Abstract

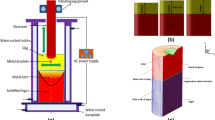

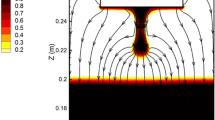

A transient three-dimensional (3D) coupled mathematical model has been developed to understand the effect of a vibrating electrode on the electromagnetic, two-phase flow and temperature fields as well as the solidification in the electroslag remelting (ESR) process. With the magnetohydrodynamic model, the Joule heating and Lorentz force, which are the source terms in the energy and momentum equations, are recalculated at each iteration as a function of the phase distribution. The influence of the vibrating electrode on the formation of the metal droplet is demonstrated by the volume of fluid approach. Additionally, the solidification of the metal is modeled by an enthalpy-based technique, in which the mushy zone is treated as a porous medium with porosity equal to the liquid fraction. The present work is the first attempt to investigate the innovative technology of the ESR process with a vibrating electrode by a transient 3D comprehensive model. A reasonable agreement between the experiment and simulation is obtained. The results indicate that the whole process is presented as a periodic activity. When the metal droplets fall from the tip of the electrode, the horizontal component of velocity will generate electrode vibration. This will lead to the distribution variation of the flow field in the slag layer. The variation of temperature distribution occurs regularly and is periodically accompanied by the behavior of the falling metal droplets. With the decreasing vibrating frequency and amplitude, the relative velocity of the electrode and molten slag increase accordingly. The diameter of the molten droplets, the maximum temperature and the depth of the molten pool gradually become smaller, lower and shallower.

Similar content being viewed by others

Abbreviations

- A m :

-

Mushy zone constant

- A x :

-

x Component of magnetic flux density (T)

- A y :

-

y Component of magnetic flux density (T)

- A z :

-

z Component of magnetic flux density (T)

- A elec :

-

The area of bottom of electrode (m2)

- \( \vec{B} \) :

-

Magnetic flux density (T)

- C p :

-

Heat capacity [J/(kg K)]

- \( \vec{E} \) :

-

Electric field intensity (N/C)

- f H :

-

Electric current frequency (Hz)

- f ℓ :

-

Liquid fraction

- \( \vec{F}_{\text{b}} \) :

-

Buoyancy force (N/m3)

- \( \vec{F}_{\text{e}} \) :

-

Electromagnetic force (N/m3)

- \( \vec{F}_{\text{p}} \) :

-

Pressure drop (m/s)

- \( \vec{g} \) :

-

Gravitational acceleration (m2/s)

- H :

-

Sensible enthalpy (J/kg)

- h ref :

-

Reference enthalpy (J/kg)

- \( \vec{H} \) :

-

Magnetic field intensity (A/m)

- H :

-

Enthalpy (J/kg)

- I rms :

-

Root mean square current (A)

- \( \vec{J} \) :

-

Current density (A/m2)

- k :

-

Turbulent kinetic energy (m2/s2)

- k e :

-

Effective thermal conductivity [W/(m K)]

- L :

-

Latent heat (J/kg)

- \( \dot{m} \) :

-

Melting rate (kg/s)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {P} \) :

-

Pressure (Pa)

- Q :

-

Joule heating (W)

- R :

-

Radius (m)

- R max :

-

Radius of the mold (m)

- S k :

-

Source term of solidification in the turbulent kinetic energy equation (m2/s3)

- S ɛ :

-

Source term of solidification in the dissipation rate of turbulent kinetic energy equation (m2/s3)

- t :

-

Time (s)

- T :

-

Temperature (K)

- T ref :

-

Reference temperature (K)

- T s :

-

Solidus temperature (K)

- T ℓ :

-

Liquidus temperature (K)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {v} \) :

-

Velocity (m/s)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {v}_{\text{cast}} \) :

-

Casting velocity (m/s)

- β :

-

Thermal expansion coefficient (1/K)

- δ :

-

Electromagnetic skin thickness (m)

- ɛ :

-

Dissipation rate of turbulent kinetic energy (m2/s3)

- η :

-

Power efficiency

- μ 0m :

-

Vacuum permittivity of metal (F/m)

- μ eff :

-

Effective viscosity (Pa s)

- ρ :

-

Density (kg/m3)

- ρ em :

-

Electric resistance of metal (Ω m)

- σ :

-

Electrical conductivity [1/(Ω m)]

- ϕ :

-

Electric potential (V)

References

B. Kalandyk and W. Wojtal, Arch. Metall. Mater. 58, 779 (2013).

A. Ludwig, A. Kharicha, and M. Wu, Metall. Metall. Mater. Trans. B 45B, 36 (2014).

B. Hernandez-Morales and A. Mitchell, Ironmak. Steelmak. 26, 423 (1999).

K. Kajikawa, S. Ganesh, K. Kimura, H. Kudo, T. Nakamura, Y. Tanaka, R. Schwant, F. Gatazka, and Y. Ling, Ironmak. Steelmak. 34, 216 (2007).

