Abstract

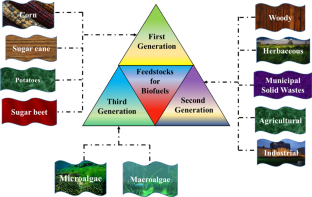

With the rise in global population, industrialization, and economic expansion, the persistent overconsumption of conventional fossil fuels has resulted in the depletion of fossil fuel reserves. This has fuelled the need to investigate and boost scientific research efforts on sustainable and renewable bioenergy feedstock. A substitute that can minimize reliance on nonrenewable energy resources while also lowering greenhouse gas emissions. In this context, biofuels have received a great deal of interest in recent years as a prospective substitute for conventional fossil fuels. The prime reason behind this is the feedstock utilized in their synthesis. The feedstocks employed here are environmentally safe, nontoxic, and emit little to no pollution. These feedstocks are classified into four generations: first, second, third, and fourth. Food crops and lignocellulosic biomass and waste constitute first- and second-generation feedstocks. The third- and fourth-generation feedstock is microalgae. This paper provides a comprehensive overview of feedstocks utilized to produce biofuels, including the various pre-treatment methods, strategies, and techno-economic analysis in order to pave the way for next-generation biofuels. It also covers the advantages, drawbacks, challenges, and current developments.

Similar content being viewed by others

Data Availability

All data and material used for preparing the manuscript appear in the submitted article.

References

Fang Y, Paul MC, Varjani S et al (2021) Concentrated solar thermochemical gasification of biomass: principles, applications, and development. Renew Sustain Energy Rev 150:111484. https://doi.org/10.1016/j.rser.2021.111484

Ramos JL, García-Lorente F, Valdivia M, Duque E (2017) Green biofuels and bioproducts: bases for sustainability analysis. Microb Biotechnol 10:1111–1113. https://doi.org/10.1111/1751-7915.12768

Papong S, Rewlay-ngoen C, Itsubo N, Malakul P (2017) Environmental life cycle assessment and social impacts of bioethanol production in Thailand. J Clean Prod 157:254–266. https://doi.org/10.1016/j.jclepro.2017.04.122

Pisarello ML, Maquirriain M, Sacripanti Olalla P et al (2018) Biodiesel production by transesterification in two steps: Kinetic effect or shift in the equilibrium conversion? Fuel Process Technol 181:244–251. https://doi.org/10.1016/j.fuproc.2018.09.028

Hirani AH, Javed N, Asif M et al (2018) A review on first-and second-generation biofuel productions. In: Biofuels: Greenhouse Gas Mitigation and Global Warming. Springer, New Delhi, pp 141–154. https://doi.org/10.1007/978-81-322-3763-1_8

Kumar P, Varkolu M, Mailaram S et al (2019) Biorefinery Polyutilization Systems : Production of Green Transportation Fuels From Biomass. Polygeneration with Polystorage for Chemical and Energy Hubs. pp 373–407. https://doi.org/10.1016/B978-0-12-813306-4.00012-4

Hassan SS, Williams GA, Jaiswal AK (2019) Moving towards the second generation of lignocellulosic biorefineries in the EU: drivers, challenges, and opportunities. Renew Sustain Energy Rev 101:590–599. https://doi.org/10.1016/j.rser.2018.11.041

Fiorentino G, Zucaro A, Ulgiati S (2019) Towards an energy efficient chemistry. Switching from fossil to bio-based products in a life cycle perspective. Energy 170:720–729. https://doi.org/10.1016/j.energy.2018.12.206

Leong WH, Lim JW, Lam MK et al (2018) Third generation biofuels: a nutritional perspective in enhancing microbial lipid production. Renew Sustain Energy Rev 91:950–961. https://doi.org/10.1016/j.rser.2018.04.066

Loredo-trevi A, Pinales-m D, Aguilar N et al (2021) Bioresource technology high-pressure technology for Sargassum spp biomass pretreatment and fractionation in the third generation of bioethanol production. Bioresour Technol 329:1–10. https://doi.org/10.1016/j.biortech.2021.124935

Abdullah B, Anuar S, Muhammad S et al (2019) Fourth generation biofuel: a review on risks and mitigation strategies. Renew Sustain Energy Rev 107:37–50. https://doi.org/10.1016/j.rser.2019.02.018

Atelge MR, Atabani AE, Banu JR et al (2020) A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 270:117494. https://doi.org/10.1016/j.fuel.2020.117494

Liu X, Lee C, Kim JY (2020) Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J Mater Cycles Waste Manag 22:1370–1381. https://doi.org/10.1007/s10163-020-01025-2

Hosseini Koupaie E, Dahadha S, Bazyar Lakeh AA et al (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production-a review. J Environ Manage 233:774–784. https://doi.org/10.1016/j.jenvman.2018.09.106

Solarte-Toro JC, Romero-García JM, Martínez-Patiño JC et al (2019) Acid pretreatment of lignocellulosic biomass for energy vectors production: a review focused on operational conditions and techno-economic assessment for bioethanol production. Renew Sustain Energy Rev 107:587–601. https://doi.org/10.1016/j.rser.2019.02.024

Tsegaye B, Balomajumder C, Roy P (2019) Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: an overview and future prospect. Bull Natl Res Cent 43:51. https://doi.org/10.1186/s42269-019-0094-x

Rajendran K, Drielak E, Sudarshan Varma V et al (2018) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production–a review. Biomass Convers Biorefinery 8:471–483. https://doi.org/10.1007/s13399-017-0269-3

Lee M, Lin YL, Chiueh P Te, Den W (2020) Environmental and energy assessment of biomass residues to biochar as fuel: a brief review with recommendations for future bioenergy systems. J Clean Prod 251:119714. https://doi.org/10.1016/j.jclepro.2019.119714

