Abstract

Thermal spraying has been present for over a century, being greatly refined and optimized during this time. It has become nowadays a reliable and cost-efficient method to deposit thick coatings with a wide variety of feedstock materials and substrates. Thermal-sprayed coatings have been successfully applied in fields such as aerospace or electricity production, becoming an essential component of today’s industry. To overpass the traditional capabilities of those coatings, new functionalities and coherent responses are being integrated, opening the field of functional and smart coatings. The aim of this paper is to present a comprehensive review of the current state of functional and smart coatings produced using thermal spraying deposition. It will first describe the different thermal spraying technologies, with a focus on how different techniques achieve the thermal and kinetic energy required to form a coating. It will as well focus on the environment to which feedstock particles are exposed in terms of temperature and velocity. It will first deal with the state-of-the-art functional and smart coatings applied using thermal spraying techniques; a discussion will follow on the fundamentals on which the coatings are designed and the efficiency of its performance; finally, the successful applications both current and potential will be described. The inherent designing flexibility of thermal-sprayed functional and smart coatings has been exploited to explore exciting new possibilities on many different fields. Some applications include, but not limited to, prevention of bacteria contamination and infection on hygienic environments. Here, thermal spray has been used to efficiently deposit antimicrobial compounds on medical furniture and appliances and to develop biocidal and biocompatible coatings for prosthetic implants. The attachment of hard and soft foulers such as algae or molluscs, which represents a considerable issue for any marine or freshwater installation, can be prevented on components where the use of traditional anti-fouling strategies such as paints is not optimal for certain materials (i.e., polymers). Another interesting approach pursued is the development of superhydrophobic surfaces, with contact angles as high as 160° and slide angles below 5°, leading to high droplet mobility. This adds capabilities as self-cleaning or corrosion resistance in addition to the characteristic robustness of thermal-sprayed coatings. The electric and magnetic properties of the feedstock materials have also led to the application of thermal spraying techniques in the creation of patterned structures with desired electromagnetic properties for their use on microelectronics. The possibility to intercalate layers of thermal-sprayed materials doped with optical-reactive elements has led to the development of online and offline temperature sensors which can be readily integrated in current thermal barrier coatings. To finalize the examples of the many applications of thermal-sprayed functional and smart coatings, autonomous self-healing or self-lubricant coatings have been developed. Advantage has been taken of a beneficial phase transformation triggered by the corresponding event (such as a crack or the tribological interactions, respectively) to promote self-healing. Another approach has been the release of an encapsulated component which effectively heals the coating or provides lubrication when required. All these exciting developments pave the way for the numerous applications that are to come in the next decade, making the field of thermal-sprayed coatings a unique opportunity for research and development.

Similar content being viewed by others

Introduction

The selection of the materials to be used in industrial applications is dictated by their intrinsic properties, which must satisfy the specified needs for the component being designed and manufactured. A clear example would be structural components, where strength or fracture resistance is of the upmost importance. Furthermore, any designed component will face a determined environment during service operation. This interaction can drastically limit its lifetime or even change its properties to an extent where it will no longer satisfy the expected demands. Two common examples which illustrate these situations would be components in corrosive environments, such as offshore structures where the combination of salt and humidity corrodes the surface of the component, gradually weakening the structure (Ref 1), and high-temperature applications such as turbine blades, where the elevated temperatures would damage unprotected components (Ref 2).

As the examples above illustrate, the interaction between the environment and the material plays a critical role, and at the heart of that interaction lies the surface. The surface of any component represents the interface between the environment and the material, and any interaction that might happen, will take place at the surface. In order to protect the surface, one successful strategy has been to deposit a relatively thin layer (when compared to the dimensions of the bulk material) of a different material, with the properties required to face the expected environment.

The development of coatings has pushed further away the inherent limits of materials, broadening the design possibilities on many cutting-edge fields. The advantages of combining the bulk properties of a substrate with the tailored capabilities of a layer at the surface opened a world of new opportunities. Nowadays, coatings are present in almost all of the most demanding environments and specialized applications. Following the examples above, offshore structures are coated with corrosion-resistant coatings such as zinc and zinc-aluminum (Ref 3), and turbine blades are commonly coated with thermal barrier coatings such as yttria-stabilized zirconia (YSZ), with low thermal conductivity and good mechanical properties.

One of the aspects that has made coatings such a popular solution is the fact that a wide range of deposition techniques are available. To cover the whole catalogue of deposition techniques available is outside the scope of this review, which will focus on thermal spray technologies. Thermal spray comprises those deposition processes in which an energy source is used to heat the initial feedstock particles (which could be presented in the form of suspension, powder, wire, or rod), being then accelerated and propelled towards the substrate using a gas stream (Ref 4). The combined thermal and kinetic energies of the particles allow the bonding with the surface of the substrate upon impact, effectively building up the coating as the particles reach the surface. Another aspect that has contributed to the wide-spread use of thermal spraying is the flexibility in the choice of materials that can be deposited with these techniques. As a general definition, any material with the capability of melting without experiencing decomposition is suitable for thermal spraying (Ref 5).

Due to the unique combination of a wide range of deposition techniques and materials available for coatings, thermal spraying has been successfully applied in numerous fields, such as corrosion and oxidation resistance (Ref 6), high-temperature protection (Ref 7), wear and erosion (Ref 8), abradable coatings and dimensional repairs (Ref 9, 10), biomedical applications (Ref 11), and electronics (Ref 12). As it can be seen, the field of thermal spraying has represented a prolific match for coatings, allowing the production of highly capable systems. Such coating also presents a great acceptance in the industry, excellent large-scale adaptability, and suitable cost–efficiency, having undoubtedly proved its value. Despite the clear success and high rate of applicability of thermal-sprayed coatings, there is an always increasing demand for systems capable of facing more aggressive environments, reliably performing at even higher temperatures, serving during longer periods of time or providing new, desirable functionalities, to name a few of the driving criteria. To overcome some of the current needs, new concepts within thermal-sprayed coatings have been developed, with functionality and smartness being the subject of investigation of this work.

One of the most successful routes in the development of thermal-sprayed coatings has been the combination of a proven material system which, due to the flexibility of allowed sprayed materials, is combined with an added component responsible for the novel functionality. The presence of a solid base of thoroughly investigated and field-tested thermal-sprayed coatings has provided an unparalleled starting point for the development of more capable and tailor-designed functional coatings. On its simplest definition, a functional coating can be described as a coating with an added functionality beyond the traditional protective capabilities (Ref 13). The classical protective case would be the already mentioned corrosion or wear protection. However, although these new functionalities provide functional coatings with a wide range of applications and possibilities, their behavior is still passive on its interaction with the environment. A smart coating, on the other hand, aims to provide coatings with an active response to certain stimuli, generated either by intrinsic or extrinsic events (Ref 14, 15). In summary, all smart coatings can be considered functional coatings due to the presence of functionality beyond simple protection, but not all functional coatings can be categorized as smart due to the lack of an active response to external stimuli. It should be noted that the categorization used in this review regarding the functional and smart coatings is not intended to be definitive—different definitions are present in existing literature. The distinction was chosen to provide a more structured approach to the review.

Several decades of investigation on the science behind thermal-sprayed coatings and the relatively new addition of functional and smart coatings has provided an invaluable opportunity for numerous industrial applications. However, further research is still required to provide cost-efficient methods with proven added value to the companies. With the unparalleled success of deposition techniques such as plasma spraying or high-velocity oxy-fuel (HVOF) thermal spraying as an example, other thermal spray technologies still need to reach that level of market penetration. This will only be attainable through strong beneficial cases with a clear understanding of the processes involved. The addition of new capabilities through the introduction of functional and smart coatings represents an added opportunity for exciting, groundbreaking research. It is essential that the industry becomes involved too, setting the requirements and needs of a market more demanding than ever, in which these technologies can present a benefit.

