Abstract

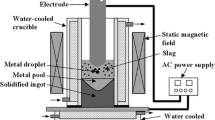

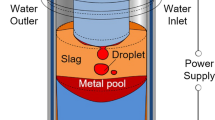

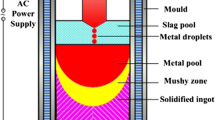

A transient three-dimensional coupled numerical model has been established to clarify the influence of the external transverse static magnetic field (TSMF) on droplet evolution behaviors during the electroslag remelting (ESR) process with an alternating current (50 Hz). The development of the electromagnetic field code and the calculation procedure showed that the periodic inverse Lorentz force (50 Hz) could be fully coupled with the volume of fluid model in each iteration when an external TSMF of 0.05 T is superimposed. The droplet evolution behaviors with and without the external TSMF were demonstrated and analyzed. The numerical results showed that the huge periodic inverse Lorentz force could smash the droplet neck into numerous smaller droplets during the ESR process with the external TSMF; simultaneously, the interfacial area and falling time could be increased, indicating that the purification efficiency could be expected to improve.

Similar content being viewed by others

Abbreviations

- \( \vec{A} \) :

-

Magnetic potential vector (V s/m)

- \( A_{x} , A_{y} , A_{z} \) :

-

Magnetic potential components in x, y, and z directions (V s/m)

- \( \vec{B}_{\text{ext}} \) :

-

External magnetic flux density (T)

- \( \vec{B}_{i} \) :

-

Induced magnetic flux density (T)

- \( \vec{F}_{e} \) :

-

Lorentz force (N/m3)

- \( f \) :

-

Current frequency (Hz)

- \( \vec{g} \) :

-

Gravitational acceleration (m/s2)

- \( I \) :

-

Root-mean-square current (A)

- \( \vec{j} \) :

-

Current density (A/m2)

- \( \vec{n} \) :

-

Unit normal vector

- \( p \) :

-

Pressure (Pa)

- \( R_{\text{m}} \) :

-

Radius of the ingot (m)

- t :

-

Time (s)

- \( \vec{v} \) :

-

Velocity (m/s)

- x, y, z :

-

Cartesian coordinates

- \( \mu_{0} \) :

-

Permeability of vacuum (H/m)

- \( \mu_{\text{eff}} \) :

-

Effective viscosity (Pa s)

- \( \bar{\rho } \) :

-

Density of the mixture phase (kg/m3)

- \( \bar{\sigma } \) :

-

Electrical conductivity of the mixture phase (S/m)

- \( \varphi \) :

-

Electrical potential (V)

References

Y. Liu, Z. Zhang, G. Li, Q. Wang, L. Wang, and B. Li, Metals 7, 185 (2017).

R. Fu, F. Li, F. Yin, D. Feng, Z. Tian, and L. Chang, Mater. Sci. Eng., A 638, 152 (2015).

J. Reitz, B. Wietbrock, S. Richter, S. Hoffmann, G. Hirt, and B. Friedrich, Adv. Eng. Mater. 13, 395 (2011).

Q.L. Wu, Y.S. Sun, F. Xue, and J. Zhou, Ironmak. Steelmak. 35, 387 (2008).

A.K. Vaish, G.V.R. Iyer, P.K. De, B.A. Lakra, A.K. Chakrabarti, and P. Ramachandrarao, J. Met. Mater. Soc. 42, 11 (2000).

Q. Wang, G. Li, Y. Gao, Z. He, and B. Li, J. Appl. Electrochem. 47, 445 (2017).

Q. Wang, Z. He, G. Li, B. Li, C. Zhu, and P. Chen, Int. J. Heat Mass Transf. 104, 943 (2017).

E. Karimi-Sibaki, A. Kharicha, M. Wu, A. Ludwig, and J. Bohacek, Steel Res. Int. 88, 1700011 (2017).

Z. Li, W. Zhou, and Y. Li, Iron Steel 15, 20 (1980).

Q. Wang, Y. Liu, F. Wang, G. Li, B. Li, and W. Qiao, Metall. Mater. Trans. B 48, 2649 (2017).

Y.Y. Kompan, I. Protokovilov, Y. Fautrelle, Y. Gelfgat, and A. Bojarevics, in Paper Presented at International Scientific Colloquium Riga, 2010, pp. 85–90

M. Murgaš, A.S. Chaus, A. Pokusa, and M. Pokusová, ISIJ Int. 40, 980 (2000).

Y. Zhong, Q. Li, Y. Fang, H. Wang, M. Peng, L. Dong, T. Zheng, Z. Lei, W. Ren, and Z. Ren, Mater. Sci. Eng., A 660, 118 (2016).