Pramanik SK, Suja FB, Zain SM, Pramanik BK (2019) The anaerobic digestion process of biogas production from food waste: prospects and constraints. Bioresour Technol Reports 8:100310. https://doi.org/10.1016/j.biteb.2019.100310

Jang Y, Malaviya A, Lee J et al (2013) Metabolic engineering of Clostridium acetobutylicum for the enhanced production of isopropanol-butanol-ethanol fuel mixture. Biotechnol Prog 29:1083–1088

Rezania S, Oryani B, Cho J et al (2020) Different pretreatment technologies of lignocellulosic biomass for bioethanol production: an overview. Energy 199:117457. https://doi.org/10.1016/j.energy.2020.117457

Su T, Zhao D, Khodadadi M, Len C (2020) Lignocellulosic biomass for bioethanol: recent advances, technology trends and barriers to industrial development. Curr Opin Green Sustain Chem. https://doi.org/10.1016/j.cogsc.2020.04.005

Manmai N, Unpaprom Y, Ramaraj R (2021) Bioethanol production from sunflower stalk: application of chemical and biological pretreatments by response surface methodology (RSM). Biomass Conv Bioref 11:1759–1773. https://doi.org/10.1007/s13399-020-00602-7

Yaashikaa PR, Kumar PS, Saravanan A et al (2020) Bioconversion of municipal solid waste into bio-based products: a review on valorisation and sustainable approach for circular bioeconomy. Sci Total Environ 748:141312

Susmozas A, Martín-Sampedro R, Ibarra D et al (2020) Process Strategies for the Transition of 1G to Advanced Bioethanol Production Processes. 8(10):1310. https://doi.org/10.3390/pr8101310

Costa D, Jesus J, Virgínio e Silva J et al (2018) Life cycle assessment of bioethanol production from sweet potato (Ipomoea batatas L.) in an experimental plant. Bioenerg Res 11:715–725. https://doi.org/10.1007/s12155-018-9932-1

Khan MT, Khan IA, Yasmeen S, Nizamani GS, Afghan S (2019) Sugarcane biofuels and bioenergy production in pakistan: current scenario, potential, and future avenues. Sugarcane Biofuels, 175-202. https://doi.org/10.1007/978-3-030-18597-8_9

Alavijeh RS, Karimi K, Berg C Van Den (2020) An integrated and optimized process for cleaner production of ethanol and biodiesel from corn stover by Mucor indicus. J Clean Prod 249:119321. https://doi.org/10.1016/j.jclepro.2019.119321

Sivamani S, Pandian A, Muthusamy C et al (2018) Evaluation of the potential of cassava-based residues for biofuels production. Rev Environ Sci Bio/Technology. https://doi.org/10.1007/s11157-018-9475-0

Kumar J, Reetu S (2014) Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. Biotech 5:337–353. https://doi.org/10.1007/s13205-014-0246-5

Manochio C, Andrade BR, Rodriguez RP, Moraes BS (2017) Ethanol from biomass: a comparative overview. Renew Sustain Energy Rev 80:743–755. https://doi.org/10.1016/j.rser.2017.05.063

Su T, Zhao D, Khodadadi M, Len C (2020) Lignocellulosic biomass for bioethanol: recent advances, technology trends, and barriers to industrial development. Curr Opin Green Sustain Chem 24:56–60. https://doi.org/10.1016/j.cogsc.2020.04.005

Chen L, Gu W, Gui X et al (2018) Complete genome sequence of Bacillus velezensis 157 isolated from Eucommia ulmoides with pathogenic bacteria inhibiting and lignocellulolytic enzymes production by SSF. 3 Biotech 8:114. https://doi.org/10.1007/s13205-018-1125-2

Prasad RK, Chatterjee S, Mazumder PB et al (2019) Bioethanol production from waste lignocelluloses: a review on microbial degradation potential. ECSN. https://doi.org/10.1016/j.chemosphere.2019.05.142

Dutta K, Daverey A, Lin J (2014) Evolution retrospective for alternative fuels: first to fourth generation. Renew Energy 69:114–122. https://doi.org/10.1016/j.renene.2014.02.044

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status , challenges , and optimization of a sustainable and renewable industry for biofuels , feed , and other products. Microb Cell Fact 17:36. https://doi.org/10.1186/s12934-018-0879-x

Jhang S, Lin Y, Chen K et al (2020) Evaluation of fuel consumption, pollutant emissions and well-to-wheel GHGs assessment from a vehicle operation fueled with bioethanol, gasoline and hydrogen. Energy 209:118436. https://doi.org/10.1016/j.energy.2020.118436

Riccio A, Chianese E, Tirimberio G, Prati MV (2017) Emission factors of inorganic ions from road traffic: a case study from the city of Naples ( Italy ). Transp Res Part D 54:239–249. https://doi.org/10.1016/j.trd.2017.05.008

Di P, Finore I, Poli A et al (2019) The production of second generation bioethanol: the biotechnology potential of thermophilic bacteria. J Clean Prod 233:1410–1417. https://doi.org/10.1016/j.jclepro.2019.06.152

Koehler N, Mccaherty J, Wilson C et al (2019) 2019 ETHANOL INDUSTRY OUTLOOK [Ebook] (1st ed.). Renewable Fuels Association. Retrieved 19 December 2021, from http://www.cornlp.com/Adobe/outlook2019.pdf

Niphadkar S, Bagade P, Ahmed S (2017) Bioethanol production: insight into past, present and future perspectives. Biofuels 0:1–10. https://doi.org/10.1080/17597269.2017.1334338