In this work, due to the importance that the different deposition techniques have on the produced functional and smart coatings, an overview of the main thermal spray technologies available is first presented. Then, attending to the division previously defined between functional and smart coatings, an extensive and comprehensive study of the current developments in the field is undertaken. With the use of thermal spraying techniques as common factor, the current state of the art for functional and smart coatings is presented attending to the different functionalities achieved.

Thermal Spraying Technologies

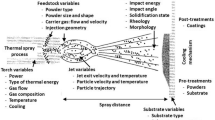

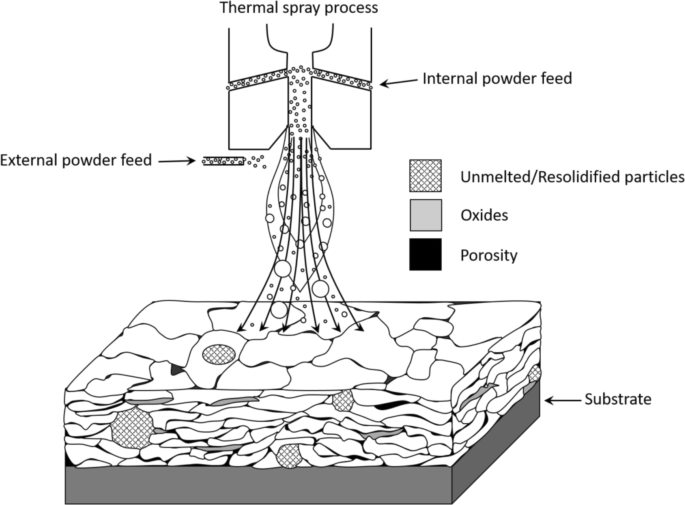

Thermal spraying processes incorporate those technologies on which metallic or nonmetallic coatings are deposited through the same principle. A heat source melts the feedstock material, and a jet is used to impart kinetic energy to the molten particles. They then impinge the substrate surface and rapidly cool down to form a solid splat, continuously building up the desired thickness (Ref 16, 17). A basic schematic of the thermal spray process can be seen in Fig. 1. The flexibility on thermal sources and jet configurations give rise to a plethora of different deposition technologies, as presented in Fig. 2, each one producing coatings with different microstructures and physical properties.

Redrawn from (Ref 4)

Schematic representation of a thermal spraying process with the two main components, a heat source and a jet, and the main features of the produced coatings.

Redrawn from (Ref 17)

Classification of the thermal spray family of deposition techniques.

The development of thermal spraying processes has been central to the evolution of functional and smart coatings, allowing new materials to be deposited and new substrates to be coated, broadening the range of accessible possibilities. This section presents an overview of the most common thermal spraying processes used in the fabrication of functional and smart coatings, with a brief description of their working principles.

Plasma Spraying

Atmospheric plasma spraying (APS) uses thermal plasmas produced through direct current (DC) arc or radio-frequency (RF) discharge as the heat source of the deposition process. This allows flame temperatures over 8000 K (reaching as high as 14,000 K in the jet core (Ref 16, 18)) and particle velocities ranging from ~ 20 up to ~ 500 m/s depending on the particle size distribution (Ref 19). The elevated temperatures produce a high proportion of particles melted, which in addition to the relatively high velocities give rise to excellent deposition densities, bond strengths, and low porosity coatings when compared to most thermal spraying processes (Ref 16). The high cost efficiency and good quality of the coatings obtained by using APS have led to a successful implementation in numerous industries.

Suspension/Solution Precursor Plasma Spraying

Due to the need of adequate flowability for the feedstock powder, APS is limited to the deposition of particles with an approximate lower limit size of 10-100 µm (Ref 20, 21). In order to allow the use of nanoscaled powders, different solutions have been developed as an alternative to the traditional injection of powder. The main representatives of these alternatives are suspension plasma spraying (SPS) and solution precursor plasma spraying (SPPS) (Ref 20,21,22,23,24,25,26,27,28,29,30). The differentiation factor between the two methods is shown in Fig. 3, with the precipitation of the deposited particles in-flight in the case of SPPS as opposed to the direct deposition (apart from the physical changes related to the exposure to the high temperature in the flame) in SPS.

Deposition and particle transformation in-flight for (a) suspension thermal spraying and (b) solution precursor thermal spraying (Ref 25)

These techniques increase the flexibility of the plasma deposition technologies, already widely used in the industry, accessing smaller particle size for the feedstock materials and allowing deposited coatings with different microstructures. A field where SPS and SPPS have found great application is the fabrication of thermal barrier coatings (TBC) for high-temperature applications. The main reasons are the strain-tolerant columnar structures or vertical cracks and fine porosity on SPS-deposited (Ref 31,32,33,34) and SPPS-deposited (Ref 35,36,37,38,39) coatings, resulting in a thermal conductivity lower than that of electron beam physical vapor deposition (EB-PVD) or traditional APS coatings.

Low-Pressure/Vacuum Plasma Spraying

Plasma spraying in controlled environments was developed in the late 1960s with the aim to reduce the adverse effects arising from the interaction of the in-flight heated particles with the environment. Such detrimental effects include oxidation and undesired contaminations in the coatings. The use of low and very low-pressure permits the development of high-quality thermal-sprayed coatings. The pressures used vary, being commonly in the range from 4000 Pa to 40,000 Pa for low-pressure plasma spraying (LPPS) and as low as 100 Pa for very low plasma spraying (VLPPS). Any value lower than that is considered as vacuum plasma spraying (VPS). This technique produces coatings with porosity values as low as 1% (Ref 16, 40) and columnar structure (Ref 41, 42) comparable to those obtained through PVD, of great interest for TBC applications. What is more, it presents the beneficial addition of an increased deposition rate over PVD methods.

Wire Arc Spraying

Wire arc spraying, also known as twin wire arc spray or electric arc spray, is based on the feeding of two consumable conductive wires (or a core of a non-conductive material on a conductive wire) between which a direct current electric arc is established. Once the material is molten, the molten layer is accelerated toward the substrate surface by a stream of atomizing gas. This promotes a further in-flight atomization of the molten particles before their deposition and posterior solidification at the substrate surface (Ref 16, 43). The advantages of this deposition method are several. They include the reduced cost of the process, both in terms of equipment and operational costs, being a very cost-efficient deposition technique. It also shows the absence of unmelted or semi-molten particles, a high deposition rate when compared to other thermal spray processes, and a low thermal transfer to the substrate. All these factors make wire arc spraying one of the less expensive techniques; nevertheless, the particular characteristics of the produced coatings such as high porosity or low bonding strength make its use somewhat limited.

Flame Spraying

Flame spray was the first of the thermal spray techniques to be devised, being developed by Schoop around 1909 (Ref 44). The basic principles are still applied to today’s modern conventional flame spray guns. The combustion of fuel gases is used to impart heat to the feedstock particles. At the same time, it produces an expanding gas flow which in combination with additional gases creates the required jet applied to accelerate the material toward the surface to be coated. Typical temperatures for this technique are around 3000 K, and particle velocities of up to 100 m/s are usually applied (Ref 16); however, in order to improve the initial design on which flame spraying is based, several variations have been developed with a focus on different flame temperatures and particles velocities.

Detonation Gun (D-Gun) Spraying

By confining oxygen and combustion gases such as acetylene within a closed tube and initiating the combustion process with a spark, a high-pressure shock wave is created. The shock wave imparts an increased heat transfer and considerable higher kinetic energy to the powder particles, reaching flame temperatures of around 4000 K and velocities of up to 1000 m/s (Ref 45). The combustion cycle is repeated with a frequency of 3-6 Hz to produce a semi-continuous stream of heated and highly accelerated particles. The result is a coating with better adherence strength and reduced porosity to those deposited through the use of conventional flame spray techniques (Ref 16, 45, 46).

