Abstract

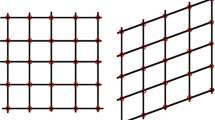

Mechanical properties are investigated for a class of microstructured materials with promising applications. Specifically, we consider a composite material with orthogonal, mutually interconnected fibers building a pantographic substructure. In order to predict the behavior of such a system in three-dimensional continuum, a reduced-order model is introduced by means of a bi-dimensional elastic surface accurately describing large deformations. The properties of this reduced-order model are characterized by an elastic energy density that involves second space derivatives of the displacement for capturing the resistance of twisted and bent fibers in plane as well as out of plane. For determining the coefficients in the elastic energy of the reduced-order model, we utilize a numerical inverse analysis and make use of ad hoc computational experiments performed by a direct numerical simulation on the microscale with detailed modeling of the pantographic substructure. This reduced-order model represents a homogenized material on macro-scale with its substructure on microscale. The homogenized model is capable of describing materials response at a significantly less computational cost than the direct numerical simulations.

Similar content being viewed by others

Notes

We use the wedge product, \(\wedge \), defined as, \(({\varvec{u}}\wedge {\varvec{v}})_{ij} = u_i v_j - v_i u_j\). Therefore, we have \({\mathbf {D}}_i\wedge {\mathbf {D}}_j = {\mathbf {D}}_i\otimes {\mathbf {D}}_j - {\mathbf {D}}_j\otimes {\mathbf {D}}_i\), where \(\otimes \) is the usual tensor (dyadic) product.

References

Abali, B.E.: Computational Reality: Solving Nonlinear and Coupled Problems in Continuum Mechanics. Advanced Structured Materials, vol. 55. Springer, Berlin (2016)

Abali, B.E., Müller, W.H., dell’Isola, F.: Theory and computation of higher gradient elasticity theories based on action principles. Arch. Appl. Mech. 87(9), 1495–1510 (2017)

Abali, B.E., Wu, C.-C., Müller, W.H.: An energy-based method to determine material constants in nonlinear rheology with applications. Contin. Mech. Thermodyn. 28(5), 1221–1246 (2016)

Alibert, J., Corte, A.Della: Second-gradient continua as homogenized limit of pantographic microstructured plates: a rigorous proof. Z. Angew. Math. Phys. 66(5), 2855–2870 (2015)

Alibert, J.-J., Seppecher, P., dell’Isola, F.: Truss modular beams with deformation energy depending on higher displacement gradients. Math. Mech. Solids 8(1), 51–73 (2003)

Alsayednoor, J., Harrison, P.: Evaluating the performance of microstructure generation algorithms for 2-D foam-like representative volume elements. Mech. Mater. 98, 44–58 (2016)

Alsayednoor, J., Harrison, P., Guo, Z.: Large strain compressive response of 2-D periodic representative volume element for random foam microstructures. Mech. Mater. 66, 7–20 (2013)

Altenbach, H., Eremeyev, V.A.: Surface viscoelasticity and effective properties of materials and structures. In: Altenbach, H., Kruch, S. (eds.) Advanced Materials Modelling for Structures, vol. 19, pp. 9–16. Springer, Berlin (2013)

Andreaus, U., dell’Isola, F., Giorgio, I., Placidi, L., Lekszycki, T., Rizzi, N.L.: Numerical simulations of classical problems in two-dimensional (non) linear second gradient elasticity. Int. J. Eng. Sci. 108, 34–50 (2016)

Andreaus, U., Spagnuolo, M., Lekszycki, T., Eugster, S.R.: A Ritz approach for the static analysis of planar pantographic structures modeled with nonlinear Euler-Bernoulli beams. Continu. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0665-3

Assidi, M., Boubaker, B.B., Ganghoffer, J.-F.: Equivalent properties of monolayer fabric from mesoscopic modelling strategies. Int. J. Solids Struct. 48(20), 2920–2930 (2011)

Barchiesi, E., Ganzosch, G., Liebold, C., Placidi, L., Grygoruk, R., Müller, W.H.: Out-of-plane buckling of pantographic fabrics in displacement-controlled shear tests: experimental results and model validation. Contin. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0626-x

Barchiesi, E., Placidi, L.: A review on models for the 3D statics and 2D dynamics of pantographic fabrics. In: Sumbatyan, M. (ed.) Wave Dynamics and Composite Mechanics for Microstructured Materials and Metamaterials, vol. 59, pp. 239–258. Springer, Singapore (2017)