Pandiyan K, Singh A, Singh S et al (2019) Technological interventions for utilization of crop residues and weedy biomass for second generation bio-ethanol production. Renew Energy 132:723–741. https://doi.org/10.1016/j.renene.2018.08.049

Satari B, Karimi K, Kumar R (2019) Cellulose solvent-based pretreatment for enhanced second-generation biofuel production: a review. Royal Society of Chemistry

Ayodele BV, Alsaffar MA, Mustapa SI (2019) An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118857

Rastogi M, Shrivastava S (2017) Recent advances in second generation bioethanol production: an insight to pretreatment, sacchari fi cation and fermentation processes. Renew Sustain Energy Rev 80:330–340. https://doi.org/10.1016/j.rser.2017.05.225

Nair RB, Lennartsson PR, Taherzadeh MJ (2017) Bioethanol production from agricultural and municipal wastes. Current Developments in Biotechnology and Bioengineering 157–190. https://doi.org/10.1016/B978-0-444-63664-5.00008-3

Chen J, Zhang B, Luo L et al (2021) A review on recycling techniques for bioethanol production from lignocellulosic biomass. Renew Sustain Energy Rev 149:111370. https://doi.org/10.1016/j.rser.2021.111370

Sharma B, Larroche C, Dussap C (2020) Comprehensive assessment of 2G bioethanol production. Bioresour Technol 313:123630. https://doi.org/10.1016/j.biortech.2020.123630

Singh D, Sharma D, Soni SL et al (2020) A comprehensive review on 1st-generation biodiesel feedstock palm oil: production , engine performance , and exhaust emissions. Bioenerg Res 14:1–22. https://doi.org/10.1007/s12155-020-10171-2

Singh D, Sharma D, Soni SL et al (2019) Review article A review on feedstocks , production processes, and yield for different generations of biodiesel. Fuel 262:116553. https://doi.org/10.1016/j.fuel.2019.116553

Sawasdee V, Haosagul S, Pisutpaisal N (2019) ScienceDirect Co-digestion of waste glycerol and glucose to enhance biogas production. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2019.03.144

Fonseca JM, Teleken JG, Almeida VDC, Silva C (2019) Biodiesel from waste frying oils : Methods of production and puri fi cation. Energy Convers Manag 184:205–218. https://doi.org/10.1016/j.enconman.2019.01.061

Ambat I, Srivastava V, Sillanpää M (2018) Recent advancement in biodiesel production methodologies using various feedstock: a review. Renew Sustain Energy Rev 90:356–369. https://doi.org/10.1016/j.rser.2018.03.069

Mohanty SS, Koul Y, Varjani S et al (2021) A critical review on various feedstocks as sustainable substrates for biosurfactants production: a way towards cleaner production. Microb Cell Fact 20:1–13

Hosseinzadeh-bandbafha H, Tabatabaei M, Aghbashlo M, Khanali M (2018) A comprehensive review on the environmental impacts of diesel / biodiesel additives. Energy Convers Manag 174:579–614. https://doi.org/10.1016/j.enconman.2018.08.050

Hazrat MA, Rasul MG, Khan MMK et al (2019) ScienceDirect ScienceDirect ScienceDirect Emission characteristics of waste tallow and waste cooking oil Emission characteristics of waste on tallow waste cooking oil based ternary biodiesel fuels based ternary biodiesel fuels Assessing of using the heat. Energy Procedia 160:842–847. https://doi.org/10.1016/j.egypro.2019.02.149

Rene ER, Ge J, Kumar G et al (2020) Resource recovery from wastewater, solid waste, and waste gas: engineering and management aspects. Environ Sci Pollut Res 27:17435–17437. https://doi.org/10.1007/s11356-020-08802-4

Sharma PK, Sharma D, Soni SL et al (2019) Characterization of the non-road modified diesel engine using a novel entropy-vikor approach: experimental investigation and numerical simulation. J Energy Resour Technol 141(8):082208. https://doi.org/10.1115/1.4042717

Das M, Sarkar M, Datta A, Santra AK (2018) Study on viscosity and surface tension properties of biodiesel-diesel blends and their effects on spray parameters for CI engines. Fuel 220:769–779. https://doi.org/10.1016/j.fuel.2018.02.021

Azhagurajan KVA, Vedaraman SCVN (2017) Rice husk as nanoadditive in diesel – biodiesel fuel blends used in diesel engine. J Therm Anal Calorim. https://doi.org/10.1007/s10973-017-6692-7

Srivastava RK, Shetti NP, Raghava K, Tejraj R (2020) Biofuels, biodiesel and biohydrogen production using bioprocesses A review United States of America. Environ Chem Lett. https://doi.org/10.1007/s10311-020-00999-7

Khan MA, Ngo HH, Guo W et al (2017) Biohydrogen production from anaerobic digestion and its potential as renewable energy. Renew Energy. https://doi.org/10.1016/j.renene.2017.04.029

Usman TMM, Banu R, Gunasekaran M, Kumar G (2019) Corresponding author Details. Bioresour Technol Rep 7:100287. https://doi.org/10.1016/j.biteb.2019.100287

Xd TX, Xd DX, Xd DX (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86. https://doi.org/10.1016/j.pecs.2017.05.004

Kannah RY, Kavitha S, Sivashanmugham P et al (2018) ScienceDirect Biohydrogen production from rice straw: effect of combinative pretreatment, modelling assessment and energy balance consideration. Int J Hydrogen Energy 44(4):2203-2215. https://doi.org/10.1016/j.ijhydene.2018.07.201

Argun H, Dao S (2016) ScienceDirect Bio-hydrogen production from waste peach pulp by dark fermentation: effect of inoculum addition. Int J Hydrogen Energy 42:2569–2574. https://doi.org/10.1016/j.ijhydene.2016.06.225

