Abstract

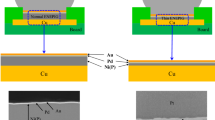

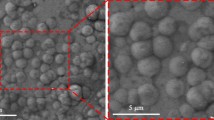

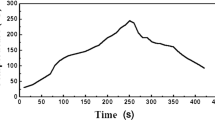

To analyze the effects of Ni(P) layer thickness and Pd layer composition on interfacial reactions and the mechanical reliabilities of Sn–58Bi solder joints, we evaluated a phosphorous-contained Ni (Ni(P)) layer thicknesses ranging from 0.3 to 1.0 μm with Au/Pd/Ni(P) or a phosphorous-contained Pd [Au/Pd(P)/Ni(P)] layer in thin-electroless-nickel electroless-palladium immersion gold (ENEPIG) with Sn–58Bi solder joint after aging test. (Pd, Au)Sn4 and Ni3Sn4 intermetallic compounds (IMCs) were dominantly formed at the interfaces of the 0.3 µm to 1.0 μm Ni(P) layers in the thin-Au/Pd/Ni(P) or thin-Au/Pd(P)/Ni(P) joints after aging at 85 °C and 95 °C for 100 h. However, the Ni3Sn4 IMC layer changed to the (Cu, Ni)6Sn5 IMC layer in the 0.3 μm Ni(P) layer contained the Au/Pd/Ni(P) joint after aging at 85 °C for 300 h, because the Cu elements in a Cu pad penetrated through the P-rich Ni layer. Otherwise, the Ni3Sn4 IMC of the 0.3 μm Ni(P) layer in the Au/Pd(P)/Ni(P) joint changed to (Ni, Cu)3Sn4 IMC after aging at 105 °C and 115 °C for 1000 h, due to the P in the Pd layer, which affects the IMC growth rate. The 0.7 µm and 1.0 μm Ni(P) layers in the Au/Pd/Ni(P) or Au/Pd(P)/Ni(P) joints were attributed to the Ni3Sn4 IMC layer for whole aging conditions because the thick P-rich Ni layer suppress Sn and Cu diffusion during aging. In a high-speed shear tests, the shear strength of the 0.3 μm Ni(P) layer in the Au/Pd/Ni(P) joints was relatively low than that of the Au/Pd(P)/Ni(P) joints after aging at 105 °C and 115 °C for 100 h. Ni3Sn4 IMC was observed at the fracture surfaces of the 0.3 μm Ni(P) layer in the Au/Pd(P)/Ni(P) joints after aging at 115 °C for 1000 h, whereas the fracture surface of the Au/Pd/Ni(P) joint was Cu substrate. Therefore, Ni(P) layer thicknesses in excess of 0.7 μm and the P-contain Pd layer in the thin-ENEPIG surface finish with Sn–58Bi solder joints are expected to be highly reliable after long-term aging treatment.

Similar content being viewed by others

References

T.K. Lee, H. Ma, K.C. Liu, J. Xue, J. Electron. Mater. 39, 2564 (2010). https://doi.org/10.1007/s11664-010-1352-8

Y. Oda, N. Fukumuro, S. Yae, J. Electron. Mater. 47, 2507 (2018). https://doi.org/10.1007/s11664-018-6067-2

Y.W. Yen, P.H. Tsai, Y.K. Fang, S.C. Lo, Y.P. Hsieh, C. Lee, J. Alloys Compd. 503, 25 (2010). https://doi.org/10.1016/j.jallcom.2010.04.241

C.Y. Ho, J.G. Duh, C.W. Lin, C.J. Lin, Y.H. Wu, H.C. Hong, T.H. Wang, J. Mater. Sci. 48, 2724 (2013). https://doi.org/10.1007/s10853-012-7070-2

T. You, Y. Kim, W. Jung, J. Moon, H. Choe, J. Alloys Compd. 486, 242 (2009). https://doi.org/10.1016/j.jallcom.2009.07.085

H.W. Miao, J.G. Duh, Mater. Chem. Phys. 71, 255 (2001). https://doi.org/10.1016/S0254-0584(01)00298-X

A.K. Gain, T. Fouzder, Y.C. Chan, W.K.C. Yung, J. Alloys Compd. 509, 3319 (2011). https://doi.org/10.1016/j.jallcom.2010.12.048

M.N. Islam, Y.C. Chan, Mater. Sci. Eng. B 117, 246 (2005). https://doi.org/10.1016/j.mseb.2004.11.027

B.F. Dyson, T.R. Anthony, D. Turnbull, Appl. Phys. Lett. 38, 3408 (1967). https://doi.org/10.1063/1.1710127

