Abstract

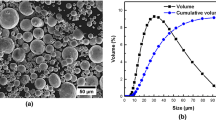

Green Al powder compacts were subjected to densification by friction stir processing (FSP). Prior to FSP, the Al powder was cold compacted at three different pressures of 50, 200 and 380 MPa to achieve green densities of 2.1, 2.3 and 2.5 g/cm3, respectively. After FSP density increased to 2.7 g/cm3 (100% densification), green density had effect on microstructure and properties obtained after FSP. The size and shape of the nugget area was found to depend on compaction pressure though the FSP parameters were unchanged. After FSP, the sample compacted at highest compaction pressure showed fine and recrystallized grains, whereas the sample compacted at lowest compaction pressure showed elongated grains with higher dislocation density. An extensive microstructural investigation suggested that grain refinement occurred by continuous dynamic recrystallization. Strengthening in sample with fine, recrystallized microstructure was dominated by grain boundary strengthening mechanism, whereas, in unrecrystallized microstructure, strengthening was due to strain hardening mechanism.

Similar content being viewed by others

References

S. Okuma, The Sintering Mechanism of Aluminium and the Anodization of Aluminium Sintered Bodies, Electrocomp. Sci. Tech., 1979, 6, p 23–29

V.S. Kruzhanov, Modern Manufacturing of Powder-Metallurgical Products with High Density and Performance by Press–Sinter Technology, Powder Metall. Met. Ceram., 2018, 57, p 431–446

E.O. Olakanmi, R.F. Cochrane, and K.W. Dalgarno, A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties, J. Prog. Mater. Sci., 2015, 74, p 401–477

W. Kehl and H.F. Fischmeister, Liquid Phase Sintering of Al-Cu Compacts, Powder Metall., 1980, 23, p 113–119

R.N. Lumley, T.B. Sercombe, and G.B. Schaffer, Surface Oxide and the Role of Magnesium during the Sintering of Aluminium, Metall. Mater. Trans. A, 1999, 30, p 457–463

M.C. Oh and B. Ahn, Effect of Mg Composition on Sintering Behaviors and Mechanical Properties of Al-Cu-Mg Alloy, Trans. Nonferrous Met. Soc. China, 2014, 24, p s53–s58

J.M. Martín, T. Gómez-Acebo, and F. Castro, Sintering Behaviour and Mechanical Properties of PM Al-Zn-Mg-Cu Alloy Containing Elemental Mg Additions, Powder Metall., 2002, 45, p 173–180

C.J. Hsu, C.Y. Chang, P.W. Kao, N.J. Ho, and C.P. Chang, Al-Al3Ti Nanocomposites Produced In Situ by Friction Stir Processing, Acta Mater., 2006, 54, p 5241–5249

I.S. Lee, C.J. Hsu, C.F. Chen, N.J. Ho, and P.W. Kao, Particle-Reinforced Aluminum Matrix Composites Produced from Powder Mixtures via Friction Stir Processing, Compos. Sci. Technol., 2011, 71, p 693–698

I.S. Lee, P.W. Kao, and N.J. Ho, Microstructure and Mechanical Properties of Al-Fe in Situ Nanocomposite Produced by Friction Stir Processing, Intermetallics, 2008, 16, p 1104–1108

G.L. You, N.J. Ho, and P.W. Kao, The Microstructure and Mechanical Properties of an Al-CuO In Situ Composite Produced Using Friction Stir Processing, Mater. Lett., 2013, 90, p 26–29

G.L. You, N.J. Ho, and P.W. Kao, In Situ Formation of Al2O3 Nanoparticles during Friction Stir Processing of AlSiO2 Composite, Mater. Charact., 2013, 80, p 1–8

C.J. Hsu, P.W. Kao, and N.J. Ho, Ultrafine-Grained Al-Al2Cu Composite Produced In Situ by Friction Stir Processing, Scr. Mater., 2005, 53, p 341–345

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78

J. Su, T.W. Nelson, and C.J. Sterling, Friction Stir Processing of Large-Area Bulk UFG Aluminum Alloys, Scr. Mater., 2005, 52, p 135–140

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, and M. Calabrese, Fine-Grain Evolution in Friction-Stir Processed 7050 Aluminum, Scr. Mater., 2003, 48, p 1451–1455

J.Y. Kwon, I. Shigematsu, and N. Saito, Mechanical Properties of Fine-Grained Aluminum Alloy Produced by Friction Stir Process, Scr. Mater., 2003, 49, p 785–789

W.B. Lee, Y.M. Yeon, and S.B. Jung, The Improvement of Mechanical Properties of Friction-Stir-Welded A356 Al Alloy, Mater. Sci. Eng. A, 2003, 355, p 154–159

P.B. Berbon, W.H. Bingel, R.S. Mishra, C.C. Bampton, and M.W. Mahoney, Friction Stir Processing: A Tool to Homogenize Nanocomposite Aluminum Alloys, Scr. Mater., 2001, 44, p 61–66

S.R.H. Zeidabadi and H. Daneshmanesh, Fabrication and Characterization of In Situ Al/Nb Metal/Intermetallic Surface Composite by Friction Stir Processing, Mater. Sci. Eng. A, 2017, 702, p 189–195

B. Li, Y. Shen, L. Luo, and W. Hu, Fabrication of TiCp/Ti-6Al-4V Surface Composite via Friction Stir Processing (FSP): Process Optimization, Particle Dispersion-Refinement Behavior and Hardening Mechanism, Mater. Sci. Eng. A, 2013, 574, p 75–85