Kant S, Sadashiv S, Ashok A et al (2021) Science of the total environment renewable biohydrogen production from lignocellulosic biomass using fermentation and integration of systems with other energy generation technologies. Sci Total Environ 765:144429. https://doi.org/10.1016/j.scitotenv.2020.144429

Haron R, Mat R, Amran T et al (2017) Overview on utilization of biodiesel by-product for biohydrogen production. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.10.160

Shanmugam S, Hari A, Pandey A, Mathimani T (2020) Comprehensive review on the application of inorganic and organic nanoparticles for enhancing biohydrogen production. Fuel 270:117453. https://doi.org/10.1016/j.fuel.2020.117453

Sarangi PK, Nanda S (2020) Biohydrogen production through dark fermentation. Chem Eng Technol 43(4): 601–612. https://doi.org/10.1002/ceat.201900452

Jarunglumlert T, Prommuak C, Putmai N (2017) Scaling-up bio-hydrogen production from food waste : Feasibilities and challenges. Int J Hydrogen Energy 43(2):634–648. https://doi.org/10.1016/j.ijhydene.2017.10.013

Mirmohamadsadeghi S, Karimi K, Tabatabaei M, Aghbashlo M (2019) Biogas production from food wastes: A review on recent developments and future perspectives. Bioresour Technol Rep 7:100202. https://doi.org/10.1016/j.biteb.2019.100202

Felipe I, Duarte N, Vieira B et al (2018) Resources, conservation & recycling assessment of potential biogas production from multiple organic wastes in Brazil : Impact on energy generation, use, and emissions abatement. Resour Conserv Recycl 131:54–63. https://doi.org/10.1016/j.resconrec.2017.12.012

Wesley O, Yaqian A, Ange Z et al (2017) A review of biogas utilisation, purification and upgrading technologies. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-016-9826-4

Zhu T, Curtis J, Clancy M (2019) Promoting agricultural biogas and biomethane production: lessons from cross-country studies. Renew Sustain Energy Rev 114:109332. https://doi.org/10.1016/j.rser.2019.109332

Lyng K, Elstad A, Jørgen O (2018) Relation between greenhouse gas emissions and economic pro fi t for different con figurations of biogas value chains: a case study on different levels of sector integration. J Clean Prod 182:737–745. https://doi.org/10.1016/j.jclepro.2018.02.126

Kapoor R, Ghosh P, Kumar M et al (2020) Valorization of agricultural waste for biogas based circular economy in India: a research outlook. Bioresour Technol 304:123036. https://doi.org/10.1016/j.biortech.2020.123036

Zareei S (2017) Evaluation of biogas potential from livestock manures and rural wastes using GIS in Iran. Renew Energy. https://doi.org/10.1016/j.renene.2017.11.026

Paudel SR, Banjara SP, Choi OK et al (2017) Pretreatment of agricultural biomass for anaerobic digestion: current state and challenges. Bioresour Technol 245:1194–1205. https://doi.org/10.1016/j.biortech.2017.08.182

Arun N, Dalai AK (2019) Environmental and socioeconomic impact assessment of biofuels from lignocellulosic biomass. Lignocellulosic Biomass to Liquid Biofuels, 283–299. https://doi.org/10.1016/B978-0-12-815936-1.00009-5

Nicoletti J, Ning C, You F (2019) Incorporating agricultural waste-to-energy pathways into biomass product and process network through data-driven nonlinear adaptive robust optimization. Energy 180:556–571. https://doi.org/10.1016/j.energy.2019.05.096

Hafid HS, Rahman NAA, Shah UKM et al (2017) Feasibility of using kitchen waste as future substrate for bioethanol production: a review. Renew Sustain Energy Rev 74:671–686. https://doi.org/10.1016/j.rser.2017.02.071

Rizwan M, Saif Y, Almansoori A, Elkamel A (2018) Optimal processing route for the utilization and conversion of municipal solid waste into energy and valuable products. J Clean Prod 174:857–867. https://doi.org/10.1016/j.jclepro.2017.10.335

Zahedi S, Sales D, García-Morales JL, Solera R (2018) Obtaining green energy from dry-thermophilic anaerobic co-digestion of municipal solid waste and biodiesel waste. Biosyst Eng 170:108–116

Moreno-Garcia L, Adjallé K, Barnabé S, Raghavan GSV (2017) Microalgae biomass production for a biorefinery system: Recent advances and the way towards sustainability. Renew Sustain Energy Rev 76:493–506. https://doi.org/10.1016/j.rser.2017.03.024

Mathur R, Srivastava VK (2019) Crop Residue Burning: Effects on Environment. Greenhouse Gas Emissions, 127–140. https://doi.org/10.1007/978-981-13-3272-2_9

Bundhoo ZMA (2018) Solid waste management in least developed countries: current status and challenges faced. J Mater Cycles Waste Manag 20:1867–1877. https://doi.org/10.1007/s10163-018-0728-3

Sharma BK, Chandel MK (2017) Life cycle assessment of potential municipal solid waste management strategies for Mumbai, India. Waste Manag Res 35:79–91. https://doi.org/10.1177/0734242X16675683

Mishra B, Varjani S, Agrawal DC et al (2020) Engineering biocatalytic material for the remediation of pollutants: a comprehensive review. Environ Technol Innov 20:101063. https://doi.org/10.1016/j.eti.2020.101063

Rajmohan KS, Chandrasekaran R, Varjani S (2020) A review on occurrence of pesticides in environment and current technologies for their remediation and management. Indian J Microbiol 60:125–138. https://doi.org/10.1007/s12088-019-00841-x

