Abstract

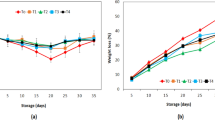

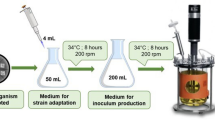

The study on fermentation kinetics of the coconut inflorescence sap is important to understand its shelf life at different storage conditions and to develop suitable value added products. The coconut inflorescence sap collected by using in-house developed coco-sap chiller device is called Kalparasa. The fermentation characteristics of Kalparasa were investigated at every 1-h interval under ambient (31 ± 2 °C) and refrigerated (5 ± 1 °C) storage conditions. The results reveal that pH of the sap and total sugar content decline rapidly under ambient conditions than under refrigerated conditions. Acidity, turbidity, and reducing sugar content significantly (p < 0.001) increases for the sap stored under ambient conditions. The reaction rate constant (k) of the vitamin C and total sugar degradation increases with the atmospheric fermentation. The degradation kinetics of vitamin C and total sugar in Kalparasa during natural fermentation (ambient condition) follow second-order equation whereas the reducing sugar follows the first-order equation.

Similar content being viewed by others

References

Adetuyi FO, Ibrahim TA (2014) Effect of fermentation time on the phenolic, flavonoid and vitamin C contents and antioxidant activities of okra (Abelmoschus esculentus) seeds. Nigerian Food J 32(2):128–137. https://doi.org/10.1016/S0189-7241(15)30128-4

AOAC (2000) Official methods of analysis of AOAC international, 17th edn. Association of Analytical Chemists International, Gaithersburg, MD

Aparajhitha S, Mahendran R (2019) Effect of plasma bubbling on free radical production and its subsequent effect on the microbial and physicochemical properties of Coconut Neera. Innov Food SciEmergTechnol 58(1–9):102230. https://doi.org/10.1016/j.ifset.2019.102230

Atputharajah JD, Widanapathirana S, Samarajeewa U (1986) Microbiology and biochemistry of natural fermentation of coconut palm sap. Food Microbiol 3(4):273–280. https://doi.org/10.1016/0740-0020(86)90009-2

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Che 28(3):350–356. https://doi.org/10.1021/ac60111a017

Ghosh S, Chakraborty R, Chatterjee G, Raychaudhuri U (2012) Study on fermentation conditions of palm juice vinegar by response surface methodology and development of a kinetic model. Braz J ChemEng 29(3):461–472. https://doi.org/10.1590/S0104-66322012000300003

Ghosh DK, Bandyopadhyay A, Das S, Hebbar K, Biswas B (2018) Coconut sap (Neera)-untapped opportunity of spinoff gains in West Bengal, India. Int J CurrMicrobiolApplSci 7:1883–1897

Gupta RC, Jain VK, Shanker G (1980) Palm sap as a potential starting material for vinegar production. Res Indu 25:5–7

Hebbar KB, Mathew AC, Arivalagan M, Samsudeen K, Thomas GV (2013) Value added products from Neera. Indian Coconut J 56(4):28–33

Hebbar KB, Arivalagan M, Manikantan MR, Mathew AC, Thamban C, Thomas GV, Chowdappa P (2015) Coconut inflorescence sap and its value addition as sugar-collection techniques, yield, properties and market perspective. Curr Sci 1411–1417. https://www.jstor.org/stable/24905994

Hebbar KB, Pandiselvam R, Manikantan MR, Arivalagan M, Beegum S, Chowdappa P (2018) Palm sap—quality profiles, fermentation chemistry, and preservation methods. Sugar Technol 20(6):621–634. https://doi.org/10.1007/s12355-018-0597-z

Hernández T, Estrella I, Pérez-Gordo M, Alegría EG, Tenorio C, Ruiz-Larrrea F, Moreno-Arribas MV (2007) Contribution of malolactic fermentation by Oenococcusoeni and Lactobacillus plantarum to the changes in the nonanthocyaninpolyphenolic composition of red wine. J Agric Food Chem 55(13):5260–5266. https://doi.org/10.1021/jf063638o

