Abstract

The present Influenza vaccine manufacturing process has posed a clear impediment to initiation of rapid mass vaccination against spreading pandemic influenza. New vaccine strategies are therefore needed that can accelerate the vaccine production. Pichia offers several advantages for rapid and economical bulk production of recombinant proteins and, hence, can be attractive alternative for producing an effective influenza HA based subunit vaccine. The recombinant Pichia harboring the transgene was subjected to fed-batch fermentation at 10 L scale. A simple fermentation and downstream processing strategy is developed for high-yield secretory expression of the recombinant Hemagglutinin protein of pandemic Swine Origin Influenza A virus using Pichia pastoris via fed-batch fermentation. Expression and purification were optimized and the expressed recombinant Hemagglutinin protein was verified by sodium dodecyl sulfate polyacrylamide gel electrophoresis, Western blot and MALDI-TOF analysis. In this paper, we describe a fed-batch fermentation protocol for the secreted production of Swine Influenza A Hemagglutinin protein in the P. pastoris GS115 strain. We have shown that there is a clear relationship between product yield and specific growth rate. The fed-batch fermentation and downstream processing methods optimized in the present study have immense practical application for high-level production of the recombinant H1N1 HA protein in a cost effective way using P. pastoris.

Similar content being viewed by others

Introduction

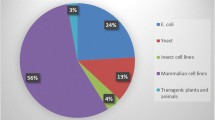

The methylotrophic yeast Pichia pastoris has raised an increasing interest for the production of recombinant proteins offering fast growth rates in low cost media, ease of genetic manipulation and the capability of post-translational modifications such as glycosylation, disulfide bond formation and protein folding. In addition, the P. pastoris system has many advantages as it secretes only low levels of endogenous proteins and a secreted heterologous protein comprises the vast majority of the total protein in the culture supernatant which facilitates easy purification [1, 26]. Unlike bacteria, the transgene in the case of yeast is integrated within the genome; hence, the transgene integration is stable and is difficult to lose the target gene when the recombinant yeast is cultured and passaged several times. Approximately so far over 700 proteins have been successfully expressed in P. pastoris [39]. High level expression of recombinant proteins may be achieved using fermentation techniques. In the controlled environment of a bioreactor, it is possible to achieve high cell densities of about 400 g L−1 cell fresh weight or 130 g L−1 cell dry weight, respectively, with P. pastoris [19]. The concentration of the product obtained from this yeast is reported to be as high as 22 g L−1 for intracellular production [18] and 14.8 g L−1 of clarified broth for secreted proteins [36]. Strong methanol inducible alcohol oxidase promoter (AOX1) that drives recombinant protein is very crucial in P. pastoris for this fast, inexpensive production. Hence, this promoter system is the most widely used in spite of the availability of many other promoters [3]. The high oxygen demand of methanol metabolism makes oxygen supply a major parameter in P. pastoris cultivations and, therefore, requires special fermentation process design strategies. In standard P. pastoris fed-batch cultivation, dissolved oxygen concentration inside the bioreactor is kept at a certain level by feeding air and/or pure oxygen to the reactor. There are safety concerns over handling of oxygen, especially at a large scale. Therefore, there is a need of a production process under oxygen-limited (only aeration) conditions.

Typically, in a fed-batch process, after the depletion of substrate such as glucose/glycerol/sorbitol in the batch media, a growth limiting substrate is fed to the reactor with a particular rate based on the culture requirement [1, 9, 13, 17, 23, 37]. The fed-batch cultivation of P. pastoris expressing a product under the control of AOX1 consists of four phases viz glycerol batch phase, glycerol fed-batch phase, transition phase and methanol fed-batch phase [11, 13, 15]. Initially, in batch mode, basal salt media contains 40 g L−1 glycerol and, after its consumption, the dissolved oxygen (DO) concentration increases in the bioreactor. At this point of time, limited glycerol feeding is started with the aim to derepress the AOX1 promoter and make cells ready for induction [10, 41]. After the glycerol feeding phase, the carbon source is switched from glycerol to methanol and methanol feeding induces the AOX1 promoter that drives the target protein expression and also serves as the carbon source for Pichia cells [7]. This methanol feeding rate depends on the genotype of the recombinant Pichia cells (Mut + or Mut s), specific growth rate of the culture and heterologous protein expression levels. In some cases, an optional transition phase is included between glycerol limited feeding and the induction phase, so that cells adapt better for protein expression. In this phase, a co-feeding of glycerol and methanol over a certain time is performed whereby the glycerol feeding is decreased slowly and methanol feeding is increased [24, 38, 40]. A mixed feed of glycerol and methanol allows faster induction of AOX1 and faster adaptation of cellular metabolism than with a sole methanol feeding [20].

