Abstract

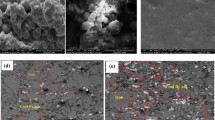

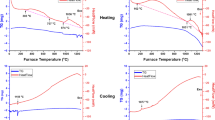

The present work elucidates the compaction and the densification behavior of iron powder and coal fly ash (CFA) mixtures during powder metallurgy (P/M) processing. The flowability and the compressibility characteristics of the starting materials were exhibited through Hausner ratio and Carr’s index. Morphological, elemental and crystallographic characterizations of the starting materials were carried out using scanning electron microscopy (SEM), energy-dispersive x-ray spectroscopy and x-ray diffraction investigations, respectively. The CFA of 0, 5, 10 and 15 wt.% was mixed with the iron powder through ball milling. Further, the cold compaction of the mixtures containing iron/CFA was performed in the hardened steel die using a uniaxial hydraulic press at pressures of 91 MPa, 138 MPa and 185 MPa, respectively. Subsequently, the preforms were sintered at 950, 1050 and 1150 °C in a tubular furnace under an inert atmosphere. The density of the preforms and the sintered pallets was estimated using weight to volume ratio and Archimedes method, respectively. The obtained mineralogy, morphology and physio-mechanical properties of the CFA are in good agreement with the ASTM standards. Further, the flowability and the compressibility characteristics of the starting materials rendered them suitable for processing through the P/M process. SEM analysis of the sintered pallets exhibited uniform distribution of CFA particulates in the iron matrix with clear and strong interfaces. An inverse effect of an increased amount of CFA inclusion has been observed on the green and sintered density of the composite. However, a linear influence of increased compacting pressure and sintering temperature has been observed on green and sintered densities, respectively. The magnitude of the green density achieved during cold compaction is considerably higher than that achieved during the sintering process. The obtained compaction data were successfully fitted using the Ge compaction equation.

Similar content being viewed by others

References

A. Malakar, V. Pancholi, and V.V. Dabhade, Recrystallization and Strengthening Mechanism in Friction-Stir-Processed Al Powder Compacts, J. Mater. Eng. Perform., 2020, 29(5), p 3243–3252

G.H. Majzoobi and K. Rahmani, Mechanical Characterization of Mg-B4C Nanocomposite Fabricated at Different Strain Rates, Int. J. Miner. Metall. Mater., 2020, 27(2), p 252–263

K.S. Narasimhan, Sintering of Powder Mixtures and the Growth of Ferrous Powder Metallurgy, Mater. Chem. Phys., 2001, 67(1–3), p 56–65

S.S. Razavi-Tousi, R. Yazdani-Rad, and S.A. Manafi, Effect of Volume Fraction and Particle Size of Alumina Reinforcement on Compaction and Densification Behavior of Al-Al2O3 Nanocomposites, Mater. Sci. Eng., A, 2011, 528(3), p 1105–1110

A.R. Kannan, K.S. Pandey, and S. Shanmugam, Some Investigation on the Cold Deformation Behaviour of Sintered Iron-0.8% Carbon Alloy Powder Preforms, J. Mater. Process. Technol., 2008, 203(1–3), p 542–547

S. Tiwari, P. Rajput, and S. Srivastava, Densification Behaviour in the Fabrication of Al-Fe Metal Matrix Composite Using Powder Metallurgy Route, Int. Sch. Res. Notices, 2012, 2012, p 1–8

J.M. Montes, F.G. Cuevas, J. Cintas, and Y. Torres, Powder Compaction Law for Cold Die Pressing, Granul. Matter, 2010, 12(6), p 617–627

S. Huo, L. Xie, J. Xiang, S. Pang, F. Hu, and U. Umer, Atomic-Level Study on Mechanical Properties and Strengthening Mechanisms of Al/SiC Nano-Composites, Appl. Phys. A Mater. Sci. Process., 2018, 124(2), p 1–12

U.R. Kanth, P.S. Rao, and M.G. Krishna, Mechanical Behaviour of Fly Ash/SiC Particles Reinforced Al-Zn Alloy-Based Metal Matrix Composites Fabricated by Stir Casting Method, J. Mater. Res. Technol. Braz. Metall. Mater. Min. Assoc., 2019, 8(1), p 737–744

F.A.R. Rozhbiany and S.R. Jalal, Influence of Reinforcement and Processing on Aluminum Matrix Composites Modified by Stir Casting Route, Adv. Compos. Lett., 2019, 28, p 1–8