High-Velocity Oxy-Fuel Spraying

High-velocity oxy-fuel (HVOF) spraying was developed based on concepts from jet engines and shares some common features with the detonation gun process. The technique relies on the combination of oxygen and fuel gases inside a combustion chamber, creating a highly pressurized mixture. A small-diameter nozzle is used to direct the gases toward the substrate surface. The combination of elevated pressures, high gas flow, and high combustion temperatures produces a supersonic gas jet at the exit, with particles velocities as high as 1000 m/s and jet temperatures of approximately 3000 K (Ref 47, 48). The main differences with detonation gun are the continuous gas stream exiting the nozzle and the free expansion of the compressed flame upon exit at the de Laval nozzle (Ref 49). These combined factors produce coatings with lower porosity and enhanced adherence strength than conventional flame spray coatings (Ref 4, 47, 50).

High-Velocity Air-Fuel Spraying

A variation of the traditional HVOF spraying technology involves the use of air instead of oxygen, giving raise to high-velocity air-fuel (HVAF) spray. The difference of this method is a reduced flame temperature, due to the lack of a highly exothermic fuel. This has a beneficial effect for feedstock materials with relatively low melting points. It also implies a change in the microstructure and final properties of the deposited coating. In addition, HVAF is less expensive than HVOF, which could represent an advantage for its implementation in the industrial landscape.

Suspension/Solution High-Velocity Oxy-Fuel Spraying

The use of suspensions and solution precursors as the injection medium has also been developed for HVOF, as well as the already seen plasma spraying technique. The underlying concept is similar, for both suspension HVOF (SHVOF) (Ref 22, 51, 52), also called high-velocity suspension flame spraying (HVSFS) (Ref 22, 53), and solution precursor HVOF (SPHVOF) (Ref 22, 51, 54,55,56). They use nano-sized particles to promote the development of coatings with different microstructures in terms of splat morphology and porosity, and therefore different physical properties from conventional flame spraying. Additional research in this field is needed to better understand the potential benefits of SPHVOF and its effect on the microstructure of the deposited coatings.

Kinetic Spraying

Kinetic or cold spraying, as the name indicates, is based on the transfer of higher amounts of kinetic energy into the feedstock particles in order to achieve the desired bonding strength upon impingement at the substrate surface. It contrasts with the usual use of heat transfer seen in other thermal spray technologies. This allows for the deposition of deformable, ductile feedstock powder particles without the need for the traditional melting, impact and posterior rapid solidification, effectively reducing the intrinsic residual stresses upon deposition and the in-flight particle oxidation (Ref 50). The basic fundamental of the process is the use of pressurized gases with reduced oxidation potential, such as nitrogen or helium. The gases are moderately heated (up to 1000 K, generally below the melting point of the feedstock particles) in order to increase the gas flow velocities rather than heating the particles themselves (Ref 4). Once the desired pressure and temperature conditions are achieved, the gas is conducted through a de Laval nozzle (Ref 49) which accelerates it to supersonic velocities (up to 1200 m/s) while reducing the gas temperature as it expands. This allows for the temperature to reach in occasions values below room temperature (Ref 3, 57). The resulting coatings have the same phase content as the powder feedstock without oxide contamination and low porosity, with preference for compressive residual stresses instead of the usual tensile stress of other thermal spray technologies and low ductility caused by the extensive work hardening involved in the deposition process (Ref 3, 50, 57).

A different approach is followed in the case of low-pressure cold spray (LPCS) which, as its name implies, produces the deposition of the feedstock particles at a lower carrier gas pressure than the common cold spray, or high-pressure cold spray. The reduced pressure required in the case of LPCS presents some advantages, such as smaller size and lower cost for the required equipment (Ref 58), making it very attractive for portable, handheld systems for on-site deposition or repairs. Nevertheless, low pressure equates to lower particle velocity, which mainly affects the deposition efficiency of LPCS, being considerably lower than high-pressure cold spray (Ref 59,60,61,62).

As a summary, Table 1 and Fig. 4 give an overview of the physical conditions for each of the thermal spraying technologies here described.

Schematic representation of the typical flame temperature and particle velocity for atmospheric plasma spray (APS), vacuum/low-pressure plasma spray (VPS/LPPS), wire arc, conventional flame spray, high-velocity oxy-fuel (HVOF), detonation gun (D-gun), and cold gas spray (CGS) (Ref 48)

Functional Coatings

The definition of functional coating varies slightly depending on the context on which it is used or the different points of view present among the experts in the field of thermal spraying; however, in this work, a functional coating has been defined as a deposited coating which has a passive, integrated, new functionality beyond the traditional protective capabilities. As such, in this section, the aforementioned definition is applied to classify the functional coatings developed attending to its functionality, for instance, its capability to kill pathogens or prevent infections on orthopedic implants, the hindering of adhesion and growth of algae and hard-shell organisms on water submerged equipment, and creation of water- and ice-repellent surfaces or the deposition of coatings with electromagnetic or electrochemical properties.

Antimicrobial

The appearance and adhesion of bacteria and microorganisms onto surfaces cause severe complications such as surgical site infection or chronic wounds in the medical field (Ref 63) or health-related issues due to expired and contaminated products in the food industry (Ref 64). For these reasons, the use of antimicrobial coatings, which prevent or hinder the development of noxious microorganisms, has gained popularity in the recent years. To achieve this antimicrobial behavior, several approaches have been taken, being summarized into three main categories. The first one is the creation of an anti-adhesive surface, which prevents the adherence of bacteria and the consecutive formation of biofilms, through physical or chemical modifications. The second approach is the creation of coatings with anti-bacterial agent release capabilities, with highly concentrated and localized doses only where needed. This in turn limits the potential toxicity and resistance development. Third is the use of biocidal (or contact killing) coatings where compounds with bactericidal activity are immobilized at the surface to provide a continuous protection effect (Ref 65, 66). Although all three methods are capable of delivering an antimicrobial effect to the coated surface, each has its own deficiencies that should be considered when designing the application.

In the case of anti-adherent surfaces, the creation of broad spectrum morphology is complicated due to the non-specificity of the method. A surface with low attachment of a specific bacterial strain might not present the same behavior with other pathogens, limiting its general application. In addition to non-specificity, anti-adherent surfaces suffer a great functionality loss when wear is present, due to the alteration of the designed morphologies. Despite these deficiencies, the absence of antibiotics or similar agents as the active principle presents a promising approach to prevent the appearance of antibiotic-resistant bacteria. As it stands now, this method is mainly applied as a secondary approach in combination with other principles, rather than the main solution against pathogen proliferation (Ref 67).

The loading of an antibiotic or anti-bacterial agent into the coating has been a popular approach to achieve antimicrobial surfaces, although the method presents one main drawback. The finite nature of an embedded reservoir within the coating implies a time constraint in the duration of the effect. After the said time, the reservoir will be depleted and the coating will fail to prevent bacteria proliferation. Despite the severity of this constraint, this method is well suited for applications where a localized and brief delivery of antibiotics is needed. An example would be the protection of implants during surgical procedures and in the following hours, to prevent contamination and infection (Ref 68).

To prevent the shortcomings associated with a limited reservoir, permanent immobilization of biocidal compounds has been explored. This method, based on the creation of a contact-killing surface rather than relying on a loaded agent, represents a compromise between the lack of specificity and the limited operation time present in the previous methods. The wide array of loaded components or enzymes covalently attached via polymeric chains provides a broad spectrum, while the covalent bonds ensure that the components remain fixed in the surface to provide the desired effect (Ref 69). This approach is not free of complications, mainly due to stability issues of the attached components, but it has been the preferred choice for anti-bacterial coatings due to its flexibility and benefits.

Despite the wide use of contact-killing coatings, some considerations should be taken into account when considering thermal spray as the deposition technique. One of the limitations of thermal spraying techniques is that they require heat-resistant feedstock materials, limiting the use of most of the chemical species traditionally used to functionalize surfaces, such as poly(ethylene glycol) (PEG) (Ref 70). In view of this limitation, the interest in the development of functional coatings with anti-bacterial properties has been focused on the modification of well-established thermal-sprayed coatings with the addition of a biocidal agent that does not degrade at high temperatures, providing a controlled release over time. With this goal in mind, first a suitable matrix should be available, one that can be efficiently deposited using thermal spray and with a proven record on the medical field. The use of thermal-sprayed hydroxyapatite (HA) coatings on orthopedic implants enjoys a wide acceptance in the medical field since the late 1980 (Ref 71), being exhaustively studied since then (Ref 72,73,74,75,76,77). As reported by Sun et al. in the early 2000s (Ref 11), the use of thermal-sprayed HA coatings on metal implants presents several advantages and a positive potential for its use in the medical field. This trend has been confirmed by the predominance of the literature published between 2010 and 2015 in the biomaterials field on the use of HA coatings on titanium substrates for implant applications (Ref 3). Taking into consideration the status of HA as the standard in thermal-sprayed coatings and the decades of research on its behavior and response to living tissue (Ref 71), the choice of HA as a base material for the development of antimicrobial functional coatings has been, with good reason, a popular one.

