Abstract

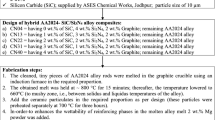

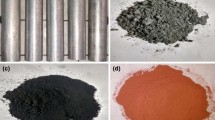

In this investigation, aluminum alloy (AA2024) composite reinforced with ceramic particulates, namely alumina (Al2O3) and aluminum nitride (AlN), were designed and fabricated through a semi-automatic stir casting route. The ceramics are added complementary (0–4 wt% @ step of 1%), resulting in five composite specimens, namely ON04, ON13, ON22, ON31, and ON40. The composite specimens are then analyzed for their densities, mechanical, and tribological behavior (steady-state sliding wear analysis), adopting ASTM standards. The Taguchi design of experiment technique was adopted for planning test preliminaries and input sliding wear operating parameters (like sliding velocity, sliding distance, normal load, composition, and environment temperature) optimization using ANOVA. Worn surface morphology studies were reported using a scanning electron microscope (SEM) along with energy-dispersive X-ray spectroscopy (EDS) to understand prevalent wear mechanisms in real time. Additionally, a decision-making technique such as the preference selection index (PSI) system was used to analyze the alloy composites ranking. The theoretical densities vary 2.784–2.798 g/cc, while actual densities vary 2.539–2.546 g/cc, and voids fraction vary within the 0.5–9.3 % range. The hardness varies 71.6–85.4 HRB, impact strength varies 54–170 J, and tensile strength varies 190–265 MPa. The ranking orders of the significance of input operating factors are environment temperature > normal load > sliding velocity > reinforcement content > sliding distance. It has been found that the alloy composite sample ON22 with an equal presence of both ceramics exhibits overall optimum mechanical properties as well as superior steady-state behavior, which was consistent with the results of the PSI ranking method.

Similar content being viewed by others

References

M. Kumar, A. Kumar, Sliding wear performance of graphite reinforced AA6061 alloy composites for rotor drum/disk application. Mater. Today Proc. 27, 1972–1976 (2019). https://doi.org/10.1016/j.matpr.2019.09.042

M. Bai, Q. Xue, Q. Ge, Wear of 2024 Al-Mo-SiC composites under lubrication. Wear 195, 100–105 (1996). https://doi.org/10.1016/0043-1648(95)06808-2

K.N. Mathan, K.S. Senthil, L.A. Kumaraswamidhas, Aerospace application on Al 2618 with reinforced – Si3N4, AlN and ZrB2 in-situ composites. J. Alloys Compd. 672, 238–250 (2016). https://doi.org/10.1016/j.jallcom.2016.02.155

A. Baradeswaran, A. Elayaperumal, I.R. Franklin, A statistical analysis of optimization of wear behaviour of Al- Al2O3 composites using taguchi technique. Procedia Eng. 64, 973–982 (2013). https://doi.org/10.1016/j.proeng.2013.09.174

B.C. Kandpal, J. Kumar, H. Singh, Fabrication and characterisation of Al2O3/aluminium alloy 6061 composites fabricated by Stir casting. Mater. Today Proc. 4, 2783–2792 (2017). https://doi.org/10.1016/j.matpr.2017.02.157

S.J. Hong, H.M. Kim, D. Huh et al., Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater. Sci. Eng. A 347, 198–204 (2003). https://doi.org/10.1016/S0921-5093(02)00593-2

G.Q. Chen, W.S. Yang, K. Ma et al., Aging and thermal expansion behavior of Si3N4p/2024Al composite fabricated by pressure infiltration method. Trans. Nonferrous Met. Soc. China 21, s262–s273 (2011). https://doi.org/10.1016/S1003-6326(11)61589-6

R. Abhijith, T.M. Harish, Fabrication analysis of aluminium (Al-2024) and tungsten carbide (WC) metal matrix composite by in-situ method. Int J Eng Res V5, 400–407 (2016). https://doi.org/10.17577/ijertv5is080332