Iwuoha CI, Eke OS (1996) Nigerian indigenous fermented foods: their traditional process operation, inherent problems, improvements and current status. Food Res Int 29(5–6):527–540. https://doi.org/10.1016/0963-9969(95)00045-3

Jaiswal AK, Abu-Ghannam N (2013) Kinetic studies for the preparation of probiotic cabbage juice: impact on phytochemicals and bioactivity. Ind Crops Prod 50:212–218. https://doi.org/10.1016/j.indcrop.2013.07.028

Kalaiyarasi K, Sangeetha K, Rajarajan S (2013) A comparative study on the microbial flora of the fresh sap from cut inflorescence and fermented sap (toddy) of Borrassusflabellifer Linn (Palmyrah tree) and of Cocos nucifera Linn (Coconut tree) to identify the microbial fermenters. Int J Res Pure ApplMicrobiol 3(3):43–47

Kaprasob R, Kerdchoechuen O, Laohakunjit N, Sarkar D, Shetty K (2017) Fermentation-based biotransformation of bioactive phenolics and volatile compounds from cashew apple juice by select lactic acid bacteria. Process Biochem 59:141–149. https://doi.org/10.1016/j.procbio.2017.05.019

Kaya Z, Unluturk S (2016) Processing of clear and turbid grape juice by a continuous flow UV system. Innov Food SciEmergTechnol 33:282–288. https://doi.org/10.1016/j.ifset.2015.12.006

Li W, Pang X, Xiao J, Wang X, He R, Zhao X (2020) Degradation kinetics of pelargonidin-3-(p-coumaroyl) diglucoside-5-(malonyl) glucoside and pelargonidin-3-(feruloyl) diglucoside-5-(malonyl) glucoside in red radish during air-impingement jet drying. LWT Food SciTechnol 127:109390. https://doi.org/10.1016/j.lwt.2020.109390

Ngoc NTM, Minh NP, Dao DTA (2013) Isolation and characterization of yeast strains for palm (Borassus Flabelliffer) wine fermentation. Int J Eng Res Technol 2(11):3602–3615

Ogbulie TE, Ogbulie JN, Njoku HO (2007) Comparative study on the microbiology and shelf life stability of palm wine from Elaeis guineensis and Raphia hookeri obtained from Okigwe, Nigeria. Afr J Biotechnol 6(7):914–922. https://www.ajol.info/index.php/ajb/article/view/56944

Ou HP, Wang CC, Lai LS (2009) Thermal degradation kinetics analysis of monacolin K in Monascus-fermented products. LWT Food SciTechnol 42(1):292–296. https://doi.org/10.1016/j.lwt.2008.05.021

Pandiselvam R, Thirupathi V, Anandakumar S (2015) Reaction kinetics of ozone gas in paddy grains. J Food Process Eng 38(6):594–600. https://doi.org/10.1111/jfpe.12189

Pandiselvam R, Kothakota A, Thirupathi V, Anandakumar S, Krishnakumar P (2017b) Numerical simulation and validation of ozone concentration profile in green gram (Vigna radiate) bulks. Ozone SciEng 39(1):54–60. https://doi.org/10.1080/01919512.2016.1244641

Pandiselvam R, Sunoj S, Manikantan MR, Kothakota A, Hebbar KB (2017a) Application and kinetics of ozone in food preservation. Ozone SciEng 39(2):115–126. https://doi.org/10.1080/01919512.2016.1268947

Pandiselvam R, Thirupathi V, Chandrasekar V, Kothakota A, Anandakumar S (2018) Numerical simulation and validation of mass transfer process of ozone gas in rice grain bulks. Ozone SciEng 40(3):191–197. https://doi.org/10.1080/01919512.2017.1404902