The addition of silver as the antimicrobial agent has been considered in the early studies of functional coatings due its biocidal effect and the difficulty for pathogens to develop resistance to it. The behavior of HA doped with Ag, with the addition of polyether ether ketone (PEEK) to form HA-Ag/PEEK coatings, was investigated by Sanpo et al. (Ref 78) using cold spray deposition. The lower temperatures involved in this method, as compared to other thermal spraying techniques as seen in “Thermal Spraying Technologies” section, preserve the feedstock powder chemistry and phase composition, as confirmed by EDX analyses. The bactericidal behavior was reported on Escherichia coli, with Ag/PEEK weight ratios varying from 20:80 to 80:20. It was demonstrated the preferential biocidal effect of silver over only PEEK, with biocidal activities 10 times higher in the case of 80:20 HA-Ag/PEEK over the 20:80 HA-Ag/PEEK coating.

The potential of hydroxyapatite combined with silver was also exploited by Noda et al. (Ref 79). They reported the use of HA powder mixed with silver oxide, taking advantage of the higher temperatures experienced during flight when using flame spraying (2700 °C) to in-flight melt the powder and form an amorphous calcium phosphate (CP) coating on top of pure titanium substrates. Within the coating, there was the presence of fully melted, amorphous Ag2O. This approach presents two main characteristics. First, the CP recrystallizes into HA after exposure to simulated body fluid at 37 °C, providing the desired biocompatibility and bone adhesion. Secondly, the presence of silver oxide in the coating, acting as a reservoir and providing a slow release of Ag ions into the environment, provides the required biocidal functionality to the coating. The reported number of viable Staphylococcus aureus bacterial colonies after incubation for 24 h was 10,000 times lower on Ag-CP coatings with respect to control CP coatings.

Although the predominance of thermal-sprayed, doped HA coatings is clear on the field of medical and dental metallic implants, the use of thermal spraying techniques for the deposition of antimicrobial has found other applications. Other base materials such as chitosan (a natural, non-toxic, biodegradable and biocompatible polymer, popular for the development of contact-killing surfaces (Ref 80)) have been doped with recognized biocidal elements such as copper (Ref 81). Cold-sprayed coatings of chitosan doped with copper and aluminum [Cu/Al ratio of 75:25 (wt.%)] were tested on Escherichia coli. After 24 h, a reduction of 22% on the presence of Escherichia coli was reported with respect to control, uncoated glass substrates (Ref 82). The same study was conducted on cold-sprayed ZnO nanopowder mixed with Al in weight ratios 20:80, 50:50, and 80:20. They reported enhanced biocidal capabilities for the higher ZnO-containing coatings. For such coating, the count for Escherichia coli after 24 h was 7 times lower than the uncoated glass substrate and coated with just pure Al (Ref 83).

It has already been established on the previous publications here presented (Ref 78, 82, 83) or on the thorough review by Vilardell et al. (Ref 84) the benefits of using a deposition technique with lower heat transfer, as in cold spraying, for the deposition of heat-sensitive powders. Incidentally, the microstructure produced by cold spraying has been demonstrated to present an increased biocidal activity, three orders of magnitude greater than other higher-temperature techniques such as plasma or wire arc spraying. This effect has been reported by Champagne and Helfritch (Ref 85) on the deposition of pure Cu on aluminum substrates, including a hospital tray entirely coated as a proof of concept. The explanation for this noticeable difference on antimicrobial capabilities lies on the work hardening of the copper particles during deposition using cold spraying. This implies a high dislocation density, which enhances the diffusion of Cu2+ ions, responsible for the pathogen elimination.

Nevertheless, cold spray is not the only available technique with that characteristic. Wire arc, also described on “Thermal Spraying Technologies” section, was used by Gutierrez et al. (Ref 86) to apply a high Cu content alloy (> 60% copper) coating onto medium-density fiber-board (MDF), a popular material in furniture. Their work demonstrated the increased antimicrobial capabilities against Staphylococcus aureus and Escherichia coli of thermally sprayed Cu coatings, with a lethality ratio 3-4 times higher for the pathogens mentioned in comparison with stainless steel or Cu metal sheets. The microstructure impact of wire arc-sprayed coatings was also investigated by Sharifahmadian et al. (Ref 87), reporting the direct correlation between the defects created by the deposition technique, such as grain size, micropores, and microcracks, and its anti-bacterial properties. The authors suggest that such features promote the release of ions from the surface into the environment, which enhances the anti-bacterial activity.

Biocidal Mechanisms of Silver, Copper, and Zinc Oxide

Several compounds have been introduced in this work as biocidal strategies on functional coatings, and in this section, the mechanism behind the pathogen elimination for each specific case is presented and explained.

As seen before, silver is a recurring choice (Ref 78, 79, 88,89,90) for its biocidal capabilities and its effectiveness against strains of antibiotic-resistant bacteria, since no Ag-resistant strain has been found yet (Ref 89). The anti-bacterial mechanism is initiated by the diffusion of Ag+ ions from the surface of the, for instance, HA coating into the surrounding tissue (Ref 88). Once the silver ions are in contact with the bacteria, several mechanisms have been proposed for the biocidal effect, but two main effects seem to be predominant: first, the alteration of microbial DNA, which in turn prevents replication and second the disturbance of the bacterial electron transport and respiratory chain, leading to its inactivation (Ref 90, 91).

The use of copper for antimicrobial purposes (Ref 81, 82, 85,86,87, 92,93,94) dates back to the Ancient Egypt, with descriptions of its use to sterilize chest wounds and purify drinking water (Ref 95). Still, the mechanisms for its biocidal activity are not fully understood. As in the case of silver, it has been proposed that the combination of multiple effects is the responsible for the destruction of pathogen cells rather than a single mechanism (Ref 81, 92). Nevertheless, the complexity of the problem is increased when different cell lines are considered, as these combined effects also vary for different bacteria (Ref 96). Despite this, different mechanisms have been identified as contributors to the biocidal activity of free copper ions, for instance, the formation of highly reactive hydroxyl radicals (OH−), with damaging effects to bacteria (Ref 94, 97), through the change in oxidation state between Cu+ and Cu2+ (Ref 81). The substitution of Zn or other metal atoms on binding sites on proteins as also been pointed out leads to conformation change and the loss of protein function (Ref 92, 93) and deactivation of protein by the substitution of iron on Fe-S clusters (Ref 98).

An example of the use of ZnO on thermal-sprayed functional coatings has been previously presented by Sanpo et al. (Ref 83), although its use as an antimicrobial component as nanoparticles and aqueous suspension has been extensively studied. Similar to the use of silver and copper, a complete understanding of the biocidal mechanism of ZnO has not been reached yet, with several effects being proposed in the literature. Three main contributions have been identified, although there is still controversy as to which one represents the main anti-bacterial pathway (Ref 99,100,101,102,103,104). Firstly, ZnO under illumination with ultraviolet and visible light presents photocatalytic effect (Ref 105,106,107,108), described in detail in “Photocatalytic Effect for Antimicrobial Applications” section, which possesses biocidal capabilities. However, ZnO exhibits a clear anti-bacterial effect even in the absence of illumination. Second is the formation of reactive oxygen species (ROS) such as the already mentioned OH− radicals and H2O2, which has been reported to inhibit bacteria growth (Ref 109,110,111,112,113,114). Thirdly, ZnO particles in direct contact with microbial membranes are known to lead to their destabilization, initiating damage and eventually causing the breakdown of the pathogens (Ref 115,116,117,118,119,120), although the specifics of this mechanism are not well understood.