Saritha M, Prasad Tollamadugu NVKV (2018) The status of research and application of biofertilizers and biopesticides: Global scenario. Recent Developments in Applied Microbiology and Biochemistry, 195–207. https://doi.org/10.1016/B978-0-12-816328-3.00015-5

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renew Sustain Energy Rev 90:877–891. https://doi.org/10.1016/j.rser.2018.03.111

García-Condado S, López-Lozano R, Panarello L et al (2019) Assessing lignocellulosic biomass production from crop residues in the European Union: modelling, analysis of the current scenario and drivers of interannual variability. GCB Bioenergy 11:809–831. https://doi.org/10.1111/gcbb.12604

Ingle AP, Rathod J, Pandit R et al (2017) Comparative evaluation of free and immobilized cellulase for enzymatic hydrolysis of lignocellulosic biomass for sustainable bioethanol production. Cellulose 24:5529–5540. https://doi.org/10.1007/s10570-017-1517-1

Singhvi MS, Gokhale DV (2019) Lignocellulosic biomass: hurdles and challenges in its valorization. Appl Microbiol Biotechnol 103:9305–9320. https://doi.org/10.1007/s00253-019-10212-7

Shrestha S, Fonoll X, Khanal SK, Raskin L (2017) Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: current status and future perspectives. Bioresour Technol 245:1245–1257. https://doi.org/10.1016/j.biortech.2017.08.089

Liang G, Li Y, Yang C et al (2020) Ash properties correlated with diverse types of biomass derived from power plants: an overview. Energy Sources, Part A Recover Util Environ Eff 00:1–12. https://doi.org/10.1080/15567036.2020.1804012

Masto RE, Pandit A, Kumar S et al (2020) Comparative evaluation of aquatic biomass feedstocks for energy application and potential for extraction of plant nutrients from their ash. Biomass Bioenerg 142:105783. https://doi.org/10.1016/j.biombioe.2020.105783

Abraham A, Mathew AK, Park H et al (2020) Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour Technol 301:122725. https://doi.org/10.1016/j.biortech.2019.122725

Varjani S, Shah AV, Vyas S, Srivastava VK (2021) Processes and prospects on valorizing solid waste for the production of valuable products employing bio-routes: a systematic review. Chemosphere 282:130954. https://doi.org/10.1016/j.chemosphere.2021.130954

Trinh LTP, Lee YJ, Park CS, Bae HJ (2019) Aqueous acidified ionic liquid pretreatment for bioethanol production and concentration of produced ethanol by pervaporation. J Ind Eng Chem 69:57–65. https://doi.org/10.1016/j.jiec.2018.09.008

Qu J, Sun Y, Awasthi MK et al (2021) Effect of different aerobic hydrolysis time on the anaerobic digestion characteristics and energy consumption analysis. Bioresour Technol 320:124332. https://doi.org/10.1016/j.biortech.2020.124332

Montoya-Rosales JJ, Peces M, González-Rodríguez LM et al (2020) A broad overview comparing a fungal, thermal and acid pre-treatment of bean straw in terms of substrate and anaerobic digestion effect. Biomass Bioenerg 142:1–8. https://doi.org/10.1016/j.biombioe.2020.105775

Chowdhury S, Kim GH, Bolan N, Longhurst P (2019) A critical review on risk evaluation and hazardous management in carcass burial. Process Saf Environ Prot 123:272–288. https://doi.org/10.1016/j.psep.2019.01.019

Biruntha M, Mariappan P, Karunai Selvi B et al (2020) Vermiremediation of urban and agricultural biomass residues for nutrient recovery and vermifertilizer production. Waste and Biomass Valorization 11:6483–6497. https://doi.org/10.1007/s12649-019-00899-0

Moustakas K, Parmaxidou P, Vakalis S (2020) Anaerobic digestion for energy production from agricultural biomass waste in Greece: capacity assessment for the region of Thessaly. Energy 191:116556. https://doi.org/10.1016/j.energy.2019.116556

Ren HY, Kong F, Zhao L et al (2019) Enhanced co-production of biohydrogen and algal lipids from agricultural biomass residues in long-term operation. Bioresour Technol 289:121774. https://doi.org/10.1016/j.biortech.2019.121774

Khattab SMR, Watanabe T (2019) Bioethanol From sugarcane bagasse: status and perspectives. Bioethanol Production from Food Crops, 187–212. https://doi.org/10.1016/B978-0-12-813766-6.00010-2

Bozkurt YC, Apul OG (2020) Critical review for microwave pretreatment of waste-activated sludge prior to anaerobic digestion. Curr Opin Environ Sci Heal 14:1–9. https://doi.org/10.1016/j.coesh.2019.10.003

Limayem A, Ricke SC (2012) Lignocellulosic biomass for bioethanol production: current perspectives, potential issues and future prospects. Prog Energy Combust Sci 38:449–467. https://doi.org/10.1016/j.pecs.2012.03.002

Shah AV, Srivastava VK, Mohanty SS, Varjani S (2021) Municipal solid waste as a sustainable resource for energy production: state-of-the-art review. J Environ Chem Eng 9:105717. https://doi.org/10.1016/j.jece.2021.105717

Ruan D, Zhou Z, Pang H et al (2019) Enhancing methane production of anaerobic sludge digestion by microaeration: enzyme activity stimulation, semi-continuous reactor validation and microbial community analysis. Bioresour Technol 289:121643. https://doi.org/10.1016/j.biortech.2019.121643

Wu Y, Ge S, Xia C et al (2021) Application of intermittent ball milling to enzymatic hydrolysis for efficient conversion of lignocellulosic biomass into glucose. Renew Sustain Energy Rev 136:110442. https://doi.org/10.1016/j.rser.2020.110442