Peerajan S, Chaiyasut C, Sirilun S, Chaiyasut K, Kesika P, Sivamaruthi BS (2016) Enrichment of nutritional value of Phyllanthusemblica fruit juice using the probiotic bacterium, Lactobacillus paracasei HII01 mediated fermentation. Food SciTechnol 36(1):116–123. https://doi.org/10.1590/1678-457X.0064

Ramalakshmi K, Nidheesh T, Chanukya BS, Jagan Mohan Rao L (2018) Changes in quality profile and flavour components of coconut sap during natural fermentation. Food Nut Curr Res 1(3):70–76

Santos CCADA, Duarte WF, Carreiro SC, Schwan RF (2013) Inoculated fermentation of orange juice (Citrus sinensis L.) for production of a citric fruit spirit. Journal of the Institute of Brewing 119(4):280–287 doi: https://doi.org/10.1002/jib.89

ShameenaBeegum PP, Manikantan MR, Pandiselvam R, Arivalagan M, Hebbar KB (2018) Comparative evaluation of natural vinegar produced from mature coconut water and coconut inflorescence sap. Int J InnovHortic 7(2):123–127

Shetty P, D’Souza A, Poojari S, Narayana J, Rajeeva P (2017) Study of fermentation kinetics of palm sap from Cocos nucifera. Int J ApplSciBiotechnol 5(3):375–381. https://doi.org/10.3126/ijasbt.v5i3.18297

Siebert TE, Smyth HE, Capone DL, Neuwöhner C, Pardon KH, Skouroumounis GK., ... Pollnitz AP (2005) Stable isotope dilution analysis of wine fermentation products by HS-SPME-GC-MS. Anal Bioanal Chem 381(4):937-947. doi: https://doi.org/10.1007/s00216-004-2992-4

Somogyi M (1952) Determination of reducing sugars by Nelson-Somogyi method. J BiolChem 200:245

Wang Y, Chen C, Cai D, Wang Z, Qin P, Tan T (2016) The optimization of L-lactic acid production from sweet sorghum juice by mixed fermentation of Bacillus coagulans and Lactobacillus rhamnosus under unsterile conditions. BioresourTechnol 218:1098–1105. https://doi.org/10.1016/j.biortech.2016.07.069

Xia Q, Li R, Zhao S, Chen W, Chen H, Xin B, ... & Tang M (2011) Chemical composition changes of post-harvest coconut inflorescence sap during natural fermentation. Afr J Biotechnol 10(66):14999-15005 doi: https://doi.org/10.5897/AJB10.2602

Xiang Q, Liu X, Li J, Liu S, Zhang H, Bai Y (2018) Effects of dielectric barrier discharge plasma on the inactivation of Zygosaccharomycesrouxii and quality of apple juice. Food Chem 254:201–207. https://doi.org/10.1016/j.foodchem.2018.02.008

Ysidor KNG, Jean-Louis KK, Roger KB, Rachel AR, Joëlle ODM, Emmanuel IA, Marius BGH (2015) Changes in physicochemical parameters during storage of the inflorescence sap derived from four coconut (Cocos nucifera L.) varieties in Côte d’Ivoire. J Exp Agric Int 352–365 https://doi.org/https://doi.org/10.9734/AJEA/2015/11035

Acknowledgements

Authors are grateful to Indian Council of Agricultural Research (ICAR) for the financial support for the research. The support provided by The Director, ICAR-CPCRI is highly appreciated.

Funding

This work was funded by Indian Council of Agricultural Research (ICAR). Grant Number: 1000767018.

Author information

Authors and Affiliations

Contributions

RP: Conceptualization; Methodology; Original draft writing. MRM: Writing—review & editing; Supervision. SMB, SVR, SB and MG: Methodology; Writing—original draft. KBH and ACM: Project administration; Resources. AK, RK and SS: Reaction kinetics & Modelling.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Ethical approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandiselvam, R., Manikantan, M.R., Binu, S.M. et al. Reaction kinetics of physico-chemical attributes in coconut inflorescence sap during fermentation. J Food Sci Technol 58, 3589–3597 (2021). https://doi.org/10.1007/s13197-021-05088-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05088-3