Photocatalytic Effect for Antimicrobial Applications

Parting from the already presented approach of release-based antimicrobial coatings, the photocatalytic effect provides an alternative method for the development of biocidal surfaces. This method does not rely on embedded agents to provide the biocidal effect, but it also differs from the traditional contact-killing solutions. The photocatalytic effect is based on the illumination of a material, which decomposes compounds by oxidation. As seen in Fig. 5, the illumination of the TiO2 coating with photons carrying energy equal or greater than the band gap results in the creation of electron–hole pairs in the titania conductance and valence band, respectively. There is a probability that these charge carriers will transfer or diffuse to the coating surface, where they can interact with adsorbed water and molecular oxygen. The produced electrons usually take part in photoreduction reactions, such as the production of O2− radicals, whereas the corresponding holes produce the photooxidation of water molecules, forming free hydroxyl radicals (OH−) (Ref 121). These present already mentioned bactericidal effect on numerous bacteria, such as Escherichia coli (Ref 122, 123) and Pseudomonas aeruginosa (Ref 124, 125).

Redrawn from (Ref 125)

Schematic of the photocatalytic effect in TiO2, with the production of free hydroxyl (OH-) upon illumination.

This mechanism has been exploited by George et al. (Ref 125) and Jeffery et al. (Ref 124), making use of the photocatalytic effect of nanostructured thermal-sprayed titania. An initial publication (Ref 124) showed the ability of HVOF-sprayed nanostructured TiO2 to kill up to 24% of Pseudomonas aeruginosa deposited after illumination with white light for 120 min. Attempting to improve these promising results, George et al. (Ref 125) deposited nanostructured and conventional TiO2 coatings using flame spraying, adding Cu as an additional biocidal component, with the aim to take advantage of the potential synergetic effects arising from both the photocatalytic effect and the biocidal nature of copper. The addition of small quantities of Cu (5 wt.%) increased the biocidal capabilities when coupled with white light, due to the production of ROS, which damage the cell wall and membrane, and the photocatalytic reaction under illumination with white light. This effect, although not easily quantifiable due to differences in cells adhesion and cell density between experiments, showed a significant enhancement of the anti-bacterial capabilities attributed to the addition of copper. The authors claimed that the difference in the spraying parameters with respect to HVOF spray, mainly the increased flame temperature and longer in-flight times, produced a disadvantageous phase transformation from the TiO2 powder anatase phase to rutile phase detected in the coating. The anatase phase has been considered the main phase responsible for the photocatalytic effect (Ref 126, 127). Nevertheless, recent studies have considered the importance of features such as porosity, the presence of nanostructures or the anatase to rutile ratio, rather than total content of anatase phase. Bai et al. (Ref 128) reported the photocatalytic behavior of SHVOF-sprayed TiO2 from rutile feedstock at different flame powers. The coating deposited at lower flame power, with an anatase content of ~ 20% and higher porosity levels than the high flame power coatings (being the anatase content ~ 65%), surprisingly presented the highest photocatalytic activity, being the current density almost twice as high. The authors suggested the produced bimodal microstructure, with completely melted areas and nano-sized agglomerations, as the cause for the increased activity. The nanostructured formations increase the specific surface area, along with the presence of mixed rutile and anatase areas in which rutile acts as an “antenna,” being the electrons captured and then stabilized through transfer into the anatase region, creating high catalytic regions in the interface.

In conclusion, thermal spray methods might not be optimal for the development of contact-killing coatings due to the limitations on temperatures experienced by the feedstock during the process, but they have been proven an excellent solution for others. The possibility to efficiently deposit a robust coating loaded with antimicrobial components represents an excellent opportunity for the medical and dental field. The localized delivery (both in location and time) of biocidal agents is a desirable characteristic rather than a drawback for such applications, preventing surgical site infections and extended release of potentially noxious substances. These characteristics, combined with the quick deposition of biocidal components such as copper over large components, i.e., hospital furniture, and the possibilities provided by the photocatalytic effect shown by well-studied components such as TiO2, make the area of thermal-sprayed antimicrobial coatings a thriving one.

Membranes for Water Filtration

Although not a direct antimicrobial application in the sense covered in the previous sections, thermal spray has been applied for the development of membranes for water purification. The ability to deposit a thick film with controlled porosity allows for the design of membranes with tailored mean pore size, effective in the removal of particulates from water. Despite the efforts made by some authors to create ceramic membranes using technologies such as wire arc (Ref 129), atmospheric plasma (Ref 130), or combustion flame (Ref 131), the manufacturing costs and performance were not comparable to more extended polymeric membranes. An interesting concept was presented in the work by Lin et al. (Ref 132) on the development of TiO2 membranes, aiming to combine the filtration capabilities of a ceramic membrane with the biocidal effect of the photocatalytic process in TiO2. Although the concept could lead to new filtration systems that tackle the solid pollutants at the same time as the biological pathogens in water, no experimental measurement on cell strains of the antimicrobial capabilities of the membrane is presented, lacking a strong pillar for the comparison with current filtration systems.

Anti-fouling

The attachment of different aquatic species, classified as soft foulers (primarily algae) and hard foulers (comprehending hard-shelled molluscs such as barnacles and mussels) (Ref 133), to surfaces exposed to submersion in water represents a critical factor when considering the efficiency or maintenance cost of any marine and freshwater equipment (Ref 134, 135). Of noteworthy consideration is the case of the attachment of fouling to the submerged section of hull in ships, which increases drag forces and the weight of vessels, directly affecting the maximum speed, increasing the fuel consumption and lowering the ship maneuverability (Ref 136,137,138,139), with a considerable economic impact.

In order to prevent the adhesion and growth of fouling species, anti-fouling coatings are routinely applied. The use of biocidal components on anti-fouling coatings has been the preferred approach; however, ecological considerations limit the use of certain compounds due to their non-specific toxicity, such as tributyltin (TBT). This compound was worldwide banned for all vessels from 2008 (Ref 139). TBT-containing coatings have been replaced by those employing copper (Ref 140), an element already mentioned in this work due to its biocidal capabilities.

Although there are some examples of the use of thermal spray of Cu-based anti-fouling coatings in industrial applications, as demonstrated by a 1984 patent on the deposition of Cu and Cu alloys via thermal spraying (Ref 141), the application of anti-fouling coatings to the hull of vessels has been primarily focused on the use of paints with copper (Ref 142). The reason for the preference of paints resides in the negative interaction between metallic copper present in the deposited coatings and the steel substrate, material widely used for ship hulls. Once copper is deposited directly onto steel, the large potential difference between the two components induces galvanic corrosion (Ref 143).

Despite the fact that the majority of anti-fouling measurements are presented in the form of paints for the reasons previously mentioned, this solution is not optimal for low surface energy thermoplastic polymers (Ref 133, 144) such as the polyurethane skins on seismic streamers. Such material presents insufficient adhesion for paints and lacks the negative interactions mentioned between steel and copper. For these reasons, the use of thermal spraying techniques, in particular cold spray, has been investigated. Vucko et al. (Ref 145) reported an effective technique to provide polymers with an embedded thin layer of Cu, with well-known biocidal capabilities covered in “Biocidal Mechanisms of Silver, Copper, and Zinc Oxide” section, using cold spray. Their initial work proved the concept for the deposition of anti-fouling metals into polymers, in this case high-density polyethylene (HDPE) and nylon. The anti-fouling capabilities of these initial results were demonstrated through the complete submersion of the coated samples, and a copper plate as a reference, into the open sea waters of Townsville, Australia. The HDPE Cu-embedded samples prevented biofouling with similar efficiency as the copper plates for up to 250 days, test failed by the nylon Cu-embedded samples. The behavior of nylon Cu-embedded samples showed reduced anti-fouling capabilities, with 54.3 ± 11.7% coverage after 181 days in the same conditions as the rest of the samples, while a coverage of 0.6 ± 0.6 and 0% was measured for HDPE and copper plates, respectively, strongly preventing soft foulers and completely preventing hard foulers. The authors pointed the different depths of embedment of copper particles for the two substrates, being 85.0 ± 1.5 µm for the HDPE Cu-embedded and 40.6 ± 0.4 µm for the nylon Cu-embedded, as the cause. The greater depth of embedment on HDPE allowed for a slow release over longer periods of time, preserving the surface free of foulers for the entire duration of the test. Another study (Ref 146) reported similar results under the same testing conditions, obtained on Cu cold-sprayed polyurethane (PU) samples. This time different spraying parameters (two robot arm lateral speeds) were used in order to elucidate the impact on biocidal capabilities. The faster lateral speed produced a lower density of copper particles, with five times less the amount of Cu per unit area, which were also embedded at a shallower depth, 58.4 ± 1.9 µm compared to 85.6 ± 1.9 µm for the slow speed samples. As a result, the coatings failed to prevent the initial stages of hard foulers after 42 days for the low-density PU Cu-embedded samples and after 210 days for the high-density PU Cu-embedded samples.