Swine Origin Influenza A virus (SOIV) is an enveloped virus with a segmented negative sense RNA genome that belongs to the Orthomyxoviridae family. The 2009 H1N1 novel virus derived its genes from viruses circulating in the pig population [6, 31, 33]. Presently there are two types of licensed vaccines available against influenza infection: inactivated vaccines (IV) and live cold adapted attenuated influenza vaccine (LAIV) [12, 25]. Both vaccines are grown in chicken eggs. The process of developing a new vaccine strain based on newly circulating viruses is laborious and requires a lot of time. It involves in vivo (in chicken eggs) or in vitro (in cell culture using reverse genetics techniques) re-assortment between the internal genes of a donor virus such as A/PR/8/34 with the Hemagglutinin (HA) and neuraminidase (NA) of the new influenza strain [21]. The manufacturing process is limited in scalability by the use of eggs and the amount of purified virus that can be produced, thus posing a clear impediment to initiation of rapid mass vaccination against spreading pandemic influenza, as was evident for the 2009 H1N1 virus. New vaccine strategies are therefore needed that can both accelerate production and provide a broader spectrum of protection. Hemagglutinin protein that constitutes Influenza A viral surface protein is the major target of neutralizing antibody response and, therefore, is a main constituent of all vaccine formulations [28]. Subunit vaccines like recombinant HA protein (rec HA) offer an alternative over conventional vaccine strategies that could save several months of manufacturing time, since the HA gene of the newly circulating strain is available shortly after virus isolation or nucleotide sequencing of the HA gene. In contrast to conventional approaches, there is no need for live influenza virus or large quantities of eggs, and subunit vaccines could be deployed earlier in the pandemic for effective reduction of morbidity and mortality. Moreover, it is also economical to produce these vaccines capable of inducing antibody that can neutralize the circulating strain of influenza virus. As it is very important to produce the antigenic protein in its native soluble form, prokaryotic systems like bacteria may not be ideal for making this vaccine protein. Previous studies on expressing the recombinant proteins of Avian Influenza virus (H5N1) viz, HA protein [29, 34, 35], neuraminidase (NA) [30] and nonstructural protein [2] in P. pastoris have shown promising results. Similarly, the HA and NA genes of H1N1 have been expressed in P. methnolica [42]. However, no reports are available on fermentation of Hemagglutinin protein from Pandemic Swine Origin Influenza A virus (H1N1) using P. pastoris.

In view of the disease threat, it is practically important to have an alternate heterologous system that can make pandemic influenza HA protein and also can overcome the limitations associated with already reported systems. As Pichia offers several advantages including rapid and economical bulk production of recombinant proteins, an effective influenza HA subunit vaccine can be made with minimal notice for pandemic variants using P. pastoris. In this study, we have successfully optimized the fermentation and downstream processing strategy for bulk production and purification of rec. HA protein of Pandemic H1N1 Influenza virus using the P. pastoris system.

Materials and methods

Molecular reagents, Pichia strain and plasmid

The DNA polymerase, restriction enzymes, and T4 DNA ligase were purchased from Fermentas (USA). Synthetic oligonucleotides and chemicals were purchased from Sigma-Aldrich (Bangalore, India). The P. pastoris GS115 (Invitrogen, USA) was used as the host strain for expression of the Pandemic Hemagglutinin protein. The yeast transfer vector pPIC9K was from Invitrogen (USA).

Construction of pPIC9KH1N1HA yeast transfer vector and recombinant Pichia strain

The synthetic gene of the Hemagglutinin from novel California/04/2009 H1N1 (Genbank accession no. FJ966082.1) was cloned into the pPIC9K yeast transfer vector (Invitrogen, USA) at EcoRI and Not I sites in frame with α-mating factor secretion signal under the control of the methanol-inducible P. pastoris alcohol oxidase 1 (AOX1) promoter (Fig. 1). Recombinant Pichia cells (GS115-H1N1HA) of His+, Mut+ genotype were generated by recombining the Sal I linearised pPIC9KH1N1HA with P. pastoris GS115 cells via electroporation as previously described by us [5]. Single positive transformant (GS115-H1N1HA) having multi-copies (4–6 copies) of the HA expression cassette integration that was also previously found to express the H1N1 HA protein [4] was used in the present study for optimizing fermentation parameters.

H1N1HA expression cassette in pPIC9K yeast transfer vector. Schematic diagram showing the H1N1 HA expression within pPIC9K yeast transfer vector. The HA gene is inserted at Eco RI—Not I sites under the control of AOX1 promoter in fusion with the secretory signal (SS) at 5′ end. Integration of the transgene within the Pichia genome is at HIS 4 locus. KanR gene present within the expression cassette confers resistance to Kanamycin (in bacteria) and Geneticin (in Yeast)

Small scale shake flask expression conditions

Glycerol stock of GS115-H1N1HA was inoculated into 10 mL of YPGy (1 % Yeast extract, 2 % bacto peptone and 1 % glycerol buffered with 100 mM potassium phosphate buffer pH 8.2) containing 500 μg/mL Geneticin and incubated for 48 h (30 °C, 250 rpm). The cells were pelleted by centrifugation at 3,000Xg for 5 min and resuspended in YPM medium (1 % Yeast extract, 2 % bacto peptone and 2 % methanol buffered with 100 mM potassium phosphate buffer, pH 8.2). Induction was sustained for 72 h by spiking the cultures once in every 24 h with 100 % methanol to a final concentration of 2 % (v/v). Subsequently, the culture was harvested by centrifugation (3000Xg for 10 min) and the supernatant collected both from pre-induced and induced cultures were analyzed for the expression of the HA protein on discontinuous poly-acrylamide gel electrophoresis under denaturing conditions.

