Abstract

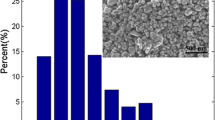

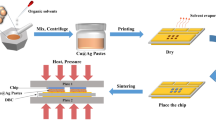

We have developed a new kind of nanosilver paste by reducing the stress and strain of the drying process with the help of some organics to bond large-area (≥100 mm2) power chips without additional pressure. This new nanosilver paste contains nanoparticles and microparticles ranging from 0.02 μm to 2 μm. The effects of sintering temperature (T), heating rate (ν), and holding time for sintering (t) on the microstructure and mechanical properties of sintered silver joints were investigated by the Taguchi method. The various factors were assigned to an L16 (43) orthogonal array. The experimental results showed that neck formation was strongly dependent on the increase of the sintering temperature, while prolonging the holding time and decreasing the heating rate were beneficial to neck growth. The pore size distribution ranged from 0.03 μm2 to 1.6 μm2, and the larger pores (0.8 μm2 to 1.6 μm2) were more irregular and clustered along the interstices between particles. The shear strength increased with increased sintering temperature, prolonged holding time, and decreased heating rate due to smaller pore size and a more homogeneous pore distribution. The fatigue and tensile behaviors of pressureless-sintered silver joints were also compared with those of soldered SAC305 joints.

Similar content being viewed by others

References

K.S. Siow, J. Electron. Mater. 43, 947 (2014).

R. Khazaka, L. Mendizabal, and D. Henry, J. Electron. Mater. 43, 2459 (2014).

K.S. Moon, H. Dong, R. Maric, S. Pothukuchi, A. Hunt, Y. Li, and C.P. Wong, J. Electron. Mater. 34, 168 (2005).

D.J. Yu, X. Chen, G. Chen, G.Q. Lu, and Z.Q. Wang, Mater. Des. 30, 4574 (2009).

J.S. Kang, J. Ryu, H.S. Kim, and H.T. Hahn, J. Electron. Mater. 40, 2268 (2011).

M. Yeadon, J.C. Yang, R.S. Averback, J.W. Bullard, and J.M. Gibson, Nanostr. Mater. 10, 731 (1998).

T. Wang, G. Chen, Y.P. Wang, X. Chen, and G.Q. Lu, Mater. Sci. Eng. A 527, 6714 (2010).

M. Bouarroudj, Z. Khatir, J.P. Ousten, F. Badel, L. Dupont, and S. Lefebvre, Microelectron. Reliab. 47, 1719 (2007).

O. Schilling, M. Schäfer, K. Mainka, M. Thoben, and F. Sauerland, Microelectron. Reliab. 52, 2347 (2012).

Y.H. Mei, G. Chen, J.Y. Cao, X. Li, D. Han, and X. Chen, J. Electron. Mater. 42, 209 (2013).

J. Zhou and J.T. Guo, Mater. Sci. Eng. A 339, 166 (2003).

I. Saini, J. Rozra, N. Chandak, S. Aggarwal, P.K. Sharma, and A. Sharma, Mater. Chem. Phys. 139, 802 (2013).

E. Kayahan, N. Ceylan, and K. Esmer, Appl. Surf. Sci. 255, 2808 (2008).

H. Yu, L.L. Li, and Y.J. Zhang, Scr. Mater. 66, 931 (2012).

E. Ide, S. Angata, A. Hirose, and K.F. Kobayashi, Acta Mater. 53, 2385 (2005).

H. Alarifi, A. Hu, M. Yavuz, and Y.N. Zhou, J. Electron. Mater. 40, 1394 (2011).

H. Ogura, M. Maruyama, R. Matsubayashi, T. Ogawa, S. Nakamura, T. Komatsu, H. Nagasawa, A. Ichimura, and S. Isoda, J. Electron. Mater. 39, 1233 (2010).

B.S. Li, G.R. Li, W.Z. Zhang, and A.L. Ding, Mater. Sci. Eng. B 121, 92 (2005).

J.F. Yan, G.S. Zou, A.P. Wu, J.L. Ren, J.C. Yan, A.M. Hu, and Y. Zou, Scr. Mater. 66, 582 (2012).

S. Wang, H.J. Ji, M.Y. Li, and C.Q. Wang, Mater. Lett. 85, 61 (2013).

K.W. Xiao, K.D.T. Ngo, and G.Q. Lu, J. Mater. Res. 29, 1 (2014).

A.D. Albert, M.F. Becker, J.W. Keto, and D. Kovar, Acta Mater. 56, 1820 (2008).

U. Lindstedt, B. Karlsson, and R. Masini, Int. J. Powder Metall. 33, 49 (1997).

J. Mccoppin, T.L. Reitz, R. Miller, H. Vijwani, S. Mukhopadhyay, and D. Young, J. Electron. Mater. 43, 3379 (2014).

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.-S. Kim, and M. Nogi, Microelectron. Reliab. 52, 375 (2012).

