Abstract

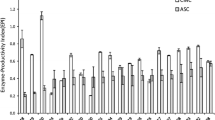

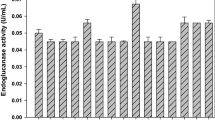

Agricultural by-products, rice straw, wheat bran juice, and soybean residue, were used as substrates for cellulase production using Rhizopus stolonifer var. reflexus TP-02. The culture medium was optimized though uniform design experimentation during shaking flask fermentation, and the ideal formulation obtained for filter paper enzyme (FPase) production was 10 % bran diffusion juice, 1 % rice straw, 0.17 % urea, 0.17 % soybean residue, 0.11 % KH2PO4, and 0.027 % Tween 80, and the maximal FPase activity in the culture supernatant was 13.16 U/mL at an incubation time of 3 days. A kinetic model for cellulase production in batch fermentation was subsequently developed. The unstructured kinetic model considered three responses, namely biomass, cellulase, and sugar. Models for the production of three types of cellulase components (i.e., endoglucanases, cellobiohydrolases, and β-glucosidases) were established to adequately describe the cellulase production pattern. It was found that the models fitted the experimental data well under pH 5.0 and 6.0, but only the avicelase production model predicted the experimental data under pH-uncontrolled conditions.

Similar content being viewed by others

Abbreviations

- X :

-

Total biomass concentration (in gram per liter)

- X 0 :

-

Initial biomass concentration (in gram per liter)

- X m :

-

Maximum biomass concentration (in gram per liter)

- μ m :

-

Maximum specific growth rate (in gram per hour)

- t :

-

Culture time (in hour)

- P, P 1, P 2, P 3, P 4 :

-

Enzyme concentration (in international unit per milliliter)

- α, α 1 , α 2 , α 3 , α 4 :

-

Constant in specific enzyme production rare (in per hour)

- β, β 1, β 2, β 3, β 4 :

-

Constant in specific enzyme production rare (in per hour)

- S :

-

Total sugar concentration (in gram per liter)

- Y x/s :

-

Yield coefficient for growth (in gram per gram)

- Y p/s :

-

Yield coefficient for products (in gram per gram)

- m s :

-

Maintenance coefficient on total sugar (in gram per gram·hour)

- k1 (1/Y x/s):

-

Specific substrate consumption rate constants for mycelia growth (in gram per gram)

- k2 (1/Y p/s):

-

Specific substrate consumption rate constants for biomass maintenance (in gram per gram)

References

Cavka, A., Alriksson, B., Rose, S. H., van Zyl, W. H., & Jonsson, L. J. (2014). Production of cellulosic ethanol and enzyme from waste fiber sludge using SSF, recycling of hydrolytic enzymes and yeast, and recombinant cellulase producing Aspergillus niger. Journal of Industrial Microbiology & Biotechnology, 41, 1191–1200.

Kiran, E. U., Trzcinski, A. P., Ng, W. J., & Liu, Y. (2014). Enzyme production from food wastes using a biorefinery concept. Waste and Biomass Valorization, 5, 903–917.

Nanda, S., Mohammad, J., Reddy, S. N., Kozinski, J. A., & Dalai, A. K. (2014). Pathways of lignocellulosic biomass conversion to renewable fuels. Biomass Conversion and Biorefinery, 4, 157–191.

Xu, Z., & Huang, F. (2014). Pretreatment methods for bioethanol production. Applied Biochemistry and Biotechnology, 174, 43–64.

Zhang, J., Pakarinen, A., & Viikari, L. (2013). Synergy between cellulases and pectinases in the hydrolysis of hemp. Bioresource Technology, 129, 302–307.

Kumar, R., Singh, S., & Singh, O. V. (2008). Bioconversion of lignocellulosic biomass: biochemical and molecular perspectives. Journal of Industrial Microbiology & Biotechnology, 35, 377–391.

Juturu, V., & Wu, J. C. (2014). Microbial cellulases: engineering, production and applications. Renewable & Sustainable Energy Reviews, 33, 188–203.

Yoon, L. W., Ang, T. N., Ngoh, G. C., & Chua, A. S. M. (2014). Fungal solid-state fermentation and various methods of enhancement in cellulase production. Biomass and Bioenergy, 67, 318–338.

Rodrigues, A. C., Felby, C., & Gama, M. (2014). Cellulase stability, adsorption/desorption profiles and recycling during successive cycles of hydrolysis and fermentation of wheat straw. Bioresource Technology, 156, 163–169.

Nonaka, H., Kobayashi, A., & Funaoka, M. (2013). Behavior of lignin-binding cellulase in the presence of fresh cellulosic substrate. Bioresource Technology, 135, 53–57.

