Abstract

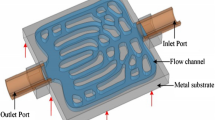

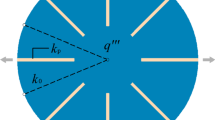

A three-dimensional disc model with non-uniform heat generating is built. A series of cooling channels are inserted to cool this disc which is strewn in a hierarchical pattern. To reveal thermal and flow characteristics, a composite objective function comprised of the maximum temperature difference (MTD) and pumping power is constructed. The deployment pattern of cooling channels contains two cases, i.e., the radial-pattern and dendritic-pattern. By capitalizing on constructal design method together with finite element method, the diameter of radial-pattern cooling channels is optimized in the first place. Next, the diameter, angle coefficient and length coefficient of dendritic-pattern cooling channels are three degrees-of-freedom to be stepwise optimized at different heat generating conditions. Furthermore, NSGA-II algorithm is introduced into the multi-objective problem. Upon obtaining its Pareto optimal solution set, Topsis method is invoked to yield the optimal solutions under given weighted coefficients. The heat generation over the entire body and the volume ratio of cooling channels operate as the primary constraints. Based on these premises, constructal design will be stepwise performed by varying three degrees-of-freedom. The obtained results state that more heating components or devices should be installed as close to the cooling water inlet as possible. This can further reduce MTD at the same cost of pumping power, thereby improve thermal and flow performance and prolong the lifespan of devices. As optimized with two degrees-of-freedom, the MTD is reduced by 18.6% compared with the counterpart obtained from single degree-of-freedom optimization, while the pumping power is increased by 59.8%. As optimized with three degrees-of-freedom, the MTD is decreased by 6.2% compared with the counterpart from two degrees-of-freedom optimization, while the pumping power is increased by 3.0%. It is manifest that when two sub-objectives form a composite objective, the performance improvement of one sub-objective will inevitably elicit the vitiation of the alternative.

Similar content being viewed by others

References

Sohel Murshed S M, Nieto de Castro C A. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew Sustain Energy Rev, 2017, 78: 821–833

Tuckerman D B, Pease R F W. High-performance heat sinking for VLSI. IEEE Electron Device Lett, 1981, 2: 126–129

Xie X L, Liu Z J, He Y L, et al. Numerical study of laminar heat transfer and pressure drop characteristics in a water-cooled minichannel heat sink. Appl Thermal Eng, 2009, 29: 64–74

Bejan A. Street network theory of organization in nature. J Adv Transp, 1996, 30: 85–107

Bejan A. Constructal-theory network of conducting paths for cooling a heat generating volume. Int J Heat Mass Transfer, 1997, 40: 799–816

Bejan A. Shape and Structure, from Engineering to Nature. Cambridge: Cambridge University Press, 2000

Bejan A, Lorente S. Design with Constructal Theory. Hoboken: Wiley, 2008

Lorenzini G, Moretti S, Conti A. Fin Shape Thermal Optimization Using Bejan’s Constructal Theory. San Francisco: Morgan & Claypool Publishers, 2011

Chen L G. Progress in study on constructal theory and its applications. Sci China Tech Sci, 2012, 55: 802–820

Bejan A. Constructal law: Optimization as design evolution. J Heat Transfer, 2015, 137: 061003

Chen L G, Feng H J. Multi-objective Constructal Optimizations for Fluid Flow, Heat and Mass Transfer Processes (in Chinese). Beijing: Science Press, 2016

Hajmohammadi M R. Introducing a Ψ-shaped cavity for cooling a heat generating medium. Int J Thermal Sci, 2017, 121: 204–212

Feng H J, Chen L G, Xie Z H. Multi-disciplinary, multi-objective and multi-scale constructal optimizations for heat and mass transfer processes performed in Naval University of Engineering, a review. Int J Heat Mass Transfer, 2017, 115: 86–98

Rocha L A O, Lorente S, Bejan A. Constructal theory in heat transfer. In: Handbook of Thermal Science and Engineering. New York: Springer, 2018. 329–360

Miguel A F, Rocha L A O. Tree-Shaped Fluid Flow and Heat Transfer. New York: Springer, 2018

Chen L G, Feng H J, Xie Z H, et al. Progress of constructal theory in China over the past decade. Int J Heat Mass Transfer, 2019, 130: 393–419

Lorente S, Bejan A. Current trends in constructal law and evolutionary design. Heat Trans Asian Res, 2019, 48: 3574–3589

