Abstract

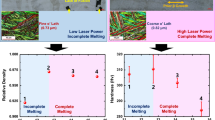

Many studies have investigated the selective laser melting (SLM) of AlSi10Mg and AlSi7Mg alloys, but there are still lack of researches focused on Al−Si−Mg alloys specifically tailored for SLM. In this work, a novel high Mg-content AlSi8Mg3 alloy was specifically designed for SLM. The results showed that this new alloy exhibited excellent SLM processability with a lowest porosity of 0.07%. Massive lattice distortion led to a high Vickers hardness in samples fabricated at a high laser power due to the precipitation of Mg2Si nanoparticles from the α-Al matrix induced by high-intensity intrinsic heat treatment during SLM. The maximum microhardness and compressive yield strength of the alloy reached HV (211 ± 4) and (526 ± 12) MPa, respectively. After aging treatment at 150°C, the maximum microhardness and compressive yield strength of the samples were further improved to HV (221 ± 4) and (577 ± 5) MPa, respectively. These values are higher than those of most known aluminum alloys fabricated by SLM. This paper provides a new idea for optimizing the mechanical properties of Al−Si−Mg alloys fabricated using SLM.

Similar content being viewed by others

Change history

10 August 2022

An Erratum to this paper has been published: https://doi.org/10.1007/s12613-022-2530-4

References

C.A. Biffi, J. Fiocchi, and A. Tuissi, Selective laser melting of AlSi10Mg: Influence of process parameters on Mg2Si precipitation and Si spheroidization, J. Alloys Compd., 755(2018), p. 100.

Y. Yang, Y. Chen, J.X. Zhang, X.H. Gu, P. Qin, N.W. Dai, X.P. Li, J.P. Kruth, and L.C. Zhang, Improved corrosion behavior of ultrafine-grained eutectic Al−12Si alloy produced by selective laser melting, Mater. Des., 146(2018), p. 239.

D. Jafari and W.W. Wits, The utilization of selective laser melting technology on heat transfer devices for thermal energy conversion applications: A review, Renewable Sustainable Energy Rev., 91(2018), p. 420.

Y.K. Xiao, Z.Y. Bian, Y. Wu, G. Ji, Y.Q. Li, M.J. Li, Q. Lian, Z. Chen, A. Addad, and H.W. Wang, Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting, J. Alloys Compd., 798(2019), p. 644.

J. Suryawanshi, K.G. Prashanth, S. Scudino, J. Eckert, O. Prakash, and U. Ramamurty, Simultaneous enhancements of strength and toughness in an Al−12Si alloy synthesized using selective laser melting, Acta Mater., 115(2016), p. 285.

I. Rosenthal, R. Shneck, and A. Stern, Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process, Mater. Sci. Eng. A, 729(2018), p. 310.

Y.C. Bai, Y.Q. Yang, Z.F. Xiao, M.K. Zhang, and D. Wang, Process optimization and mechanical property evolution of AlSiMg0.75 by selective laser melting, Mater. Des., 140(2018), p. 257.

K. Schmidtke, F. Palm, A. Hawkins, and C. Emmelmann, Process and mechanical properties: Applicability of a scandium modified Al-alloy for laser additive manufacturing, Phys. Procedia, 12(2011), p. 369.

Q.B. Jia, P. Rometsch, P. Kürnsteiner, Q. Chao, A.J. Huang, M. Weyland, L. Bourgeois, and X.H. Wu, Selective laser melting of a high strength Al−Mn−Sc alloy: Alloy design and strengthening mechanisms, Acta Mater., 171(2019), p. 108.

L. Thijs, K. Kempen, J.P. Kruth, and J.V. Humbeeck, Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder, Acta Mater., 61(2013), No. 5, p. 1809.

Y. Cao, X. Lin, Q.Z. Wang, S.Q. Shi, L. Ma, N. Kang, and W.D. Huang, Microstructure evolution and mechanical properties at high temperature of selective laser melted AlSi10Mg, J. Mater. Sci. Technol., 62(2021), p. 162.