Qaisar, S., Zohra, R. R., Aman, A., & Qader, S. A. U. (2014). Enhanced production of cellulose degrading CMCase by newly isolated strain of Aspergillus versicolor. Carbohydrate Polymers, 104, 199–203.

Karmakar, M., & Ray, R. R. (2011). Current trends in research and application of microbial cellulases. Research Journal of Microbiology, 6, 41–53.

Vu, V. H., Pham, T. A., & Kim, K. (2011). Improvement of fungal cellulase production by mutation and optimization of solid state fermentation. Mycobiology, 39, 20–25.

Nathan, V. K., Rani, M. E., Rathinasamy, G., Dhiraviam, K. N., & Jayavel, S. (2014). Process optimization and production kinetics for cellulase production by Trichoderma viride VKF3. SpringerPlus, 3, 92.

Bannari, R., Bannari, A., Vermette, P., & Proulx, P. (2012). A model for cellulase production from Trichoderma reesei in an airlift reactor. Biotechnology and Bioengineering, 109, 2025–2038.

Kubicek, C. P., Mikus, M., Schuster, A., Schmoll, M., & Seiboth, B. (2009). Metabolic engineering strategies for the improvement of cellulase production by Hypocrea jecorina. Biotechnology and Biofuels, 2, 19.

Chahal, P. S., Chahal, D. S., & Le, G. B. B. (1996). Production of cellulase in solid-state fermentation with Trichoderma reesei MCG 80 on wheat straw. Applied Biochemistry and Biotechnology, 57(58), 433–442.

Goldbeck, R., Ramos, M. M., Pereira, G. A. G., & Maugeri-Filho, F. (2013). Cellulase production from a new strain Acremonium strictum isolated from the Brazilian biome using different substrates. Bioresource Technology, 128, 797–803.

Reis, L., Schneider, W. D. H., Fontana, R. C., Camassola, M., & Dillon, A. J. P. (2014). Cellulase and xylanase expression in response to different pH levels of Penicillium echinulatum S1M29 medium. Bioenergy Research, 7, 60–67.

Kumar, S., Sharma, K. K., & Sarkar, B. C. (2011). Effect of substrate and fermentation conditions on pectinase and cellulase production by Aspergillus niger NCIM 548 in submerged (SmF) and solid state fermentation (SSF). Food Science and Biotechnology, 20, 1289–1298.

Mehboob, N., Asad, M. J., Asgher, M., Gulfraz, M., Mukhtar, T., & Mahmood, R. T. (2014). Exploring thermophilic cellulolytic enzyme production potential of Aspergillus fumigates by the solid-state fermentation of wheat straw. Applied Biochemistry and Biotechnology, 172, 3646–3655.

Rodriguez-Zuniga, U. F., Bertucci Neto, V., Couri, S., Crestana, S., & Farinas, C. S. (2014). Use of spectroscopic and imaging techniques to evaluate pretreated sugarcane bagasse as a substrate for cellulase production under solid-state fermentation. Applied Biochemistry and Biotechnology, 172, 2348–2362.

Salihu, A., Sallau, A. B., Adamu, A., Kudu, F. A., Tajo, M. M., Bala, T. F., & Yashim, W. D. (2014). Utilization of groundnut husk as a solid substrate for cellulase production by Aspergillus niger using response surface methodology. Waste and Biomass Valorization, 5, 585–593.

Sun, W., Cheng, C., & Lee, W. (2008). Protein expression and enzymatic activity of cellulases produced by Trichoderma reesei Rut C-30 on rice straw. Process Biochemistry, 43, 1083–1087.

Lan, T., Wei, D., Yang, S., & Liu, X. (2013). Enhanced cellulase production by Trichoderma viride in a rotating fibrous bed bioreactor. Bioresource Technology, 133, 175–182.

Villena, G. K., & Gutierrez-Correa, M. (2012). Kinetic analysis of Aspergillus niger cellulase and xylanase production in biofilm and submerged fermentation. Journal of Microbiology and Biotechnology Research, 2, 805–814.

Tholudur, A., Ramirez, W. F., & McMillan, J. D. (1999). Mathematical modeling and optimization of cellulase protein production using Trichoderma reesei RL-P37. Biotechnology and Bioengineering, 66, 1–16.

Tang, B., Pan, H., Zhang, Q., & Ding, L. (2009). Cloning and expression of cellulase gene EG1 from Rhizopus stolonifer var. reflexus TP-02 in Escherichia coli. Bioresource Technology, 100, 6129–6132.

Tang, B., Pan, H., Tang, W., Zhang, Q., Ding, L., & Zhang, F. (2012). Fermentation and purification of cellulase from a novel strain Rhizopus stolonifer var. reflexus TP-02. Biomass and Bioenergy, 36, 366–372.