Sekar M, Mathimani T, Alagumalai A et al (2021) A review on the pyrolysis of algal biomass for biochar and bio-oil – bottlenecks and scope. Fuel 283:119190. https://doi.org/10.1016/j.fuel.2020.119190

Vaish B, Sharma B, Srivastava V et al (2019) Energy recovery potential and environmental impact of gasification for municipal solid waste. Biofuels 10:87–100. https://doi.org/10.1080/17597269.2017.1368061

Nile A, Nile SH, Kim DH et al (2018) Valorization of onion solid waste and their flavonols for assessment of cytotoxicity, enzyme inhibitory and antioxidant activities. Food Chem Toxicol 119:281–289. https://doi.org/10.1016/j.fct.2018.02.056

Rosen Y, Mamane H, Gerchman Y (2019) Short ozonation of lignocellulosic waste as energetically favorable pretreatment. Bioenergy Res 12:292–301. https://doi.org/10.1007/s12155-019-9962-3

Saggi SK, Gupta G, Dey P (2017) Biological pretreatment of lignocellulosic biomaterials. Adv Biofeedstocks Biofuels 1:97–119. https://doi.org/10.1002/9781119117322.ch5

Tsapekos P, Kougias PG, Angelidaki I (2018) Mechanical pretreatment for increased biogas production from lignocellulosic biomass; predicting the methane yield from structural plant components. Waste Manag 78:903–910. https://doi.org/10.1016/j.wasman.2018.07.017

Wu D, Wei Z, Qu F et al (2020) Effect of Fenton pretreatment combined with bacteria inoculation on humic substances formation during lignocellulosic biomass composting derived from rice straw. Bioresour Technol 303:122849. https://doi.org/10.1016/j.biortech.2020.122849

Vinayak V, Khan MJ, Varjani S et al (2021) Microbial fuel cells for remediation of environmental pollutants and value addition: special focus on coupling diatom microbial fuel cells with photocatalytic and photoelectric fuel cells. J Biotechnol 338:5–19. https://doi.org/10.1016/j.jbiotec.2021.07.003

Nagarajan D, Varjani S, Lee DJ, Chang JS (2021) Sustainable aquaculture and animal feed from microalgae – nutritive value and techno-functional components. Renew Sustain Energy Rev 150:111549. https://doi.org/10.1016/j.rser.2021.111549

Czatzkowska M, Harnisz M, Korzeniewska E, Koniuszewska I (2020) Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review. Energy Sci Eng 8:1880–1897. https://doi.org/10.1002/ese3.609

Kushkevych I, Kobzová E, Vítězová M et al (2019) Acetogenic microorganisms in operating biogas plants depending on substrate combinations. Biologia (Bratisl) 74:1229–1236. https://doi.org/10.2478/s11756-019-00283-2

Sudhakar MP, Kumar BR, Mathimani T, Arunkumar K (2019) A review on bioenergy and bioactive compounds from microalgae and macroalgae-sustainable energy perspective. J Clean Prod 228:1320–1333. https://doi.org/10.1016/j.jclepro.2019.04.287

Gan YY, Chen WH, Ong HC et al (2020) Effects of dry and wet torrefaction pretreatment on microalgae pyrolysis analyzed by TG-FTIR and double-shot Py-GC/MS. Energy 210:118579. https://doi.org/10.1016/j.energy.2020.118579

Isa MH, Wong LP, Bashir MJK et al (2020) Improved anaerobic digestion of palm oil mill effluent and biogas production by ultrasonication pretreatment. Sci Total Environ 722:137833. https://doi.org/10.1016/j.scitotenv.2020.137833

Whiting K, Carmona LG, Sousa T (2017) A review of the use of exergy to evaluate the sustainability of fossil fuels and non-fuel mineral depletion. Renew Sustain Energy Rev 76:202–211. https://doi.org/10.1016/j.rser.2017.03.059

Azizi K, Keshavarz Moraveji M, Abedini Najafabadi H (2018) A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew Sustain Energy Rev 82:3046–3059. https://doi.org/10.1016/j.rser.2017.10.033

Zabed HM, Akter S, Yun J et al (2019) Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew Sustain Energy Rev 105:105–128. https://doi.org/10.1016/j.rser.2019.01.048

Fasciotti M (2017) Perspectives for the use of biotechnology in green chemistry applied to biopolymers, fuels and organic synthesis: from concepts to a critical point of view. Sustain Chem Pharm 6:82–89. https://doi.org/10.1016/j.scp.2017.09.002

Bharagava RN, Chowdhary P (2018) Emerging and eco-friendly approaches for waste management. https://doi.org/10.1007/978-981-10-8669-4

Mohd Azhar SH, Abdulla R, Jambo SA et al (2017) Yeasts in sustainable bioethanol production: A review. Biochem Biophys Reports 10:52–61. https://doi.org/10.1016/j.bbrep.2017.03.003

Bolatkhan K, Kossalbayev BD, Zayadan BK et al (2019) Hydrogen production from phototrophic microorganisms: reality and perspectives. Int J Hydrogen Energy 44:5799–5811. https://doi.org/10.1016/j.ijhydene.2019.01.092

Zhang J, Zhang X, Yang M et al (2021) Transforming lignocellulosic biomass into biofuels enabled by ionic liquid pretreatment. Bioresour Technol 322:124522. https://doi.org/10.1016/j.biortech.2020.124522

Vasudev V, Ku X, Lin J (2019) Kinetic study and pyrolysis characteristics of algal and lignocellulosic biomasses. Bioresour Technol 288:121496. https://doi.org/10.1016/j.biortech.2019.121496