Fed batch fermentation set up

Fermentation was carried out in a 22-liters Scigenics fermenter (Scigenics, India) with ten liters of fermentation medium [To the basal salt medium BSM (26.7 mL L−1 phosphoric acid, 14.9 g L−1 MgSO4.7H2O, 0.93 g L−1 CaSO4.2H2O, 18.2 g L−1 K2SO4, 4.13 g L−1 KOH,40 g L−1 glycerol), 4 mL L−1 sterile-filtered trace element solution PTM1 (6 g L−1 CuSO4.5H2O, 0.08 g L−1 NaI, 3 g L−1 MnSO4.H2O, 0.2 g L−1 Na2MoO4.2H2O, 0.02 g L−1 H3BO3, 0.5 g L−1 CoCl2, 20 g L−1 ZnCl2, 65 g L−1 FeSO4.7H2O, 0.2 g L−1 Biotin, 5 mL. conc.H2SO4)] was added after autoclaving [17]. The temperature was maintained at 30 °C and the pH was maintained at 8.0 by pumping in a liquid ammonium solution. The dissolved oxygen (DO) was maintained in a range of 40–70 % and controlled by agitation/air/O2 flow cascade. In addition to the supply of air, pure oxygen (5–10 %) was supplemented as per requirement. The stirrer speed was adjusted between 200 and 500 rpm to maintain the DO range. Active Silicone polymer antifoam-A solution (Sigma, USA) was added manually on demand.

The recombinant P. pastoris GS115-H1N1HA strain was grown in a 1-liter shake flask with 200 mL YPGy medium for 18–24 h at 30 °C and 250 rpm to an optical density (A600) of 4–8 using normal shaker incubator. Following microscopic examination for bacterial contamination, the pre-culture was aseptically inoculated into the fermentation medium. To increase the bio-mass and simultaneously prepare the cells for methanol induction, a glycerol fed-batch phase was started after 16 h growth by feeding the cells with 50 %glycerol (containing 12 mL L−1 PTM trace salts) at a rate of 20 mL L−1/h for 28 h. Following the fed-batch phase, a transition phase of 4 h was applied to shorten the time required for the cells to fully adapt to methanol. The transition phase was initiated by the addition of 100 % methanol at a feeding rate of 1.5 mL L−1/h methanol. Simultaneously, the glycerol feed rate was ramped down linearly from 20 L−1/h to 0 over a period of 4 h. By the end of the transition phase, the cells were fully adapted to methanol, which was confirmed by a sharp DO spike. Once the cells were fully adapted to methanol, the methanol fed-batch phase was started. The 100 % methanol was supplemented with 12 mL L−1 of PTM fed at a rate of 10 mL L−1/h for 68 h. The batch was terminated after 120 h of total run. Samples at different time points at an interval of 4 h of post induction were collected and culture supernatant was separated from the cells by centrifuging at 8,000×g for 20 min at 4 °C. Expression of the HA protein was monitored on SDS-PAGE gel. Wet weight, dry weight, OD and total protein content of the culture were determined as given below.

Biomass analysis

Total cell concentration was determined by measuring the absorbance of the fermentation broth at A600nm using a spectrophotometer (Eppendorf, USA). Samples were diluted if the absorbance was above 0.8. To determine the biomass concentration in terms of cell weight, samples of the culture broth (10 mL) were taken in duplicate, centrifuged as mentioned above and washed twice with deionized water. The wet weight of the pellet was recorded. Subsequently the cell pellets were dried in a hot air oven at 90 °C until a constant weight was achieved. The dry weights of the bio mass were recorded and interpreted as g/L for further analysis.

SDS-PAGE analysis of expressed rec.HA protein after fed batch fermentation

Ten microliters of post induced fermentation broth collected after every 8 h were mixed with 10 μL of 2 × SDS-sample buffer (5 % SDS, 10 % glycerol, 0.002 % bromo phenol blue, 0.0062 M Tris- HCl, pH 7.0), supplemented with 2 % mercapto ethanol that were run on 12.5 % poly acrylamide gels with a 5 % stacking gel under reduced conditions [22]. The proteins were separated on SDS-PAGE and were visualized after Coomassie staining.

Downstream processing of yeast derived rec.HA protein

After 72 h, a total of nine liters of cultivation medium was obtained. The culture supernatant was separated from the cells by centrifugation at 5,000×g for 30 min at 4 °C in a swinging bucket rotor using a Sorvall evolution RC centrifuge (Thermo Scientific, USA). Upon centrifugation, approximately eight liters of clear culture supernatant was obtained that was filtered through a 0.45 μm filter. The filtrate was further concentrated approximately twenty times via a tangential flow filtration unit (Millipore, USA) using a 30 kDa Molecular weight cut off (MWCO) filter membrane and the volume was reduced to 400 mL. Sodium azide and PMSF were added at the concentrations of 0.05 % and 10 mM, respectively, to the final concentrate and stored at −80 °C until used further for purification.

