Abstract

The excessive usage of non-renewable resources to produce plastic commodities has incongruously influenced the environment’s health. Especially in the times of COVID-19, the need for plastic-based health products has increased predominantly. Given the rise in global warming and greenhouse gas emissions, the lifecycle of plastic has been established to contribute to it significantly. Bioplastics such as polyhydroxy alkanoates, polylactic acid, etc. derived from renewable energy origin have been a magnificent alternative to conventional plastics and reconnoitered exclusively for combating the environmental footprint of petrochemical plastic. However, the economically reasonable and environmentally friendly procedure of microbial bioplastic production has been a hard nut to crack due to less scouted and inefficient process optimization and downstream processing methodologies. Thereby, meticulous employment of computational tools such as genome-scale metabolic modeling and flux balance analysis has been practiced in recent times to understand the effect of genomic and environmental perturbations on the phenotype of the microorganism. In-silico results not only aid us in determining the biorefinery abilities of the model microorganism but also curb our reliance on equipment, raw materials, and capital investment for optimizing the best conditions. Additionally, to accomplish sustainable large-scale production of microbial bioplastic in a circular bioeconomy, extraction, and refinement of bioplastic needs to be investigated extensively by practicing techno-economic analysis and life cycle assessment. This review put forth state-of-the-art know-how on the proficiency of these computational techniques in laying the foundation of an efficient bioplastic manufacturing blueprint, chiefly focusing on microbial polyhydroxy alkanoates (PHA) production and its efficacy in outplacing fossil based plastic products.

Similar content being viewed by others

Introduction

Plastic, a supremely advantageous and procurable material, is often characterized by excessive indulgence in this world yet is entitled to gradually accentuate the deterioration of the environment. As per CIEL (Center for International Environmental Law) report May 2019, most of the plastic in the world is produced from the processing of fossil fuels, and the production of plastic has been associated with about 4–8% of annual global oil consumption (CIEL [12]. Despite a myriad of climate change consequences, if humankind continues being explicitly hooked on plastic commodities, it has been forecasted by World Economic Forum that by 2050, approximately 20% of the world’s oil consumption will be concerning plastic [130]. Additionally, an assessment of the plastics lifecycle (cradle to grave) demonstrates that the emission of greenhouse gases (GHGs) takes place at every stage, including extraction and end of life. According to literature, it has been projected that if the constitution of plastic persists as it is today, then by 2030, GHGs will reach 1.34 gigatons every year, eventually contributing to the rise in the average global temperature. However, as per the Glasgow Climate Pact adopted at COP26 2021 UN Climate Change Conference, nations have agreed to curb GHG emissions to restrain global warming up to 1.5 °C, which has been expected to exceed the limit above pre-industrial levels. For accomplishing the COP26 goal, it has been postulated that the carbon dioxide emissions must be curtailed by 45% by 2030 as compared to the emissions recorded in 2010. Still, while considering the recent GHGs emissions corresponding to the usage of plastics, it has been anticipated that CO2 emissions will rise to about 14% by 2030 relative to that in 2010. Therefore, to maintain the remaining carbon budget by 2050, carbon neutralization by attaining CO2 removal seems the only solution [13, 14, 106].

While researchers established a strong connection between the change in climate and plastic pollution, the root cause of both predicaments was determined as the excessive usage of definite resources (fossil fuels) to produce plastic. Thus, the concept of circular bioeconomy came into frame, and it was strategized that apart from emulating the reduce, reuse and recycle venture, modulation at every stage of plastics lifecycle, including its production, must go hand in hand to alleviate environmental repercussions. Eventually, bioplastics became part of this initiative to curb our reliance on conventional plastics as well as their ecological footprint to keep a strong check on GHG emissions and global warming. Bioplastics or bio-based plastics are the ones derived from biomass, comprehensively that of animals, plants, or microorganisms. Most bio-based plastics are known to undergo microbial degradation, in the presence or absence of oxygen into secondary molecules, including water, carbon dioxide, and methane. Further, it has been postulated by Spierling and colleagues that the CO2 equivalents produced due to plastic could also potentially reduce due to the replacement of 65.8% of the fossil-based plastics present worldwide by bio-based plastics [23, 29, 101, 112, 144].

However, to garner a considerable amount of bioplastic precursors from microorganisms-for economical and sustainable bioplastic production, three quintessential aspects need to be envisaged: First and foremost, acquiring a microorganism strain with high biomass yield and bioplastic metabolite content; Subsequently optimizing a cultivation methodology for coherent conversion of substrates into the metabolite of interest; and at last, designing a provident and productive harvesting strategy geared towards the extraction of bioplastic [26, 67, 68, 100]. Therefore, in anticipation of sustainable bioprocessing of bioplastic, endeavors such as systems metabolic engineering and omics analysis, including fluxomics, metabolomics, proteomics, transcriptomics, and genomics, are ascertained moderately. Scientists have adopted the in-silico methodologies maneuvering pathway scrutinizing tools and metabolic models to understand the microbial system consisting of biochemical pathways and metabolic profile. These techniques proselytize the amelioration of microbial strain for augmenting accretion of the product of interest as well as its biomass yield by unraveling the metabolic attributes and the corresponding phenotypical characteristics of the cell. The genome-wide computational predictive modeling of a biochemical portfolio of cellular metabolism is perceived to endow the blueprint of metabolic nexus, triggering the desired metabolite production [5, 25, 136].

Genome-scale metabolic reconstruction is a systems-level, computational approach that exploits an organism’s biochemical data to speculate its feedback to genetically or environmentally evolved stress. It is an emerging alternative to wet-lab experiments to predict an organism’s bioprocessing efficiency in an economical and time-effective manner. Metabolic reconstruction is a model built methodically by integrating the annotated genomic sequence, omics information, and patrimonial knowledge supplemented with the aid of bioinformatics. There are specific optimization tools such as Flux Balance Analysis (FBA), Flux Variability Analysis (FVA), Elementary Mode Flux Analysis (EMFA), etc. that have been employed previously for modeling the metabolic framework of diverse microorganisms [49, 85, 123, 133, 143].

Hence, the objective of this review is to put forth a detailed conceptual outline of the computational techniques that could be explored for bioplastic production especially polyhydroxy alkanoate in detail (PHA). On a similar note, a broad description of genome-scale metabolic model reconstruction, followed by elucidating different optimization tools and techniques, will be discussed comprehensively. It will also shed some light on the aspects that determine the viability of bioplastic production technology. Lastly, economic and environmental demerits and merits of the bioplastic production technology, focusing mainly on the polyhydroxy alkanoate have been discussed while focusing on the significance of techniques such as Techno-Economic Analysis (TEA) and Life-Cycle Assessment (LCA).

Metabolic Modeling of Microorganisms

Several microorganisms, such as lower eukaryotes, aerobic/anaerobic bacteria, and archaea, are distinguished as the best contenders to have bioplastic-producing capabilities. Bacteria, including Bacillus, Escherichia coli, Pseudomonas, Cupriavidus, Corynebacterium, etc., and algae including Chlorella, Spirulina, Phaeodactylum tricornutum, Nostoc muscorum, Synechocystis, etc. have been speculated emphatically for felicitous production of bioplastic precursors such as PHA, PLA, EPS, etc. [7, 37, 47, 70, 110, 142, 146]. However, researchers have communicated numerous culture conditions and parameters in the literature that influence microbes’ growth and PHA content. Some of the essential factors, including nutrient concentration, CO2 uptake, salinity, pH, light, temperature, carbon source, etc., have been discussed to be even more malevolent in the view of large-scale production [18, 99]. The need of systems biology-based approaches for understanding the metabolic interplay between EPS production and microbial metabolism have also been reviewed comprehensively by Ozlem Ates in 2015, thus concluding the significance of mechanism behind EPS biosynthesis and factors affecting the production of EPS [3]. Therefore, a more extraordinary cognizance of metabolic and enzymatic pathways involved in the biosynthesis of bioplastic precursors comes up to be the prime prerequisite for executing sustainable and economical bioplastic bioprocessing. It encompasses multiple imperatives such as maximal bioplastic producing strain, affordable substrate, optimizing culture conditions, fabricating appropriate bioreactors, and optimizing different large-scale production attributes [121, 122].