Bejan A. Freedom and Evolution: Hierarchy in Nature, Society and Science. Cham: Springer, 2020

Yang A B, Chen L G, Xie Z H, et al. Constructal heat transfer rate maximization for cylindrical pin-fin heat sinks. Appl Thermal Eng, 2016, 108: 427–435

Lu Z, Zhang K, Liu J, et al. Effect of branching level on the performance of constructal theory based Y-shaped liquid cooling heat sink. Appl Thermal Eng, 2020, 168: 114824

Chen L G, Yang A B, Feng H J, et al. Constructal design progress for eight types of heat sinks. Sci China Tech Sci, 2020, 63: 879–911

Hajmohammadi M R, Mohammadifar M, Ahmadian-Elmi M. Optimal placement and sizing of heat sink attachments on a heat-generating piece for minimization of peak temperature. ThermoChim Acta, 2020, 689: 178645

Wang L, Xie Z H, Chen L G, et al. Equivalent thermal resistance minimization for a circular disc heat sink with reverting microchannels based on constructal theory and entransy theory. Sci China Tech Sci, 2021, 64: 111–121

Gong S W, Chen L G, Xie Z H, et al. Constructal optimization of cylindrical heat sources with forced convection based on entransy dissipation rate minimization. Sci China Tech Sci, 2016, 59: 631–639

Zhou S B, Chen L G, Sun F R. Constructal optimization for a solid-gas reactor based on triangular element. Sci China Ser E-Tech Sci, 2008, 51: 1554–1562

Feng H, Chen L, Xie Z, et al. “Disc-point” heat and mass transfer constructal optimization for solid-gas reactors based on entropy generation minimization. Energy, 2015, 83: 431–437

Feng H, Chen L, Xie Z, et al. Generalized constructal optimization for solidification heat transfer process of slab continuous casting based on heat loss rate. Energy, 2014, 66: 991–998

Feng H J, Chen L G, Xie Z H, et al. Generalized constructal optimization for the secondary cooling process of slab continuous casting based on entransy theory. Sci China Tech Sci, 2014, 57: 784–795

Feng H J, Chen L G, Liu X, et al. Generalized constructal optimization of strip laminar cooling process based on entransy theory. Sci China Tech Sci, 2016, 59: 1687–1695

Liu X, Feng H J, Chen L G, et al. Hot metal yield optimization of a blast furnace based on constructal theory. Energy, 2016, 104: 33–41

Liu X, Chen L G, Feng H J, et al. Constructal design for blast furnace wall based on the entransy theory. Appl Thermal Eng, 2016, 100: 798–804

Liu X, Chen L G, Feng H J, et al. Constructal design of a blast furnace iron-making process based on multi-objective optimization. Energy, 2016, 109: 137–151

Chen L G, Liu X, Feng H J, et al. Molten steel yield optimization of a converter based on constructal theory. Sci China Tech Sci, 2018, 61: 496–505

Feng H J, Chen L G, Liu X, et al. Constructal optimization of a sinter cooling process based on exergy output maximization. Appl Thermal Eng, 2016, 96: 161–166

Feng H J, Chen L G, Xie Z H, et al. Thermal insulation constructal optimization for steel rolling reheating furnace wall based on entransy dissipation extremum principle. Sci China Tech Sci, 2012, 55: 3322–3333

Feng H J, Chen L G, Xie Z H, et al. Constructal designs for insulation layers of steel rolling reheating furnace wall with convective and radiative boundary conditions. Appl Thermal Eng, 2016, 100: 925–931

Feng H J, Chen L G, Xie Z H, et al. Constructal design for X-shaped hot water network over a rectangular area. Appl Thermal Eng, 2015, 87: 760–767

Feng H J, Chen L G, Xie Z H, et al. Constructal design for gas-turbine blade based on minimization of maximum thermal resistance. Appl Thermal Eng, 2015, 90: 792–797

Feng H J, Chen L G, Xie Z H, et al. Constructal optimization for H-shaped multi-scale heat exchanger based on entransy theory. Sci China Tech Sci, 2013, 56: 299–307

Chen L, Feng H, Xie Z, et al. Thermal efficiency maximization for H-and X-shaped heat exchangers based on constructal theory. Appl Thermal Eng, 2015, 91: 456–462

Hajabdollahi H. Multi-objective optimization of plate fin heat exchanger using constructal theory. Int Commun Heat Mass Transfer, 2019, 108: 104283