The concentrated protein sample was desalted and was subjected to anion exchange chromatography using a 5 mL DEAE Sepharose anion exchange column (Toyo, Japan) in an AKTA explorer system (GE Healthcare, USA) as per the instructions given by the manufacturer. A partial volume of protein sample (5 mL) was loaded onto a DEAE Sepharose column pre-equilibrated with 20 mM Tris.Cl (pH 7.72). The unbound proteins were extensively washed using 20 mM Tris.Cl (pH 7.72) and the bound proteins were eluted with 0–1 M NaCl linear gradient (in 20 mM Tris.Cl pH 7.7) at a flow rate of 1 mL/min. The protein peaks obtained were collected and analyzed by SDS-PAGE for their purity. The concentration of H1N1 HA was determined using the Bradford assay [8].

Characterization and confirmation of the purified rec.HA protein via immunoblotting

The selected fractions collected from the anion exchange column were run on SDS-PAGE under reduced conditions as described earlier and separated proteins were blotted onto a Immobilon-P membrane (Millipore, India) using tris–glycine transfer buffer (25 mM Tris; 192 mM glycine; 10 % v/v methanol) using semi dry blotting apparatus (Bio-Rad-USA). The blot was blocked for 2 h in 3 % w/v BSA in Phosphate buffered saline-T (PBS; 0.05 % v/v Tween 20). The target protein was reacted first with rabbit anti-H1N1 HA antibodies (Genscript, USA) and then with anti-rabbit HRP conjugate. Finally, signals were developed using DAB-H2O2 substrate/chromogen solution.

MALDI TOF/MS analysis of yeast derived recombinant HA protein

The HA protein expressed from Pichia cells was further confirmed using a MALDI-TOF/MS study. The Coomassie-stained recombinant HA protein excised from the gel was washed thrice in destaining solvent (50 % v/v ACN in 25 mM NH4HCO3) by constant vortexing. The washed gel pieces were dehydrated with 200 μl of 100 % ACN and dried in a speed-vac centrifuge (Thermo, USA). The protein in the gel slices were subjected to digestion using 25 μl (20 μg/100 μl) of trypsin in 50 mM NH4HCO3 at 37 °C for overnight in a shaker incubator at 100 rpm. The peptides were extracted into 200 μl of extraction solvent (50 % ACN, 5 % TFA) and lyophilized for complete removal of the solvent. The pellets obtained after lyophilization were reconstituted in 8 μl milli Q water and was subsequently eluted using Mini Tip C18 micro tips (Sigma, USA). Finally, 1 μl of the purified peptide along with 1 μl of HCCA matrix was spotted onto a MALDI plate in a predetermined order. Mass spectrometric analysis was performed using a MALDI-TOF instrument (Bruker Microflex LRF-20, Flex Control Workstation, Bermen, Germany) equipped with delayed extraction (150 ns) and a UV ionization laser (N2, 337 nm) with a 3-ns pulse width. The accelerating voltage was 20 kV and the grid voltage was set to 19 kV and the laser repetition rate was 20 Hz. For the peptide mass fingerprinting, the instrument was operated in the reflector mode using α-Cyano-4-hydroxy cinnamic acid (HCCA) as matrix and hundred shots were averaged per spectra and seven hundred laser shots were accumulated. The spectra were evaluated using the Flex Analysis Software (Bruker Daltonics). The MS spectra obtained was submitted to MASCOT search via Bio tools version 3.1. The search parameters used were partial methionine oxidation, one missed cleavage, peptide mass tolerance 200 ppm and the database selected was NCBI.

Endotoxin estimation of the purified rec.HA protein

The purified protein was analyzed for endotoxin analysis using Endosafe-PTS endotoxin detection system (Charles River, USA) as per the instructions given by the manufacturer. Briefly, 25 μl of purified protein was diluted in an equal volume of Lal reagent water. From this diluted sample, 25 μl was applied onto a PTS test cartridge (Lot No. 3420179, sensitivity range 5—0.05EU/mL.) and was analyzed for endotoxin concentration.

Results and discussion

Small scale shake flask expression analysis

The GS115-H1N1HA Pichia transformant after methanol induction was checked after 72 h for the expression of recombinant HA protein. As expected, a distinct band of ~80 kDa was observed only in case of post induced culture supernatant. Un-induced negative control did not show such a band as seen in Fig. 2. The increased size of HA protein obtained here may be attributed to a glycosylation event that takes place within P. pastoris. Earlier studies also reported similar sized H1N1 HA (80 kDa), H3N2 HA (75–78 kDa) expression in P. pastoris [5, 27]. From the shaker flask expression analysis, it is evident that the Pichia clone (GS115-H1N1HA) used in the present study is known to express the rec. HA protein.