J.W. Yoon, S.B. Jung, J. Alloys Compd. 448, 177 (2008). https://doi.org/10.1016/j.jallcom.2006.10.052

C.M. Tsai, W.C. Luo, C.W. Chang, Y.C. Shieh, C.R. Kao, J. Electron. Mater. 33, 1424 (2004). https://doi.org/10.1007/s11664-004-0082-1

J.W. Yoon, S.B. Jung, J. Alloys Compd. 458, 200 (2008). https://doi.org/10.1016/j.jallcom.2007.04.014

Y.L. Lin, Y.S. Lai, C.M. Tsai, C.R. Kao, J. Electron. Mater. 35, 2147 (2006). https://doi.org/10.1007/s11664-006-0325-4

P. Liu, P. Yao, J. Liu, J. Alloys Compd. 470, 188 (2009). https://doi.org/10.1016/j.jallcom.2008.02.102

L.C. Tsao, M.W. Wu, S.Y. Chang, J. Mater. Sci: Mater. Electron. 23, 681 (2012). https://doi.org/10.1007/s10854-011-0471-1

C.F. Tseng, J.G. Duh, Mater. Sci. Eng. A 580, 169 (2013). https://doi.org/10.1016/j.msea.2013.05.058

C.M. Liu, C.E. Ho, W.T. Chen, C.R. Kao, J. Electron. Mater. 30, 1152 (2001). https://doi.org/10.1007/s11664-001-0143-7

W.C. Luo, C.E. Ho, J.Y. Tsai, Y.L. Lin, C.R. Kao, Mater. Sci. Eng. A 396, 385 (2005). https://doi.org/10.1016/j.msea.2005.02.008

C.Y. Ho, J.G. Duh, Mater. Sci. Eng. A 611, 162 (2014). https://doi.org/10.1016/j.msea.2014.05.049

W.H. Wu, C.S. Lin, S.H. Huang, C.E. Ho, J. Electron. Mater. 39, 2387 (2010). https://doi.org/10.1007/s11664-010-1351-9

B.M. Chung, Y.H. Baek, J. Choi, J.Y. Huh, J. Electron. Mater. 41, 3348 (2012). https://doi.org/10.1007/s11664-012-2320-2

K.P.L. Pun, M.N. Islam, J. Rotanson, C.W. Cheung, A.H.S. Chan, J. Electron. Mater. 47, 5191 (2018). https://doi.org/10.1007/s11664-018-6385-4

Z. Liu, J. Cai, Q. Wang, X. He, Y. Chen, J. Electron. Mater. 43, 3341 (2014). https://doi.org/10.1007/s11664-014-3236-9

J.W. Yoon, B.I. Noh, S.B. Jung, J. Electron. Mater. 40, 1950 (2011). https://doi.org/10.1007/s11664-011-1686-x

Y.M. Kim, J.Y. Park, Y.H. Kim, J. Electron. Mater. 41, 763 (2012). https://doi.org/10.1007/s11664-012-1921-0

C.E. Ho, L.H. Hsu, C.H. Yang, T.C. Yeh, P.T. Lee, Thin Solid Films 584, 257 (2015). https://doi.org/10.1016/j.tsf.2014.12.026

T.T. Chou, C.J. Fleshman, H. Chen, J.G. Duh, J. Mater. Sci: Mater. Electron. 30, 2342 (2019). https://doi.org/10.1007/s10854-018-0507-x

J.W. Yoon, J.H. Back, S.B. Jung, Surf. Interface Anal. 50, 1046 (2018). https://doi.org/10.1002/sia.6419

J. Keller, D. Baither, U. Wilke, G. Schmitz, Acta Mater. 59, 2731 (2011). https://doi.org/10.1016/j.actamat.2011.01.012

J.H.L. Pang, T.H. Low, B.S. Xiong, X. Luhua, C.C. Neo, Thin Solid Films 462–463, 370 (2004). https://doi.org/10.1016/j.tsf.2004.05.092

J. Kim, S.B. Jung, J.W. Yoon, J. Alloys Compd. 820, 153396 (2020). https://doi.org/10.1016/j.jallcom.2019.153396

M. Aamir, R. Muhammad, N. Ahmed, M. Waqas, Microelectron. Reliab. 78, 311 (2017). https://doi.org/10.1016/j.microrel.2017.09.022

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, J., Jung, SB. & Yoon, JW. Effects of Ni(P) layer thickness and Pd layer type in thin-Au/Pd/Ni(P) surface finishes on interfacial reactions and mechanical strength of Sn–58Bi solder joints during aging. J Mater Sci: Mater Electron 31, 19852–19874 (2020). https://doi.org/10.1007/s10854-020-04509-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04509-x