Barchiesi, E., Spagnuolo, M., Placidi, L.: Mechanical metamaterials: a state of the art. Math. Mech. Solids. (2018). https://doi.org/10.1177/1081286517735695

Battista, A., Cardillo, C., Del Vescovo, D., Rizzi, N.L., Turco, E.: Frequency shifts induced by large deformations in planar pantographic continua. Nanomech. Sci. Technol. Int. J. 6(2), 161–178 (2015)

Boutin, C., dell’Isola, F., Giorgio, I., Placidi, L.: Linear pantographic sheets: asymptotic micro-macro models identification. Math. Mech. Complex Syst. 5(2), 127–162 (2017)

Carinci, G., De Masi, A., Giardinà, C., Presutti, Errico: Hydrodynamic limit in a particle system with topological interactions. Arab. J. Math. 3(4), 381–471 (2014)

Challamel, N., Kocsis, A., Wang, C.M.: Discrete and non-local elastica. Int. J. Non-Linear Mech. 77, 128–140 (2015)

Chaouachi, F., Rahali, Y., Ganghoffer, J.-F.: A micromechanical model of woven structures accounting for yarn-yarn contact based on Hertz theory and energy minimization. Compos. Part B: Eng. 66, 368–380 (2014)

Cuomo, M., dell’Isola, F., Greco, L.: Simplified analysis of a generalized bias test for fabrics with two families of inextensible fibres. Z. Angew. Math. Phys. 67(3), 1–23 (2016)

De Masi, A., Merola, I., Presutti, E., Vignaud, Y.: Potts models in the continuum. Uniqueness and exponential decay in the restricted ensembles. J. Stat. Phys. 133(2), 281–345 (2008)

Del Vescovo, D., Giorgio, I.: Dynamic problems for metamaterials: review of existing models and ideas for further research. Int. J. Eng. Sci. 80, 153–172 (2014)

dell’Isola, F., Cuomo, M., Greco, L., Corte, A.Della: Bias extension test for pantographic sheets: numerical simulations based on second gradient shear energies. J. Eng. Math. 103(1), 127–157 (2016)

dell’Isola, F., Corte, A.Della, Giorgio, I., Scerrato, D.: Pantographic 2D sheets: discussion of some numericalinvestigations and potential applications. Int. J. Non-Linear Mech. 80, 200–208 (2016)

dell’Isola, F., Corte, A.Della, Greco, L., Luongo, A.: Plane bias extension test for a continuum with two inextensible families of fibers: a variational treatment with lagrange multipliers and a perturbation solution. Int. J. Solids Struct. 81, 1–12 (2016)

dell’Isola, F., Giorgio, I., Pawlikowski, M., Rizzi, N.: Large deformations of planar extensible beams and pantographic lattices: heuristic homogenization, experimental and numerical examples of equilibrium. Proc. R. Soc. A 472(2185), 23 (2016)

dell’Isola, F., Lekszycki, T., Pawlikowski, M., Grygoruk, R., Greco, L.: Designing a light fabric metamaterial being highly macroscopically tough under directional extension: first experimental evidence. Z. Angew. Math. Phys. 66, 3473–3498 (2015)

dell’Isola, F., Seppecher, P., et al.: Pantographic metamaterials: an example of mathematically driven design and of its technological challenges. Contin. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0689-8

dell’Isola, F., Steigmann, D.J.: A two-dimensional gradient-elasticity theory for woven fabrics. J. Elast. 18, 113–125 (2015)

Di Cosmo, F., Laudato, M., Spagnuolo, M.: Acoustic metamaterialsbased on local resonances: Homogenization, optimization andapplications. In: Altenbach, H., Pouget, J., Rousseau, M., Collet, B., Michelitsch, T. (eds.) Generalized Models and Non-classical Approaches in Complex Materials 1, vol. 89, pp. 247–274. Springer, Cham (2018)

Dos Reis, F., Ganghoffer, J.-F.: Discrete homogenization of architectured materials: implementation of the method in a simulation tool for the systematic prediction of their effective elastic properties. Tech. Mech. 30(1–3), 85–109 (2010)

Dos Reis, F., Ganghoffer, J.-F.: Construction of micropolar continua from the asymptotic homogenization of beam lattices. Comput. Struct. 112, 354–363 (2012)

Dos Reis, F., Ganghoffer, J.-F.: Homogenized elastoplastic response of repetitive 2D lattice truss materials. Comput. Mater. Sci. 84, 145–155 (2014)

