Abstract

Aim

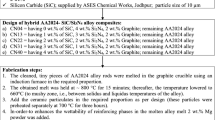

The novelty of this research work lies in (i) designing and fabrication of hybrid AA356-Al2O3/SiC/Graphite alloy composite materials via semi-automatic stir casting method as per the standard industrial procedure. The ceramic particulates Al2O3/SiC were reinforced in a complementary manner (0–8 wt.%, in the step of 2%) along with constant 3 wt.% of graphite bringing about five alloy composite specimens namely SA-08, SA-26, SA-44, SA-62, and SA-80 respectively.

Methodology

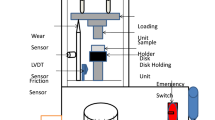

The prepared specimens were explored for any synergistic effect of ceramic combinations on physical (density and void content), mechanical (tensile strength, flexural strength, impact strength and hardness), and sliding wear performance adopting ASTM standards. Simultaneously, optimization of sliding wear process parameters (like sliding velocity, sliding distance, normal load, etc.) using the Taguchi design of experiment and Grey Relational Analysis techniques were explored. Further, surface micrographs were analyzed to understand the underlying wear mechanisms and elemental presence/dispersion over the worn-out surfaces. Thereafter, the ranking of compositions was analyzed using a hybrid AHP-GRA material selection method for optimal selection and recommendations.

Results

It has been found that both Taguchi and GRA techniques were effective in parameter optimization and gives an attuned outcome. Composition, SA-44 hybrid alloy composite, having the equal presence of both the ceramic particulates tend to optimize the overall performance criteria. The results of ranking obtained by hybrid AHP-GRA analysis attunes to the subjective analysis.

Similar content being viewed by others

References

Bhaskar S, Kumar M, Patnaik A (2019) A review on tribological and mechanical properties of Al alloy composites. Mater Today Proc. 25:810–815. https://doi.org/10.1016/j.matpr.2019.09.032

Bhaskar S, Kumar M, Patnaik A (2019) Mechanical and Tribological overview of ceramic particulates reinforced aluminium alloy composites. Rev Adv Mater Sci 58:280–294

Bhaskar S, Kumar M, Patnaik A (2019) Microstructure, thermal, thermo-mechanical and fracture analyses of hybrid AA2024-SiC alloy composites. Trans Indian Inst Metals 73:181–190. https://doi.org/10.1007/s12666-019-01819-5

Kumar MSA, Kumar KCM, Prasad SLA (2018) Experimental investigations on mechanical and Tribological properties of extruded Aluminium A356 - Al2O3 stir cast MMC. Mater Today Proc 5:3044–3051. https://doi.org/10.1016/j.matpr.2018.01.105

Prasad Reddy A, Vamsi Krishna P, Narasimha Rao R, Murthy NV (2017) Silicon carbide reinforced Aluminium metal matrix Nano composites-a review. Mater Today Proc 4:3959–3971. https://doi.org/10.1016/j.matpr.2017.02.296

Alhawari KS, Omar MZ, Ghazali MJ, Salleh MS, Mohammed MN (2013) Wear properties of A356/Al2O3 metal matrix composites produced by semisolid processing. Procedia Eng 68:186–192. https://doi.org/10.1016/j.proeng.2013.12.166

Ghandvar H, Idris MH, Ahmad N, Moslemi N (2017) Microstructure development, mechanical and tribological properties of a semisolid A356/xSiCp composite. J Appl Res Technol 15:533–544. https://doi.org/10.1016/j.jart.2017.06.002

Mazahery A, Shabani MO (2012) Characterization of cast A356 alloy reinforced with nano SiC composites. Trans nonferrous met Soc China (English Ed 22:275–280. https://doi.org/10.1016/S1003-6326(11)61171-0

Sajjadi SA, Torabi Parizi M, Ezatpour HR, Sedghi A (2012) Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J Alloys Compd 511:226–231. https://doi.org/10.1016/j.jallcom.2011.08.105

Amouri K, Kazemi S, Momeni A, Kazazi M (2016) Microstructure and mechanical properties of Al-nano/micro SiC composites produced by stir casting technique. Mater Sci Eng A 674:569–578. https://doi.org/10.1016/j.msea.2016.08.027

Shivamurthy RC, Surappa MK (2011) Tribological characteristics of A356 Al alloy-SiCP composite discs. Wear 271:1946–1950. https://doi.org/10.1016/j.wear.2011.01.075

Radhika N, Subramaniam R, Venkat PS (2011) Tribological behaviour of aluminium/alumina/graphite hybrid metal matrix composites using Taguchi’s techniques. J Miner Mater Charact Eng 10:427–443. https://doi.org/10.1108/00368791311311169

Basavarajappa S, Chandramohan G, Paulo Davim J (2007) Application of Taguchi techniques to study dry sliding wear behaviour of metal matrix composites. Mater Des 28:1393–1398. https://doi.org/10.1016/j.matdes.2006.01.006

Wang X (2019) Application of Grey relation analysis theory to choose high reliability of the network node. J Phys Conf Ser 1237:1–5. https://doi.org/10.1088/1742-6596/1237/3/032056