M. Raaft, T.S. Mahmoud, H.M. Zakaria, and T.A. Khalifa, Microstructural, Mechanical and Wear Behavior of A390/Graphite and A390/Al2O3 Surface Composites Fabricated Using FSP, Mater. Sci. Eng. A, 2011, 528, p 5741–5746

M. Narimani, B. Lot, and Z. Sadeghian, Investigating the Microstructure and Mechanical Properties of Al-TiB2 Composite Fabricated by Friction Stir Processing (FSP), Mater. Sci. Eng. A, 2016, 673, p 436–442

C.M. Hu, C.M. Lai, P.W. Kao, N.J. Ho, and J.C. Huang, Solute-Enhanced Tensile Ductility of Ultrafine-Grained Al-Zn Alloy Fabricated by Friction Stir Processing, Scr. Mater., 2009, 60, p 639–642

G.L. You, N.J. Ho, and P.W. Kao, Aluminum Based In Situ Nanocomposite Produced from Al-Mg-CuO Powder Mixture by Using Friction Stir Processing, Mater. Lett., 2013, 100, p 219–222

C.M. Hu, C.M. Lai, X.H. Du, N.J. Ho, and J.C. Huang, Enhanced Tensile Plasticity in Ultrafine-Grained Metallic Composite Fabricated by Friction Stir Process, Scr. Mater., 2008, 59, p 1163–1166

P.J. James, Particle Deformation during Cold Isostatic Pressing of Metal Powders, Powder Metall., 1977, 20, p 199–204

J.K. Mackenzie and M.J. Thomson, Some Statistics Associated with the Random Disorientation Of Cubes, Biometrika, 1957, 44, p 205–210

I. Samajdar and R.D. Doherty, Grain Boundary Misorientation in DC-Cast Aluminum Alloy, Scr. Metall., 1994, 31, p 527–530

H. Qiu, L.N. Wang, J.G. Qi, H. Zuo, and K. Hiraoka, Enhancement of Fracture Toughness of High-Strength Cr-Ni Weld Metals by Strain-Induced Martensite Transformation, Mater. Sci. Eng. A, 2013, 579, p 71–76

A. Gerlich, P. Su, M. Yamamoto, and T.H. North, Effect of Welding Parameters on the Strain Rate and Microstructure of Friction Stir Spot Welded 2024 Aluminum Alloy, J. Mater. Sci., 2007, 42, p 5589–5601

C.I. Chang, C.J. Lee, and J.C. Huang, Relationship Between Grain Size and Zener–Holloman Parameter during Friction Stir Processing in AZ31 Mg Alloys, Scr. Mater., 2004, 51, p 509–514

G. Chen, Z. Feng, Y. Zhu, and Q. Shi, An Alternative Frictional Boundary Condition for Computational Fluid Dynamics Simulation of Friction Stir Welding, J. Mater. Eng. Perform., 2016, 25, p 4016–4023

A.G. Rao, K.R. Ravi, B. Ramakrishnarao, V.P. Deshmukh, A. Sharma, N. Prabhu, and B.P. Kashyap, Recrystallization Phenomena during Friction Stir Processing of Hypereutectic Aluminum-Silicon Alloy, Metall. Mater. Trans. A, 2013, 44, p 1519–1529

J.J. Jonas, M. Sellars, and W.J.M.G. Tegart, Strength and Structure under Hot-Working Conditions, Metall. Rev., 1969, 14, p 1–24

C.Y. Yu, P.W. Kao, and C.P. Chang, Transition of Tensile Deformation Behaviors in Ultrafine-Grained Aluminum, Acta Mater., 2005, 53, p 4019–4028

S.J. Lee, Y. Sun, and H. Fujii, Stacking-Fault Energy, Mechanical Twinning and Strain Hardening of Fe-18Mn-0.6C-(0, 1.5)Al Twinning-Induced Plasticity Steels during Friction Stir Welding, Acta Mater., 2018, 148, p 235–248

E. Breitbarth, S. Zae, F. Archie, M. Besel, D. Raabe, and G. Requena, Evolution of Dislocation Patterns Inside the Plastic Zone Introduced by Fatigue in an Aged Aluminium Alloy AA2024-T3, Mater. Sci. Eng. A, 2018, 718, p 345–349

Y. Tomota, M. Ojima, S. Harjo, W. Gong, S. Sato, and T. Ungár, Dislocation Densities and Intergranular Stresses of Plastically Deformed Austenitic Steels, Mater. Sci. Eng. A, 2019, 743, p 32–39

C. Ha, J. Bohlen, S. Yi, X. Zhou, H. Brokmeier, N. Schell, D. Letzig, and K.U. Kainer, Influence of Nd or Ca Addition on the Dislocation Activity and Texture Changes of Mg-Zn Alloy Sheets under Uniaxial Tensile Loading, Mater. Sci. Eng. A, 2019, 761, p 138053

C.W. Sinclair, W.J. Poole, and Y. Bréchet, A Model for the Grain Size Dependent Work Hardening of Copper, Scr. Mater., 2006, 55, p 739–742

A. Das and S. Tarafder, Geometry of Dimples and Its Correlation with Mechanical Properties in Austenitic Stainless Steel, Scr. Mater., 2008, 59, p 1014–1017

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malakar, A., Pancholi, V. & Dabhade, V.V. Recrystallization and Strengthening Mechanism in Friction-Stir-Processed Al Powder Compacts. J. of Materi Eng and Perform 29, 3243–3252 (2020). https://doi.org/10.1007/s11665-020-04806-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04806-w