M. Choudhary and J. Szekely, Metall. Mater. Trans. B 12B, 418 (1981).

K. Miyazawa, T. Fukaya, S. Asai, I. Muchi, M. Choudhary, and J. Szekely, Trans. ISIJ 25, 386 (1985).

M. Choudhary, J. Szekely, B.I. Medovar, and Y.G. Emelyanenko, Metall. Mater. Trans. B 13B, 35 (1982).

A. Mitchell and B. Hernandez-Morales, Metall. Mater. Trans. B 21B, 723 (1990).

F. Wang, Y.C. Lou, R. Chen, Z.W. Song, and B.K. Li, China Foundry 12, 285 (2015).

S. Iijima, Y. Kondo, and T. Saito, Tetsu-to-Hagane 67, S645 (1978).

B. Li and F. Wang, in Paper presented at the 6th International Symposium on Electromagnetic Processing of Materials, Dresden, 2009, pp. 607–615.

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Rybéron, V. Schmitt, S. Hans, and H. Poisson, Metall. Mater. Trans. B 40B, 271 (2009).

A. Jardy, D. Ablitzer, and J.F. Wadier, Metall. Mater. Trans. B 22B, 111 (1991).

K.M. Kelkar, S.V. Patanker, A.Mitchell, in Paper presented at Proceedings of the 2005 International Symposium on Liquid Metal Processing and Casting, Santa Fe, UM, 2005, pp. 137–144.

M. Choudhary, J. Szekely, and T.I. Min, Metall. C. 90, 164 (1981).

M. Choudhary and J. Szekely, Ironmak. Steelmak. 8, 225 (1981).

A.H. Dilawari and J. Szekely, Ironmak. Steelmak. 4, 308 (1977).

Q. Wang, L. Gosselin, and B.K. Li, ISIJ Int. 54, 2821 (2014).

B.K. Li, B. Wang, and F. Tsukihashi, Metall. Mater. Trans. B 45B, 1122 (2014).

A.H. Dilawari and J. Szekely, Metall. Mater. Trans. B 9B, 77 (1978).

J. Yanke and M. Krane, in Paper presented at Proceedings of the 2013 International Symposium on Liquid Metal Processing and Casting, Austin, TX, 2013, pp. 71–78.

A.H. Dilawari and J. Szekely, Metall. Mater. Trans. B 8B, 227 (1977).

C.W. Hirt and B.D. Nichols, J. Comput. Phys. 39, 201 (1981).

M. Meier, G. Yadigaroglu, and B.L. Smith, Eur. J. Mech. B 21, 61 (2002).

A. Kharicha, A. Ludwig, and M. Wu, Mater. Sci. Eng. A 413, 29 (2005).

A. Kharicha, W. Schützenhöfer, A. Ludwig, G. Reiter, and M. Wu, Steel Res. Int. 79, 632 (2008).

A.D. Patel, in Paper presented at Proceedings of the 2007 International Symposium on Liquid Metal Processing and Casting, Nancy, France, 2007, pp. 95–105.

A. Kharicha, A. Ludwig, and M. Wu, in Paper presented at Proceedings of the 2011 International Symposium on Liquid Metal Processing and Casting, Nancy, France, 2011, pp. 113–119.

Q. Wang, R.J. Zhao, M. Fafard, and B.K. Li, Appl. Therm. Eng. 80, 178 (2015).

Acknowledgements

The authors’ gratitude goes to National Natural Science Foundation of People’s Republic of China [Nos. 51275320 and 51210007].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Wang, Q., Lou, Y. et al. Investigation of Heat Transfer and Magnetohydrodynamic Flow in Electroslag Remelting Furnace Using Vibrating Electrode. JOM 68, 410–420 (2016). https://doi.org/10.1007/s11837-015-1684-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1684-1