In the present scenario, computational and systematic modeling proves to be a valuable perspective for increasing the significance of bio-based plastics in the biotechnology industry. The in-silico approach further elaborates on demystifying the intercommunication between several metabolic pathways engaged in the biosynthesis of essential metabolites, thus determining the bioplastic production capabilities of microbes without putting much time into experimental explorations. The in-silico modeling of metabolic nexus deploys the reconstruction of the genome-scale metabolic model by taking into account the knowledge derived from omics and biochemical analysis of microbial strain. The FBA of the model thus prepared helps understand the factors and parameters to be optimized for upstream and downstream processing of bioplastic production [34, 57, 78]. Henceforth, most ubiquitously distributed biochemical interactions and ecological factors occurring inside microbes and in between different microbial communities are elucidated by employing computational tools such as constraint-based models or stoichiometric metabolic network models, followed by performing in-silico simulations with the help of algorithms such as FBA, DFBA, FVA, etc.

Genome-Scale Metabolic Reconstruction

The genome-scale metabolic model (GEM) of a microorganism emphatically contemplates the enzymatic modulations occurring inside the cellular integrals and focuses on the comprehension of genomic rewiring that superintends the biochemical pathway for targeting enhanced and sustainable bioproduct biosynthesis. While pursuing model reconstruction, the reactions, metabolites, and enzymes corresponding to a particular metabolite biosynthesis are scrutinized, followed by speculating the entire cellular metabolic network in its reference. Conclusively, the reconstruction encapsulates the accumulation of genetic details relevant to cell metabolism and further systemizes selective information in the form of a stoichiometric metabolic network/constraint-based metabolic model/ genome-scale metabolic framework [20, 66]. Figure 1 illustrates the important prospects of generating a genome-scale metabolic model for predictive metabolic modeling.

Significance of genome-scale metabolic model for predictive metabolic modeling of large-scale bioplastic production. A PHA/PHB producing microorganism; B Microorganism’s genome annotation is taken into account primarily for GEM model reconstruction followed by (C) incorporating biochemical and physiochemical database along with the experimentation literature; D Existing metabolic network models of the phylogenetically close organisms along with all the previously gathered (E) analytical and statistical information are utilized for the formation of (F) Stoichiometric matrix/ genome-scale metabolic model reconstruction, which helps in the predictive modeling for the evaluation of metabolic framework and analyze the phenotypic characteristics corresponding to environmental and genetic perturbations in order to attain (G) sustainable commercial production of a metabolite of interest

Construction of GEM comprehends five crucial stages, which are as follows:

-

1.

Drafting a framework of metabolic network based on genomic annotations;

-

2.

Ameliorating the model content manually by integrating gene-protein interactions along with diverse characteristics of each metabolite;

-

3.

Transforming metabolic network framework into a mathematical stoichiometric model.

-

4.

Assessing and authenticating the network to validate the model’s ability to produce high-end products by analyzing and filling the gaps and breaches in the metabolic network pathway.

-

5.

Finally, the reconstructed model is validated by correlating the results obtained from the wet-lab with that of the computational simulations.

However, the fundamental prerequisite for the construction of the metabolic network includes the procurement of omics datasets such as genomics, proteomics, and metabolomics, along with the knowledge of specific biochemical pathways of an individual microorganism. Genome-scale metabolic modeling has emerged as a tool to comprehend metabolic networks’ organization within each compartment of these microbes. This approach can help us enhance the production of commercially viable bio-based plastic and help us discover new gene functions in a particular metabolic network. Furthermore, while summarizing the data sources—the genomics knowledge of specific microorganisms is accomplished from the genomic databases available online such as Genome Online Database (GOLD), SEED database, DOE Joint Genome Institute, etc.; BRENDA and UniProt being a source of proteomic information, mainly consist of gene-protein interactions and enzymatic activities. The knowledge of proteomics and the information relevant to biochemical pathways is procured from biochemical databases such as KEGG, pKa Plugin, pKa DB, Transport DB, PubChem, ChlamyCyc, AraCyc, etc. To further visualize and evaluate the metabolic framework, metabolic pathways are represented in the form of maps. Various tools, such as pathway tools, COBRA, etc., are used extensively for developing organism-specific biochemical pathways. Furthermore, metabolic reactions must be confined to specific cellular compartments because the enzymes and metabolites participating in a particular metabolic pathway might reside in different microbial compartments [64, 109, 119].

Interestingly, it has been observed that the metabolic modeling methodology comprising of genome-scale metabolic model reconstruction has been employed effectively for accelerating the production of different bioplastic precursors such as polysaccharides, butanediols, polylactic acid (PLA), carboxylic acids, and polyhydroxyalkanoates (PHA) synthesized either by genetically engineered or natural microorganisms [132]. In-silico genome-scale metabolic model of certain microorganisms such as Escherichia coli, Pseudomonas putida, Pseudomonas sp., Halomonas sp., Saccharomyces cerevisiae, Corynebacterium glutamicum, Ralstonia eutropha, Rhodobacter spaeroides, Clostridium autoethanogenum, Synechocystis sp., [3, 40, 45, 56, 74, 77, 78, 111, 139], etc. have been reconstructed in the past. The focus of reconstruction has been to simulate and understand the metabolic framework of biochemical pathways responsible for the accreted bioplastic precursor production. Description of such models and different optimization tools have been summarized in Table 1.

However, the goal of augmenting bio-based plastic calls for the reconstruction and validation of more such genome-scale metabolic models of microbial species explored highly for bioplastic monomer production. Although a knowledge gap still exists, which ultimately hinders the complete utilization of microorganisms to extract and produce bioplastic monomers. The metabolic modeling via reconstruction of stoichiometric constrained-based models aids in prevailing over all such obstructions and even proves to be time-effective. Thus, a reconstructed model can be exploited recurrently by researchers for optimizing beneficial culture conditions, speculating the effect of gene knockouts and additions, or the importance of the presence of a particular substrate for the production of the metabolite of interest. Eventually, the systems biology approach to genome-scale metabolic reconstruction can prove as a boon in comprehensively understanding the detailed biotransformation pathways of microorganisms subjected to various growth conditions and nutrient combinations. It creates a mathematical framework that undergoes computational simulations and predictions to know the fate of a metabolite in a biochemical pathway and acquaint us with the know-how of the microbial metabolic nexus.

Metabolic Modeling Optimization Algorithms

After the continuous manual enhancement of the draft microbial GEM model, a final GEM model intended to acknowledge disparate characteristics of cell metabolism has been reconstructed. However, the reconstruction of the model is not enough to determine the metabolite production potential of certain microbes; therefore, researchers have introduced various optimization algorithms for adequately scrutinizing the flux allocation of different metabolites and the concentrations of metabolites or the dynamics of the flow of metabolites. FBA, DFBA, FVA, etc., are some optimization algorithms practiced by scientists to accomplish the prime goal of in-silico metabolic modeling.

Flux Balance Analysis (FBA)

A constraint-based in-silico methodology has been the most explored and implemented optimization technique. It has been known to aid in simulating in and out the drift of the metabolites from the metabolic framework. Moreover, it has been practiced significantly to achieve a definite cellular objective, which generally embodies cellular growth maximization or enhanced yield of biotechnologically essential metabolites. FBA expedites computation prediction of microbial phenotypic attributes along with the know-how of microorganism’s ability to render diverse perturbations, including both genetic and environmental factors. FBA envisages the interpretation of database derived from experiments to accomplish certain goals, including formulating optimal culture media compositions, strategizing regulation and modeling of the bioprocess, and facilitating the quantitation of metabolic physiology—a thought behind metabolic engineering [125]. FBA simulations are carried out by deploying explicit computational tools, including the COBRA toolbox (Constraint-Based Reconstruction and Analysis)—a MATLAB toolbox, BioMet, which specifically estimates cell metabolism and omics database on the bases of genomic knowledge [64].

When a microorganism has been subjected to specific physiological or environmental conditions, then FBA stipulates an overall evaluation of the rate of all the metabolic network reactions occurring under those circumstances. At an explicit steady state, the combination of a specific rate of responses has been termed flux distribution (v), where the unit measurement of the rate of reaction is devised as mmol gDW−1 h−1. Whereas the unsteady mass balance dedicated for each metabolite present in the metabolic framework has been expressed as the following equation in FBA:

In the above equation, v is the flux vector expressing the flow of metabolites through all the reactions in the system; S stands for the stoichiometric matrix of m x n dimensions (where m and n delineate the number of metabolites and reactions present in the microbial system respectively); X depicts the vector quantity of metabolite; t represents time.

While considering the growth of cells in relation to their varying environmental conditions, the reformations in the metabolism occur for a brief period. Thus, the concept of assuming the occurrence of metabolic permutations in a steady-state comes into the picture. During constant state, the metabolite concentration deviation with time is considered equal to zero, which substantially enunciates that the fluxes of metabolite (1) production are consistent with its flux of deterioration and, consequently, results in zero after the addition of all the system fluxes. In a nutshell, the biomass participating in the network flushes out conclusively and neglects the idea of metabolite cumulation (2).