A. Kharicha, M. Wu, A. Ludwig, and E. Karimi-Sibaki, Metall. Mater. Trans. B 47, 1427 (2016).

H. Wang, Y. Zhong, Q. Li, W. Li, W. Ren, Z. Lei, Z. Ren, and Q. He, ISIJ Int. 57, 2157 (2017).

H. Wang, Y. Zhong, Q. Li, Y. Fang, W. Ren, Z. Lei, and Z. Ren, Metall. Mater. Trans. B 48, 655 (2016).

H. Wang, Y. Zhong, Q. Li, Y. Fang, W. Ren, Z. Lei, and Z. Ren, ISIJ Int. 56, 255 (2016).

H. Wang, Y. Zhong, Q. Li, Y. Fang, and Z. Lei, in Paper Presented at 8th International Conference on Electromagnetic Processing of Materials, Cannes, France, 2015, pp. 419–422

Q. Wang and B. Li, ISIJ Int. 56, 282 (2016).

F. Wang, Q. Wang, Y. Lou, R. Chen, Z. Song, and B. Li, JOM 68, 410 (2016).

X. Wang and Y. Li, Metall. Mater. Trans. B 46, 1837 (2015).

A. Kharicha, A. Ludwig, and M. Wu, ISIJ Int. 54, 1621 (2014).

Q. Wang, Z. He, B. Li, and F. Tsukihashi, Metall. Mater. Trans. B 45, 2425 (2014).

F. Wang, Q. Wang, and B. Li, ISIJ Int. 57, 91 (2017).

A. Kharicha, A. Ludwig, and M. Wu, in Paper presented at LMPC 2011, Nancy, 2011, pp. 41–48

A.H. Dilawari, J. Szekely, and T.W. Eagar, Mater. Trans. B 9, 371 (1978).

Q. Wang, W. Rong, and B. Li, JOM 67, 2705 (2015).

A. Kharicha, E. Karimi-Sibaki, M. Wu, A. Ludwig, and J. Bohacek, Steel Res. Int. 89, 1700100 (2017).

Q. Wang, R. Zhao, M. Fafard, and B. Li, Appl. Therm. Eng. 80, 178 (2015).

Y. Dong, Z. Jiang, H. Cao, X. Wang, Y. Cao, and D. Hou, ISIJ Int. 56, 1386 (2016).

J. Campbell, J. Met. 22, 23 (1970).

O.A. Troyanskyy, in Paper Presented at Proceedings of the International Workshop on Metal–Slag Interaction, Yalta, Ukraine, 2010, pp. 149–156

C. Vivès, Metall. Mater. Trans. B 27, 445 (1996).

A.F. Kolesnichenko, ISIJ Int. 30, 8 (1990).

Acknowledgements

The authors gratefully acknowledge financial support from the National Key Research and Development Program of China (No. 2016YFB0300401), National Natural Science Foundation of China (Nos. U1732276 and 51704193), General Financial Grant from the China Postdoctoral Science Foundation (No. 2017M621431), Science and Technology Commission of Shanghai Municipality (No. 15520711000), and Independent Research and Development Project of State Key of Advanced Special Steel, Shanghai University (SKLASS2015-Z021, SELF-2014-02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Zhong, Y., Dong, L. et al. Coupled 3D Numerical Model of Droplet Evolution Behaviors during the Magnetically Controlled Electroslag Remelting Process. JOM 70, 2917–2926 (2018). https://doi.org/10.1007/s11837-018-3029-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3029-3