El Nady, K., Dos Reis, F., Ganghoffer, J.-F.: Computation of the homogenized nonlinear elastic response of 2D and 3D auxetic structures based on micropolar continuum models. Compos. Struct. 170, 271–290 (2017)

Eremeyev, V.A., dell’Isola, F., Boutin, C., Steigmann, D.: Linear pantographic sheets: existence and uniqueness of weak solutions. J. Elast. 132(2), 175–196 (2018)

Eremeyev, V.A., Pietraszkiewicz, W.: Material symmetry group and constitutive equations of micropolar anisotropic elastic solids. Math. Mech. Solids 21(2), 210–221 (2016)

Franciosi, P., Spagnuolo, M., Salman, O.U.: Mean Green operators of deformable fiber networks embedded in a compliant matrix and property estimates. Contin. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0668-0

Ganzosch, G., dell’Isola, F., Turco, e, Lekszycki, T., Müller, W.H.: Shearing tests applied to pantographic structures. Acta Polytech. CTU Proc. 7, 1–6 (2016)

Giorgio, I.: Numerical identification procedure between a micro-Cauchy model and a macro-second gradient model for planar pantographic structures. Z. Angew. Math. Phys. 67(4), 1–17 (2016)

Giorgio, I., Corte, A.Della, dell’Isola, F., Steigmann, D.: Buckling modes in pantographic lattices. C. R. Mec. 344(7), 487–501 (2016)

Giorgio, I., Harrison, P., dell’Isola, F., Alsayednoor, J., Turco, E.: Wrinkling in engineering fabrics: a comparison between two different comprehensive modelling approaches. Proc. R. Soc. A 474(2216), 20 (2018)

Giorgio, I., Rizzi, N.L., Turco, E.: Continuum modelling of pantographic sheets for out-of-plane bifurcation and vibrational analysis. Proc. R. Soc. A 473(2207), 21 (2017). https://doi.org/10.1098/rspa.2017.0636

Goda, I., Assidi, M., Ganghoffer, J.-F.: Equivalent mechanical properties of textile monolayers from discrete asymptotic homogenization. J. Mech. Phys. Solids 61(12), 2537–2565 (2013)

Golaszewski, M., Grygoruk, R., Giorgio, I., Laudato, M., Di Cosmo, F.: Metamaterials with relative displacements in their microstructure: technological challenges in 3D printing, experiments and numerical predictions. Contin. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0692-0

Greco, L., Cuomo, M., Contrafatto, L.: A reconstructed local \({\bar{B}}\) formulation for isogeometric Kirchhoff-Love shells. Comput. Methods Appl. Mech. Eng. 332, 462–487 (2018)

Greco, L., Giorgio, I., Battista, A.: In plane shear and bending for first gradient inextensible pantographic sheets: numerical study of deformed shapes and global constraint reactions. Math. Mech. Solids 22(10), 1950–1975 (2017)

Guo, Z., Shi, X., Chen, Y., Chen, H., Peng, X., Harrison, P.: Mechanical modeling of incompressible particle-reinforced neo-Hookean composites based on numerical homogenization. Mech. Mater. 70, 1–17 (2014)

Harrison, P.: Modelling the forming mechanics of engineering fabrics using a mutually constrained pantographic beam and membrane mesh. Compos. Part A Appl. Sci. Manuf. 81, 145–157 (2016)

Harrison, P., Alvarez, M.F., Anderson, D.: Towards comprehensive characterisation and modelling of the forming and wrinkling mechanics of engineering fabrics. Int. J. Solids Struct. (2017). https://doi.org/10.1016/j.ijsolstr.2016.11.008

Khakalo, S., Balobanov, V., Niiranen, J.: Modelling size-dependent bending, buckling and vibrations of 2D triangular lattices by strain gradient elasticity models: applications to sandwich beams and auxetics. Int. J. Eng. Sci. 127, 33–52 (2018)

Khakalo, S., Niiranen, J.: Form II of Mindlin’s second strain gradient theory of elasticity with a simplification: for materials and structures from nano-to macro-scales. Eur. J. Mech. A Solids 71, 292–319 (2018)

Laudato, M., Di Cosmo, F.: Euromech 579 Arpino 3–8 April 2017: Generalized and microstructured continua: new ideas in modeling and/or applications to structures with (nearly) inextensible fibers—a review of presentations and discussions. Continu. Mech. Thermodyn. https://doi.org/10.1007/s00161-018-0654-6 (2018)

Mandadapu, K.K., Abali, B.E., Papadopoulos, P.: On the polar nature and invariance properties of a thermomechanical theory for continuum-on-continuum homogenization. arXiv preprint arXiv:1808.02540 (2018)