S. Pournaderi, F. Akhlaghi, Wear behaviour of Al6061-Al2O3 composites produced by in-situ powder metallurgy (IPM). Powder Technol. 313, 184–190 (2017). https://doi.org/10.1016/j.powtec.2017.03.019

F. Akhlaghi, A. Zare-Bidaki, Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024-graphite composites produced by in situ powder metallurgy method. Wear 266, 37–45 (2009). https://doi.org/10.1016/j.wear.2008.05.013

N. Hosseini, F. Karimzadeh, M.H. Abbasi, M.H. Enayati, A comparative study on the wear properties of coarse-grained Al6061 alloy and nanostructured Al6061-Al2O3 composites. Tribol Int 54, 58–67 (2012). https://doi.org/10.1016/j.triboint.2012.04.020

R.S.J. David, I. Dinaharan, P.S. Vibin, P.M. Mashinini, Microstructure and mechanical characterization of in situ synthesized AA6061/(TiB2+Al2O3) hybrid aluminum matrix composites. J. Alloys Compd. 740, 529–535 (2018). https://doi.org/10.1016/j.jallcom.2018.01.016

G. Iacob, V.G. Ghica, M. Buzatu et al., Studies on wear rate and micro-hardness of the Al/Al2O3/Gr hybrid composites produced via powder metallurgy. Compos. Part B Eng. 69, 603–611 (2015). https://doi.org/10.1016/j.compositesb.2014.07.008

P. Sharma, S. Sharma, D. Khanduja, Production and some properties of Si3N4 reinforced aluminium alloy composites. J. Asian Ceram. Soc. 3, 352–359 (2015). https://doi.org/10.1016/j.jascer.2015.07.002

K. Umanath, K. Palanikumar, S.T. Selvamani, Analysis of dry sliding wear behaviour of Al6061/SiC/Al2O3 hybrid metal matrix composites. Compos. Part B Eng. 53, 159–168 (2013). https://doi.org/10.1016/j.compositesb.2013.04.051

A. Devaraju, A. Kumar, B. Kotiveerachari, Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061–T6 hybrid composites via friction stir processing. Trans. Nonferrous Met. Soc. China 23, 1275–1280 (2013). https://doi.org/10.1016/S1003-6326(13)62593-5

S. Dharmalingam, R. Subramanian, V.K. Somasundara, B. Anandavel, Optimization of tribological properties in aluminum hybrid metal matrix composites using gray-taguchi method. J Mater Eng Perform 20, 1457–1466 (2011). https://doi.org/10.1007/s11665-010-9800-4

M. Kok, Abrasive wear of Al2O3 particle reinforced 2024 aluminium alloy composites fabricated by vortex method. Compos. Part A Appl. Sci. Manuf. 37, 457–464 (2006). https://doi.org/10.1016/j.compositesa.2005.05.038

I. Ozdemir, S. Muecklich, H. Podlesak, B. Wielage, Thixoforming of AA 2017 aluminum alloy composites. J. Mater. Process Technol. 211, 1260–1267 (2011). https://doi.org/10.1016/j.jmatprotec.2011.02.008

S. Bhaskar, M. Kumar, A. Patnaik, Silicon carbide ceramic particulate reinforced AA2024 alloy composite - part I: evaluation of mechanical and sliding tribology performance. SILICON 12, 843–865 (2020). https://doi.org/10.1007/s12633-019-00181-x

S. Bhaskar, M. Kumar, A. Patnaik, Microstructure, thermal, thermo-mechanical and fracture analyses of hybrid AA2024-SiC alloy composites. Trans. Indian Inst. Met. 73, 181–190 (2020). https://doi.org/10.1007/s12666-019-01819-5

