Abstract

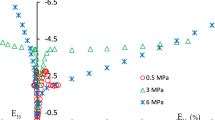

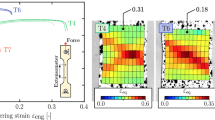

In the present investigation, a coupled crystal plasticity finite-element (CPFE) and cellular automaton (CA) model was developed to predict the microstructure of recrystallization in single-crystal (SX) Ni-based superalloy. The quasi-static compressive tests of [001] orientated SX DD6 superalloy were conducted on Gleeble3500 tester to calibrate the CPFE model based on crystal slip kinematics. The simulated stress–strain curve agrees well with the experimental results. Quantitative deformation amount was introduced in the deformed samples of simulation and experiment, and these samples were subsequently subjected to the standard solution heat treatment (SSHT). Results of CA simulation show that the recrystallization (RX) nucleation tends to occur at the third stage of SSHT process due to the high critical temperature of RX nucleation for the samples deformed at room temperature. The inhomogeneous RX grains gradually coarsen and compete to reach more stable status by reducing the system energy. Simulated RX grain density decreases from 7.500 to 1.875 mm−1, agreeing well with the value of 1.920 mm−1 from electron backscattered diffraction (EBSD) detection of the experimental sample.

Similar content being viewed by others

References

Reed RC. The superalloys fundamentals and applications. New York: Cambridge University Press; 2006. 1.

Perepezko JH. The hotter the engine, the better. Science. 2009;326(5956):1068.

Meng XB, Li JG, Chen ZQ, Wang YH, Zhu SZ, Bai XF, Wang F, Zhang J, Jin T, Sun XF, Hu ZQ. Effect of platform dimension on the dendrite growth and stray grain formation in a Ni-base single-crystal superalloy. Metall Mater Trans A. 2012;44(4):1955.

Meng XB, Li JG, Zhu SZ, Du HQ, Yuan ZH, Wang J, Jin T, Sun XF, Hu ZQ. Method of stray grain inhibition in the platforms with different dimensions during directional solidification of a Ni-base superalloy. Metall Mater Trans A. 2013;45(3):1230.

Aveson JW, Tennant PA, Foss BJ, Shollock BA, Stone HJ, Souza ND. On the origin of sliver defects in single crystal investment castings. Acta Mater. 2013;61(14):5162.

Meng J, Jin T, Sun X, Hu Z. Effect of surface recrystallization on the creep rupture properties of a nickel-base single crystal superalloy. Mater Sci Eng A. 2010;527(23):6119.

Zhang B, Lu X, Liu D, Tao C. Influence of recrystallization on high-temperature stress rupture property and fracture behavior of single crystal superalloy. Mater Sci Eng A. 2012;551:149.

He YH, Hou XQ, Tao CH, Han FK. Recrystallization and fatigue fracture of single crystal turbine blades. Eng Fail Anal. 2011;18(3):944.

Wang DL, Jin T, Yang SQ, Wei Z, Li JB, Hu ZQ. Surface recrystallization and its effect on rupture life of SRR99 single crystal superalloy. Mater Sci Forum. 2007;546–549:1229.

Zhang B, Liu C, Lu X, Tao C, Jiang T. Effect of surface recrystallization on the creep rupture property of a single-crystal superalloy. Rare Met. 2010;29(4):413.

Zhuo L, Liang S, Wang F, Xu T, Wang Y, Yuan Z, Xiong J, Li J, Zhu J. Kinetics and microstructural evolution during recrystallization of a single crystal superalloy. Mater Charact. 2015;108:16.

Wang L, Xie G, Zhang J, Lou LH. On the role of carbides during the recrystallization of a directionally solidified nickel-base superalloy. Scr Mater. 2006;55(5):457.

Wang L, Pyczak F, Zhang J, Lou LH, Singer RF. Effect of eutectics on plastic deformation and subsequent recrystallization in the single crystal nickel base superalloy CMSX-4. Mater Sci Eng A. 2012;532:487.

Wu Y, Yang R, Li S, Ma Y, Gong S, Han Y. Surface recrystallization of a Ni3Al based single crystal superalloy at different annealing temperature and blasting pressure. Rare Met. 2012;31(3):209.

