Abstract

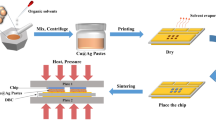

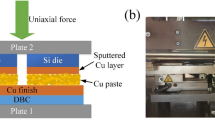

Nanosilver paste is a promising lead-free die-attach material suitable for power electronic packaging, especially for high-temperature applications. Compared with conventional hot-pressing method, electric-current-assisted sintering (ECAS) can greatly improve the efficiency and properties of sintered nanosilver joint. In this paper, the rapid sintering behaviors and mechanical properties, including temperature profile, removal of organics, shrinkage, pore size, particle size, and shear strength, of nanosilver joint at different stages of ECAS were studied to help understand the fundamental mechanism. Based on the results, rapid sintering by high direct current, e.g., 6 kA, can sinter nanosilver for copper bonding at low temperature within 1200 ms under uniaxial load, e.g., 10 MPa. And the ECAS process can be divided into three stages. At the initial stage, the removal of most organics and the rearrangement of nanosilver particles cause rapid shrinkage of the joint. After initial stage the nanosilver particles come into direct contact with each other, and the shear strength of the joint increases quickly due to the diffusion of atoms through the melted region between the particles. At the final stage, further shrinkage of the joint proceeds by plastic deformation under loading and high temperature (above 400 °C). The elimination of crystal defects also contributes to the shrinkage at the final stage. The sintering of nanosilver finally increases the shear strength of the joint to about 50 MPa.

Similar content being viewed by others

References

X. Li, G. Chen, L. Wang, Y.H. Mei, X. Chen, G.Q. Lu, Mechanical property evaluation of nano-silver paste sintered joint using lap-shear test. Mater. Sci. Eng. A 579, 108–113 (2013)

R.W. Johnson, J.L. Evans, P. Jacobsen, J.R. Thompson, M. Christopher. The changing automotive environment: high-temperature electronics. IEEE Trans. Electron. Packag.Manuf 27 164–176 (2004)

D.J. Yu, X. Chen, G. Chen, G.Q. Lu, Z.Q. Wang, Applying Anand model to low-temperature sintered nanoscale silver paste chip attachment. Mater. Des. 30, 4574–4579 (2009)

G. Chen, L. Yu, Y.H. Mei, X. Li, X. Chen, G.Q. Lu, Uniaxial ratcheting behavior of sintered nanosilver joint for electronic packaging. Mater. Sci. Eng. A 591, 121–129 (2014)

Y.H. Mei, G. Chen, X. Li, G.Q. Lu, X. Chen. Evolution of curvature under thermal cycling in sandwich assembly bonded by sintered nanosilver paste. Solder. Surf. Mt. Technol 25, (2013) 107–116

Y. H Mei, G. Chen, G.Q. Lu, X. Chen. Effect of joint sizes of low-temperature sintered nano-silver on thermal residual curvature of sandwiched assembly. Int. J. Adhes. Adhes. 35, 88–93 (2013)

J.G. Bai, Z.Z. Zhang, J.N. Calata, G.Q. Lu. Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE Trans. Compon. Packag.Technol. 29, 589–593 (2006)

Y.H. Mei, T. Wang, X. Cao, G. Chen, G.Q. Lu, X. Chen. Transient thermal impedance measurements on low-temperature-sintered nanoscale silver joints. J. Electron. Mater. 41, 3152–3160 (2012)

L. Coppola, D. Huff, F. Wang, R. Burgos, D. Boroyevich, Survey on high-temperature packaging materials for SiC-based power electronics modules. In: Power Electronics Specialists Conference, Orlando (2007), pp. 2234–2240

E. Ide, S. Angata, A. Hirose, K. Kobayashi. Metal-metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 53, 2385–2393 (2005)

H. Alarifi, A. Hu, M. Yavuz, Y.N. Zhou. Silver nanoparticle paste for low-temperature bonding of copper. J. Electron. Mater. 40, 1394–1402 (2011)

Y.H. Mei, G.Q. Lu, X. Chen, S.F. Luo, D. Ibitayo. Migration of sintered nanosilver die-attach material on alumina substrate between 250℃and 400℃in dry air. IEEE. Trans. Device Mater. Reliab. 11, 316–322 (2011)