Obileke KC, Nwokolo N, Makaka G et al (2021) Anaerobic digestion: technology for biogas production as a source of renewable energy—a review. Energy Environ 32:191–225. https://doi.org/10.1177/0958305X20923117

Kumar A, Samadder SR (2017) A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag 69:407–422. https://doi.org/10.1016/j.wasman.2017.08.046

Schmieder H, Abeln J, Boukis N et al (2000) Hydrothermal gasification of biomass and organic wastes. J Supercrit Fluids 17:145–153

Sharma HK, Xu C, Qin W (2019) Biological Pretreatment of lignocellulosic biomass for biofuels and bioproducts: an overview. Waste and Biomass Valorization 10:235–251. https://doi.org/10.1007/s12649-017-0059-y

Abuabdou SMA, Ahmad W, Aun NC, Bashir MJK (2020) A review of anaerobic membrane bioreactors (AnMBR) for the treatment of highly contaminated landfill leachate and biogas production: effectiveness, limitations and future perspectives. J Clean Prod 255:120215. https://doi.org/10.1016/j.jclepro.2020.120215

Srivastava SK (2020) Advancement in biogas production from the solid waste by optimizing the anaerobic digestion. Waste Dispos Sustain Energy 2:85–103. https://doi.org/10.1007/s42768-020-00036-x

Chen YC, Tsai PY (2017) Evaluating the operational risks of biomedical waste using failure mode and effects analysis. Waste Manag Res 35:593–601. https://doi.org/10.1177/0734242X17700717

Mengistu T, Gebrekidan H, Kibret K et al (2018) Comparative effectiveness of different composting methods on the stabilization, maturation and sanitization of municipal organic solid wastes and dried faecal sludge mixtures. Environ Syst Res 6:5. https://doi.org/10.1186/s40068-017-0079-4

Moset V, de Almeida Neves Xavier C, Feng L et al (2018) Combined low thermal alkali addition and mechanical pre-treatment to improve biogas yield from wheat straw. J Clean Prod 172:1391–1398. https://doi.org/10.1016/j.jclepro.2017.10.173

Feng RZ, Zaidi AA, Zhang K, Shi Y (2019) Optimisation of microwave pretreatment for biogas enhancement through anaerobic digestion of microalgal biomass. Period Polytech Chem Eng 63:65–72. https://doi.org/10.3311/PPch.12334

Cho D-W, Tsang DCW, Kim S et al (2018) Thermochemical conversion of cobalt-loaded spent coffee grounds for production of energy resource and environmental catalyst. Bioresour Technol 270:346–351

Han Y, Zhuo Y, Peng D et al (2017) Influence of thermal hydrolysis pretreatment on organic transformation characteristics of high solid anaerobic digestion. Bioresour Technol 244:836–843. https://doi.org/10.1016/j.biortech.2017.07.166

Bahreini G, Nazari L, Ho D et al (2020) Enzymatic pre-treatment for enhancement of primary sludge fermentation. Bioresour Technol 305:123071. https://doi.org/10.1016/j.biortech.2020.123071

Kumar S, Smith SR, Fowler G et al (2017) Challenges and opportunities associated with waste management in India. R Soc Open Sci 4(3):160764. https://doi.org/10.1098/rsos.160764

Scown CD, Baral NR, Yang M et al (2021) Technoeconomic analysis for biofuels and bioproducts. Curr Opin Biotechnol 67:58–64

Balasubramani R, Muthunarayanan V, Periakaruppan R et al (2021) Treatment of Waste. Waste Valorisation, 33–49. https://doi.org/10.1002/9781119502753.ch3

Zhu Q, Li G, Jiang Z et al (2020) Investigating the variation of dissolved organic matters and the evolution of autotrophic microbial community in composting with organic and inorganic carbon sources. Bioresour Technol 304:123013. https://doi.org/10.1016/j.biortech.2020.123013

Coarita Fernandez H, Teixeira Franco R, Bayard R, Buffiere P (2020) Mechanical pre-treatments evaluation of cattle manure before anaerobic digestion. Waste and Biomass Valorization 11:5175–5184. https://doi.org/10.1007/s12649-020-01022-4

Khanh Nguyen V, Kumar Chaudhary D, Hari Dahal R et al (2021) Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 285:119105. https://doi.org/10.1016/j.fuel.2020.119105

Ma X, Yu M, Song N et al (2020) Effect of ethanol pre-fermentation on organic load rate and stability of semi-continuous anaerobic digestion of food waste. Bioresour Technol 299:122587. https://doi.org/10.1016/j.biortech.2019.122587

Moya D, Aldás C, López G, Kaparaju P (2017) Municipal solid waste as a valuable renewable energy resource: a worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia 134:286–295. https://doi.org/10.1016/j.egypro.2017.09.618

Pandey BK, Vyas S, Pandey M, Gaur A (2016) Municipal solid waste to energy conversion methodology as physical, thermal, and biological methods. Curr Sci Perspect 2:39–44

Nath BK, Chaliha C, Bhuyan B et al (2018) GIS mapping-based impact assessment of groundwater contamination by arsenic and other heavy metal contaminants in the Brahmaputra River valley: a water quality assessment study. J Clean Prod 201:1001–1011. https://doi.org/10.1016/j.jclepro.2018.08.084

Qian C, Li Q, Zhang Z et al (2020) Prediction of higher heating values of biochar from proximate and ultimate analysis. Fuel 265:116925. https://doi.org/10.1016/j.fuel.2019.116925

Gaur VK, Sharma P, Sirohi R et al (2020) Assessing the impact of industrial waste on environment and mitigation strategies: a comprehensive review. J Hazard Mater 398:123019. https://doi.org/10.1016/j.jhazmat.2020.123019