Feng H, Chen L, Wu Z, et al. Constructal design of a shell-and-tube heat exchanger for organic fluid evaporation process. Int J Heat Mass Transfer, 2019, 131: 750–756

Feng H J, Xie Z H, Chen L G, et al. Constructal design for supercharged boiler superheater. Energy, 2020, 191: 116484

Feng H J, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for leaf-like fins. Sci China Tech Sci, 2012, 55: 515–526

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization for helm-shaped fin with inner heat sources. Sci China Tech Sci, 2015, 58: 1084–1090

Das R, Kundu B. Forward and inverse nonlinear heat transfer analysis for optimization of a constructal T-shape fin under dry and wet conditions. Int J Heat Mass Transfer, 2019, 137: 461–475

Hajmohammadi M R, Ahmadian M, Nourazar S S. Introducing highly conductive materials into a fin for heat transfer enhancement. Int J Mech Sci, 2019, 150: 420–426

Hazarika S A, Deshmukhya T, Bhanja D, et al. A novel optimum constructal fork-shaped fin array design for simultaneous heat and mass transfer application in a space-constrained situation. Int J Thermal Sci, 2020, 150: 106225

Hajmohammadi M R, Gholamrezaie S, Ahmadpour A, et al. Effects of applying uniform and non-uniform external magnetic fields on the optimal design of microchannel heat sinks. Int J Mech Sci, 2020, 186: 105886

Hajmohammadi M R, Rasouli E, Ahmadian Elmi M. Geometric optimization of a highly conductive insert intruding an annular fin. Int J Heat Mass Transfer, 2020, 146: 118910

Feng H J, Chen L G, Xie Z H. Constructal entransy dissipation rate minimization for X-shaped vascular networks. Sci China Tech Sci, 2019, 62: 2195–2203

Wu Z X, Feng H J, Chen L G, et al. Optimal design of dual-pressure turbine in OTEC system based on constructal theory. Energy Convers Manage, 2019, 201: 112179

Joshi V, Rathod M K. Constructal enhancement of thermal transport in latent heat storage systems assisted with fins. Int J Thermal Sci, 2019, 145: 105984

Wu Z X, Feng H J, Chen L G, et al. Pumping power minimization of an evaporator in ocean thermal energy conversion system based on constructal theory. Energy, 2019, 181: 974–984

Wu Z X, Feng H J, Chen L G, et al. Constructal thermodynamic optimization for ocean thermal energy conversion system with dual-pressure organic Rankine cycle. Energy Convers Manage, 2020, 210: 112727

Wechsatol W, Lorente S, Bejan A. Optimal tree-shaped networks for fluid flow in a disc-shaped body. Int J Heat Mass Transfer, 2002, 45: 4911–4924

Lorente S, Wechsatol W, Bejan A. Optimization of tree-shaped flow distribution structures over a disc-shaped area. Int J Energy Res, 2003, 27: 715–723

Wechsatol W, Lorente S, Bejan A. Tree-shaped flow structures: are both thermal-resistance and flow-resistance minimisations necessary? Int J Exergy, 2004, 1: 2–17

Reddy B V K, Ramana P V, Narasimhan A. Steady and transient thermo-hydraulic performance of disc with tree-shaped micro-channel networks with and without radial inclination. Int J Thermal Sci, 2008, 47: 1482–1489

Revellin R, Thome J R, Bejan A, et al. Constructal tree-shaped microchannel networks for maximizing the saturated critical heat flux. Int J Thermal Sci, 2009, 48: 342–352

Daguenet-Frick X, Bonjour J, Revellin R. Constructal microchannel network for flow boiling in a disc-shaped body. IEEE Trans Comp Packag Technol, 2010, 33: 115–126

Ghaedamini H, Salimpour M R, Campo A. Constructal design of reverting microchannels for convective cooling of a circular disc. Int J Thermal Sci, 2011, 50: 1051–1061

Feng H, Chen L, Xie Z, et al. Constructal optimization of a discshaped body with cooling channels for specified power pumping. Int J Low-Carbon Tech, 2015, 10: 229–237

Salimpour M R, Menbari A. Analytical optimization of constructal channels used for cooling a ring shaped body based on minimum flow and thermal resistances. Energy, 2015, 81: 645–651

Bejan A, Errera M R. Convective trees of fluid channels for volumetric cooling. Int J Heat Mass Transfer, 2000, 43: 3105–3118

Bello-Ochende T, Liebenberg L, Meyer J P. Constructal cooling channels for micro-channel heat sinks. Int J Heat Mass Transfer, 2007, 50: 4141–4150