To define the limits of the microbial system for the generation of mathematical models, environmental and physicochemical constraints are specified for an individual rate of reactions (5 classes of constraints: physicochemical, thermodynamic, genotypical, topological, and environmental). The bounds/ constraints incorporated on each metabolic reaction influence and minimize the solutions possible for the flux balance equation as a whole. Since the constrained microbial metabolic system is underdetermined due to more reactions than metabolites, a defined solution for the distribution of flux cannot be concluded. Therefore, the computational algorithms need to be defined to determine the optimal flux that affects the defined objective function (Z). An objective function is typically defined to either maximize the biomass production rate or the rate of production of the metabolite of interest. However, the solution of FBA determined by linear programming comes out to be a specific flux vector that fulfills the objective function defined [30, 80, 81, 91, 125].

Shi et al. in 1999 developed a stoichiometric model of Escherichia coli to envisage the hypothetical maximal potential of a microbe to produce PHB (polyhydroxybutyrate) when subjected to different metabolic transients. The flux balance analysis performed by imposing environmental and genetic perturbations demonstrated that the existence of NADPH and acetyl-CoA is significant for boosting the yield of PHB. Similarly, the FBA of the E. coli model has also been performed to elucidate the cells’ redox conditions. A group of scientists reconstructed the genome-scale metabolic model of Pseudomonas putida KT2440, followed by exercising flux balance analysis to explain the PHA production efficiency of bacteria under different carbon sources supplementation. Interestingly, the metabolic modeling approach also correlated bacteria’s PHA biosynthesis ability and survival [90, 103, 107].

The genome-scale flux analysis of two reconstructed models of E. coli K-12 and Rhodococcus jostii RHA1 has been executed to evaluate PHB dynamics under the growth cycle of feast and famine-activated sludge. It has been predicted by the model that the presence of succinate in the form of the substrate during the activated sludge growth regime leads to a high yield of PHB, pinpointing the byproduct formation potential of bacteria in the presence of wastewater. Park and his colleagues systematically analyzed the metabolic attributes as well as an optimized whole metabolic framework of Ralstonia eutropha H16 by effectuating FBA of the microbial model. PHB production was finally predicted under the treatment of varying pH levels as well as uptake ratios of C/N source, paving the way for optimizing PHA production capabilities of the bacteria under the treatment of more such environmental, genetic or physicochemical perturbations. Likewise, the metabolic model based on genomic annotations of Azotobacter vinelandii has been developed to comprehend the metabolic pathways related to PHB production and nitrogen fixation in the presence of a variety of experimentally derived constraints [9, 85, 116, 117].

Soon after the metabolic modeling of bacteria emerged as an essential tool, the genome-scale metabolic modeling strategy for understanding the metabolism of algal species has also been explored extensively by the scientific community. The metabolic framework based on model alga’s central core metabolism, Chlamydomonas reinhardtii, has been primarily constructed by Boyle and Morgan, targeting its genetic and metabolic knowledge base and subsequently performing its simulation in the presence of varying growth regimes. The compartmentalization of the metabolic network has been the first ever established in this study. The study considered mitochondria, chloroplast, and cytosol as the three metabolically active cellular compartments [6].

The biochemical network of microalgae has been categorically composed of specific prime metabolic pathways. Thus, to procure commercially important metabolites from algae, one must gather enormous knowledge of these pathways as they account for a significant part of the algal metabolic network. Various biological processes and pathways are as follows [6]:

-

1.

Photosynthesis utilizes light and inorganic carbon to convert them into biomass composed of primary metabolites sequentially;

-

2.

Glycolysis yields precursors meant for target metabolite production along with the generation of energy;

-

3.

Tricarboxylic acid cycle, a prime pathway leading to the production of energy as well as bioproducts;

-

4.

Oxidative phosphorylation of ADP to yield ATP in the form of energy.

-

5.

Pentose phosphate pathway produces pentose, a precursor for nucleotide synthesis supplemented by the energy in the form of NADPH;

-

6.

Biosynthesis of carbohydrate and triacylglycerides (TAG) as a carbon storage molecule;

-

7.

Synthesis of vital cellular components such as DNA, RNA, protein, chlorophyll, etc., owing to the synergistic contribution of nutrient composition and internal metabolite precursors.

Joshi et al. reconstructed a metabolic model of prokaryotic algae, Synechocystis sp. PCC 6803 to elucidate that the systems biology tool can help strategize the algal strain and its environmental conditions to simultaneously enhance CO2 sequestration and bio-product formation [45]. Yang et al. devised a stoichiometric model for eukaryotic microalgae, Chlorella pyrenoidosa, composed of 2 compartments and embracing 61 metabolites and 67 metabolic reactions, thus predicting the impact of different trophic modes on the central metabolism and energy production with the aid of metabolic flux analysis [137]. Another group of scientists reconstructed a genome-scale metabolic network model of Chlorella vulgaris (iCZ946). They embraced a methodology that combines an omics database and metabolic models to optimize the uptake of nutrients on the verge of the algal cell’s tweaked metabolic conditions under different nutrient combinations [59].

Dynamic Flux Balance Analysis (DFBA)

While predicting an organism’s metabolism in response to environmental perturbations, considering transitions occurring between several instantaneous steady states while incorporating the kinetics behind the uptake and excretion of metabolites leads to DFBA [62]. The versatile and ever-changing microbial feedback to the surrounding changes has been embodied by practicing DFBA. It encompasses the FBA of the microbial metabolic framework and its respective kinetic models in various time profiles and process attributes to simulate the dynamic behavior of metabolism. DFBA aids in unraveling the imperative pathways in the biochemical network and predicting the phenotypic response of cells under modified conditions [62, 82]. Recently, Sun et al. simulated and modeled the cell metabolism of Cupriavidus necator DSM545 for a deep insight into the PHB amelioration under varying batch fermentation modes while altering the aeration parameters and glycerol content. Performing DFBA provided an in-depth understanding of PHB metabolism and its relation with cell growth under the influence of different growth parameters. Conclusively, the results obtained from computational simulation should be adopted experimentally for invigorating PHB production [114].

Flux Variability Analysis (FVA)

While considering the underdetermined attribute of microbial metabolic nexus, the dimensions of the allowable solution space simulated through mathematical algorithms can modulate based on the metabolic structure and applied constraints. However, FVA, a variant of FBA, is a mathematical approach that initiates the assessment of an overall optimal flux solution space for the FBA optimization performed. It aids in empirically determining the minimum and the maximum flux values of each metabolic reaction participating in the fulfillment of an objective function [63, 90]. The biosynthesis potential of polyhydroxyalkanoates (PHA) in Ralstonia eutropha has been optimized under varying pH values and different uptake ratios of carbon/nitrogen by reconstructing its genome-scale metabolic model and performing FVA. After simulation, the metabolic model and the metabolic pathway analysis tool successfully depicted the metabolic capabilities and projected corresponding physiological changes under the influence of environmental and genetic perturbations [85].

Recently, Testa et al. developed a metabolic model of cyanobacteria Synechocystis sp. PCC 6803 used the model to study the in-silico PHB production potential of the photoautotroph under two different scenarios. In this study, in-silico gene knockouts have been implemented to attain synergistically enhanced production of biomass and PHB. Secondly, a two-stage cultivation strategy has been simulated with the help of DFBA to understand the effect of the growth and production phases on the concentration of PHB produced. It has been observed that practicing a two-stage production technique gives more PHB concentration (4.764 gPHB/L) than the PHB produced due to mutation (0.391 gPHB/L). Interestingly, it has also been inferred that the PHB content per cell dry weight obtained in the in-silico study of cyanobacteria is higher than the ones obtained experimentally. Thus, such research studies put forth an opportunity for practicing more in-silico assessments based on metabolic models for unveiling the photosynthetic production of PHB [118].