Zhang, Q., Lo, M., & Ju, L. (2007). Factors affecting foaming behavior in cellulase fermentation by Trichoderma reesei Rut C-30. Bioresource Technology, 98, 753–760.

Chen, S., Hong, Y., Shao, Z., & Liu, Z. (2010). A cold-active β-glucosidase (Bgl1C) from a sea bacteria Exiguobacterium oxidotolerans A011. World Journal of Microbiology and Biotechnology, 26, 1427–1435.

Chow, P. S., & Landhausser, S. M. (2004). A method for routine measurement of total sugar and starch content in woody plant tissues. Tree Physiology, 24, 1129–1136.

Bouguettoucha, A., Balannec, B., & Amrane, A. (2011). Unstructured models for lactic acid fermentation—a review. Food Technology and Biotechnology, 49, 3–12.

Velkovska, S., Marten, M. R., & Ollis, D. F. (1997). Kinetic model for batch cellulase production by Trichoderma reesei RUT C30. Journal of Biotechnology, 54, 83–94.

Ma, L., Li, C., Yang, Z., Jia, W., Zhang, D., & Chen, S. (2013). Kinetic studies on batch cultivation of Trichoderma reesei and application to enhance cellulase production by fed-batch fermentation. Journal of Biotechnology, 166, 192–197.

Bader, J., Klingspohn, U., Bellgardt, K. H., & Schugerl, K. (1993). Modelling and simulation of the growth and enzyme production of Trichoderma reesei Rut C30. Journal of Biotechnology, 29, 21–135.

Muthuvelayudham, R., & Viruthagiri, T. (2006). Fermentative production and kinetics of cellulase protein on Trichoderma reesei using sugarcane bagasse and rice straw. African Journal of Biotechnology, 5, 1873–1881.

Prosser, J. I., & Tough, A. J. (1991). Growth mechanisms and growth kinetics of filamentous microorganisms. Critical Reviews in Biotechnology, 10, 253–274.

Fang, X., Yano, S., Inoue, H., & Sawayama, S. (2008). Lactose enhances cellulase production by the filamentous fungus Acremonium cellulolyticus. Journal of Bioscience and Bioengineering, 10, 115–120.

Lo, C.-M., Zhang, Q., Callow, N. V., & Ju, L.-K. (2010). Roles of extracellular lactose hydrolysis in cellulase production by Trichoderma reesei Rut C30 using lactose as inducing substrate. Process Biochemistry, 45, 1494–1503.

Sehnem, N. T., de Bittencourt, L. R., Camassola, M., & Dillon, A. J. P. (2006). Cellulase production by Penicillium echinulatum on lactose. Applied Microbiology and Biotechnology, 72, 163–167.

Fang, K.T., & Ma, C.X. (2001). Orthogonal and uniform experimental design. pp. 83–85 and 144–152. (in Chinese) Sciences Press, Beijing, China.

Pathak, P., Bhardwaj, N. K., & Singh, A. K. (2014). Production of crude cellulase and xylanase from Trichoderma harzianum PPDDN10 NFCCI-2925 and its application in photocopier waste paper recycling. Applied Biochemistry and Biotechnology, 172, 3776–3797.

Prasetyo, J., Sumita, S., Okuda, N., & Park, E. Y. (2010). Response of cellulase activity in pH controlled cultures of the filamentous fungus Acremonium cellulolyticus. Applied Biochemistry and Biotechnology, 162, 52–61.

Juhasz, T., Szengyel, Z., Szijarto, N., & Reczey, K. (2004). Effect of pH on cellulase production of Trichoderma reesei RUT C30. Effect of pH on cellulase production of Trichoderma reesei RUT C30. Applied Biochemistry and Biotechnology, 113–116, 201–211.

Li, C., Yang, Z., Zhang, R. H., Zhang, D., Chen, S., & Ma, L. (2013). Effect of pH on cellulase production and morphology of Trichoderma reesei and the application in cellulosic material hydrolysis. Journal of Biotechnology, 168, 470–477.

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (grant no. 31270135), the Provincial Natural Science Foundation for the Youth of Anhui province of China (grant no. 1408085QC61) and the Natural Science Foundation for the Youth of China (grant no. 31401630).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, S., Tang, B., Xu, Z. et al. Fermentation Optimization and Unstructured Kinetic Model for Cellulase Production by Rhizopus stolonifer var. reflexus TP-02 on Agriculture By-Products. Appl Biochem Biotechnol 177, 1589–1606 (2015). https://doi.org/10.1007/s12010-015-1839-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1839-0