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.S. Kim, M. Nogi, Low-temperature low-pressure die attach with hybrid silver particle paste. Microelectron. Reliab. 52, 375–380 (2012)

J. Yan, G. Zou, A.P. Wu, J. Ren, J. Yan, A. Hu, Y. Zhou, Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scr. Mater. 66, 582–585 (2012)

X. Li, G. Chen, X. Chen, G.Q. Lu, L. Wang, Y.H. Mei. Mechanical property evaluation of nano-silver paste sintered joint using lap-shear test. Solder. Surf. Mt. Technol. 24, 120–126 (2012)

J.G. Bai, T.G. Lei, J.N. Calata, G.Q. Lu, Control of nanosilver sintering attained through organic binder burnout. J. Mater. Res. 22, 3494 (2007)

R. Roy, D. Agrawal, J. Cheng, S. Gedevanishvili, Full sintering of powdered-metal bodies in a microwave field. Nature 399, 668–670 (1999)

M. Agarwala, D. Bourell, J. Beaman, H. Marcus, J. Barlow, Direct selective laser sintering of metals. Rapid Prototyping J 1, 26–36 (1995)

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, G. Cao. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R 63, 127–287 (2009)

M. Oghbaei, O. Mirzaee, Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 494, 175–189 (2010)

D. He, Z. Fu, W. Wang, J. Zhang, Z.A. Munir, P. Liu, Temperature-gradient joining of Ti–6Al–4 V alloys by pulsed electric current sintering. Mater. Sci. Eng. A 535, 182–188 (2012)

Z. Munir, U. Anselmi-Tamburini, M. Ohyanagi, The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 41, 763–777 (2006)

Y. Fu, C. Shearwood, B. Xu, L. Yu, K. Khor. Characterization of spark plasma sintered Ag nanopowders. Nanotechnology 21, 115707 (2010)

M.L. Allen, M. Aronniemi, T. Mattila, A. Alastalo, K. Ojanperä, M. Suhonen, H. Seppä, Electrical sintering of nanoparticle structures. Nanotechnology 19, 175201 (2008)

Y.H. Mei, Y. J Cao, G. Chen, X. Li, G. Lu, X. Chen. Rapid sintering nanosilver joint by pulse current for power electronics packaging. IEEE. Trans. Device Mater. Reliab. 13, 258–265 (2013)

Y.H. Mei, Y. J Cao, G. Chen, X. Li, G. Lu, X. Chen, Characterization and reliability of sinter nanosilver joints by a rapid current-assisted method for power electronic packaging. IEEE. Trans. Device Mater. Reliab. 14, (2014) 262–267

R. Chaim, Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng. A 443, 25–32 (2007)

T.G. Lei, J.N. Calata, G.Q. Lu, X. Chen, S.F. Luo, Low-temperature sintering of nanoscale silver paste for attaching large-area (>100mm2) chips. IEEE Trans. Compon. Packag. Manuf. Technol. 33, 98–104 (2010)

Y.H. Mei, G. Chen, Y. J Cao, X. Li, D. Han, X. Chen, Simplification of low-temperature sintering nanosilver for power electronics packaging. J. Electron. Mater 42, 1209–1218 (2013)

Z.L. Li, F. Becker, M.P. Stoll, Z. Wan, Evaluation of six methods for extracting relative emissivity spectra from thermal infrared images. Remote Sens. Environ 69, 197–214 (1999)

E. Helland, R. Occelli, L. Tadrist, Numerical study of cluster formation in a gas–particle circulating fluidized bed. Powder Technol 110, 210–221 (2000)

W. Kingery, Densification during sintering in the presence of a liquid phase. I. Theory. J. Appl. Phys 30, 301–306 (1959)

C. Tekmen, I. Ozdemir, U. Cocen, K. Onel, The mechanical response of Al–Si–Mg/SiCp composite: influence of porosity. Mater. Sci. Eng. A 360, 365–371 (2003)

Q. Mei, K. Lu, Melting and superheating of crystalline solids: from bulk to nanocrystals. Prog. Mater. Sci. 52, 1175–1262 (2007)