SDS-PAGE analysis of Pichia shake flask culture for expression of H1N1 HA. Lane M Pre stained molecular marker (Fermentas, USA, Cat no: SM1811), Lane 1 Culture supernatant from uninduced GS115-H1N1HA cells (Negative control), Lane 2 Culture supernatant from methanol induced GS115-H1N1HA cells after 72 h post induction

Optimization of fermentation parameters

In order to achieve high-density cultivation that leads to large scale production of rec. HA protein, fed batch fermentation was followed. As seen in Fig. 3, there was a fall in DO level to 34 % with a corresponding OD of 2.71 after 16 h of growth indicating active division of cells. To sustain DO level, agitation and airflow were increased during 8–16 h of growth (Fig. 4). For increasing the bio-mass and simultaneously prepare the cells for methanol induction, a glycerol feeding was started at 16th hour of growth and this was continued for a period of 28 h. By the end of 44 h of growth, the OD of the culture increased to 17.5 (Fig. 5). At this stage a transition from glycerol to methanol was done by slowly ramping down the glycerol feed rate. In 4 h time, the cells were able to adapt to the new methanol carbon source. Thus, the fermenter, in fed-batch, can replenish the nutrients that are depleted. The fermenter also enables dissolved oxygen (DO) levels to be raised, not just by increasing agitation, but by increasing air flow, by supplementing the air stream with pure oxygen, or by doing all three either in series or in parallel. Following methanol adaption, methanol fed-batch phase was started after 48 h of growth that lasted for up to 116 h during which the OD reached 119.48. There was no significant increase in the OD after 112 h of growth (Fig. 5) and the DO level was also continuously increasing (Fig. 3). This clearly suggested that the cells were not in an active phase of division. Considering the fact that excessive methanol feeding may lead to cell death thus leading to loss of protein yield [11, 32], it was decided to stop the methanol feeding after 116 h. Dissolved oxygen concentration is a critical parameter for high cell density cultivations [14]. The continuous increase in DO level in spite of low agitation and airflow (Figs. 3, 4, 5) indicated the depletion of nutrients and carbon source in the culture medium. Considering the above experimental facts (DO, agitation, airflow and OD), the batch termination period of 120 h is justifiable.

Dissolved oxygen (DO), Agitation (rpm) profiles relative to fermentation time (hours) maintained during GS115H1N1HA fed batch fermentation. Dissolved oxygen (rhombus), agitation speed in rpm (triangle) are plotted with respect to time. Different events of fed batch fermentation are indicated. Glycerol feeding (fed batch) started after 16 h of growth, transition phase (44–48 h), Methanol induction was initiated after 48 h of growth and methanol feeding was continued up to 116 h. The fermentation was terminated after 120 h of growth

Fermentation parameters of GS115H1N1HA. Plotted parameters show Airflow (cross), Dissolved oxygen (square) profiles relative to 120 h of fermentation time (hours) maintained during fermentation process. DO was maintained between 40 and 70 % throughout the fermentation process by airflow that ranged between 8 and 27 LPM

From our earlier study [3, 5] it is quite evident that the rec.HA requires slightly alkaline pH for its stability rather than acidic pH environment that favors better growth of Pichia cells. A similar observation has been also made by Saelens Xavier [27] in the case of H3N2 HA expression. However, as the current study was focused mainly on producing a stable and active form of rec HA protein, a constant pH of 8.0 was maintained throughout the fermentation process. This may be the main reason for not achieving more than 120.61 OD in the present study.

Bio-mass analysis

In order to estimate the biomass of the fermentation harvest, a systematic analysis on wet weight and dry weight was made after every 4 h of growth as described under materials and methods. As seen in Fig. 5, there was a proportional increase of both wet weight and dry weight of the Pichia biomass as fermentation progressed. At the time of harvest, a total 73 g/L wet weight was obtained and the corresponding dry weight was 18.27 g/L. This accounts for a biomass of ~0.15 g/L dry cell weight with every one unit of OD (A600). In the case of an earlier reported porcine interferon production using model based glycerol feeding strategy [16], a dry cell weight (DCW) of about 90 g/L was achieved. In comparison to this, the present dry cell weight appears to be very much less. Hence, there is a scope for further improvement in the P. pastoris biomass through modeling approach. As seen in Fig. 6, there was an increase in the total protein concentration with increased OD. At the time of harvest, the OD reached up to 120.61. The total protein concentration as determined by Bradford assay at the time of harvest was 1.62 g/L. Although the highest reported protein concentration in the clarified broth is 14.8 g/L [36], the observed low protein yield can be attributed to the lower biomass obtained in the present study.

SDS-PAGE analysis

The culture supernatants collected after every 8 h of post induction were analyzed on the protein gel. The expression of rec.HA was visible from 8 h of post induction. However, a distinct band was observed after 16 h of post induction as seen in Fig. 7. The protein band intensity increased as fermentation progressed. As noticed on the SDS-PAGE gel, minor degradation of protein was observed at 72 h suggesting that it is undesirable to continue the fermentation beyond this time point. Our earlier studies conducted to elevate the expression level with increased incubation period resulted in loss of protein yield due to host specific proteolytic degradation [5]. As the stability of the expressed protein was a major concern, the culture was harvested after 72 h of post induction. Although the acidic pH environment of the medium favors the growth of Pichia cells and also protects the secreted proteins against proteolysis to some extent; acidic pH environment could not be used in the present study due to the instability of rec.HA protein at acidic pH. Although the protein concentration of the clarified broth was found to be 1.62 g/L, it accounts for nearly 10 fold increase in the protein yield in comparison to shake flask culture as published by us earlier [4].

