0108-0

K. Zeng, K.N. Tu, Mater. Sci. Eng. R 38, 55 (2002). https://doi.org/10.1016/S0927-796X(02)00007-4

Y.D. Jeon, A. Ostmann, H. Reichl, and K.W. Paik, in 2003 Electronic Components and Technology Conference Proceedings (2003), pp. 1203–1208.

J.W. Yoon, Y.H. Lee, D.G. Kim, H.B. Kang, S.J. Suh, C.W. Yang, C.B. Lee, J.M. Jung, C.S. Yoo, S.B. Jung, J. Alloys. Compd. 381, 151 (2004). https://doi.org/10.1016/j.jallcom.2004.03.076

H.W. Miao, J.G. Duh, Mater. Chem. Phys. 71, 255 (2001). https://doi.org/10.1016/S0254-0584(01)00298-X

P.J. Shang, Z.Q. Liu, D.X. Li, J.K. Shang, J. Electron. Mater. 38, 2579 (2009). https://doi.org/10.1007/s11664-009-0894-0

S.Y. Lee, H.M. Lee, J.H. Park, S.M. Shin, W.J. Kim, T. J. Choi, and K.W. Paik, in 2008 Electronic Components and Technology Conference Proceedings (2008), pp. 649–654. https://doi.org/10.1109/ECTC.2018.00103.

Y. Zhang, Z. Cai, J. C. Suhling, P. Lall, and M. J. Bozack, in 2008 Electronic Components and Technology Conference proceedings (2008), pp. 99–112. https://doi.org/10.1109/ECT.2008.4549956.

A.A. El-Daly, Y. Swilem, M.H. Makled, M.G. El-shaarawy, A.M. Abdraboh, J. Alloys. Compd. 484, 134 (2009). https://doi.org/10.1016/j.jallcom.2009.04.108

J.W. Yoon, B.I. Noh, Y.H. Lee, H.S. Lee, S.B. Jung, Microelectron. Reliab. 48, 1864 (2008). https://doi.org/10.1016/j.microrel.2008.07.065

D. Herkommer, J. Punch, M. Reid, Microelectron. Reliab. 50, 116 (2010). https://doi.org/10.1016/j.microrel.2009.08.008

D.A. Shnawah, M.F.M. Sabri, A. Badruddin, Microelectron. Reliab. 52, 90 (2012). https://doi.org/10.1016/j.microrel.2011.07.093

A.K. Gain, T. Fouzder, Y.C. Chan, W.K.C. Yung, J. Alloys. Compd. 509, 3319 (2011). https://doi.org/10.1016/j.jallcom.2010.12.048

G. Ju, X. Wei, J. Liu, Solder. Surf. Mt. Technol. 20, 4 (2008). https://doi.org/10.1108/09540910810885660

A.K. Gain, Y.C. Chan, Intermetallics 29, 48 (2012). https://doi.org/10.1016/j.intermet.2012.04.019

P. Liu, P. Yao, J. Liu, J. Alloys. Compd. 470, 188 (2009). https://doi.org/10.1016/j.jallcom.2008.02.102

R. Zhang, F. Guo, J. Liu, H. Shen, F. Tai, J. Electron. Mater. 38, 241 (2009). https://doi.org/10.1007/s11664-008-0582-5

S.J. Wang, C.Y. Liu, Scr. Mater. 49, 813 (2003). https://doi.org/10.1016/S1359-6462(03)00486-X

M.S. Kim, H. Nishikawa, Microelectron. Reliab. 76–77, 420 (2017). https://doi.org/10.1016/j.microrel.2017.06.083

K. Zeng, R. Stierman, D. Abbot, and M. Murtuza, in 10th Intersociety Conference on Phenomena in Electronic Systems conference Proceedings, (2006) pp. 1111–1119. https://doi.org/10.1109/ITHERM.2006.1645469.

C.F. Tseng, T.K. Lee, G. Ramakrishna, K.C. Liu, J.G. Duh, Mater. Lett. 65, 3216 (2011). https://doi.org/10.1016/j.matlet.2011.07.015

J.W. Yoon, B.I. Noh, J.H. Yoon, H.B. Kang, S.B. Jung, J. Alloys. Compd. 509, L153 (2011). https://doi.org/10.1016/j.jallcom.2011.01.015

J.W. Yoon, B.I. Noh, S.B. Jung, J. Electron. Mater. 40, 1950 (2011). https://doi.org/10.1007/s11664-011-1686-x

Chaillot, N. Venet, P.E. Tegehall, J. Hokka, and J.L. Lortal, in 2013 European Microelectronics Packaging Conference (EMPC) proceedings, (2013) pp. 1–6.

K.P.L. Pun, M.N. Islam, J. Rotanson, C.W. Cheung, A.H.S. Chan, J. Electron. Mater. 47, 5191 (2018). https://doi.org/10.1007/s11664-018-6385-4

J. Palmer, D. Chu, and L. Fang, in Electronic Components and Technology Conference (ECTC) proceedings, (2012), pp. 1159–1162. https://doi.org/10.1109/ECTC.2012.6248982.

L.B. Belykh, N.I. Skripov, T.P. Sterenchuk, V.V. Akimov, V.L. Tauson, F.K. Schmidt, Russ. J. Gen. Chem. 86, 1454 (2016). https://doi.org/10.1134/S1070363216090073

C.E. Ho, L.H. Hsu, C.H. Yang, T.C. Yeh, P.T. Lee, Thin Solid Films 584, 257 (2015). https://doi.org/10.1016/j.tsf.2014.12.026

C.Y. Ho, J.G. Duh, C.W. Lin, C.J. Lin, Y.H. Wu, H.C. Hong, T.H. Wang, J. Mater. Sci. 48, 2724 (2013). https://doi.org/10.1007/s10853-012-7070-2

C.E. Ho, C.W. Fan, W.Z. Hsieh, Surf. Coat. Tech. 259, 244 (2014). https://doi.org/10.1016/j.surfcoat.2014.04.027

S.S. Ha, J.K. Jang, S.O. Ha, J.W. Kim, J.W. Yoon, B.W. Kim, S.K. Park, S.B. Jung, J. Electron. Mater. 38, 2489 (2009). https://doi.org/10.1007/s11664-009-0916-y

J.W. Yoon, B.I. Noh, S.B. Jung, I.E.E.E. Trans, Comp. Packag. Technol. 33, 222 (2010). https://doi.org/10.1109/TCAPT.2009.2028134

Acknowledgements

This work was supported by a research project grant from the Ministry of Trade, Industry and Energy, Republic of Korea [Grant Number 20003904].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, J., Back, JH., Jung, SB. et al. Interfacial reactions and mechanical properties of Sn–3.0Ag–0.5Cu solder with pure Pd or Pd(P) layers containing thin-Au/Pd/Ni(P) surface-finished PCBs during aging. J Mater Sci: Mater Electron 31, 4027–4039 (2020). https://doi.org/10.1007/s10854-020-02950-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-02950-6