T. Kimura, T. Nakamoto, T. Ozaki, K. Sugita, M. Mizuno, and H. Araki, Microstructural formation and characterization mechanisms of selective laser melted Al−Si−Mg alloys with increasing magnesium content, Mater. Sci. Eng. A, 754(2019), p. 786.

J. Wu, X.Q. Wang, W. Wang, M.M. Attallah, and M.H. Loretto, Microstructure and strength of selectively laser melted AlSi10Mg, Acta Mater., 117(2016), p. 311.

Y.X. Geng, S.M. Fan, J.L. Jian, S. Xu, Z.J. Zhang, H.B. Ju, L.H. Yu, and J.H. Xu, Mechanical properties of AlSiMg alloy specifically designed for selective laser melting, Acta Metall. Sin., 56(2020), No. 6, p. 821.

Y.X. Geng, Y.M. Wang, J.H. Xu, S.B. Mi, S.M. Fan, Y.K. Xiao, Y. Wu, and J.H. Luan, A high-strength AlSiMg1.4 alloy fabricated by selective laser melting, J. Alloys Compd., 867(2021), art. No. 159103.

M. Fousová, D. Dvorský, A. Michalcová, and D. Vojtěch, Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures, Mater. Charact., 137(2018), p. 119.

J.H. Rao, Y. Zhang, K. Zhang, A.J. Huang, C.H.J. Davies, and X.H. Wu, Multiple precipitation pathways in an Al−7Si−0.6Mg alloy fabricated by selective laser melting, Scripta Mater., 160(2019), p. 66.

K.V. Yang, P. Rometsch, C.H.J. Davies, A.J. Huang, and X.H. Wu, Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting, Mater. Des., 154(2018), p. 275.

U.S. Bertoli, A.J. Wolfer, M.J. Matthews, J.P.R. Delplanque, and J.M. Schoenung, On the limitations of volumetric energy density as a design parameter for selective laser melting, Mater. Des., 113(2017), p. 331.

K.G. Prashanth, S. Scudino, T. Maity, J. Das, and J. Eckert, Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett., 5(2017), No. 6, p. 386.

L.Z. Wang, S. Wang, and J.J. Wu, Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting, Opt. Laser Technol., 96(2017), p. 88.

C. Weingarten, D. Buchbinder, N. Pirch, W. Meiners, K. Wissenbach, and R. Poprawe, Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg, J. Mater. Process. Technol., 221(2015), p. 112.

L. Zhao, J.G.S. Macías, L.P. Ding, H. Idrissi, and A. Simar, Damage mechanisms in selective laser melted AlSi10Mg under as built and different post-treatment conditions, Mater. Sci. Eng. A, 764(2019), art. No. 138210.

J.L. Lu, X. Lin, H.L. Liao, N. Kang, W.D. Huang, and C. Coddet, Compression behaviour of quasicrystal/Al composite with powder mixture driven layered microstructure prepared by selective laser melting, Opt. Laser Technol., 129(2020), art. No. 106277.

J. Bi, Z.L. Lei, Y.B. Chen, X. Chen, Z. Tian, J.W. Liang, X.K. Qin, and X.R. Zhang, Densification, microstructure and mechanical properties of an Al−14.1Mg−0.47Si−0.31Sc−0.17Zr alloy printed by selective laser melting, Mater. Sci. Eng. A, 774(2020), art. No. 138931.

J.H. Rao, Y. Zhang, X.Y. Fang, Y. Chen, X.H. Wu, and C.H.J. Davies, The origins for tensile properties of selective laser melted aluminium alloy A357, Addit. Manuf., 17(2017), p. 113.

D. Feng, G.Y. Wang, H.M. Chen, and X.M. Zhang, Effect of grain size inhomogeneity of ingot on dynamic softening behavior and processing map of Al−8Zn−2Mg−2Cu alloy, Met. Mater. Int., 24(2018), No. 1, p. 195.