Cox DC, Roebuck B, Rae C, Reed RC. Recrystallisation of single crystal superalloy CMSX-4. Mater Sci Technol. 2003;19(4):440.

Mathur HN, Panwisawas C, Jones CN, Reed RC, Rae CMF. Nucleation of recrystallisation in castings of single crystal Ni-based superalloys. Acta Mater. 2017;129:112.

Zhuo L, Xu T, Wang F, Xiong J, Zhu J. Microstructural evolution on the initiation of sub-solvus recrystallization of a grit-blasted single-crystal superalloy. Mater Lett. 2015;148:159.

Zhang H, Xu Q. Multi-scale simulation of directional dendrites growth in superalloys. J Mater Process Technol. 2016;238:132.

Tang N, Wang YL, Xu QY, Zhao XH, Liu BC. Numerical simulation of directional solidified microstructure of wide-chord aero blade by Bridgeman process. Acta Metal Sin. 2015;51(4):499.

Wang R, Yan X, Li Z, Xu Q, Liu B. Effect of construction manner of mould cluster on stray grain formation in dummy blade of DD6 superalloy. High Temp Mater Process. 2017;36(4):399.

Zhang W, Liu L. Solidification microstructure of directionally solidified superalloy under high temperature gradient. Rare Met. 2012;31(6):541.

Liu G, Liu L, Han Z, Zhang G, Zhang J. Solidification behavior of Re- and Ru-containing Ni-based single-crystal superalloys with thermal and metallographic analysis. Rare Met. 2017;36(10):792.

Chun YB, Hwang SK. Monte carlo modeling of microstructure evolution during the static recrystallization of cold-rolled, commercial-purity titanium. Acta Mater. 2006;54(14):3673.

Crumbach M, Gottstein G. Modelling of recrystallisation textures in aluminium alloys: i. Model set-up and integration. Acta Mater. 2006;54(12):3275.

Crumbach M, Gottstein G. Modelling of recrystallisation textures in aluminium alloys: ii. Model performance and experimental validation. Acta Mater. 2006;54(12):3291.

Li Z, Xu Q, Liu B. Microstructure simulation on recrystallization of an as-cast nickel based single crystal superalloy. Comput Mater Sci. 2015;107:122.

Zambaldi C, Roters F, Raabe D, Glatzel U. Modeling and experiments on the indentation deformation and recrystallization of a single-crystal nickel-base superalloy. Mater Sci Eng A. 2007;454:433.

Taylor GI. Plastic strain in metals. J Inst Met. 1938;62:307.

Hill R. A self-consistent mechanics of composite materials. J Mech Phys Solids. 1965;13:213.

Hill R, Rice JR. Constitutive analysis of elastic-plastic crystals at arbitrary strain. J Mech Phys Solids. 1972;20:401.

Peirce D, Asaro RJ, Needleman A. Material rate dependence and localized deformation in crystalline solids. Acta Metall. 1983;31:1951.

Zambaldi C, Zehnder C, Raabe D. Orientation dependent deformation by slip and twinning in magnesium during single crystal indentation. Acta Metall. 2015;91:267.

Eidel B. Crystal plasticity finite-element analysis versus experimental results of pyramidal indentation into (001) fcc single crystal. Acta Metall. 2011;59(4):1761.

Li Z, Xu Q, Liu B. Experimental investigation on recrystallization mechanism of a Ni-base single crystal superalloy. J Alloys Compd. 2016;672:457.

Editorial committee. Engineering Materials Handbook. Beijing: Standards Press of China; 2001. 812.

Porter AJ, Ralph B. Ralph, Recrystallization of a nickel-base superalloy: kinetics and microstructural development. Mater Sci Eng. 1983;59(1):69.

Li Z, Fan X, Xu Q, Liu B. Influence of deformation temperature on recrystallization in a Ni-based single crystal superalloy. Mater Lett. 2015;160:318.

Acknowledgements

This study was financially supported by the National Key R&D Program of China (No. 2017YFB0701503) and the National Basic Research Program of China (No. 2011CB706801).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, RN., Xu, QY. & Liu, BC. A model for simulation of recrystallization microstructure in single-crystal superalloy. Rare Met. 37, 1027–1034 (2018). https://doi.org/10.1007/s12598-018-1093-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1093-z