Maurin, F., Greco, F., Desmet, W.: Isogeometric analysis for nonlinear planar pantographic lattice: discrete and continuum models. Contin. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0641-y

Milton, G., Briane, M., Harutyunyan, D.: On the possible effective elasticity tensors of 2-dimensional and 3-dimensional printed materials. Math. Mech. Complex Syst. 5(1), 41–94 (2017)

Misra, A., Poorsolhjouy, P.: Identification of higher-order elastic constants for grain assemblies based upon granular micromechanics. Math. Mech. Complex Syst. 3(3), 285–308 (2015)

Niiranen, J., Balobanov, V., Kiendl, J., Hosseini, S.B.: Variational formulations, model comparisons and numerical methods for Euler–Bernoulli micro-and nano-beam models. Math. Mech. Solids. (2017). https://doi.org/10.1177/1081286517739669

Placidi, L., Andreaus, U., Corte, A.Della, Lekszycki, T.: Gedanken experiments for the determination of two-dimensional linear second gradient elasticity coefficients. Z. Angew. Math. Phys. 66(6), 3699–3725 (2015)

Placidi, L., Andreaus, U., Giorgio, I.: Identification of two-dimensional pantographic structure via a linear D4 orthotropic second gradient elastic model. J. Eng. Math. 103(1), 1–21 (2017)

Placidi, L., El Dhaba, A.R.: Semi-inverse method à la Saint-Venant for two-dimensional linear isotropic homogeneous second-gradient elasticity. Math. Mech. Solids 22(5), 919–937 (2017)

Placidi, L., Greco, L., Bucci, S., Turco, E., Rizzi, N.L.: A second gradient formulation for a 2D fabric sheet with inextensible fibres. Z. Angew. Math. Phys. 67(5), 114 (2016)

Polizzotto, Castrenze: A second strain gradient elasticity theory with second velocity gradient inertia-Part I: constitutive equations and quasi-static behavior. Int. J. Solids Struct. 50(24), 3749–3765 (2013)

Polizzotto, Castrenze: A second strain gradient elasticity theory with second velocity gradient inertia-Part II: dynamic behavior. Int. J. Solids Struct. 50(24), 3766–3777 (2013)

Queiruga, A., Zohdi, T.: Microscale modeling of effective mechanical and electrical properties of textiles. Int. J. Numer. Methods Eng. 108(13), 1603–1625 (2016)

Rahali, Y., Ganghoffer, J.-F., Chaouachi, F., Zghal, : Strain gradient continuum models for linear pantographic structures: a classification based on material symmetries. J. Geom. Symmetry Phys. 40, 35–52 (2015)

Rahali, Y., Giorgio, I., Ganghoffer, J.F., dell’Isola, F.: Homogenization à la Piola produces second gradient continuum models for linear pantographic lattices. Int. J. Eng. Sci. 97, 148–172 (2015)

Rahali, Y., Goda, I., Ganghoffer, J.-F.: Numerical identification of classical and nonclassical moduli of 3D woven textiles and analysis of scale effects. Compos. Struct. 135, 122–139 (2016)

Saeb, S., Steinmann, P., Javili, A.: Aspects of computational homogenization at finite deformations: a unifying review from Reuss’ to Voigt’s bound. Appl. Mech. Rev. 68(5), 050801 (2016)

Scerrato, D., Giorgio, I., Rizzi, N.: Three-dimensional instabilities of pantographic sheets with parabolic lattices: numerical investigations. Z. Angew. Math. Phys. 67(3), 1–19 (2016)

Scerrato, D., Zhurba Eremeeva, I.A., Lekszycki, T., Rizzi, N.L.: On the effect of shear stiffness on the plane deformation of linear second gradient pantographic sheets. Z. Angew. Math. Mech.: ZAMM 96(11), 1268–1279 (2016)

Shirani, M., Luo, C., Steigmann, D.J.: Cosserat elasticity of lattice shells with kinematically independent flexure and twist. Continu. Mech. Thermodyn. (2018). https://doi.org/10.1007/s00161-018-0679-x

Spagnuolo, M., Barcz, K., Pfaff, A., dell’Isola, F., Franciosi, P.: Qualitative pivot damage analysis in aluminum printed pantographic sheets: numerics and experiments. Mech. Res. Commun. 83, 47–52 (2017)

Steigmann, D.J., dell’Isola, F.: Mechanical response of fabric sheets to three-dimensional bending, twisting, and stretching. Acta Mech. Sin. 31(3), 373–382 (2015)