N.K. Bhoi, H. Singh, and S. Pratap, Developments in the Aluminum Metal Matrix Composites Reinforced by Micro/Nano Particles—A Review, J. Compos. Mater., 2020, 54(6), p 813–833

A. Trivedi and V.K. Sud, Grain Characteristics and Engineering Properties of Coal Ash, Granul. Matter, 2002, 4(3), p 93–101

R. Manimaran, I. Jayakumar, R. Mohammad Giyahudeen, and L. Narayanan, Mechanical Properties of Fly Ash Composites—A Review, Energy Sources Part A Recovery Util. Environ. Eff., 2018, 40(8), p 887–893

M. Ahmaruzzaman, A Review on the Utilization of Fly Ash, Prog. Energy Combust. Sci., 2010, 36(3), p 327–363

R.Q. Guo, P.K. Rohatgi, and D. Nath, Compacting Characteristics of Aluminium-Fly Ash Powder Mixtures, J. Mater. Sci., 1996, 31, p 5513–5519

A.K. Kasar, N. Gupta, P.K. Rohatgi, and P.L. Menezes, A Brief Review of Fly Ash as Reinforcement for Composites with Improved Mechanical and Tribological Properties, JOM, 2020, 72(6), p 2340–2351

J.J. Biernacki, A.K. Vazrala, and H.W. Leimer, Sintering of a Class F Fly Ash, Fuel, 2008, 87, p 782–792

R.Q. Guo and P.K. Rohatgi, Preparation of Aluminium-Fly Ash Particulate Composite by Powder Metallurgy Technique, J. Mater. Sci., 1997, 2(32), p 3971–3974

Y.Z. Zhu, Z.M. Yin, Z.D. Xiang, and Z. Zhe, Cold Densification Behaviour of Multiple Alloy Powder Containing Fe-Cr and Fe-Mo Hard Particles, Powder Metall., 2008, 51(2), p 143–149

D. Bouvard, Densification Behaviour of Mixtures of Hard and Soft Powders under Pressure, Powder Technol., 2000, 111(3), p 231–239

G. Sethi, N.S. Myers, and R.M. German, An Overview of Dynamic Compaction in Powder Metallurgy, Int. Mater. Rev., 2008, 53(4), p 219–234

U.J. Prasanna Kumar, P. Gupta, A.K. Jha, and D. Kumar, Closed Die Deformation Behavior of Cylindrical Iron-Alumina Metal Matrix Composites During Cold Sinter Forging, J. Inst. Eng. (India) Ser. D, 2016, 97(2), p 135–151

S. Narayan and A. Rajeshkannan, Densification Behaviour in Forming of Sintered Iron-03.5% Carbon Powder Metallurgy Preform during Cold Upsetting, Mater. Des., 2011, 32(2), p 1006–1013

R. Raj and D.G. Thakur, Qualitative and Quantitative Assessment of Microstructure in Al-B4C Metal Matrix Composite Processed by Modified Stir Casting Technique, Arch. Civ. Mech. Eng., 2016, 16(4), p 949–960

M. Marin and F. B. Marin, Quantitative Image Analysis in Some Iron Powder Metallurgy Materials. in IOP Conference Series: Materials Science and Engineering, 2019

S.L.G. Petroni, PM Compaction Equations Applied for the Modelling of Titanium Hydride Powders Compressibility Data, Powder Metall., 2020, 63(1), p 35–42

N.M. Abbas, X. Deng, and A.P. Reynolds, Compaction of Machining Chips: Extended Experiments and Modeling, Mech. Mater., 2020, 141, p 103249

F. Güner, Ö.N. Cora, and H. Sofuoğlu, Numerical Modeling of Cold Powder Compaction Using Multi Particle and Continuum Media Approaches, Powder Technol., 2015, 271, p 238–247

A. Saboori, C. Novara, M. Pavese, C. Badini, F. Giorgis, and P. Fino, An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy, J. Mater. Eng. Perform., 2017, 26(3), p 993–999

R. Machaka and H.K. Chikwanda, Analysis of the Cold Compaction Behavior of Titanium Powders: A Comprehensive Inter-Model Comparison Study of Compaction Equations, Metall. Mater. Trans. A, 2015, 46(9), p 4286–4297