Proving the anti-fouling capabilities of cold-sprayed Cu particles into polymer components, additional research has been carried out to identify the optimal deposition conditions. Lupoi et al. (Ref 144) studied the capabilities of unheated, pressurized carrier gas in cold spray, in contrast to the heated conditions previously used, 100 °C (Ref 145) and 400 °C (Ref 146), using a high-speed nozzle design instead to achieve sufficient depth of embedment and surface coverage on different polymer substrates. The authors found out that HDPE substrates suffered from erosion at gas pressures above 2 MPa, achieving optimal depth of embedment and surface coverage using 1.5 MPa, with values of around 35 µm and 57-60%, respectively. The addition of computational fluid dynamics simulations to the previous results, allowing to predict the impact velocity of the particles, was reported by Stenson et al. (Ref 133). Table 2 summarizes the deposition parameters and results achieved on the studies here mentioned.

The use of a high-speed nozzle made it possible to deposit the copper particles with unheated carrier gas, preventing potential thermal degradation and deformation of the polymer substrate. However, it also hindered the penetration of particles into the deeper layers, which would have required the use of high carrier gas pressures (2 MPa and above). On the other hand, higher pressures resulted in the erosion of the surface and lower surface coverages. As proved by Vucko et al. (Ref 145, 146), depth of embedment was the critical factor for longer anti-fouling capabilities and therefore, the use of unheated carrier gases limits the effectivity of the coated components. Further studies on the effects of exposure to heated gases for the relevant polymer substrates applied in the marine industry, such as PU on seismic streamer skins, would be beneficial to clarify the potential side effects and extend the use of thermal spray for anti-fouling applications, being currently limited to niche applications.

Hydrophobicity

A hydrophobic surface is defined as having superior water-repellent properties, which present several advantages such as reduced contact time with corrosion agents or self-cleaning capabilities, produced by the rolling droplets of water, which carries away dirt. In order to quantitatively evaluate a surface, two parameters are commonly used, namely water contact angle (CA) and slide angle (SA). Contact angle is defined by the tangent to the liquid–vapor interface where it meets the surface, as shown in Fig. 6 by the angle θ. The slide angle is the tilt angle required for a static droplet deposited on a surface to start rolling down. As a general definition, any surface with CA > 90° can be considered hydrophobic, while values of CA > 150° and SA < 10° are generally required for a surface to be considered as superhydrophobic.

Adapted from (Ref 147)

(a) Hydrophobic behavior of a water droplet on a smooth surface, along with (b) rough hydrophobic and (c) superhydrophobic surfaces, with their respective contact angles. Schematic (b) shows a single-scale/rough morphology, described by the Cassie–Baxter model. Schematic (c) shows an improved dual-scale/hierarchical morphology.

Hydrophobicity has two contributions that explain the particular behavior presented. First of all, a low surface energy ensures that the attraction between the water droplets and the surface is minimized. Second is a structured surface morphology. As seen in Fig. 6, the different levels on the morphology have a direct impact on the hydrophobicity of the surface. Two main models are used to describe different hydrophobic states present on surfaces. The first one, called Wenzel state (Ref 147), assumes the wetting of the entire surface, including in-between the structural features present. On the other hand, the Cassie–Baxter state (Ref 148) assumes that only the upper regions of the rough surface have contact with the liquid, with pockets of air in between such features, as it can be seen in Fig. 6(c). Hydrophobicity can be seen in the nature, as in the commonly known case of the lotus leaf (Ref 149) or the wings of certain insects (Ref 150); however, very few are the surfaces that present inherent hydrophobicity features. Therefore, the development of functional coatings that can be easily applied and are readily available for industrial applications has gained substantial interest in the past decades.

The most extended methods to produce hydrophobic materials revolve around the morphological modification of the surface, using techniques such as plasma etching or through the controlled growth of structures using methods such as chemical vapor deposition or lithographic techniques. Another approach is the functionalization of the surface energy using chemical compounds such as polytetrafluoroethylene (PTFE) or poly(ethylene glycol) (PEG) (Ref 151,152,153,154). Nevertheless, the use of polymers as hydrophobic coatings has a clear disadvantage on environments where robust mechanical properties are required due to the presence of wear or loads. The application of metals and oxides through the use of thermal spraying techniques allows the production of mechanically sound coatings with excellent hydrophobic capabilities.

Although nowadays the need to address the two contributing factors for hydrophobicity (namely surface energy and surface topography) is generally accepted, the first developments of thermally sprayed hydrophobic coatings focused on topography due to the natural predisposition of thermal spray to produce desirable morphologies. An early example by Teisala et al. (Ref 155) presents the development of a nanostructured TiO2 coating deposited on top of paperboard using liquid flame spray with a roll-to-roll setup at ambient pressure, clearly showing the industrial potential of thermally sprayed hydrophobic coatings. Due to the surface morphology, lacking a hierarchical structure, the coating presented an elevated sliding angle. Accounting for the excellent contact angle (up to 160°), the authors proposed the term “highly hydrophobic adhesive surface” instead of superhydrophobic. The reason for this behavior can be understood considering that the coating is on a Wenzel state, effectively wetting the totality of the coating surface, which increases the adhesive forces, while maintaining a high CA.

Later iterations acknowledged the need for a combined approach between surface energy and topography. A robust and corrosion-resistant hydrophobic coating was achieved by Zhang et al. (Ref 156) on Fe-based amorphous coating deposited via HVOF. Superhydrophobicity was reached after the addition of a lowering surface energy coating via immersion of the samples on dodecanethiol. An initial study of the as-sprayed Fe-based coating revealed the essential relationship between powder feedstock size and deposition parameters and the final roughness of the coating, which influences its hydrophobic capabilities. The authors established that small powder particles and high spraying energy lead to completely molten particles and flatter surfaces (characterized by arithmetic mean surface roughness Ra values of 5.4 ± 0.7 µm), without hydrophobicity characteristics (CA = 71°). The increase in powder particle size and reduction in spraying energy led to higher surfaces roughness, with Ra values between 9.4 and 13.2 µm, and clear hydrophobic capabilities (CA between 120° and 140°). Unfortunately no information on sliding angle of the as-sprayed coatings is given, being only the chemically treated superhydrophobic surface values reported, with CA as high as 160° and SA around 9°.