SDS-PAGE analysis fed-batch fermentation culture supernatant for expression of H1N1 HA. Lane 1–9 Harvests of culture supernatants from fed-batch fermentation of GS115-H1N1HA cells after 8, 16, 24, 32, 40, 48, 56, 64, 72 h post induction respectively, Lane M Pre stained molecular marker (Fermentas, USA, Cat no: 06711)

Downstream processing of H1N1 HA recombinant protein

Anion exchange chromatography

The anion-exchange chromatography was chosen as rec.HA is known to bind to an anion exchanger. The captured protein on the exchange column was recovered with 200 mM NaCl as shown in Fig. 8. The 20 mM Tris.Cl, pH 7.72 buffer used in the present study offers a high binding capacity of rec.HA protein and also good resolution. On SDS-PAGE gel, the fractions corresponding to the protein peak eluted using gradient NaCl showed a single protein band that matched the size of the H1N1 HA protein as seen in Fig. 9a, whereas the wash fractions did not show such a band. The concentration of the purified protein as estimated by the Bradford assay was 430 mg/L.

Anion exchange chromatogram of H1N1 HA purification. The crude HA protein diluted in equilibration/binding buffer (20 mM Tris.Cl, pH 7.72) was loaded onto DEAE -Sepharose anion exchange column (Tokyo, Japan) and non specific proteins were washed with 20 mM Tris.Cl, pH 7.72. The bound protein was eluted with sodium chloride linear gradient (0–1 M NaCl in 20 mM Tris.Cl, pH 7.72) at a flow rate of 1 mL/min using Akta purifier (GE Health care, USA)

a SDS-PAGE analysis of anion exchange chromatography purified recombinant H1N1 HA. Lane M: Pre stained molecular marker (Fermentas, USA, Cat no: 1811), Lane 1, 2, 3 Fractions collected from washing steps (wash buffer: 20 mM Tris.Cl, pH 7.72) Lane 4, 5: H1N1 HA fraction eluted with 0–1 M NaCl (in 20 mM Tris.Cl, pH 7.72) continuous linear gradient. b Immuno blot analysis of anion exchange chromatography purified recombinant H1N1 HA. Lane M Pre stained molecular marker (Fermentas, USA, Cat no: 1811), Lane 1 Purified H1N1 HA fraction eluted after anion exchange chromatography, Lane 2 washed fraction

Characterization and confirmation of the purified rec.HA protein via immunoblotting

The purified rec.HA protein was analyzed for its authenticity via immunoblotting using commercial anti-H1N1 HA specific antibodies (Genscript, USA). As seen in Fig. 9b, the purified rec.HA was recognized by the anti-HA antibodies, no such signal was noticed in the case of the washed fraction.

MALDI-TOF/MS analysis

The authenticity of the yeast expressed recombinant HA protein was further confirmed via MALDI-TOF/MS analysis. The 80 kDa protein band corresponding to recombinant HA was enzymatically digested as previously reported [4]. The peptide mass profiles obtained from the destained band are depicted in Fig. 10. Sixteen peptides (range 599–2,698 Da) were used for the peptide mass database search which identified HA protein with 43 % sequence coverage (data not shown).

Endotoxin estimation of the purified protein

Analysis of the purified rec.HA protein for its endotoxin impurity using an Endosafe-PTS device revealed that the endotoxin level of the purified protein was <0.05 EU/mL. This suggests a very low level of endotoxin impurity present with the purified rec.HA protein and is acceptable for in vivo use. From the obtained results, it is quite evident that unlike bacteria, P. pastoris produces rec.HA protein which is free from endotoxin contamination. This further strengthens the argument that yeast derived rec.HA protein is safe for further evaluation as a prophylactic agent in different animal models.

In conclusion, fed-batch fermentation protocol for the secreted production of Swine Influenza A Hemagglutinin protein in P. pastoris GS115 strain has been optimized. We have shown that there is a clear relationship between product yield and specific growth rate. Cultivation of the cells up to 72 h of post induction resulted in a volumetric yield of 1.62 g of crude protein per liter fermentation broth. The expressed protein was purified via anion exchange chromatography and the authenticity of the purified protein was confirmed by immunoblotting and MALDI-TOF/MS analysis. The purified rec.HA protein had a negligible level of endotoxin and was found to be safe for in vivo use. To date, no study has been published on large scale production of H1N1 HA protein via fed batch fermentation using Pichia as the expression host. Our studies indicate that P. pastoris can be an excellent alternative for large-scale production of this recombinant protein. The recombinant GS115H1N1HA Pichia cells may be considered for large scale production of recombinant HA protein for several reasons including the practical feasibility like ease of expression and purification of the recombinant protein.

Abbreviations

- AOX1:

-

Alcohol oxidase promoter 1

- DO:

-

Dissolved oxygen

- OD:

-

Optical Density

- HA:

-

Hemagglutinin

- PBS:

-

Phosphate buffered saline

- MALDI TOF/MS:

-

Matrix-assisted laser desorption/ionization Time of Flight/Mass spectrometry

- HCCA:

-

α-Cyano-4-hydroxy cinnamic acid

- EU:

-

European units

- MWCO:

-

Molecular weight cut off

- DEAE:

-

Diethylaminoethanol

References

Abad S, Nahalka J, Winkler M, Bergler G, Speight R, Glieder A, Nidetzky B (2011) High-level expression of Rhodotorula gracilis D-amino acid oxidase in Pichia pastoris. Biotechnol Lett 33:557–563