G. Allen, R. Bayles, W. Gile, W. Jesser, Small particle melting of pure metals. Thin Solid Films 144, 297–308 (1986)

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, C.X. Xu, Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 97, 153117 (2010)

K. Vanmeensel, A. Laptev, J. Hennicke, J. Vleugels, O. Van der Biest. Modelling of the temperature distribution during field assisted sintering. Acta Mater. 53, 4379–4388 (2005)

K.S. Moon, H. Dong, R. Maric, S. Pothukuchi, A. Hunt, Y. Li, C. Wong. Thermal behavior of silver nanoparticles for low-temperature interconnect applications. J. Electron. Mater. 34, 168–175 (2005)

J. She, K. Ueno, Effect of additive content on liquid-phase sintering on silicon carbide ceramics. Mater. Res. Bull 34, 1629–1636 (1999)

Y. Wang, L. Zhou, M. Zhang, X. Chen, J.M. Liu, Z. Liu, Room-temperature saturated ferroelectric polarization in BiFeO3 ceramics synthesized by rapid liquid phase sintering. Appl. Phys. Lett. 84, 1731–1733 (2004)

H.A. Alarifi, M. Atis, C. Özdoğan, A. Hu, M. Yavuz, Y. Zhou, Molecular dynamics simulation of sintering and surface premelting of silver nanoparticles. Mater. Trans. 54, 884–889 (2013)

X. Chen, R. Li, K. Qi, G.Q. Lu, Tensile behaviors and ratcheting effects of partially sintered chip-attachment films of a nanoscale silver paste. J. Electron. Mater. 37, 1574–1579 (2008)

Z. Zhang, G.Q. Lu, Pressure-assisted low-temperature sintering of silver paste as an alternative die-attach solution to solder reflow. IEEE Trans. Electron. Packag. Manuf. 25, 279–283 (2002)

T. Wang, X. Chen, G.Q. Lu, G.Y. Lei, Low-temperature sintering with nano-silver paste in die-attached interconnection. J. Electron. Mater. 36, 1333–1340 (2007)

Y. Akada, H. Tatsumi, T. Yamaguchi, A. Hirose, T. Morita, E. Ide. Interfacial bonding mechanism using silver metallo-organic nanoparticles to bulk metals and observation of sintering behavior. Mater. Trans. 49, 1537–1545 (2008)

D.H. Kim, C.H. Kim, Effect of heating rate on pore shrinkage in yttria-doped zirconia. J. Am. Ceram. Soc. 76, 1877–1878 (1993)

J.G. Bai, J.N. Calata, G. Lei, G.Q. Lu, Thermomechanical reliability of low-temperature sintered silver die-attachment. In: The tenth intersociety conference on thermal and thermomechanical phenomena in electronics systems, New York, (2006), pp 1126–1130

N. Wang, Z. Wang, K. Aust, U. Erb, Effect of grain size on mechanical properties of nanocrystalline materials. Acta Mater. 43, 519–528 (1995)

J. Burke. Role of grain boundaries in sintering. J. Am. Ceram. Soc. 40, 80–85 (1957)

R. German, J. Lathrop, Simulation of spherical powder sintering by surface diffusion. J. Mater. Sci. 13, 921–929 (1978)

N. Hirosaki, Y. Akimune, M. Mitomo, Effect of grain growth of β-Silicon Nitride on strength, weibull modulus, and fracture toughness. J. Am. Ceram. Soc. 76, 1892–1894 (1993)

M.J. Mayo. Processing of nanocrystalline ceramics from ultrafine particles. Int. Mater. Rev. 41, 85–115 (1996)

Acknowledgements

The authors would like to gratefully acknowledge the financial supports from the National Natural Science Foundation of China (No. 61334010), the National High Technology Research and Development Program of China (No. 2016YFB0100602), and and the Tianjin Municipal Natural Science Foundation (Nos. 13ZCZDGX01106 and 13JCQNJC06600).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mei, Y., Li, L., Li, X. et al. Electric-current-assisted sintering of nanosilver paste for copper bonding. J Mater Sci: Mater Electron 28, 9155–9166 (2017). https://doi.org/10.1007/s10854-017-6649-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6649-4