Sharifi et al. (Ref 157) investigated the impact of the different morphology features present on APS and SPS titania. Due to the use of different deposition techniques, involving aqueous and ethanol suspensions with different dispersing agents, submersion into stearic acid was used to equalize the surface energy of the different samples in order to eliminate the possibility of different surface chemistries, effectively isolating the morphology influence. Their results showed a clear impact of the deposition technique used, with APS presenting SA over 60°. This was attributed to the larger and non-uniform features of APS, with a surface roughness Ra of ~ 3.7 µm, which prompted a Wenzel state. On the other hand, SPS produced a finer, hierarchical morphology with higher Ra of 6.2-6.7 µm described by a Cassie–Baxter state, with CA and SA values of 161° and 1°. Following the success on the reported superhydrophobic surface, a more detailed study of SPS-deposited TiO2 revealed the optimal deposition parameters for improved hydrophobicity (Ref 158). Similar to the conclusion reached by Teisala et al. (Ref 155), high contact angles (CA > 150°) were achieved in most of the samples. The sliding angle was the critical factor, with values ranging from over 20°, which can therefore be considered “highly hydrophobic adhesive surfaces” to as low as 1.3° ± 0.3°. These values were achieved on an ethanol-based suspension with 10 wt.% TiO2 deposited on a grit-blasted stainless steel to a surface roughness of 1.5 µm, using 36 kW as the plasma deposition power with a nozzle diameter equal to 8 mm and a standoff distance of 50 mm. The samples presented excellent superhydrophobic characteristics (CA = 168° ± 1° and SA = 1.3° ± 0.3°) and arithmetical mean height of the surface (Sa) value of 8.3 ± 0.1 µm.

As a deeper understanding of the connection between spraying parameters, produced surface topography and hydrophobicity was achieved, attempts to simplify the process were tackled. Still using both morphology and low surface energy modifications, with the difference that only thermal spraying methods were applied, Chen et al. (Ref 159) used different deposition techniques to produce hydrophobic coatings. A stainless steel substrate was initially coated with Al using high-velocity arc spray, being further coated with polyurethane (PU)/nano-Al2O3 using suspension flame spraying. Surprisingly, the arc-sprayed Al coatings showed hydrophilic characteristics with CA below 5°, while the addition of flame-sprayed nano-Al2O3 alone (without the presence of PU) further maintained the hydrophilic behavior, with CA below 5°. The marked hydrophilic nature of nano-Al2O3 is considered responsible for this effect, despite the presence of hierarchical morphology at the surface. The combined effect of a rough surface morphology (although no surface roughness values are reported) with a lowered surface energy induced by the addition of 2 wt.% PU, allowed for superhydrophobic CA values over 150° and SA values of 6.5°. An additional benefit of the superhydrophobic coating was an excellent corrosion resistance, demonstrated by its good electrochemical behavior on 3.5 wt.% NaCl aqueous solution at room temperature. Following on the synergetic effects of morphology and surface energy, a refined system was achieved by the introduction of a dual-scale, or hierarchical, morphology (Ref 160). The use of a mesh as a micropatterning plate introduced cone-shaped microstructures with finer nanoroughness (no Ra values are reported) on TiO2 APS-coated samples. Once more, the surface energy was lowered depositing a thin film of PTFE/nano-Cu using suspension flame. The reported values for the CA and SA of the surface were 153° and 2°, respectively, with the benefit of being a mechanically robust and easy to repair coating.

Despite the fact that the developments allowed to tailor the surface morphology and energy treatments within the realm of thermal spraying, they ultimately relied on the chemical modification of the surface to achieve superhydrophobic behaviors. A recent development made by Cai et al. (Ref 161) further increases the possibilities for the superhydrophobicity behavior of functional coatings, without requiring an additional chemical modification of the surface energy. Their work used rare earths, specifically ytterbium nitrate pentahydrate (Yb(NO3)3)-5H2O, with inherent hydrophobic behavior accounting for their electronic structure (Ref 162, 163). The deposition was done using two mediums, only distilled water and 50% water/50% ethanol, using the SPPS technique. This allowed to directly produce Yb2O3 superhydrophobic coatings. The combined hydrophobic capabilities, due to the chemical properties of the coating, and the hierarchical structures obtained through the use of SPPS produced superhydrophobic surfaces with contact angle 165° ± 2° and roughness values of Ra = 0.9 µm. The elimination of the chemical functionalization of the surface, and the high deposition rates of the thermal spray technique, represents a very interesting candidate for industrial implementation on large structures. Further investigations have been carried out by Xu et al. (Ref 164) using the same deposition technique and materials, producing superhydrophobic coatings with SA values of ~ 163° and sliding angle ~ 6.5°. Following this rationale, Bai et al. (Ref 165) present the use of another cost-efficient deposition technique, SHVOF spraying, to deposit a different rare-earth oxide (CeO2). They produced robust, near-superhydrophobic coatings with CA values ranging between 134° (for Al alloy substrate) and 146° (for stainless steel substrate) with surface rough height SA of 3.6 µm, although no sliding angle results are presented.

Icephobicity

A natural extension of surfaces with the capability to repel water droplets is the consideration of similar mechanisms that prevent the formation or adherence of ice. The development of icephobic surfaces represents a field of interest with multitude of applications such as aerospace structures, solar panels or wind turbines, where ice causes a loss in efficiency and an increase in costs. Nevertheless, the mechanisms involved in the prevention of ice accumulation are more complex than those encountered with water in liquid form, creating a thriving field aiming to determine the fundamental interactions (Ref 166,167,168). On a first consideration, ice needs to be prevented to form in the surface, and if formed, the adhesion strength to the coating should be less than the uncoated equivalent, facilitating its removal. In addition, the different routes involved in the formation of ice and the several solid configurations that water can experience, such as frost, glaze, rime, snow, or ice (Ref 166, 169), add an additional complexity layer to the problem. Sojoudi et al. (Ref 166) present the main differences between the mechanism behind superhydrophobic surfaces and those involved in the development of icephobic (or pagophobic as they prefer to call them, from the Greek word “pagos” for ice). Figure 7 gives an overview of the main mechanisms considered when designing an icephobic surface. Here, three parameters play the key role: first, topography, which determines the presence of a Wenzel or Cassie–Baxter state, as explained in the previous section; second, elasticity, being a common example the use of silicon for ice cube trays accounting for its flexibility and low surface energy; third, the liquid extent, where a micro-/nanoporous material is infused with lubricant liquid with a low freezing point, providing a smooth liquid interface that reduces droplet retention and ice adhesion strength.

Classification of the three main mechanisms applied in the development of icephobic coatings (Ref 166)

The use of thermal spray technology to produce icephobic coatings is limited for several reasons. The surface roughness exploited in most thermal-sprayed hydrophobic coatings can be detrimental under certain conditions such as high humidity (Ref 170, 171). This makes the use of chemical functionalization of smooth surfaces and liquid extent pathways the preferred alternatives. Noteworthy is the work of Koivuluoto et al. (Ref 172) on the deposition of polymers (specifically polyethylene) using flame spray. Their results emphasize the difference with hydrophobic coatings, with a reduction on the ice adhesion strength on the as-sprayed coatings and after polishing of 20-25%. When compared with uncoated, polished substrates, the thermal-sprayed coatings presented ice adhesion strength ~ 5 times lower than stainless steel and ~ 7 times lower for aluminum substrate.

The application of new mechanisms already proven in hydrophobic coatings, such as the use of rare-earth compounds with intrinsic hydrophobic behavior even on smooth surfaces, presents a new field to be investigated which could potentially increase the presence of thermal-sprayed anti-icing coatings.

Electromagnetic and Electrochemical Properties

Electromagnetic Properties

Thermal-sprayed electrical and magnetic functional coatings comprise the use of materials deposited using thermal spraying techniques with a focus on its electromagnetic properties instead of its chemical properties or as passive barriers. This gives rise to a wide range of applications such as integrated circuits. The importance of these materials is easily understood if the role of thick-film-based electronics in today’s world is considered, being the base of the microelectronics industry. Such importance is demonstrated by a patent by Prinz et al. (Ref 173) registered on 1994 on the development of electronic packages by thermal spray. They created electronics structures through the application of masks, building up the different components on each spray run. The use of thermal spraying deposition, capable of efficiently and cost-effectively depositing continuous layers or patterned designs of conductive and isolating materials, has gained interest over the last decades. In particular, the desire to produce patterns with linewidths as reduced as possible has driven the investigation of novel deposition techniques within the thermal spray field. Nowadays, two different trends can be identified in the development of thermal-sprayed microelectronics.