T.J. Griffiths and A. Ghanizadeh, Determination of Elastic Constants for Porous Sintered Iron Powder Compacts, Powder Metall., 1986, 29(2), p 129–133

A. Singh, J. Singh, M.K. Sinha, R. Kumar, and V. Verma, Investigations on Microstructural and Microhardness Developments in Sintered Iron–Coal Fly Ash Composites, Sādhanā, 2020, 45, p 1–13

C. Igathinathane, L.O. Pordesimo, E.P. Columbus, W.D. Batchelor, and S.R. Methuku, Shape Identification and Particles Size Distribution from Basic Shape Parameters Using ImageJ, Comput. Electron. Agric., 2008, 63(2), p 168–182

P. Verma, R. Saha, and D. Chaira, Waste Steel Scrap to Nanostructured Powder and Superior Compact through Powder Metallurgy: Powder Generation, Process. Charact. Powder Technol., 2018, 326, p 159–167

A. Saker, M.G. Cares-Pacheco, P. Marchal, and V. Falk, Powders Flowability Assessment in Granular Compaction: What about the Consistency of Hausner Ratio?, Powder Technol., 2019, 354, p 52–63

M.R.I. Shishir, F.S. Taip, N.A. Aziz, and R.A. Talib, Physical Properties of Spray-Dried Pink Guava (Psidium Guajava) Powder, Agric. Agric. Sci. Procedia, 2014, 2, p 74–81

A. Bhatt, S. Priyadarshini, A. Acharath Mohanakrishnan, A. Abri, M. Sattler, and S. Techapaphawit, Physical, Chemical, and Geotechnical Properties of Coal Fly Ash: A Global Review, Case Studies in Construction Materials, 2019, 11, p 1–11

T. Matsunaga, J.K. Kim, S. Hardcastle, and P.K. Rohatgi, Crystallinity and Selected Properties of Fly Ash Particles, Mater. Sci. Eng., A, 2002, 325, p 333–343

C.A. Leon, G. Rodriguez-Ortiz, and E.A. Aguilar-Reyes, Cold Compaction of Metal-Ceramic Powders in the Preparation of Copper Base Hybrid Materials, Mater. Sci. Eng., A, 2009, 526(1–2), p 106–112

R. Stevens, T. Vendlinski, J. Palacio-Cayetano, J. Underdahl, P. Paek, M. Sprang, and E. Simpson, Tracing the Development, Transfer, and Persistence of Problem Solving Skills, Mater. Des., 2001, 24, p 561–575

D. Poquillon, J. Lemaitre, V. Baco-Carles, P. Tailhades, and J. Lacaze, Cold Compaction of Iron Powders—Relations between Powder Morphology and Mechanical Properties: Part I: Powder Preparation and Compaction, Powder Technol., 2002, 126(1), p 65–74

A. Fathy, O. El-Kady, and M.M.M. Mohammed, Effect of Iron Addition on Microstructure, Mechanical and Magnetic Properties of Al-Matrix Composite Produced by Powder Metallurgy Route, Trans. Nonferrous Met. Soc. China, 2015, 25(1), p 46–53

M. Andasmas, P. Langlois, N. Fagnon, T. Chauveau, A. Hendaoui, and D. Vrel, Phenomenological Study of the Densification Behavior of Aluminum-Nickel Powder Mixtures during Cold Isostatic Pressing and Differential Hydrostatic Extrusion, Powder Technol., 2011, 207(1–3), p 304–310

S. Mahdavi and F. Akhlaghi, Effect of SiC Content on the Processing, Compaction Behavior, and Properties of Al6061/SiC/Gr Hybrid Composites, J. Mater. Sci., 2011, 46(5), p 1502–1511

H.F. Fischmeister, Eighteenth John Player Lecture. Powder Compaction: Fundamentals and Recent Developments, Proc. Instn. Mech. Engrs., 1982, 196, p 105–121

C. Manière and E.A. Olevsky, Porosity Dependence of Powder Compaction Constitutive Parameters: Determination Based on Spark Plasma Sintering Tests, Scripta Mater., 2017, 141, p 62–66

F. Ludewig, N. Vandewalle, and S. Dorbolo, Compaction of Granular Mixtures, Granul. Matter, 2006, 8(2), p 87–91

J.P. Panakkal, H. Willems, and W. Arnold, Nondestructive Evaluation of Elastic Parameters of Sintered Iron Powder Compacts, J. Mater. Sci., 1990, 25(2), p 1397–1402