Sharma P, Gaur VK, Kim S, Pandey A (2019) Microbial strategies for bio-transforming food waste into resources. Bioresour Technol 299:122580. https://doi.org/10.1016/j.biortech.2019.122580

Dornau A, Robson JF, Thomas GH, McQueen-Mason SJ (2020) Robust microorganisms for biofuel and chemical production from municipal solid waste. Microb Cell Fact 19:1–18

Noh HJ, Woo JE, Lee SY, Jang Y-S (2018) Metabolic engineering of Clostridium acetobutylicum for the production of butyl butyrate. Appl Microbiol Biotechnol 102:8319–8327

Thapa B, Patidar SK, Khatiwada NR et al (2019) Production of ethanol from municipal solid waste of India and Nepal. Waste Valorisation and Recycling, 47–58. https://doi.org/10.1007/978-981-13-2784-1_5

Solera R (2018) Science Direct Obtaining green energy from dry-thermophilic anaerobic co-digestion of municipal solid waste and biodiesel waste. 170:108–116. https://doi.org/10.1016/j.biosystemseng.2018.04.005

Zahedi S (2018) Energy efficiency: importance of indigenous microorganisms contained in the municipal solid wastes. Waste Manag 78:763–769

Byadgi SA, Kalburgi PB (2016) Production of bioethanol from waste newspaper. Procedia Environ Sci 35:555–562

Prasoulas G, Gentikis A, Konti A et al (2020) Bioethanol production from food waste applying the multienzyme system produced on-site by Fusarium oxysporum F3 and mixed microbial cultures. Fermentation 6:39

Matsakas L, Gao Q, Jansson S et al (2017) Green conversion of municipal solid wastes into fuels and chemicals. Electron J Biotechnol 26:69–83

Chen G, Ali I, Raza S et al (2020) ScienceDirect Hydrogen-rich syngas production from municipal solid waste gasification through the application of central composite design : An optimization study. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2020.09.118

Experimental I, Gandidi IM, Susila MD (2017) Author ’ s accepted manuscript production of valuable pyrolytic oils from mixed municipal solid waste ( msw ) in Indonesia using Reference: To appear in: Case Studies in thermal engineering waste (MSW) in indonesia using non-isothermal and isothermal. Case Stud Therm Eng. https://doi.org/10.1016/j.csite.2017.08.003

Verma M, Godbout S, Brar SK et al (2012) Biofuels production from biomass by thermochemical conversion technologies. Int J Chem Eng 1-18. https://doi.org/10.1155/2012/542426

Mahesh D, Ahmad S, Kumar R et al (2021) Hydrothermal liquefaction of municipal solid wastes for high quality bio-crude production using glycerol as co-solvent. Bioresour Technol 339:125537

Shah AV, Singh A, Sabyasachi S, Kumar V (2022) Bioresource technology organic solid waste: biorefinery approach as a sustainable strategy in circular bioeconomy. Bioresour Technol 349:126835. https://doi.org/10.1016/j.biortech.2022.126835

Soleymani M, Rosentrater KA (2017) Techno-economic analysis of biofuel production from macroalgae (seaweed). Bioengineering 4:92

Vasco-Correa J, Khanal S, Manandhar A, Shah A (2018) Anaerobic digestion for bioenergy production: global status, environmental and techno-economic implications, and government policies. Bioresour Technol 247:1015–1026

Hannula I (2016) Hydrogen enhancement potential of synthetic biofuels manufacture in the European context: a techno-economic assessment. Energy 104:199–212

Phillips SD, Tarud JK, Biddy MJ, Dutta A (2011) Gasoline from woody biomass via thermochemical gasification, methanol synthesis, and methanol-to-gasoline technologies: a technoeconomic analysis. Ind Eng Chem Res 50:11734–11745

Sindhu R, Binod P, Pandey A et al (2019) Biofuel Production from biomass: toward sustainable development. Current Developments In Biotechnology and Bioengineering 79–92. https://doi.org/10.1016/B978-0-444-64083-3.00005-1

Torres M, Janaína N, Luana M, Basso G (2020) Biofuels and their connections with the sustainable development goals : a bibliometric and systematic review. Environ Dev Sustain. https://doi.org/10.1007/s10668-020-01110-4

Adegboye MF, Ojuederie OB, Talia PM, Babalola OO (2021) Bioprospecting of microbial strains for biofuel production: metabolic engineering, applications, and challenges. Biotechnol Biofuels 14:1–21

Chen G, Jamro IA, Samo SR et al (2020) Hydrogen-rich syngas production from municipal solid waste gasification through the application of central composite design: an optimization study. Int J Hydrogen Energy 45:33260–33273

Gandidi IM, Susila MD, Pambudi NA (2017) Production of valuable pyrolytic oils from mixed municipal solid waste (MSW) in Indonesia using non-isothermal and isothermal experimental. Case Stud Therm Eng 10:357–361

Boscagli C, Morgano MT, Raffelt K et al (2018) Influence of feedstock, catalyst, pyrolysis and hydrotreatment temperature on the composition of upgraded oils from intermediate pyrolysis. Biomass Bioenerg 116:236–248

Acknowledgements

Aditi Singh, Priya Prajapati, and Shaili Vyas are grateful to authorities of GPCB for allowing them to undergo an internship with “A scheme on Project, Thesis or Internship at GPCB.” The authors would like to thank Gujarat Pollution Control Board for encouragement and support during manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, A., Prajapati, P., Vyas, S. et al. A Comprehensive Review of Feedstocks as Sustainable Substrates for Next-Generation Biofuels. Bioenerg. Res. 16, 105–122 (2023). https://doi.org/10.1007/s12155-022-10440-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10440-2