The first one, called additive-only, relies on the miniaturization of the thermal spray equipment itself and the use of dynamic apertures at the nozzle (Ref 174). This achieves a smaller flame capable of directly depositing features with a range of thicknesses between 250 µm and a few millimeters. This technique has been successfully applied in the development of electromagnetic shields (Ref 175), antennas for unmanned aerial vehicles (Ref 176) or gas sensors on heat-sensitive substrates (Ref 177). The approach has several advantages present on traditional thermal spray techniques, such as the capability to deposit on heat-sensitive substrates, the flexibility of choice in deposited materials and the readily available infrastructure in the industry. An extensive review on its use and applications accounting to the different properties exploited, such as dielectricity, conductance, resistance, magnetism, or superconductivity, was written by Sampath (Ref 12). In his work, an analysis of the microstructure and intrinsic physical properties of thermal-sprayed functional materials is first presented, with focus on how to understand and control the said properties. The different devices that have emerged from the application of electromagnetic thermal-sprayed materials are then outlined, with examples of multilayered circuits, antennas, ohmic contacts, and sensors, to name a few. The review concludes identifying the key factors for the limited spread of thermal spray for electric and magnetic applications, mainly the poor understanding of the material properties and the lack of precise enough tools to achieve the required miniaturization.

The second approach involves the use of machining methods, such as laser micromachining (Ref 178), on a thermal-sprayed layer to form the desired pattern as shown in Fig. 8. It is therefore labeled additive–subtractive, for obvious reasons. The addition of a second processing step, although it pushes the linewidth down to 15-20 µm, considerably increases the time required to fabricate the device. Another effect is the added cost due to the need of a parallel machining infrastructure, when compared to a single thermal spraying unit as in the case of additive-only. Nevertheless, its capabilities have been exploited in the development of thermopiles for power generation or temperature sensing (Ref 179, 180), embedded microheaters (Ref 181), and strain gauges (Ref 182). As proven by the recent work in the field, the additive–subtractive approach represents a great technique with potential in the field of prototyping and specialized components, where longer manufacturing times and increased costs per unit are not as critical as in large-scale production.

Schematic of the additive–subtractive method used to produce precise patterns through the addition of laser micromachining to a thermal-sprayed layer (Ref 12)

Despite the advancements made toward miniaturization of thermal-sprayed components, their uses are still limited to laboratory scale and cannot compete with the current, well-established methods used in the electronics industry. Nevertheless, the production of electrical circuits is not the only application where thermal-sprayed materials can be of use. Plenty of modern devices require components of reduced size and suitable electrical properties. For instance, the ability of thermal spray to produce dense, thick ceramic films is more desirable in cases such as piezoelectric components for microdevices, presenting a clear advantage over other competing methods such as chemical vapor deposition.

In addition to the capability to deposit thick ceramic coatings, another crucial advantage when considering the use of thermal spraying for electrical applications is the confinement of the high-temperature process to the actual deposition. This translates into a very low heat transfer to the substrate. On the other hand, when developing multilayered structures through alternative techniques, such as traditional ceramic coating production (e.g., tape casting, doctor blade), the temperatures required to fire the ceramics might prove too high for the rest of the components, or it could induce undesirable chemical reactions. This implies an investment on high-temperature equipment, high melting point substrates and protective layers to avoid the reactions, further increasing the manufacturing costs when compared with thermal spray deposition.

Despite the lower heat transfer present in thermal spray, another factor to be taken into account is that melting of the feedstock particles may lead to undesirable phase transformations, demanding post-deposition heat treatments if the initial microstructure is to be recovered. Therefore, research in this field has been predominately focused on kinetic deposition techniques, such as cold spray, described on “Kinetic Spraying” section or aerosol deposition (AD). The underlying working principle of such techniques is the ejection of submicrometer powder particles with the aid of a carrier gas. The aerosol flow is directed toward the substrate, being kept under vacuum during the whole process. Since the bonding mechanism relies on the adhesion of the fine particles, these techniques do not alter the feedstock phase composition or suffer from heat-induced damage to the substrate (Ref 183). The goal in these cases is to produce a dense layer with unaffected electrical properties.

Considerable success has been achieved in the use of those techniques to develop electrical devices, such as piezoelectrics (Ref 184, 185), microwave filters for radio-frequency applications (Ref 186), electro-optic complex films (Ref 187), electrodes for solid-state lithium batteries (Ref 188) or TiO2 films for dye-sensitized solar cells (Ref 189, 190). In all the examples presented above, kinetic spraying allowed for a higher deposition rate than comparable thick-film deposition techniques such as screen printing (Ref 191), with the benefit of an absence of high-temperature exposure, characteristic of other thermal spray techniques. A comprehensive overview by Akedo (Ref 192) covers the applications of kinetic spraying, or room-temperature impact consolidation (RTIC), for microdevices. His work presents a thorough comparison of the challenges and opportunities in the fabrication of microactuators, requiring dense and thick films of piezoelectric or electrostrictive materials, using conventional methods such as solgel or chemical vapor deposition and RTIC. The higher deposition efficiency of thermal spray methods and the advantages mentioned related to the higher control over the microstructure using RTIC, proved the potential of this approach.

Electrochemical Properties

The advancement in electrochemical cells, both for the conversion of energy and the electrolysis of water, has been an active research topic for the past decades. The specific environment to which the components are exposed (high temperatures, corrosive chemicals, and varying electrical current) makes the electrodes a particular interesting point for the improvement and development of better performing electrochemical cells. In addition to an outstanding physical and chemical stability, the electrodes need to have surface area as high as possible, aiming to increase the accessibility of the electrolyte to the electrode surface and to allow an enhanced detachment of the gases produced in the process, which effectively increases the electrocatalytic activity (Ref 193).

When used on power consumption mode, for instance, to perform alkaline water electrolysis, electrochemical cells are regarded as one of the prime future techniques for the mass production of hydrogen. The process is not new and has been extensively investigated. This includes the use of thermal spray techniques for the fabrication of electrodes, as proven by a 1977 patent (Ref 194). Nevertheless, the ever-increasing demand for hydrogen, mainly due to its applications as clean fuel for transportation powering systems, has boosted the interest for more cost-effective systems. The use of thermal spray techniques has been proven as an effective way to produce electrodes, achieving an excellent control of the microstructure and surface properties due to the flexibility on deposition parameters and different techniques, as shown in Table 3.

A higher cell temperature benefits conductivity and the detachment of hydrogen bubbles produced, increasing the electroactivity of the electrode. It carries, however, unwanted effects, such as accelerated corrosion and higher consumption. For these reasons, a carefully designed surface topography presenting multi-hierarchical structures has been favored to increase the surface area allowing for a reduction in the operating temperature (Ref 195,196,197,198,199,200,201,202,203,204).

Alternatively, electrochemical cells can be used for the generation of electricity, as in the example of solid oxide fuel cells (SOFCs). Different challenges are present for the development of SOFC components, as the configuration is not the same. Firstly, the elevated temperatures needed for the efficient operation of SOFCs (generally above 600 °C) require a different set of materials than those used for alkaline water electrolysis. Secondly, the design of SOFCs requires a thin, gas-tight electrolyte that provides effective insulation between the two electrodes, while permitting the conduction of oxygen ions, along with microporous electrodes that allow for the fuel and air to penetrate. For these reasons, ceramics have been the material of choice, including perovskites such as lanthanum strontium manganese oxide for the cathode, YSZ for the electrolyte, and a mixture of Ni and YSZ for the anode (Ref 205, 206).

Traditional fabrication methods for those ceramic components present several disadvantages that thermal spray could help to overcome. The high temperature required for the firing process, for instance, presents a bottleneck on the mass production of SOFCs, greatly increasing their cost. It also implies problems such as thermal mismatch stresses on large components, side reactions between adjacent layers and the difficulty of using low-melting materials in the multilayered structure (Ref 207). The increased time efficiency of thermal spray techniques such as plasma spray and the reduced heat transfer to the substrate (allowing the use of cheaper materials) arise as potential solutions to the previous problems, meaning that thermal spray could drastically reduce the cost of current SOFCs.