Hasani H, Tabatabaei SA, Amiri G (2012) Grey relational analysis to determine the optimum process parameters for open-end spinning yarns. J Eng Fiber Fabr 7:81–86. https://doi.org/10.1177/155892501200700212

Pandya VJ, Rathod PP (2019) Optimization of mechanical properties of green composites by gray relational analysis. Mater Today Proc 27:8–11. https://doi.org/10.1016/j.matpr.2019.08.166

Tharian BK, Jacob E, Johnson J, Hari V (2019) Multi-objective parametric optimization in EDM using grey relational analysis. Mater Today Proc 16:1013–1019. https://doi.org/10.1016/j.matpr.2019.05.190

Kanchana J, Prasath V, Krishnaraj V, Geetha Priyadharshini B (2019) Multi response optimization of process parameters using grey relational analysis for milling of hardened custom 465 steel. Procedia Manuf 30:451–458. https://doi.org/10.1016/j.promfg.2019.02.064

Manivelmuralidaran V, Senthilkumar K (2020) Multi objective optimization of cold crack susceptibility of high strength low alloy steel 950A using Grey relational analysis. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.11.326

Hubeatir KA (2020) Laser transmission welding of PMMA using IR semiconductor laser complemented by the Taguchi method and grey relational analysis. Mater Today Proc 20:466–473. https://doi.org/10.1016/j.matpr.2019.09.167

Kuo Y, Yang T, Huang GW (2008) The use of grey relational analysis in solving multiple attribute decision-making problems. Comput Ind Eng 55:80–93. https://doi.org/10.1016/j.cie.2007.12.002

Jeyaprakash N, Yang C-H, Raj Kumar D (2019) Machinability study on CFRP composite using Taguchi based grey relational analysis. Mater Today Proc 21:1425–1431. https://doi.org/10.1016/j.matpr.2019.08.212

Hussain MZ, Khan S, Sarmah P (2019) Optimization of powder metallurgy processing parameters of Al2O3/cu composite through Taguchi method with Grey relational analysis. J King Saud Univ - Eng Sci 32:274–286. https://doi.org/10.1016/j.jksues.2019.01.003

Wu C-R, Lin C-T, Lin Y-C (2009) The best prophylaxis if medical disputes via the AHP-GRA model. J Stat Manag Syst 12:47–58. https://doi.org/10.1080/09720510.2009.10701372

Pitchipoo P, Venkumar P, Rajakarunakaran S (2013) Modeling and development of a decision support system for supplier selection in the process industry. J Ind Eng Int 9:1–15. https://doi.org/10.1186/2251-712X-9-23

Akcan S, Guldes M (2019) Integrated multicriteria decision-making methods to solve supplier selection problem: a case study in a hospital. J Healthc Eng 2019:. https://doi.org/10.1155/2019/5614892, 2019, 1, 10

(1999) Material Properties Charts

(1990) ASM Handbook Properties and Selection: Non ferrous alloys and special purpose materials. ASM International

Bhaskar S, Kumar M, Patnaik A (2019) Silicon carbide ceramic particulate reinforced AA2024 alloy composite - part I: evaluation of mechanical and sliding tribology performance. Silicon. 12:843–865. https://doi.org/10.1007/s12633-019-00181-x

Bhaskar S, Kumar M, Patnaik A (2019) Application of hybrid AHP-TOPSIS technique in analyzing material performance of silicon carbide ceramic particulate reinforced AA2024 alloy composite. Silicon. 12:1075–1084. https://doi.org/10.1007/s12633-019-00211-8

ASTM standards (2013) D792–13: Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. In: ASTM Int.

Kumar M, Kumar A (2019) Sliding wear performance of graphite reinforced AA6061 alloy composites for rotor drum/disk application. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.09.042

Kumar A, Kumar M (2019) Mechanical and dry sliding wear behaviour of B4C and rice husk ash reinfroced Al 7075 alloy hybrid composite for armors application by using taguchi techniques. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.11.075

Sallehuddin R, Mariyam S, Shamsuddin H, et al (2008) Grey Relational Analysis And Its Application On Multivariate Time Series . Proc IEEE Int Conf Intell Syst Des Appl (Vol 2) 1–8. https://doi.org/10.1109/ISDA.2008.181

Srikanth K, Nandan TDH, Naidu KK, Shaik S (2019) Analysis of Tribological characteristics using GRA for Aluminium hybrid composites

Acknowledgments

The author expresses their sincere gratitude to the Department of Mechanical Engineering of Malaviya National Institute of Technology, Jaipur-302017, Rajasthan, INDIA for their all kind of financial as well as other miscellaneous infrastructural support. The authors also acknowledge the aid and facilities provided by the Advanced Research Lab for Tribology and Material Research Centre of the Institute for experimentation and characterization work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The author(s) declared no potential conflicts of interest concerning the research, authorship, and publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, M. Mechanical and Sliding Wear Performance of AA356-Al2O3/SiC/Graphite Alloy Composite Materials: Parametric and Ranking Optimization Using Taguchi DOE and Hybrid AHP-GRA Method. Silicon 13, 2461–2477 (2021). https://doi.org/10.1007/s12633-020-00544-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00544-9