S. Bhaskar, M. Kumar, A. Patnaik, Application of hybrid AHP-TOPSIS technique in analyzing material performance of silicon carbide ceramic particulate reinforced AA2024 alloy composite. SILICON 12, 1075–1084 (2020). https://doi.org/10.1007/s12633-019-00211-8

A. Patnaik, P. Kumar, S. Biswas, M. Kumar, Investigations on micro-mechanical and thermal characteristics of glass fiber reinforced epoxy based binary composite structure using finite element method. Comput. Mater. Sci. 62, 142–151 (2012). https://doi.org/10.1016/j.commatsci.2012.05.020

A. Kumar, A. Patnaik, I.K. Bhat, Effect of titanium metal powder on thermo- mechanical and sliding wear behavior of Al7075/Ti alloy composites for gear application. Mater. Today Proc. 5, 16919–16927 (2018). https://doi.org/10.1016/j.matpr.2018.04.095

A. Kumar, A. Patnaik, I.K. Bhat, Tribology analysis of cobalt particulate filled Al 7075 alloy for gear materials: a comparative study. SILICON 11, 1295–1311 (2018). https://doi.org/10.1007/s12633-018-9920-2

D. Petković, M. Madić, M. Radovanović, V. Gečevska, Application of the performance selection index method for solving machining mcdm problems. Facta Univ. Ser. Mech. Eng. 15, 97 (2017). https://doi.org/10.22190/FUME151120001P

R. Attri, S. Grover, Application of preference selection index method for decision making over the design stage of production system life cycle. J. King Saud Univ. – Eng. Sci. 27, 207–216 (2015). https://doi.org/10.1016/j.jksues.2013.06.003

K. Jha, S. Chamoli, Y.K. Tyagi, H.O. Maurya, Characterization of biodegradable composites and application of preference selection index for deciding optimum phase combination. Mater. Today Proc. 5, 3353–3360 (2018). https://doi.org/10.1016/j.matpr.2017.11.579

R. Khorshidi, A. Hassani, Comparative analysis between TOPSIS and PSI methods of materials selection to achieve a desirable combination of strength and workability in Al/SiC composite. Mater. Des. 52, 999–1010 (2013). https://doi.org/10.1016/j.matdes.2013.06.011

M. Panahi, H. Gitinavard, Evaluating the sustainable mining contractor selection problems: an imprecise last aggregation preference selection index method. J. Sustain. Min. 16, 207–218 (2018). https://doi.org/10.1016/j.jsm.2017.12.006

K.T. Mesran, D.S. Ronda, T.W. Fince, Determination of education scholarship recipients using preference selection index. Sci. Technol. 3, 230–234 (2017)

S.Y. Jian, S.J. Tao, X.R. Huang, Preference selection index method for machine selection in a flexible manufacturing cell. Adv. Mater. Res. 1078, 290–293 (2014). https://doi.org/10.4028/www.scientific.net/AMR.1078.290

M. Rahimian, N. Ehsani, N. Parvin, H.R. Baharvandi, The effect of particle size, sintering temperature and sintering time on the properties of Al-Al2O3 composites, made by powder metallurgy. J. Mater. Process Technol. 209, 5387–5393 (2009). https://doi.org/10.1016/j.jmatprotec.2009.04.007

A. Mazahery, M.O. Shabani, Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting. Trans. Nonferrous Met. Soc. China 23, 1905–1914 (2013). https://doi.org/10.1016/S1003-6326(13)62676-X

K.S. Santhosh, M. Devaiah, B.V. Seshu, T. Rajasekharan, Mechanical properties of SiC p /Al2O3 ceramic matrix composites prepared by directed oxidation of an aluminum alloy. Ceram. Int. 38, 1139–1147 (2012). https://doi.org/10.1016/j.ceramint.2011.08.042

B.M. Mahendra, K.P. Arulshri, N. Iyandurai, Evaluation of mechanical properties of Aluminium alloy 2024 reinforced with silicon carbide and fly ash hybrid metal matrix composites. Am. J. Appl. Sci. 10, 219–229 (2013). https://doi.org/10.3844/ajassp.2013.219.229