P. Ponnusamy, S.H. Masood, D. Ruan, S. Palanisamy, and R. Rashid, High strain rate dynamic behaviour of AlSi12 alloy processed by selective laser melting, Int. J. Adv. Manuf. Technol., 97(2018), No. 1–4, p. 1023.

D.R. Manca, A.Y. Churyumov, A.V. Pozdniakov, D.K. Ryabov, V.A. Korolev, and D.K. Daubarayte, Novel heat-resistant Al−Si−Ni−Fe alloy manufactured by selective laser melting, Mater. Lett., 236(2019), p. 676.

P. Wei, Z.Y. Wei, Z. Chen, J. Du, Y.Y. He, J.F. Li, and Y.T. Zhou, The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior, Appl. Surf. Sci., 408(2017), p. 38.

N. Kang, P. Coddet, C.Y. Chen, Y. Wang, H.L. Liao, and C. Coddet, Microstructure and wear behavior of in situ hypereutectic Al-high Si alloys produced by selective laser melting, Mater. Des., 99(2016), p. 120.

L. Xi, P. Wang, K.G. Prashanth, H. Li, H.V. Prykhodko, S. Scudino, and I. Kaban, Effect of TiB2 particles on microstructure and crystallographic texture of Al−12Si fabricated by selective laser melting, J. Alloys Compd., 786(2019), p. 551.

Y. Zhou, S.F. Wen, C. Wang, L.C. Duan, Q.S. Wei, and Y.S. Shi, Effect of TiC content on the Al−15Si alloy processed by selective laser melting: Microstructure and mechanical properties, Opt. Laser Technol., 120(2019), art. No. 105719.

X.P. Li, G. Ji, Z. Chen, A. Addad, Y. Wu, H.W. Wang, J. Vleugels, J.V. Humbeeck, and J.P. Kruth, Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility, Acta Mater., 129(2017), p. 183.

L.Z. Wang, T. Chen, and S. Wang, Microstructural characteristics and mechanical properties of carbon nanotube reinforced AlSi10Mg composites fabricated by selective laser melting, Optik, 143(2017), p. 173.

G. Xue, L.D. Ke, H.H. Zhu, H.L. Liao, J.J. Zhu, and X.Y. Zeng, Influence of processing parameters on selective laser melted SiCp/AlSi10Mg composites: Densification, microstructure and mechanical properties, Mater. Sci. Eng. A, 764(2019), art. No. 138155.

Y.J. Shi, P. Rometsch, K. Yang, F. Palm, and X.H. Wu, Characterisation of a novel Sc and Zr modified Al−Mg alloy fabricated by selective laser melting, Mater. Lett., 196(2017), p. 347.

Q.B. Jia, P. Rometsch, S. Cao, K. Zhang, and X.H. Wu, Towards a high strength aluminium alloy development methodology for selective laser melting, Mater. Des., 174(2019), art. No. 107775.

H. Tang, Y.X. Geng, S.N. Bian, J.H. Xu, and Z.J. Zhang, An ultra-high strength over 700 MPa in Al−Mn−Mg−Sc−Zr alloy fabricated by selective laser melting, Acta Metall. Sinica Engl. Lett., 35(2022), No. 3, p. 466.

Y.F. Wang, X. Lin, N. Kang, Z.H. Wang, Q.Z. Wang, Y.X. Liu, and W.D. Huang, Laser powder bed fusion of Zr-modified Al−Cu−Mg alloy: Crack-inhibiting, grain refinement, and mechanical properties, Mater. Sci. Eng. A, 838(2022), art. No. 142618.

X.J. Nie, H. Zhang, H.H. Zhu, Z.H. Hu, L.D. Ke, and X.Y. Zeng, Analysis of processing parameters and characteristics of selective laser melted high strength Al−Cu−Mg alloys: From single tracks to cubic samples, J. Mater. Process. Technol., 256(2018), p. 69.