Elementary Mode Flux Analysis (EMFA)

Similar to FBA and DFBA techniques, EMFA has also been a beneficial tool for scrutinizing the metabolic pathway. It ascertains the framework of a metabolic network associated with the cell’s phenotype corresponding to its genotype. Elementary modes usually depict the minimal sub-networks that enable the genome-scale metabolic reconstruction nexus to function under a steady-state environment. The metabolic framework’s stoichiometric matrix consists of a combination of vectors that have been identified as elementary modes [102, 120]. The elementary modes have been distinguished by specific characteristics such as the distinctiveness of all the elementary modes present in a particular metabolic network; their non-decomposable nature, which portrays the fact that the removal of any reaction from the elementary mode disregards the functionality of the entire elementary mode; and lastly, it encompasses all those pathways which commensurate with the non-decomposable behavior of the mode [10, 11]. In the field of bioplastics, EMFA has been utilized to determine the metabolic condition of the PHB-yielding cells at each stage when grown in the sequence of a five-stage fermentation bioreactor. EMFA has been a valuable tool for in-depth optimization of process parameters, especially in the case of constrained growth conditions (such as nutrient composition, photoperiod, temperature, pH, toxins, etc.) that stimulate PHB/PHA production but hinder the growth of microbial cells [60].

Metabolic Flux Analysis (MFA)

MFA another optimization tool similar to FBA, has been determined to obey the steady-state mass balance condition to measure fluxes involved in the core metabolic intracellular reactions. It has been described that the mass balance plays an essential role in MFA for elucidating the internal or external flow of metabolites through different biochemical pathways embedded in the metabolic network. MFA is often applicable to predetermined systems; thus, defining an objective function for metabolic pathway analysis rules out. It invigorates the quantitative simulation of cellular physiology corresponding to the varying metabolic state in response to numerous factors, such as carbon sources in PHA biosynthesis [126]. MFA has been practiced explicitly for investigating the carbon flux partition at the time of PHB/PHA microbial synthesis under the supplementation of varying carbon derivatives as a substrate [32, 75, 108, 135, 141].

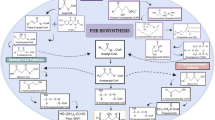

Genome-scale metabolic model reconstruction followed by practicing specific in-silico simulation (optimization) tools such as FBA, DFBA, FVA, EMFA, and MFA mediates the comprehension of metabolic pathways associated with bioplastic precursor accumulation and eventually fosters the bioprocess optimization approach. Figure 2A incorporates the frequency distribution of varying modeling algorithms, and Fig. 2B depicts the percentage of metabolic models employed for the simulation of bioplastic precursor biosynthesis. Constraint-based modeling stimulates the accurate prediction of metabolic phenotypes of microorganisms. It has also been maneuvered extensively for discerning appropriate growth conditions as well as genetic strategies to boost the bioproduction process, despite that more such computational modeling aspects need to be explored comprehensively. For instance, the constraint-based genome-scale metabolic model reconstruction of algal species has been in its infancy and must be researched meticulously, specifically concerning their bioplastic production potential. Though certain algal strains (microalgae as well as cyanobacteria) are subjected to genome-scale modeling, however, while considering the current bioplastic production scenario, the research community must consummate inevitably the flux balance analysis of microbes such as bacteria and algae to get a deep insight into the biochemical pathways and metabolic networks engaged in the formulation of bioplastic monomers or precursors under different environmental perturbations and metabolic transitions.

A Frequency of metabolic modeling algorithms employed to solve the constraint-based models for bioplastic production: flux balance analysis (FBA), flux variability analysis (FVA), dynamic flux balance analysis (DFBA), elementary mode flux analysis (EMFA), metabolic flux analysis (MFA); B Percentage of publications of microbial metabolic models utilized for predictive modeling and simulation of bioplastic precursor biosynthesis

Conclusively, microbial bioplastic has immense potential to supersede the traditional plastic market and mitigate ecological issues related to fossil-based plastic lifecycle. However, a few crucial challenges need to be resolved for economically viable and environmentally feasible commercial production of bioplastics. Some of them can be determined and solved by technical analyses based on the metabolic models, considering the technical and experimental capabilities present in the current scenario.

The Ecological and Economical Perspective of Microbial Bioplastic Production

As discussed in Sect. 2, the in-silico technique, genome-scale metabolic modeling, has assisted in understanding the microbial growth conditions and constraints essential for producing the desired metabolite. The simulation results can project the production strategy that could be applied to produce microbial bioplastic. Thus, reducing the cost involved in the optimization experiments that had to be performed in the laboratory for finalizing the parameters favorable for microbial growth and metabolite accumulation. However, the knowledge of metabolism and microorganism is not sufficient for making the microbial bioplastic thus produced economically and environmentally so stable that it can become a better alternative to petroleum-based plastic. Apart from having mechanical and physical characteristics, the bioplastic derived from microorganisms should also preferably be at a similar economic status to fossil-based plastic.

Additionally, the sustainable lifecycle of bioplastic and the environment-friendly nature of plastic produced has been a topic of concern for the past few decades. For inspecting and validating the sustainability and economic feasibility of the bioplastic derived from microorganisms, two prominent techniques, life-cycle assessment (LCA) and techno-economic analysis (TEA), have been exercised exclusively. The subsequent sub-sections have discussed the significance and methodology of these techniques corresponding to the microbial bioplastic framework.

Life Cycle Assessment (LCA) of Bioplastic

The ecological footprint accompanying bioplastics’ manufacturing and utilization has recurrently proved to be an imperative consideration for their production and advancement. Researchers have described that to assess the environmental impact of bioplastics meticulously, an analysis must be performed while encompassing petrochemical plastics and the production and recovery of bioplastics. LCA is a standardized decision-reinforcement tool maneuvered for investigating the environmental footprints of different resources, production methodologies, and products [52, 98, 104]. LCA considers the holistic bioplastic life cycle as shown in Fig. 3, including development, usage, and disposal activities and systems (prerequisite processes, energy and raw components, manufacturing, disbursement, appliance, recovery, and end-of-life management). The prime goal is to unravel the outcome of the interaction taking place between the environment and the desired product/procedure/resources during its production, usage, and disposal [22, 39, 113]. International Standards Organization (ISO) has standardized and organized the LCA framework in ISO-14040 [42] and ISO-14044 [43], which comprises of following four interlinked principle steps that have to be practiced iteratively to get the results: [87, 93, 131]

-

A.

Elucidating goal and scope of the analysis (ISO 14041)

For the product and/or application whose LCA needs to be performed, the objectives (the functional unit), relevant elements (system boundaries), and the drawback of the study, along with the impact categories, have to be enunciated while working on the goal of the research study.

-

B.

Inventory analysis (ISO 14041):

The inventory evaluation is the epicenter of life cycle methodology and endeavors to map the recognized product or process paradigm while defining the study’s goal and scope. It has been followed by outlining a model, describing the state of affairs, and validating the data repetitively. All the essential technical, analytical, and environmental entities related to each unit present within the system’s boundary (determined by the study goal) must be embodied in the inventory [24]. In addition to that, the uncertainties associated with factors such as type of experimental data provided, variation required for the study and the desired output contributes to the inventory analysis. The uncertainties are further refined by performing sensitivity analysis revolving around the deviation of the output from the varying inputs and processes [17].

-

C.

Impact assessment (ISO 14042):

With the help of the life cycle framework, impact assessment aims at assessing the magnitude of participation of input data flow on specific environmental parameters such as carbon footprint, energy usage, ozone depletion, acidification, smog formation, eutrophication, land usage, water footprint, ecotoxicity, human toxicity, etc., while considering the system’s boundary. The extent of the environmental impact of a product or activity is characterized based on the possibility of several impact factors under consideration, both individually and cumulatively.

-

D.

Interpretation (ISO 14043):

The results obtained from the previous two steps are epitomized in this step, focusing on the significant involvements, uncertainties, and sensitivity analysis in anticipation of the conclusions and suggestions drawn from the study for the future outlook of the intended product or process.

The system boundaries of fundamental LCA methodology, adapted for various investigations, include cradle to gate and cradle to grave, differentiated by the exclusion and inclusion of end-of-life management/ disposal perspective, respectively, in the whole process initiated from the procurement of the raw materials [1, 39, 44, 124]. The biodegradability and renewability of bioplastics compared to fossil-derived plastics has been a ubiquitous perspective. However, the large-scale production of bioplastics still needs to be under surveillance to acknowledge their ecological or environmental footprint, which will ultimately aid in ascertaining the statistics of future bioplastic manufacturing. The LCA tool has been maneuvered substantially to scrutinize the environmental, dynamic, and productive sustainability of bioplastic production, specifically PHA biosynthesis [35, 38, 73, 115]. Table 2 summarizes LCA studies on PHA production.