S. Wilson, A.T. Alpas, Effect of temperature on the sliding wear performance of Al alloys and Al matrix composites. Wear 196, 270–278 (1996). https://doi.org/10.1016/0043-1648(96)06923-2

P. Ravindran, K. Manisekar, P. Rathika, P. Narayanasamy, Tribological properties of powder metallurgy - Processed aluminium self lubricating hybrid composites with SiC additions. Mater. Des. 45, 561–570 (2013). https://doi.org/10.1016/j.matdes.2012.09.015

B.A. Kumar, Murugan n, Dinaharan I, Dry sliding wear behavior of stir cast AA6061-T6/AlNp composite. Trans. Nonferrous Met. Soc. China 24, 2785–2795 (2014). https://doi.org/10.1016/S1003-6326(14)63410-5

S. Mahdavi, F. Akhlaghi, Effect of the graphite content on the tribological behavior of Al/Gr and Al/30SiC/Gr composites processed by in situ powder metallurgy (IPM) method. Tribol. Lett. 44, 1–12 (2011). https://doi.org/10.1007/s11249-011-9818-2

S. Gangwar, A. Patnaik, I.K. Bhat, Tribological and thermomechanical analysis of CaO (quicklime) particulates filled ZA-27 alloy composites for bearing application. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 232, 20–34 (2018). https://doi.org/10.1177/1464420715609196

H.Y. Chu, J.F. Lin, Experimental analysis of the tribological behavior of electroless nickel-coated graphite particles in aluminum matrix composites under reciprocating motion. Wear 239, 126–142 (2000). https://doi.org/10.1016/S0043-1648(00)00316-1

D. Lu, M. Gu, Z. Shi, Materials transfer and formation of mechanically mixed layer in dry sliding wear of metal matrix composites against steel. Tribol. Lett. 6, 57–61 (1999). https://doi.org/10.1023/A:1019182817316

Y.H. Chae, S.S. Kim, Sliding wear behavior of ceramic, plasma sprayed on casting aluminum alloy against SiC ball. Tribol. Lett. 8, 35–40 (2000). https://doi.org/10.1023/A:1019110512715

K.N. Tandon, Z.C. Feng, X.Y. Li, Wear behavior of SiC particulate reinforced aluminum composites sliding against steel balls under dry and lubricated conditions. Tribol. Lett. 6, 113–122 (1999). https://doi.org/10.1023/A:1019155505930

A. Kumar, M. Kumar, Fracture toughness and thermal investigations of al7075: cobalt particulates reinforced alloy composites prepared using high vacuum casting method for gear applications: proposed thermal conductivity and fracture toughness modeling. Inter. J. Metal Casting. (2022). https://doi.org/10.1007/s40962-022-00901-x

A. Kumar, M. Kumar, Investigations on physical, mechanical and sliding wear assessment of ZA27 -Gr alloy composites using preference selection Index Method. Inter. J. Metal Casting (2023). https://doi.org/10.1007/s40962-022-00953-z

Acknowledgements

The authors express their sincere gratitude to the Department of Mechanical Engineering of Malaviya National Institute of Technology, Jaipur-302017, Rajasthan, INDIA, for their all kinds of financial as well as other miscellaneous infrastructural support. The authors also acknowledge the aid and facilities provided by the Advanced Research Lab for Tribology and Material Research Centre of the Institute for experimentation and characterization work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest concerning this article's research, authorship, and publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, M., Kumar, R., Bhaskar, S. et al. Parametric Optimization and Ranking Analysis of AA2024−Al2O3/AlN Alloy Composites Fabricated Via Stir Casting Route Under Dry Sliding Wear Investigation. Inter Metalcast 18, 667–687 (2024). https://doi.org/10.1007/s40962-023-01053-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01053-2