G.Q. Lu, W.L. Li, Y.H. Mei, G. Chen, X. Li, X. Chen, and I.E.E.E. Trans, Device Mater. Reliab. 14, 623 (2014).

N. Chawla and X. Deng, Mater. Sci. Eng. A 390, 98 (2005).

E.M. Bouta, C.W. McCarthy, A. Keima, H.B. Wang, R.J. Gilbert, and J. Goldman, Acta Biomater. 7, 1104 (2011).

C.H. Ji, N.H. Loh, K.A. Khor, and S.B. Tor, Mater. Sci. Eng. A 311, 74 (2001).

D. Jurkow and J. Stiernstedt, Ceram. Int. 40, 10447 (2014).

J.K. Mackenzie and R. Shuttleworth, Proc. Phys. Soc. 62, 833 (1949).

J.N. Calata, G.Q. Lu, and T.J. Chuang, Surf. Interface Anal. 31, 673 (2001).

A. Hu, J.Y. Guo, J. Alarifi, G. Patane, Y. Zhou, G. Compagnini, and C.X. Xu, Appl. Phys. Lett. 97, 153117 (2010).

K. Dick, T. Dhanasekaren, Z. Zhang, and D. Meisel, J. Am. Chem. Soc. 124, 2312 (2002).

J.G. Bai, T.G. Lei, J.N. Calata, and G.Q. Lu, J. Mater. Res. 22, 3494 (2007).

E.R. Leite, M.A.L. Nobre, M.D. Ribeiro, E. Longo, and J.A. Varela, J. Mater. Sci. 33, 4791 (1998).

T. Wang, X. Chen, G.Q. Lu, and G.Y. Lei, J. Electron. Mater. 36, 1333 (2007).

E.A. Olevskya, G.A. Shoales, and R.M. Germanb, Mater. Res. Bull. 36, 449 (2001).

M.J. Mayo and D.C. Hague, Nanostr. Mater. 3, 43 (1993).

M.L. Gu, H.J. Xua, J.H. Zhang, Z. Wei, and A.P. Xua, Mater. Sci. Eng. A 545, 1 (2012).

S.J. Polasik, J.J. Williams, and N. Chawla, Metall. Mater. Trans. A 33, 73 (2002).

K.D. Zilnyk, G.S. Leite, H.R.Z. Sandim, and P.R. Rios, Acta Mater. 61, 5821 (2013).

T. Nakamura, G. Qian, and C.C. Berndt, J. Am. Ceram. Soc. 83, 578 (2000).

L.A. Stanciu, V.Y. Kodash, and J.R. Grozametall, Mater. Trans. A 32, 2633 (2001).

F.F. Lange and B.J. Kellett, J. Am. Ceram. Soc. 72, 735 (1989).

Y. Wen, L. Nan, and B.Q. Han, Am. Ceram. Soc. Bull. 84, 9201 (2005).

D.M. Liu, Ceram. Int. 23, 135 (1997).

K.L. Lin, W.Y. Zhai, S.Y. Ni, J.A. Chang, Y. Zeng, and W.J. Qian, Ceram. Int. 31, 323 (2005).

K. Tanaka and T.A. Mura, J. Appl. Mech. 48, 98 (1981).

V. Stolkart, L. Keer, and M. Fine, J. Mech. Phys. Solids 47, 2451 (1999).

Q.K. Zhang and Z.F. Zhang, Acta Mater. 59, 6017 (2011).

Q.K. Zhang, Q.S. Zhu, H.F. Zou, and Z.F. Zhang, Mater. Sci. Eng. A 527, 1367 (2010).

K.J. Puttlitz and G.T. Galyon, J. Mater. Sci-Mater El. 18, 347 (2007).

M.N. Wang, J.Q. Wang, H. Feng, and W. Ke, J. Mater. Sci.-Mater. El. 23, 148 (2012).

X.Y. Li and Z.S. Wang, J. Mater. Proc. Technol. 183, 6 (2007).

K.S. Kim, S.H. Huh, and K. Suganuma, J. Alloys Compd. 352, 226 (2003).

Y.T. Chin, P.K. Lam, H.K. Yow, and T.Y. Tou, Microelectron. Reliab. 48, 1079 (2008).

M.L. Huang, Z.J. Zhang, S.M. Zhou, and L.D. Chen, J. Mater. Res. 29, 2556 (2014).

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (No. 61334010), the Tianjin Municipal Natural Science Foundation (under Grants 13JCQNJC06600 and 13JCZDJC33600), the National Science & Technology Pillar Program (Grant No. 2013BAG02B01), and the National High Technology Research and Development Program of China (No. 2015AA034501). The work was supported by and corresponds to Dr. Yunhui Mei of Tianjin University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, S., Mei, Y., Li, X. et al. Parametric Study on Pressureless Sintering of Nanosilver Paste to Bond Large-Area (≥100 mm2) Power Chips at Low Temperatures for Electronic Packaging. J. Electron. Mater. 44, 3973–3984 (2015). https://doi.org/10.1007/s11664-015-3842-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3842-1