M.L. Montero-Sistiaga, R. Mertens, B. Vrancken, X.B. Wang, B.V. Hooreweder, J.P. Kruth, and J.V. Humbeeck, Changing the alloy composition of Al7075 for better processability by selective laser melting, J. Mater. Process. Technol., 238(2016), p. 437.

S.Y. Sun, P. Liu, J.Y. Hu, C. Hong, X. Qiao, S.Y. Liu, R.Y. Zhang, and C.G. Wu, Effect of solid solution plus double aging on microstructural characterization of 7075 Al alloys fabricated by selective laser melting (SLM), Opt. Laser Technol., 114(2019), p. 158.

X.J. Nie, H. Zhang, H.H. Zhu, Z.H. Hu, L.D. Ke, and X.Y. Zeng, Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al−4.24Cu−1.97Mg−0.56Mn alloys, J. Alloys Compd., 764 (2018), p. 977.

N.T. Aboulkhair, I. Maskery, C. Tuck, I. Ashcroft, and N.M. Everitt, The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment, Mater. Sci. Eng. A, 667(2016), p. 139.

C.A. Biffi, J. Fiocchi, P. Bassani, and A. Tuissi, Continuous wave vs pulsed wave laser emission in selective laser melting of AlSi10Mg parts with industrial optimized process parameters: Microstructure and mechanical behaviour, Addit. Manuf., 24(2018), p. 639.

Y. Zhou, L.C. Duan, S.F. Wen, Q.S. Wei, and Y.S. Shi, Enhanced micro-hardness and wear resistance of Al−15Si/TiC fabricated by selective laser melting, Compos. Commun., 10(2018), p. 64.

P. Wang, C. Gammer, F. Brenne, T. Niendorf, J. Eckert, and S. Scudino, A heat treatable TiB2/Al−3.5Cu−1.5Mg−1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties, Composites Part B, 147(2018), p. 162.

R.D. Li, M.B. Wang, T.C. Yuan, B. Song, C. Chen, K.C. Zhou, and P. Cao, Selective laser melting of a novel Sc and Zr modified Al−6.2 Mg alloy: Processing, microstructure, and properties, Powder Technol., 319(2017), p. 117.

J. Bi, Z.L. Lei, Y.B. Chen, X. Chen, Z. Tian, J.W. Liang, X.R. Zhang, and X.K. Qin, Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting, Mater. Sci. Eng. A, 768(2019), art. No. 138478.

J. Bi, Z.L. Lei, X. Chen, P. Li, N.N. Lu, and Y.B. Chen, Microstructure and mechanical properties of TiB2-reinforced 7075 aluminum matrix composites fabricated by laser melting deposition, Ceram. Int., 45(2019), No. 5, p. 5680.

C. Varvenne, G.P.M. Leyson, M. Ghazisaeidi, and W.A. Curtin, Solute strengthening in random alloys, Acta Mater., 124(2017), p. 660.

Q. Wang, Z. Li, S.J. Pang, X.N. Li, C. Dong, and P.K. Liaw, Coherent precipitation and strengthening in compositionally complex alloys: A review, Entropy, 20(2018), No. 11, art. No. 878.

Acknowledgements

This work was financially supported by the the National Natural Science Foundation of China (Nos. 51801079 and 52001140), the Natural Science Foundation for Young Scientists of Jiangsu, China (Nos. BK20180985 and BK20180987), and the Open Foundation of Zhenjiang Key Laboratory for High Technology Research on Marine Functional Films (No. ZHZ2019001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest to this work.

Rights and permissions

About this article

Cite this article

Geng, Y., Tang, H., Xu, J. et al. Influence of process parameters and aging treatment on the microstructure and mechanical properties of AlSi8Mg3 alloy fabricated by selective laser melting. Int J Miner Metall Mater 29, 1770–1779 (2022). https://doi.org/10.1007/s12613-021-2287-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2287-1