Abstract

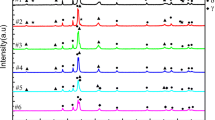

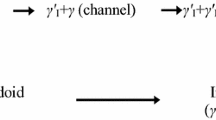

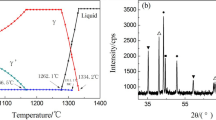

To clarify the solidification behavior of Re- and Ru-containing Ni-based single-crystal superalloys, four experimental alloys with varied contents of Re and Ru were investigated by differential scanning calorimetry (DSC) and metallographic techniques. To obtain the γ′-solvus temperatures, the stepwise solution and aging heat treatments were used. DSC analysis shows that Re leads to the increase in freezing range and γ′-solvus temperature. On the contrast, Ru only has negligible influence on the freezing range, but leads to the lower γ′-solvus temperature. In comparison with Ru, Re leads to more severe segregation and higher eutectic fractions in as-cast microstructures. Furthermore, the castability and phase stability of Ni-based superalloys were analyzed by the results of DSC and metallographic analysis, such as freezing range, critical nucleation temperature, γ′-solvus temperature and eutectic fractions. It shows that Re leads to the wider freezing range and lower critical nucleation temperature, indicating the worse castability of Re-containing Ni-based single-crystal superalloys.

Graphical Abstract

The characteristic phase transformation temperatures of Re-containing single-crystal superalloy are determined by DSC analysis. For as-cast samples, the liquidus, solidus, critical nucleation and eutectic reaction temperature are clearly shown in DSC curves. After a stepwise solution and aging heat treatments, the higher amount of γ′ phase with cubic morphology can be obtained. Finally, the precipitation temperature of γ′ phase is determined by DSC analysis for the heat-treated samples.

Similar content being viewed by others

References

Reed RC, Tao T, Warnken N. Alloy-by-design: application to nickel-based single crystal superalloys. Acta Mater. 2009;57(19):5898.

Chen JY, Cao LM, Xue M, Liu LJ. Microstructure and stress rupture property of an experimental single crystal Ni-base superalloy with different heat treatments. Rare Met. 2014;33(2):144.

Xu KD, Ren ZM, Li CJ. Progress in application of rare metals in superalloys. Rare Met. 2014;33(2):111.

Han YF, Ma WY, Dong ZQ, Li SS, Gong SK. Effects of ruthenium on microstructure and stress rupture properties of a single crystal nickel-base superalloy. In: Superalloys 2008 Conference. Warrendale; 2008. 91.

Rae CMF, Reed RC. The precipitation of topological close-packed phases in rhenium-containing superalloys. Acta Mater. 2001;49(19):4113.

Hobbs RA, Zhang L, Rae CMF, Tin S. The effect of ruthenium on the intermediate to high temperature creep response of high refractory content single crystal nickel-base superalloy. Mater Sci Eng A. 2008;489(1–2):65.

Gao S, Zhou YZ, Li CF, Cui JP, Liu ZQ, Jin T. In situ investigation on the precipitation of topologically close packed phase in Ni-base single crystal superalloy. J Alloys Compd. 2014;610(15):589.

Hegde SR, Kearsey RM, Beddoes JC. Designing homogenization-solution heat treatments for single crystal superalloys. Mater Sci Eng A. 2010;527(21):5528.

Li FL, Fu R, Feng D, Tian ZL. Hot workability characteristics of Rene88DT superalloy with directionally solidified microstructure. Rare Met. 2015;34(1):51.

Liu L, Huang TW, Qu M, Liu G, Zhang J, Fu HZ. High thermal gradient directional solidification and its application in the processing of nickel-based superalloys. Mater Process Technol. 2010;210(1):159.

Beckermann C, Gu JP, Boettinger WJ. Development of a freckle predictor via rayleigh number method for single crystal nickel-base superalloy casting. Metall Mater Trans A. 2000;31(10):2545.

Kurz W, Fisher DJ. Fundamentals of Solidification. Enfield, Switzerland: Trans Tech Publications Ltd.; 1998. 69.

Caron P. High γ′ solvus new generation nickel-based superalloys for single crystal turbine blade applications. In: Superalloys 2000 Conference. Warrendale; 2000. 737.

Tian SG, Wang MG, Li T, Quan BJ, Xie J. Influence of TCP phase and its morphology on creep properties of single crystal nickel-based superalloys. Mater Sci Eng A. 2010;527(21–22):5444.

D’Souza N, Dong HB. An analysis of solidification path in the Ni-base superalloy CMSX-10K. In: Superalloys 2008 Conference. Warrendale; 2008. 261.

Liu G, Liu L, Ai C, Ge BM, Zhang J, Fu HZ. Influence of withdrawal rate on the microstructure of Ni-base single-crystal superalloys containing Re and Ru. J Alloys Compd. 2011;509(19):5866.

Acknowledgments

This study was financially supported by the National High Technology Research and Development Program of China (No. 2012AA03A511), the National Natural Science Foundation of China (Nos. 51171151 and 51331005), the State Key Laboratory of Solidification Processing in Northwestern Polytechnical University (No. SKLSP201310), the Science and Technology Program of Shaanxi Province (No. 2013JQ6003) and the Research Foundation of Education Bureau of Shaanxi Province (No. 2013JK0898).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, G., Liu, L., Han, ZH. et al. Solidification behavior of Re- and Ru-containing Ni-based single-crystal superalloys with thermal and metallographic analysis. Rare Met. 36, 792–798 (2017). https://doi.org/10.1007/s12598-016-0755-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0755-y