Turco, E., dell’Isola, F., Cazzani, A., Rizzi, N.L.: Hencky-type discrete model for pantographic structures: numerical comparison with second gradient continuum models. Z. Angew. Math. Phys. 67, 28 (2016)

Turco, E., Giorgio, I., Misra, A., dell’Isola, F.: King post truss as a motif for internal structure of (meta) material with controlled elastic properties. R. Soc. Open Sci. 4(10), 20 (2017)

Turco, E., Golaszewski, M., Giorgio, I., D’Annibale, F.: Pantographic lattices with non-orthogonal fibres: experiments and their numerical simulations. Compos. Part B Eng. 118, 1–14 (2017)

Turco, E., Misra, A., Pawlikowski, M., dell’Isola, F., Hild, F.: Enhanced Piola-Hencky discrete models for pantographic sheets with pivots without deformation energy: numerics and experiments. Int. J. Solids Struct. 147, 94–109 (2018)

Turco, E., Rizzi, N.L.: Pantographic structures presenting statistically distributed defects: numerical investigations of the effects on deformation fields. Mech. Res. Commun. 77, 65–69 (2016)

Yang, H., Ganzosch, G., Giorgio, I., Abali, B.E.: Material characterization and computations of a polymeric metamaterial with a pantographic substructure. Z. Angew. Math. Phys. 69(4), 16 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

A Appendix: Sensitivity of identified parameters

A Appendix: Sensitivity of identified parameters

The identification process made possible to find a set of stiffnesses characterizing the mechanical behavior of the pantographic structure. The subsequent step of our investigation consists in estimating the sensitivity of the objective function upon changes in the constitutive parameters.

To this aim, further simulations were carried out using the macroscopic model. The values of identified stiffnesses were changed individually, and the results were compared with those obtained using such unchanged stiffnesses.

The in-plane bias extension test and the three stiffnesses \(K_e\), \(K_{g}\) and \(K_{s}\) that characterize its mechanical behavior were initially considered. As mentioned before, in each simulation mechanical parameters were increased or decreased individually by \(\pm \,10\% \) and \(\pm \,20\% \). The outcome of such analysis is that there is one mechanical parameter which characterizes most the response under extension, that is, the stiffness \(K_{s}\) related to the shear strain. Indeed, it is possible to notice that a change in \(K_{s}\) produces the greatest differences on every contribution to the objective function in Eq. (18) (see Figs. 20b, 22b, 24b). In Figs. 21b, 23b and 25b, the relative differences of contributions to the objective function with respect to the unchanged identified stiffnesses are plotted.

In Fig. 22a–c, the angle \(\theta \) is plotted varying the parameters \(K_e\), \(K_{s}\) and \(K_{g}\), respectively, in a neighborhood of the identified stiffnesses. In Fig. 23a–c, the relative difference for the angle \(\theta \) is plotted varying, respectively, \(K_e\), \(K_{s}\) and \(K_{g}\). From this last figure, it can be observed that the relative difference of \(\theta \) is comparable for similar relative changes in the stiffnesses \(K_e\) and \(K_{s}\), while relative differences are much less when \(K_{g}\) changes.

It is remarkable that the angle \(\phi \) seems to depend on all the three stiffnesses in a similar way, as they produce comparable effects in each parametric study (see Figs. 24, 25).

Sensitivity analysis varying the constitutive stiffnesses has been carried out for the out-of-plane bias shear test too. As for the previous case, we want to evaluate the changes in the quantities involved in the objective function when \(K_{n}\) and \(K_{t}\) are varied of a certain amount. Also in this case, we consider relative changes of stiffnesses of \(\pm \,10\% \) and \(\pm \,20\% \). In Fig. 26, we observe that the magnitude of strain energy depends similarly both on \(K_{n}\) and on \(K_{t}\). Furthermore, the sensitivity of the model is relevant for these two stiffnesses as shown by plots in Fig. 27. Indeed, relative changes of the stiffnesses, say of \(X\%\), produce relative differences in the related quantities appearing in the objective function of about \(X/2\%\).

Rights and permissions

About this article

Cite this article

De Angelo, M., Barchiesi, E., Giorgio, I. et al. Numerical identification of constitutive parameters in reduced-order bi-dimensional models for pantographic structures: application to out-of-plane buckling. Arch Appl Mech 89, 1333–1358 (2019). https://doi.org/10.1007/s00419-018-01506-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-018-01506-9