In order to consider different bioplastics for commercialization it is essential to evaluate their economic feasibility. LCA studies of bioplastics such as PHA, Polylactic acid (PLA), Bacterial cellulose (BC), Exopolysaccharide (EPS), etc. have been performed by various researchers so as to comprehend their economic profitability. A polyester, PLA, has been known as a bioplastic precursor derived from sources such as corn, bacteria, and microalgae. LCA studies comprising of different goals and system boundaries have been carried out to understand the feasibility of PLA production, product formation, degradation and recycling scenarios and its detailed description and discussion has been recently reviewed in detail by Rezvani Ghomi and colleagues [94]. They concluded that the conversion of PLA is the stage that consumes maximum energy and its optimization will lead to the production of low-carbon material, essential for replacing the products produced from high energy resources. A few years back, Bussa and the team executed the LCA of polylactic acid (PLA) (bioplastic precursor) production from microalgae. They concluded that microalgal-PLA showed higher potentials in terms of terrestrial ecotoxicity and land usage and lower potentials for human toxicity, acidification, and eutrophication. Thus, it has been recommended that more investigation must be performed to optimize the growth conditions and PLA accumulation [8]. LCA demonstrated the environmental impact of each technology under consideration. Beckstrom has also illustrated the life cycle impact analysis results of the integrated biorefinery approach of microalgae feedstock for bioplastic and fuel production. Nine varying scenarios for production have been analyzed, and it has been inferred that the bioplastic feedstock showed improved environmental performance compared to fossil-based plastic feedstock owing to the rection in GHGs emissions [4].

Numerous investigations have also been performed to assess PHA production's life cycle (cradle-to-gate). However, the results of some studies portray questionable ecological advantages of bioplastic (PHAs) production over conventional plastic [27, 28, 55]. In contrast, some studies have exhibited a positive environmental impact of PHAs over petrochemical plastics [1, 79, 140]. The high variability in the LCA results depicts that considering global warming potential, GHGs, and energy requirements like lesser impact categories have not been sufficient to understand the holistic environmental sustainability of the bioplastic thus produced. Harding and colleagues primarily evaluated a complete LCA (cradle-to-gate) of polyhydroxy butyric acid biosynthesis while considering all essential impact factors along with the net CO2 generation. They discovered that PHB production has been more advantageous than the production of polypropylene (PP) due to the considerable reduction in ozone layer depletion, toxicity levels, acidification, and abiotic depletion values of PHB compared to PP production. However, the deduction in PHB's eutrophication and global warming potential was less significant and showed a greater environmental impact than PP production [35, 50, 51, 115].

A cradle-to-cradle cycle of PHB production from methane biogas and its disintegration back to methane has been scrutinized by performing cradle-to-gate LCA. It has been concluded that a productive connection of waste-to-energy methodologies could aid in fulfilling the requirement of external energy and carbon for the production of PHB and thus make the process ecologically feasible [97]. Several authors have also evaluated the environmental behavior of PHA production conjoint with wastewater treatment. They have demonstrated the strategy’s environmental sustainability and specific improvements that can be integrated and optimized to implement the process on a large scale [21, 33, 36, 69, 97, 129].

The substrate required for considerable PHA accumulation also significantly determines the system’s environmental performance. A sustainable process index symbolizing LCA has been evaluated for whey-derived archaebacterial PHA production. The study demonstrated that PHA stimulated higher pressure on ecology than fossil-based plastic [53]. Recently, researchers performed LCIA (Life Cycle Impact Assessment) to determine different factors that influence the environmental behavior of PHA-based plastics as a whole. In this study, various climate tipping points have been considered a part of the impact category intended for evaluating the performance of PHA plastic in the environment. It has been discussed that for improving the sustainability of PHA plastics, factors such as PHA productivity, stability, environmental conditions, process parameters, essential feedstocks, geographic location, upscaling the production, etc., must be focused on and optimized extensively as per different climate tipping LCA impact category [127]. Likewise, the downstream procedures adapted for extraction and recovery of PHA significantly affect the PHA life cycle’s environmental performance. The LCA has been executed to determine the environmental impact of the dimethyl carbonate PHB extraction protocol. The study’s findings established that this protocol has a much better performance than halogenated hydrocarbons. Therefore, more LCA needs to be performed to analyze the environmental performance of purification and extraction protocols so that the most beneficial of them can be discovered and executed for large-scale bioplastic production [95]. Researchers have recently assessed the life cycle of PHB production in multiple scenarios, such as anaerobic digestion, anaerobic digestion and booster, and anaerobic digestion and PHB production [128].

However, studies concerning the cost-effectiveness of bioplastics such as EPS, cellulose, etc. have been very limited and needs to be studied in detail in near future as some of the products made from such bioplastics have been produced widely commercially. Interestingly, the European bioplastic association (EBP) has also elucidated LCA’s significance in substantiating the bioplastics’ eco-sustainability [19]. Nonetheless, scientists have recommended further exploration of environmental impact in the context of bioplastic to facilitate the production process, neglect the potential burden shift, and broaden the impact assessment by practicing overlooked categories such as land and water utilization and eutrophication. Some reviewers have also depicted LCA’s highly variable nature due to the incorporation of varying techniques and disparate routes and selections (functional unit, system boundary, etc.) for performing the LCA [2, 15, 21, 31, 54, 61, 128, 138]. It is also noteworthy that LCA does not incorporate the economic profiles or risk reports for the intended process/product. Hence, techniques such as techno-economic analysis (TEA), life cycle costing (LCC), environmental risk assessment, and resource sustainability evaluation of the product or methodology need to be performed along with LCA to accomplish its comprehensive sustainability sketch [72].

Techno-Economic Assessment (TEA) of Bioplastic

Bioplastic has overshadowed conventional plastics as an efficient alternative. Despite that, increased production cost compared to fossil-based plastics has been the prime predicament in the large-scale framework. It has been concluded from the literature that three fundamental attributes play a significant role in increased manufacturing cost, including the energy requirement, the yield of bioplastic against specific sources, and, lastly, the downstream processing potential [21]. Therefore, to effectively execute large-scale bioplastic production, assessing the economic and technical feasibility of the intended methodology to be upgraded at a commercial scale is essential.

A techno-economic analysis is one approach employed for performing protocol design and simulation, supported by the practical database to evaluate energy and mass balances, integrated with economic characteristics such as capital, operational, and feedstock expenditure. Techno-economic investigation empowers industrialists and researchers with a framework to estimate the commercial feasibility and the integrated cost-effectiveness of industrial plants or processes along with that the dynamics used. The expenditure estimation is done in order to enumerate the expenditure linked with the economy, profit, selling price of the product, raw feedstock, utility, and equipment of the protocol under consideration. The economic sustainability of any large-scale commercial process is linked thoroughly with the feasibility of the technique adopted and thus needs to be practiced consistently to introduce a feasible industrial process or plant [58].

The expenditure related to any product or material is further grouped into three main classes: general cost, fixed cost, and direct cost. The general expenditure comprises overheads preserved for the continuance of the operational industrial plant, administrative activities, and funding of the research and development undertakings. The fixed expense incorporates the cost of all activities occurring even during the operational plant’s halt and thus excludes the material production rate. The direct cost is composed of all the expenditures directly linked to the output rate cumulative to all the utilities’ expenses, the labor involved in the operation, and raw feedstock [88]. TEA has often been performed at different levels based on the desired requirement of economical accuracy. Like LCA, the goal and scope of the assessment are defined in TEA as well, followed by underlining the estimation parameters, which include the extent of magnitude (10%-50% accurate), study or factored evaluation (30%), preliminary or budget authorization (20%), Definitive or project control (10%), in-depth evaluation or contractor’s estimate (5%). All the unattainable perspectives have been excluded while considering the order of magnitude estimation. The TEA study evaluation has usually been performed by exploiting commercial software such as SuperPro and Aspen. The study estimate includes recognizing the flow of a process, essential individual operations, and process optimization, followed by determining the commercial or industrial feasibility of the techniques or plant under varying scenarios [71].