Abubakar MB, Aini I, Omar AR, Hair-Bejo M (2011) Cloning and expression of highly pathogenic avian influenza virus full-length nonstructural gene in Pichia pastoris. J Biomed Biotechnol 2011:414198. doi:10.1155/2011/414198

Athmaram TN, Bali G, Khang GG, Dwarakanath S (2007) Heterologous expression of Bluetongue VP2 viral protein fragment in Pichia pastoris. Virus Genes 35(2):265–267

Athmaram TN, Saraswat Shweta, Singh AK, Kameswara Rao M, Gopalan N, Suryanarayana VVS, Rao PVL (2012) Influence of copy number on the expression levels of pandemic influenza hemagglutinin recombinant protein in methylotrophic yeast Pichia pastoris. Virus Genes. doi:10.1007/s11262-012-0809-7

Athmaram TN, Saraswat Shweta, Santhosh SR, Singh AK, Suryanarayana VVS, Priya R, Gopalan N, Parida M, Lakshmana Rao PV, Vijayaraghavan R (2011) Yeast expressed recombinant Hemagglutinin protein of Novel H1N1 elicits neutralising antibodies in rabbits and mice. Virol J 8:524

Bahl J, Vijaykrishna D, Zhang J, Poon LL (2009) Dating the emergence of pandemic influenza viruses. Proc Natl Acad Sci USA 106:11709–11712

Bawa Z, Darby RA (2012) Optimising Pichia pastoris induction. Methods Mol Biol 866:181–190

Bradford MM (1976) Rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Celik E, Calik P, Oliver SG (2009) Fed-batch methanol feeding strategy for recombinant protein production by Pichia pastoris in the presence of co-substrate sorbitol. Yeast 26(9):473–484

Cereghino GP, Cereghino JL, Ilgen C, Cregg JM (2002) Production of recombinant proteins in fermenter cultures of the yeast Pichia pastoris. Curr Opin Biotechnol 13:329–332

Cereghino JL, Cregg JM (2000) Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev 24:45–66

Cheng X, Eisenbraun M, Xu Q, Zhou H, Kulkarni D et al (2009) H5N1 vaccine-specific B cell responses in ferrets primed with live attenuated seasonal influenza vaccines. PLoS One 4:e4436. doi:10.1371/journal.pone.0004436

Cos O, Ramon R, Montesinos JL, Valero F (2006) A simple model-based control for Pichia pastoris allows a more efficient heterologous protein production bioprocess. Biotechnol Bioeng 95:145–154

Cunha AE, Clemente JJ, Gomes R, Pinto F, Thomaz M, Miranda S, Pinto R, Moosmayer D, Donner P, Carrondo MJ (2004) Methanol induction optimization for scFv antibody fragment production in Pichia pastoris. Biotechnol Bioeng 86:458–467

Daly R, Hearn MT (2005) Expression of heterologous proteins in Pichia pastoris: a useful experimental tool in protein engineering and production. J Mol Recognit 18(2):119–138

Gao MJ, Zheng ZY, Wu JR, Dong SJ, Li Z, Jin H, Zhan XB, Lin CC (2012) Improvement of specific growth rate of Pichia pastoris for effective porcine interferon-(+or-) production with an on-line model-based glycerol feeding strategy. Appl Microbiol Biotechnol 93(4):1437–1445

Gurramkonda C, Polez S, Skoko N, Adnan A, Gabel T, Chugh D, Swaminathan S, Khanna N, Tisminetzky S, Rinas U (2010) Application of simple fed-batch technique to high-level secretory production of insulin precursor using Pichia pastoris with subsequent purification and conversion to human insulin. Microb Cell Fact 9:31. doi:10.1186/1475-2859-9-31

Hasslacher M, Schall M, Hayn M, Bona R, Rumbold K, Luckl J, Griengl H, Kohlwein SD, Schwab H (1997) High-level intracellular expression of hydroxynitrile lyase from the tropical rubber tree Hevea brasiliensis in microbial hosts. Protein Expr Purif 11:61–71

Jahic M, Rotticci-Mulder JC, Martinelle M, Hult K, Enfors SO (2002) Modeling of growth and energy metabolism of Pichia pastoris producing a fusion protein. Bioprocess Biosyst Eng 24:385–393

Jungo C, Marison I, Von Stockar U (2007) Regulation of alcohol oxidase of a recombinant Pichia pastoris Mut+strain in transient continuous cultures. J Biotechnol 130:236–246

Khurana S, Verma S, Verma N, Crevar CJ, Carter DM et al (2010) Properly folded bacterially expressed H1N1 hemagglutinin globular head and ectodomain vaccines protect ferrets against H1N1 pandemic influenza virus. PLoS One 5(7):11548. doi:10.1371/journal.pone.0011548

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Li SY, Srivastava R, Suib SL, Li Y, Parnas RS (2011) Performance of batch, fed-batch, and continuous A-B-E fermentation with pH-control. Bioresour Technol 102:4241–4250

Minning S, Serrano A, Ferrer P, Solá C, Schmid RD, Valero F (2001) Optimization of the high-level production of Rhizopus oryzae lipase in Pichia pastoris. J Biotechnol 86:59–70

