Abstract

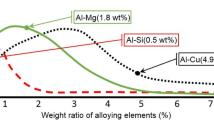

Selective laser melting (SLM) technology based on atomized powder was used to fabricate Al–8.5Fe–1.3V–1.7Si (wt%) alloy parts. The microstructure and crack characterization of SLM samples fabricated at various conditions were presented. Results show that the cracks appear periodically along the building direction, initiate preferably at the outer edges of the as-built samples and propagated along the remelting border zone (RBZ) into deposited layers. Solid-phase cracking is proposed according to the fracture morphology. The thermal-induced residual stress during SLM combined with the precipitation of relatively large-sized AlmFe phase in the RBZ results in the formation of cracks. Enhancing scanning speed and hatch distance enable to reduce the cracking sensitivity. The crack-free Al–8.5Fe–1.3V–1.7Si parts can be fabricated at optimized parameters of laser power of 320 W, scanning speed of 1000 mm·s−1 and hatch distance of 0.10 mm along with proper laser pre-heating procedure. The samples built horizontally show good ultimate tensile properties of 454 MPa in average with the elongation of 7.2%.

Similar content being viewed by others

References

Skinner DJ, Bye RL, Raybould D. Dispersion strengthened Al–Fe–V–Si alloys. Scr Metall. 1986;20(6):867.

Skinner DJ, Kim YW, Griffith WM. Dispersion Strengthened Aluminium Alloys. Warrendale: TMS; 1988. 181.

Frank RE, Hawk JA. Effect of very high temperatures on the mechanical properties of Al–Fe–V–Si alloy. Scr Metall. 1989;23(1):113.

Khatri SC, Lawley A, Koczak MJ, Grassett KG. Creep and microstructural stability of dispersion strengthened Al–Fe–V–Si–Er alloy. Mater Sci Eng A. 1993;167(1–2):11.

Hariprasad S, Sastry SML, Jerina KL, Lederich RJ. Microstructures and mechanical properties of dispersion-strengthened high-temperature Al–8.5Fe–1.2V–1.7Si alloys produced by atomized melt deposition process. Metall Trans A. 1993;24(4):865.

Hariprasad S, Sastry SML, Jerina KL. Deformation behavior of a rapidly solidified fine grained Al–8.5%Fe–1.2%V–1.7%Si alloy. Acta Mater. 1996;44(1):383.

Yan QQ, Fu DF, Deng XF, Zhang H, Chen ZH. Tensile deformation behavior of spray-deposited FVS0812 heat-resistant aluminum alloy sheet at elevated temperatures. Mater Charact. 2007;58(6):575.

Yao B, Ma XL, Lin F, Ge WJ. Microstructure and mechanical properties of Ti–6Al–4V components fabricated by laser micro cladding deposition. Rare Met. 2015;34(7):445.

Shao JZ, Li J, Song R, Bai L, Chen JL, Qu CC. Microstructure and wear behaviors of TiB/TiC reinforced Ti2Ni/α (Ti) matrix coating produced by laser cladding. Rare Met. 2016. doi:10.1007/s12598-016-0787-3.

Thijs L, Kempen K, Kruth JP, Humbeeck JV. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10 Mg powder. Acta Mater. 2013;61(5):1809.

Read N, Wang W, Essa K, Attallah MM. Selective laser melting of AlSi10 Mg alloy: process optimisation and mechanical properties development. Mater Des. 2015;65:417.

Brandl E, Heckenberger U, Holzinger V, Buchbinder D. Additive manufactured AlSi10 Mg samples using selective laser melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater Des. 2012;34:159.

Sun SB, Zheng LJ, Liu YY, Liu JH, Zhang H. Selective laser melting of Al–Fe–V–Si heat-resistant aluminum alloy powder: modeling and experiments. Int J Adv Manuf Technol. 2015;80(9):1787.

Sun SB, Zheng LJ, Liu YY, Liu JH, Zhang H. Characterization of Al–Fe–V–Si heat-resistant aluminum alloy components fabricated by selective laser melting. J Mater Res. 2015;30(10):1661.

Cao X, Wallace W, Immarigeon JP, Poon C. Research and progress in laser welding of wrought aluminum alloys. II. Metallurgical microstructures, defects, and mechanical properties. Mater Manuf Process. 2003;18(1):23.

Wang J, Wang HP, Wang X, Cui H, Lu F. Statistical analysis of process parameters to eliminate hot cracking of fiber laser welded aluminum alloy. Opt Laser Eng. 2015;66:15.

Kou S. Welding Metallurgy. 2nd ed. Hoboken: Wiley; 2003. 50.

Ghost SK, Partha S. Crack and wear behavior of SiC particulate reinforced aluminum based metal matrix composite fabricated by direct laser sintering process. Mater Des. 2012;32(1):139.

Yaneva S, Petrov K, Petrov R, Stoichev N, Avdeev G, Kuziak R. Influence of silicon content on phase development in Al–Fe–V–Si alloys. Mater Sci Eng A. 2009;515(1):59.

Lu Y, Wu S, Gan Y, Huang T, Yang C, Junjie L, Lin J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt Laser Eng. 2015;75:197.

Mei Y, Liu Y, Liu C, Li C, Yu L, Guo Q, Li H. Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718. Mater Des. 2016;89:964.

Hussein A, Hao L, Yan C, Everson R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater Des. 2013;52:638.

Alimardani M, Toyserkani E, Huissoon JP, Paul CP. On the delamination and crack formation in a thin wall fabricated using laser solid freeform fabrication process: an experimental-numerical investigation. Opt Laser Eng. 2009;47(11):1160.

Mercelis P, Kruth JP. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp J. 2006;12(5):254.

Harrison NJ, Todd I, Mumtaz K. Reduction of micro-cracking in nickel superalloys processed by selective laser melting: a fundamental alloy design approach. Acta Mater. 2015;94:59.

Moat RJ, Pinkerton AJ, Li L, Withers PJ, Preuss M. Residual stresses in laser direct metal deposited Waspaloy. Mater Sci Eng A. 2011;528(6):2288.

Ding J, Colegrove P, Mehnen J, Ganguly S, Almeida PS, Wang F, Williams S. Thermo-mechanical analysis of wire and arc additive layer manufacturing process on large multi-layer parts. Comput Mater Sci. 2011;50(12):3315.

Yang J, Li F, Wang Z, Zeng X. Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication. J Mater Process Technol. 2015;225:229.

Jia QB, Gu DD. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: densification, microstructure and properties. J Alloys Compd. 2014;585:713.

Hu B, Richardson IM. Mechanism and possible solution for transverse solidification cracking in laser welding of high strength aluminium alloys. Mater Sci Eng A. 2006;429(1):287.

Wang F, Zhu BH, Xiong BQ, Zhang YG, Liu HW, Zhang RH. An investigation on the microstructure and mechanical properties of spray-deposited Al–8.5Fe–1.1V–1.9Si alloy. J Mater Process Technol. 2007;183(2–3):386.

Acknowledgements

This study was financially supported by the National High-Tech Program of China (No. 21100002013101006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, SB., Zheng, LJ., Liu, JH. et al. Microstructure, cracking behavior and control of Al–Fe–V–Si alloy produced by selective laser melting. Rare Met. 42, 1353–1362 (2023). https://doi.org/10.1007/s12598-016-0846-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0846-9