While looking into the techno-economic analysis of bioplastics such as polylactic acid (PLA) and polybutylene succinate (PBS) produced from various renewable sources like sugarcane molasses and bagasse, it was observed that lowest selling cost of PLA was US$ 2.9/kg and of PBS was US$ 2.9/kg [92], whereas PLA and PBS produced from sugar beet pulp were found to have a selling price of US$ 1.14/kg and US$ 1.37/kg, respectively [41]. Furthermore, while looking into the bioplastics produced from microbes such as PHA, very few financial profitability studies have been performed such as considering the bottlenecks in PHA production, Moncada et al. conducted a study to analyze the biorefinery approach (sugar, bioethanol, anthocyanins, and electricity) and PHA production under the supplementation of cane molasses and juice through varying biochemical conversion pathways. They concluded that the expedient economic feasibility had been defined by the biorefinery pathway comprising cumulative production of PHB and bioethanol [65]. Furthermore, the ANIMPOL project has employed a detailed economic assessment of PHA during consumption of a meta-bone meal, offal matter, and low-quality biodiesel in pursuance of the waste-to-biorefinery notion. The results suggested that the production cost of PHA varied in accordance with the substrate and had the potential to influence the revenue generated from the PHA commercial market [105]. The PHB production assessment by methanotrophic fermentation and its extraction by solvent has been performed by conducting a techno-economic sustainability analysis with US$ 4.1–6.8/kg PHB of normalized production cost. The study’s observations determined that replacing sugar substrate with methane and the presence of thermophilic methanotrophs led to a reduction in raw material expenditure and the yielding cost as a whole [58]. A group of researchers performed an economic analysis of the production of PHB by Cupriavidus necator while using waste citric molasses and evaluating different extraction techniques. It has been observed in the study that the PHB production capacity had a substantial effect on the production cost of the bioplastic (i.e., from US$ 5.50/kg for 2000 tonnes/year production capacity to US$ 2.71/kg for 10,000 tonnes/year). The biomass content obtained at the end of the process has also been determined to impact the cultivation cost significantly. Consequently, the capital investment can be reduced while focusing on the requirements for PHB production, including the production and extraction equipment and raw materials. It has also been presented that PHB extraction from biomass in an environment of high temperature and pressure also contributes significantly to reducing its production cost [86].

In addition to that, the technoeconomic analysis of PHB produced via the promising photosynthetic pathways have been in native stage. The TEA of PHB produced from cyanobacteria was primarily performed by Panuschka et al., evaluating the cost of PHB yield under different scenarios and summarized that while considering 60% PHB yield with thin layer system cultivation scenario, the lowest cost of PHB obtained was US$ 26.4/kg. It was demonstrated that the economic impact of different emulating extraction and recovery protocols needs to be scrutinized in order to minimize the proportion of downstream processing expense in the manufacturing cost, leading to the invention of an economically feasible process [83]. Recently, Price et al., also studied the profitability of cultivating cyanobacteria in open raceway ponds followed by solvent extraction for producing 10,000 tonnes of PHB from biomass every year. They found the lowest selling price of PHB with 10% of PHB yield as US$ 18/kg, though while considering different scenarios for reducing the cost and enhancing the cost-effectiveness of cyanobacterial PHB production, they observed that several factors such as PHB yield, cultivation system, treating wastewater, and different operational parameters affect the minimum selling price of the PHB. Thus, after optimizing all the essential factors, the minimum price of selling photosynthetic PHB was determined to be US$ 7.7/kg. These studies paved the way ahead for understanding the economic feasibility of different techniques (especially involving the scope of photosynthetic pathway) adopted commercially for the production of PHB [89].

The different extraction routes comprising solvent, alkali, and surfactant-hypochlorite to recover PHB produced from wastewater have been evaluated economically. Along with the production cost, global warming potential and non-renewable energy usage have also been estimated. Interestingly, the employment of alkali gave significant results compared to the other two protocols. It has also been exhibited that compared to the sugar fermentation approach, the expenses of downstream processing of PHB produced from wastewater have been much higher. However, the production expenditure for PHB from wastewater has been much less than sugar fermentation. In a nutshell, though, the production cost can be reduced while focusing on different aspects of production and extraction, but it does not resemble the petrochemical bioplastics; therefore, more focus needs to be drawn on the techno-economic element of the process or product desired [16, 21].

From the literature study of the economic aspect, it can be summarized that the accumulation of biomass and production scope have been some of the essential factors that directly influence the requirement of raw feedstocks and the equipment size for an enhanced cultivation system. The above-said factors eventually induce the cost deduction in both the operational and capital fields, making bioplastic production economically viable. Furthermore, in the context of downstream processing of bioplastics, factors such as protocol, synthesis method, expenses related to processing prerequisites, recovery potential of the process, and the market environment play a significant role and need to be considered extensively while performing techno-economic analysis.

Concluding Remarks and Future Perspectives

The advancing correlation between rising GHGs emissions and, in turn, global warming with the different stages of the lifecycle of fossil-based plastics has attracted the attention of government officials, policymakers, and scientists worldwide. Researchers globally have been working on various renewable sources to produce bioplastic, and microbes such as bacteria and algae, after several studies have been known to be a significant candidate. The microbial bioplastic manufacturing industries have already paved their way into the global plastic market. However, the sustainability and feasibility of microbial bioplastic synthesis, consumption, and end-of-life management have still been a concern. In anticipation of unraveling the cellular peculiarities related to bioplastic precursors’ (PHA) accumulation, genome-scale metabolic modeling has evolved as a crucial technical tool while considering the limitations of the wet lab experimentation approach. The formation of the metabolic model and the execution of various optimization algorithms (FBA, FVA, DFBA, EMFA, etc.) provides a deep insight into a microorganism’s metabolic and gene-level behavior in response to genetic and environmental apprehensions while aiming at augmented bioplastic production. After optimizing microbial aspects for PHA production comes the challenge of making the process and product, budget and ecology friendly. In the past, researchers have performed very few techno-economic analyses and life cycle assessments of diverse bioplastic production methodologies and recapitulated their significance in optimizing the process at different production levels.

Furthermore, contemplating just the economic and environmental impact of bioplastic (PHA and PLA) production procedures will not resolve the cellular level challenges while practicing large-scale commercial bioplastic manufacturing. Henceforth, in-silico genome-scale metabolic rewiring in conjunction with a systems analysis approach, specifically techno-economic assessment and life cycle analysis, can lay a strong foundation for introducing economically feasible and environmentally sustainable processes and techniques for the production of microbial bioplastic commodities. Eventually, while targeting the huge plastic market, introducing and setting up a considerable proportion of biodegradable bioplastic in the market so that it can compete with petroleum plastic characteristically and monetarily has become the main agenda of the research industry. Thus, this review highlights the in-silico techniques and possibilities essential to accomplish the goal of making the world free from petroleum-based, non-biodegradable plastic.

Abbreviations

- CIEL:

-

Center for international environmental law

- WEF:

-

World economic forum

- GHGs:

-

Green house gases

- COP26:

-

26Th UN climate change conference of the parties

- FBA:

-

Flux balance analysis

- FVA:

-

Flux variability analysis

- EMFA:

-

Elementary mode flux analysis

- DFBA:

-

Dynamic flux balance analysis

- MFA:

-

Metabolic flux analysis

- TEA:

-

Techno-economic analysis

- LCA:

-

Life-cycle assessment

- PHA:

-

Poly-hydroxy alkanoates

- PHB:

-

Poly-hydroxy butyrate

- GEM:

-

GEnome-scale metabolic Model

- GOLD:

-

Genome online database

- DOE:

-

Department of energy

- BRENDA:

-

BRaunschweig enzyme dAtabase

- KEGG:

-

Kyoto encyclopedia of genes and genomes

- COBRA:

-

Constraint-based reconstruction and analysis

- PLA:

-

PolyLactic acid

- MMC:

-

Mixed microbial culture

- NADPH:

-

Nicotinamide adenine dinucleotide phosphate hydrogen

- ATP:

-

Adenosine tri phosphate

- ADP:

-

Adenosine di phosphate

- TAG:

-

TriAcyl glycerol

- DNA:

-

Deoxyribo nucleic acid

- RNA:

-

Ribo nucleic acid

- ISO:

-

International standard organization

- GWP:

-

Global warming potential

- COD:

-

Chemical oxygen demand

- OD:

-

Ozone depletion

- HT:

-

Human toxicity

- AP:

-

Acidification Potential

- EP:

-

Eutrophication potential

- FE:

-

Freshwater ecotoxicity

- TE:

-

Terrestrial ecotoxicity

- PO:

-

Photochemical oxidation

- AD:

-

Abiotic depletion

- OFP:

-

Ozone formation potential

- POFP:

-

Photo-oxidant formation potential

- EuF:

-

Freshwater eutrophication

- EuM:

-

Marine eutrophication

- EuT:

-

Terrestrial eutrophication

- PM:

-

Particulate matter formation

- IR:

-

Ionizing radiation

- RD:

-

Resource depletion

- WD:

-

Water depletion

- LU:

-

Land use

- NREU:

-

Non-renewable energy use

- PP:

-

Polypropylene

- LCIA:

-

Life-cycle impact assessment

- EBP:

-

European bioplastic association

- LCC:

-

Life-cycle costing

References

Akiyama M, Tsuge T, Doi Y (2003) Environmental life cycle comparison of polyhydroxyalkanoates produced from renewable carbon resources by bacterial fermentation. Polym Degrad Stab 80:183–194. https://doi.org/10.1016/S0141-3910(02)00400-7

Álvarez-Chávez CR, Edwards S, Moure-Eraso R, Geiser K (2012) Sustainability of bio-based plastics: general comparative analysis and recommendations for improvement. J Clean Prod 23:47–56. https://doi.org/10.1016/j.jclepro.2011.10.003

Ates O (2015) Systems Biology of Microbial Exopolysaccharides Production. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2015.00200

Beckstrom BD, Wilson MH, Crocker M, Quinn JC (2020) Bioplastic feedstock production from microalgae with fuel co-products: a techno-economic and life cycle impact assessment. Algal Res 46:101769. https://doi.org/10.1016/j.algal.2019.101769

Blazeck J, Alper H (2010) Systems metabolic engineering: genome-scale models and beyond. Biotechnol J. https://doi.org/10.1002/biot.200900247

Boyle NR, Morgan JA (2009) Flux balance analysis of primary metabolism in Chlamydomonas reinhardtii. BMC Syst Biol 3:1–14. https://doi.org/10.1186/1752-0509-3-4

Brojanigo S, Parro E, Cazzorla T, Favaro L, Basaglia M, Casella S (2020) Conversion of starchy waste streams into polyhydroxyalkanoates using Cupriavidus necator DSM 545. Polymers (Basel) 12:1496. https://doi.org/10.3390/polym12071496

Bussa M, Eisen A, Zollfrank C, Röder H (2019) Life cycle assessment of microalgae products: state of the art and their potential for the production of polylactid acid. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.12.048

Campos DT, Zuñiga C, Passi A, Del Toro J, Tibocha-Bonilla JD, Zepeda A, Betenbaugh MJ, Zengler K (2020) Modeling of nitrogen fixation and polymer production in the heterotrophic diazotroph Azotobacter vinelandii DJ: Genome-scale metabolic modeling of Azotobacter vinelandii DJ. Metab. Eng. Commun. 11:e00132. https://doi.org/10.1016/j.mec.2020.e00132

Carlson R, Srienc F (2004) Fundamental escherichia coli biochemical pathways for biomass and energy production: identification of reactions. Biotechnol Bioeng 85:1–19. https://doi.org/10.1002/bit.10812

Carlson R, Srienc F (2004) Fundamental Escherichia coli biochemical pathways for biomass and energy production: creation of overall flux states. Biotechnol Bioeng 86:149–162. https://doi.org/10.1002/bit.20044

CIEL Report, 2019. Plastic and Climate: The Hidden Costs of a Plastic Planet - Center for International Environmental Law [WWW Document]. URL https://www.ciel.org/plasticandclimate/ (accessed 2.17.22).

COP26 goals, 2021. COP26 Goals - UN Climate Change Conference (COP26) at the SEC – Glasgow 2021 [WWW Document]. URL https://ukcop26.org/cop26-goals/ (accessed 2.17.22).

COP26 outcomes, 2021. COP26 Outcomes - UN Climate Change Conference (COP26) at the SEC – Glasgow 2021 [WWW Document]. URL https://ukcop26.org/the-conference/cop26-outcomes/ (accessed 2.17.22).

Cristóbal J, Matos CT, Aurambout JP, Manfredi S, Kavalov B (2016) Environmental sustainability assessment of bioeconomy value chains. Biomass Bioenerg 89:159–171. https://doi.org/10.1016/j.biombioe.2016.02.002

Crutchik D, Franchi O, Caminos L, Jeison D, Belmonte M, Pedrouso A, Val del Rio A, Mosquera-Corral A, Campos JL (2020) Polyhydroxyalkanoates (PHAs) production: A feasible economic option for the treatment of sewage sludge in municipalwastewater treatment plants? Water 12:1118. https://doi.org/10.3390/W12041118

Cucurachi S, Blanco CF, Steubing B, Heijungs R (2022) Implementation of uncertainty analysis and moment-independent global sensitivity analysis for full-scale life cycle assessment models. J Ind Ecol 26:374–391. https://doi.org/10.1111/jiec.13194

De Philippis R, Ena A, Guastiini M, Sili C, Vincenzini M (1992) Factors affecting poly-Î2-hydroxybutyrate accumulation in cyanobacteria and in purple non-sulfur bacteria. FEMS Microbiol Lett 103:187–194. https://doi.org/10.1111/j.1574-6968.1992.tb05837.x

European Bioplastics, n.d. EUBP’s policy recommendations to use sound LCAs as a basis for policy formulation – European Bioplastics. URL https://www.european-bioplastics.org/eubps-policy-recommendations-to-use-sound-lcas-as-a-basis-for-policy-formulation/ (accessed 2.18.22).

Feist AM, Herrgård MJ, Thiele I, Reed JL, Palsson B (2009) Reconstruction of biochemical networks in microorganisms. Nat Rev Microbiol. https://doi.org/10.1038/nrmicro1949

Fernández-Dacosta C, Posada JA, Kleerebezem R, Cuellar MC, Ramirez A (2015) Microbial community-based polyhydroxyalkanoates (PHAs) production from wastewater: techno-economic analysis and ex-ante environmental assessment. Bioresour Technol 185:368–377. https://doi.org/10.1016/j.biortech.2015.03.025

Finnveden G, Lindfors LG (1996) On the nordic guidelines for life cycle assessment. Int J Life Cycle Assess 1:45–48. https://doi.org/10.1007/bf02978635

Ford HV, Jones NH, Davies AJ, Godley BJ, Jambeck JR, Napper IE, Suckling CC, Williams GJ, Woodall LC, Koldewey HJ (2022) The fundamental links between climate change and marine plastic pollution. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2021.150392

Frischknecht R (2011) Ecoinvent database [WWW Document]. Inf Syst Sustain Dev. https://doi.org/10.4018/9781591403425.ch003

Fukui T, Chou K, Harada K, Orita I, Nakayama Y, Bamba T, Nakamura S, Fukusaki E (2014) Metabolite profiles of polyhydroxyalkanoate-producing Ralstonia eutropha H16. Metabolomics 10:190–202. https://doi.org/10.1007/s11306-013-0567-0

Fukui T, Mukoyama M, Orita I, Nakamura S (2014) Enhancement of glycerol utilization ability of Ralstonia eutropha H16 for production of polyhydroxyalkanoates. Appl Microbiol Biotechnol 98:7559–7568. https://doi.org/10.1007/s00253-014-5831-3

Gerngross TU (1999) Can biotechnology move us toward a sustainable society? Nat Biotechnol. https://doi.org/10.1038/9843

Gerngross TU, Slater SC (2000) How green are green plastics? Sci Am 283:37–41. https://doi.org/10.1038/scientificamerican0800-36

Geyer, R., Jambeck, J.R., Law, K.L., 2017. Production, use, and fate of all plastics ever made. Sci. Adv. 3. https://doi.org/10.1126/sciadv.1700782

Gianchandani EP, Chavali AK, Papin JA (2010) The application of flux balance analysis in systems biology. Wiley Interdiscip Rev Syst Biol Med 2:372–382. https://doi.org/10.1002/wsbm.60

Gong J, Darling SB, You F (2015) Perovskite photovoltaics: Life-cycle assessment of energy and environmental impacts. Energy Environ Sci 8:1953–1968. https://doi.org/10.1039/c5ee00615e

Grousseau E, Blanchet E, Déléris S, Albuquerque MGE, Paul E, Uribelarrea JL (2013) Impact of sustaining a controlled residual growth on polyhydroxybutyrate yield and production kinetics in Cupriavidus necator. Bioresour Technol 148:30–38. https://doi.org/10.1016/j.biortech.2013.08.120

Gurieff N, Lant P (2007) Comparative life cycle assessment and financial analysis of mixed culture polyhydroxyalkanoate production. Bioresour Technol 98:3393–3403. https://doi.org/10.1016/j.biortech.2006.10.046

Hanemaaijer M, Röling WFM, Olivier BG, Khandelwal RA, Teusink B, Bruggeman FJ (2015) Systems modeling approaches for microbial community studies: From metagenomics to inference of the community structure. Front Microbiol 6:213. https://doi.org/10.3389/fmicb.2015.00213

Harding KG, Dennis JS, von Blottnitz H, Harrison STL (2007) Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol 130:57–66. https://doi.org/10.1016/j.jbiotec.2007.02.012