Ohmit SE, Victor JC, Rotthoff JR, Teich ER, Truscon RK et al (2006) Prevention of antigenically drifted influenza by inactivated and live attenuated vaccines. N Engl J Med 355:2513–2522

Romanos MA, Scorer CA, Clare JJ (1992) Foreign gene 490 expression in yeast: a review. Yeast 8(6):423–488

Saelens X, Van Landschoot P, Martinet W, Maras M, Neirynck S, Contreras R, Fiers W, Jou WM (1999) Protection of mice against a lethal influenza virus challenge after immunisation with yeast derived secreted Influenza virus Hemagglutinin. Eur J Biochem 260:166–175

Sahini L et al (2010) Large-scale sequence analysis of hemagglutinin of influenza A virus identifies conserved regions suitable for targeting an anti-viral response. PLoS One 5(2):e9268. doi:10.1371/journal.pone.0009268

Shehata AA et al (2012) Development of a recombinant ELISA using yeast (Pichia pastoris)-Expressed polypeptides for detection of antibodies against avian influenza A subtype H5. J Virol Methods 180(1-2):18–25

Yang YL, Chang SH, Gong X, Wu J, Liu B (2012) Expression, purification and characterization of low-glycosylation influenza neuraminidase in (+or-)-1, 6-mannosyltransferase defective Pichia pastoris. Mol Biol Rep 39(2):857–864

Shinde V, Bridges CB, Uyeki TM, Shu B, Balish A (2009) Triple reassortant swine influenza A (H1) in humans in the United States, 2005–2009. N Engl J Med 360:2616–2625

Sinha J, Plantz BA, Zhang W, Gouthro M, Schlegel V, Liu CP, Meagher MM (2003) Improved production of recombinant Ovine Interferon- by mut+strain of Pichia pastoris using an optimized methanol feed profile. Biotechnol Prog 19:794–802

Smith GJ, Vijaykrishna D, Bahl J, Lycett SJ, Worobey M (2009) Origins and evolutionary genomics of the 2009 swine-origin H1N1 influenza A epidemic. Nature 459:1122–1125

Murugan S, Ponsekaran S, Kannivel L, Mangamoori LN, Chandran D, Villuppanoor Alwar S, Chakravarty C, Lal SK (2013) Recombinant haemagglutinin protein of highly pathogenic avian influenza A (H5N1) virus expressed in Pichia pastoris elicits a neutralizing antibody response in mice. J Virol Methods 187(1):20–25. doi:10.1016/j.jviromet.2012.07.026

Wasilenko JL, Sarmento L, Spatz S, Pantin-Jackwood M (2010) Cell surface display of highly pathogenic avian influenza virus hemagglutinin on the surface of Pichia pastoris cells using alpha-agglutinin for production of oral vaccines. Biotechnol Prog 26(2):542–547

Werten MW, Van den Bosch TJ, Wind RD, Mooibroek H, de Wolf FA (1999) High-yield secretion of recombinant gelatins by Pichia pastoris. Yeast 15:1087–1096

Yamawaki S, Matsumoto T, Ohnishi Y, Kumada Y, Shiomi N, Katsuda T, Lee EK, Katoh S (2007) Production of single-chain variable fragment antibody (scFv) in fedbatch and continuous culture of Pichia pastoris by two different methanol feeding methods. J Biosci Bioeng 104:403–407

Yu R, Dong S, Zhu Y, Jin H, Gao M, Duan Z, Zheng Z, Shi Z, Li Z (2010) Effective and stable porcine interferon-alpha production by Pichia pastoris fed-batch cultivation with multi-variables clustering and analysis. Bioprocess Biosyst Eng 33(4):473–483

Zhang AL, Luo JX, Zhang TY, Pan YW, Tan YH, Fu CY, Tu FZ (2009) Recent advances on the GAP promoter derived expression system of Pichia pastoris. Mol Biol Rep 36:1611–1619

Zhang W, Bevins MA, Plantz BA, Smith LA, Meagher MM (2000) Modeling Pichia pastoris growth on methanol and optimizing the production of a recombinant protein, the heavy-chain fragment C of botulinum neurotoxin, Serotype A. Biotechnol Bioeng 70:1–8

Zhang W, Inan M, Meagher M (2000) Fermentation strategies for recombinant protein expression in the methylotrophic yeast Pichia pastoris. Biotechnol Bioprocess Eng 5:275–287

Zhang Y, Yu Z, Xin L, Chen Y, Tang Q, Chen Y, Chen Q, Shu Y (2010) Expression of the hemagglutinin and neuramidinase gene of influenza A virus H1N1 in Pichia methanolica. Sheng Wu Gong Cheng Xue Bao 26(8):1068–1073

Acknowledgments

The authors are thankful to Dr. B.K. Bhattacharya, Head, Division of Biochemistry, for his help on MALDI-TOF/MS study. The authors also acknowledge Director, DRDE, Gwalior, Madhya Pradesh-474 002 for his support in executing this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Athmaram, T.N., Singh, A.K., Saraswat, S. et al. A simple Pichia pastoris fermentation and downstream processing strategy for making recombinant pandemic Swine Origin Influenza A virus Hemagglutinin protein. J Ind Microbiol Biotechnol 40, 245–255 (2013). https://doi.org/10.1007/s10295-012-1220-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1220-z