Y. Tian, Z. Dou, L. Niu, and T. Zhang, Effect of Nanoboron Carbide Particles on Properties of Copper-Matrix/Graphite Composite Materials, Mater. Res. Express, 2019, 6(9), p 0950c7

M. Zhou, S. Huang, Y. Lei, W. Liu, and S. Yan, Investigation on Compaction Densification Behaviors of Multicomponent Mixed Metal Powders to Manufacture Silver-Based Filler Metal Sheets, Arab. J. Sci. Eng., 2019, 44(2), p 1321–1335

M. Andrezak and B. Schiffer, Kanban and Technical Excellence or: Why Daily Releases Are a Great Objective to Meet, in Lecture Notes in Business Information Processing, 2010, p 115–117.

W. Chen, J. Wang, S. Wang, P. Chen, J. Cheng, W. Chen, J. Wang, S. Wang, P. Chen, and J. Cheng, On the Processing Properties and Friction Behaviours during Compaction of Powder Mixtures, Mater. Sci. Technol., 2020, 36, p 1057–1064

P.J. Denny, Compaction Equations: A Comparison of the Heckel and Kawakita Equations, Powder Technol., 2002, 127, p 162–172

C. Machio, R. Machaka, T. Shabalala, and H.K. Chikwanda, Analysis of the Cold Compaction Behaviour of TiH2-316L Nanocomposite Powder Blend Using Compaction Models, Mater. Sci. Forum, 2015, 828–829(June), p 121–128

H. Abdollahi, R. Mahdavinejad, and R.P. Leavoli, Investigation and Optimization of Properties of Sintered Iron/Recycled Grey Cast Iron Powder Metallurgy Parts, J. Eng. Manuf., 2015, 229(6), p 1010–1020

G. Arora and S. Sharma, A Review on Monolithic and Hybrid Metal-Matrix Composites Reinforced with Industrial-Agro Wastes, J. Braz. Soc. Mech. Sci. Eng., 2017, 39(11), p 4819–4835

D.C. Jana, P. Barick, and B.P. Saha, Effect of Sintering Temperature on Density and Mechanical Properties of Solid-State Sintered Silicon Carbide Ceramics and Evaluation of Failure Origin, J. Mater. Eng. Perform., 2018, 27(6), p 2960–2966

A. Nirala and A. Upadhyaya, Experimental Characterization and Sintering Behavior in Mixed Atmosphere (N2 and H2) of Fe3P-Added Ferritic Stainless Steel (434L), J. Mater. Eng. Perform., 2020, 29(5), p 2926–2935

J. William D. Callister and Department, Fundamentals of Materials Science and Engineering. W. Anderson, Ed., Fifth, 2001, Wiley, New York.

H. Abdollahi, R. Mahdavinejad, M. Ghambari, and M. Moradi, Investigation of Green Properties of Iron/Jet-Milled Grey Cast Iron Compacts by Response Surface Method, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2014, 228(4), p 493–503

P. Balamurugan and M. Uthayakumar, Influence of Process Parameters on Cu-Fly Ash Composite by Powder Metallurgy Technique, Mater. Manuf. Process., 2015, 30(3), p 313–319

P. Ruano, L.L. Delgado, S. Picco, L. Villegas, F. Tonelli, M. Merlo, J. Rigau, D. Diaz, and M. Masuelli, We Are Intech Open the World’s Leading Publisher of Open Access Books Built by Scientists, Intech, 2016, p 13.

E. Biguereau, D. Bouvard, J.M. Chaix, and S. Roure, On the Swelling of Silver Powder during Sintering, Powder Metall., 2016, 59(5), p 394–400

F. Lin, Z. Chen, B. Liu, Y. Liu, and C. Zhou, Microstructure and Mechanical Properties of Iron-Containing Titanium Metal-Metal Composites, Int. J. Refract Metal Hard Mater., 2020, 90, p 1–6

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, A., Singh, J., Sinha, M.K. et al. Compaction and Densification Characteristics of Iron Powder/Coal Fly Ash Mixtures Processed by Powder Metallurgy Technique. J. of Materi Eng and Perform 30, 1207–1220 (2021). https://doi.org/10.1007/s11665-020-05429-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05429-x