Heimersson S, Morgan-Sagastume F, Peters GM, Werker A, Svanström M (2014) Methodological issues in life cycle assessment of mixed-culture polyhydroxyalkanoate production utilising waste as feedstock. N Biotechnol 31:383–393. https://doi.org/10.1016/j.nbt.2013.09.003

Hempel F, Bozarth AS, Lindenkamp N, Klingl A, Zauner S, Linne U, Steinbüchel A, Maier UG (2011) Microalgae as bioreactors for bioplastic production. Microb Cell Fact 10:1–6. https://doi.org/10.1186/1475-2859-10-81

Hohenschuh W, Kumar D, Murthy GS (2014) Economic and cradle-to-gate life cycle assessment of poly-3-hydroxybutyrate production from plastic producing, genetically modified hybrid poplar leaves. J Renew Sustain Energy 6:063113. https://doi.org/10.1063/1.4901870

Hottle TA, Bilec MM, Landis AE (2013) Sustainability assessments of bio-based polymers. Polym Degrad Stab 98:1898–1907. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2013.06.016

Imam S, Yilmaz S, Sohmen U, Gorzalski AS, Reed JL, Noguera DR, Donohue TJ (2011) IRsp1095: a genome-scale reconstruction of the Rhodobacter sphaeroides metabolic network. BMC Syst Biol 5:1–17. https://doi.org/10.1186/1752-0509-5-116

Ioannidou SM, Ladakis D, Moutousidi E, Dheskali E, Kookos IK, Câmara-Salim I, Moreira MT, Koutinas A (2022) Techno-economic risk assessment, life cycle analysis and life cycle costing for poly(butylene succinate) and poly(lactic acid) production using renewable resources. Sci Total Environ 806:150594. https://doi.org/10.1016/j.scitotenv.2021.150594

ISO 14040, 2020. ISO 14040 Environmental management. Life cycle assessment. Principles and framework. Amendment. Eur. Stand. 1.

ISO 14044, 2006. ISO 14044:2006 Environmental management - Life Cycle Assessment - Requirements and Guidelines.

Jiménez-González C, Kim S, Overcash MR (2000) Methodology for developing gate-to-gate life cycle inventory information. Int J Life Cycle Assess 5:153–159. https://doi.org/10.1007/BF02978615

Joshi CJ, Peebles CAM, Prasad A (2017) Modeling and analysis of flux distribution and bioproduct formation in Synechocystis sp. PCC 6803 using a new genome-scale metabolic reconstruction. Algal Res 27:295–310. https://doi.org/10.1016/j.algal.2017.09.013

Jung HM, Im DK, Lim JH, Jung GY, Oh MK (2019) Metabolic perturbations in mutants of glucose transporters and their applications in metabolite production in Escherichia coli. Microb Cell Fact 18:1–14. https://doi.org/10.1186/s12934-019-1224-8

Kamravamanesh D, Pflügl S, Nischkauer W, Limbeck A, Lackner M, Herwig C (2017) Photosynthetic poly-β-hydroxybutyrate accumulation in unicellular cyanobacterium Synechocystis sp. PCC 6714. AMB Express 7:143–143. https://doi.org/10.1186/s13568-017-0443-9

Kendall A (2012) A life cycle assessment of biopolymer production from material recovery facility residuals. Resour Conserv Recycl 61:69–74. https://doi.org/10.1016/j.resconrec.2012.01.008

Kim B, Kim WJ, Kim DI, Lee SY (2015) Applications of genome-scale metabolic network model in metabolic engineering. J Ind Microbiol Biotechnol 42:339–348. https://doi.org/10.1007/s10295-014-1554-9

Kim S, Dale BE (2008) Energy and greenhouse gas profiles of polyhydroxybutyrates derived from corn grain: a life cycle perspective. Environ Sci Technol 42:7690–7695. https://doi.org/10.1021/es8004199

Kim S, Dale BE (2005) Life cycle assessment study of biopolymers (Polyhydroxyalkanoates) derived from no-tilled corn. Int J Life Cycle Assess 10:200–210. https://doi.org/10.1065/lca2004.08.171

Klöpffer W, Grahl B (2014) Life Cycle Assessment (LCA): A Guide to Best Practice. Wiley Blackwell, NewYork. https://doi.org/10.1002/9783527655625

Koller M, Sandholzer D, Salerno A, Braunegg G, Narodoslawsky M (2013) Biopolymer from industrial residues: Life cycle assessment of poly(hydroxyalkanoates) from whey. Resour Conserv Recycl 73:64–71. https://doi.org/10.1016/j.resconrec.2013.01.017

Kookos IK, Koutinas A, Vlysidis A (2019) Life cycle assessment of bioprocessing schemes for poly(3-hydroxybutyrate) production using soybean oil and sucrose as carbon sources. Resour Conserv Recycl 141:317–328. https://doi.org/10.1016/j.resconrec.2018.10.025

Kurdikar D, Fournet L, Slater SC, Paster M, Gruys KJ, Gerngross TU, Coulon R (2000) Greenhouse gas profile of a plastic material derived from a genetically modified plant. J Ind Ecol 4:107–122. https://doi.org/10.1162/108819800300106410

de Lemgruber R, S.P., Valgepea, K., Tappel, R., Behrendorff, J.B., Palfreyman, R.W., Plan, M., Hodson, M.P., Simpson, S.D., Nielsen, L.K., Köpke, M., Marcellin, E., (2019) Systems-level engineering and characterisation of Clostridium autoethanogenum through heterologous production of poly-3-hydroxybutyrate (PHB). Metab Eng 53:14–23. https://doi.org/10.1016/j.ymben.2019.01.003

Lerman JA, Hyduke DR, Latif H, Portnoy VA, Lewis NE, Orth JD, Schrimpe-Rutledge AC, Smith RD, Adkins JN, Zengler K, Palsson BO (2012) In silico method for modelling metabolism and gene product expression at genome scale. Nat Commun 3:1–10. https://doi.org/10.1038/ncomms1928

Levett I, Birkett G, Davies N, Bell A, Langford A, Laycock B, Lant P, Pratt S (2016) Techno-economic assessment of poly-3-hydroxybutyrate (PHB) production from methane - The case for thermophilic bioprocessing. J Environ Chem Eng 4:3724–3733. https://doi.org/10.1016/j.jece.2016.07.033

Li CT, Yelsky J, Chen Y, Zuñiga C, Eng R, Jiang L, Shapiro A, Huang KW, Zengler K, Betenbaugh MJ (2019) Utilizing genome-scale models to optimize nutrient supply for sustained algal growth and lipid productivity. npj Syst. Biol Appl 5:1–11. https://doi.org/10.1038/s41540-019-0110-7

Lopar M, Špoljarić IV, Cepanec N, Koller M, Braunegg G, Horvat P (2014) Study of metabolic network of Cupriavidus necator DSM 545 growing on glycerol by applying elementary flux modes and yield space analysis. J Ind Microbiol Biotechnol 41:913–930. https://doi.org/10.1007/s10295-014-1439-y

Lopez-Arenas T, González-Contreras M, Anaya-Reza O, Sales-Cruz M (2017) Analysis of the fermentation strategy and its impact on the economics of the production process of PHB (polyhydroxybutyrate). Comput Chem Eng 107:140–150. https://doi.org/10.1016/j.compchemeng.2017.03.009

Mahadevan R, Edwards JS, Doyle FJ (2002) Dynamic flux balance analysis of diauxic growth in Escherichia coli. Biophys J 83:1331–1340. https://doi.org/10.1016/S0006-3495(02)73903-9

Mahadevan R, Schilling CH (2003) The effects of alternate optimal solutions in constraint-based genome-scale metabolic models. Metab Eng 5:264–276. https://doi.org/10.1016/j.ymben.2003.09.002

Mendoza SN, Olivier BG, Molenaar D, Teusink B (2019) A systematic assessment of current genome-scale metabolic reconstruction tools. Genome Biol 20:1–20. https://doi.org/10.1186/s13059-019-1769-1

Moncada J, El-Halwagi MM, Cardona CA (2013) Techno-economic analysis for a sugarcane biorefinery: Colombian case. Bioresour Technol 135:533–543. https://doi.org/10.1016/j.biortech.2012.08.137

Monk J, Nogales J, Palsson BO (2014) Optimizing genome-scale network reconstructions. Nat Biotechnol. https://doi.org/10.1038/nbt.2870

Monshupanee T, Incharoensakdi A (2014) Enhanced accumulation of glycogen, lipids and polyhydroxybutyrate under optimal nutrients and light intensities in the cyanobacterium Synechocystis sp. PCC 6803. J Appl Microbiol 116:830–838. https://doi.org/10.1111/jam.12409