Xiao Q H, Chen L G, Sun F R. Constructal entransy dissipation rate and flow-resistance minimizations for cooling channels. Sci China Techl Sci, 2010, 53: 2458–2468

Zhang C, Chen Y, Wu R, et al. Flow boiling in constructal tree-shaped minichannel network. Int J Heat Mass Transfer, 2011, 54: 202–209

Olakoyejo O T, Bello-Ochende T, Meyer J P. Constructal conjugate cooling channels with internal heat generation. Int J Heat Mass Transfer, 2012, 55: 4385–4396

Xie G, Asadi M, Sunden B, et al. Constructal theory based geometric optimization of wavy channels in the low Reynolds number regime. J Electron Packaging, 2014, 136: 031013

Farzaneh M, Salimpour M R, Tavakoli M R. Design of bifurcating microchannels with/without loops for cooling of square-shaped electronic components. Appl Thermal Eng, 2016, 108: 581–595

Yang A B. Performance analyses and multi-objective constructal optimizations for four kinds of heat sinks (in Chinese). Dissertation for Doctoral Degree. Wuhan: Naval University of Engineering, 2017

Feijó B C, Lorenzini G, Isoldi L A, et al. Constructal design of forced convective flows in channels with two alternated rectangular heated bodies. Int J Heat Mass Transfer, 2018, 125: 710–721

Samal B, Barik A K, Awad M M. Thermo-fluid and entropy generation analysis of newly designed loops for constructal cooling of a square plate. Appl Thermal Eng, 2019, 156: 250–262

Khalifa M A, Jaffal H M. Effects of channel configuration on hydrothermal performance of the cylindrical mini-channel heat sinks. Appl Thermal Eng, 2019, 148: 1107–1130

Lugarini A, Franco A T, Errera M R. Flow distribution uniformity in a comb-like microchannel network. Microfluid Nanofluid, 2019, 23: 44

You J, Feng H, Chen L, et al. Constructal design and experimental validation of a non-uniform heat generating body with rectangular cross-section and parallel circular cooling channels. Int J Heat Mass Transfer, 2020, 148: 119028

Feng H, Chen L, Xie Z, et al. Constructal design for a rectangular body with nonuniform heat generation. Eur Phys J Plus, 2016, 131: 274

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization of a rectangular body with nonuniform heat generation. Sci China Tech Sci, 2016, 59: 1352–1359

You J, Feng H, Chen L, et al. Constructal optimization for cooling a non-uniform heat generating radial-pattern disc by conduction. Entropy, 2018, 20: 685

Konan H C, Cetkin E. Snowflake shaped high-conductivity inserts for heat transfer enhancement. Int J Heat Mass Transfer, 2018, 127: 473–482

You J, Feng H, Chen L, et al. Heat conduction constructal optimization for nonuniform heat generating area based on triangular element. Int J Heat Mass Transfer, 2018, 117: 896–902

Chen L, You J, Feng H, et al. Constructal optimization for “disc-point” heat conduction with nonuniform heat generating. Int J Heat Mass Transfer, 2019, 134: 1191–1198

You J, Feng H, Chen L, et al. Constructal design of nonuniform heat generating area based on triangular elements: A case of entropy generation minimization. Int J Thermal Sci, 2019, 139: 403–412

Razera A L, da Fonseca R J C, Isoldi L A, et al. Constructal design of a semi-elliptical fin inserted in a lid-driven square cavity with mixed convection. Int J Heat Mass Transfer, 2018, 126: 81–94

Cetkin E, Oliani A. The natural emergence of asymmetric tree-shaped pathways for cooling of a non-uniformly heated domain. J Appl Phys, 2015, 118: 024902

Ge Y, Wang S, Liu Z, et al. Optimal shape design of a minichannel heat sink applying multi-objective optimization algorithm and three-dimensional numerical method. Appl Thermal Eng, 2019, 148: 120–128

Tang C Q, Feng H J, Chen L G, et al. Power density analysis and multi-objective optimization for a modified endoreversible simple closed Brayton cycle with one isothermal heating process. Energy Rep, 2020, 6: 1648–1657

Zhang L, Chen L G, Xia S J, et al. Multi-objective optimization for helium-heated reverse water gas shift reactor by using NSGA-II. Int J Heat Mass Transfer, 2020, 148: 119025

Wu Z X, Feng H J, Chen L G, et al. Performance optimization of a condenser in ocean thermal energy conversion (otec) system based on constructal theory and a multi-objective genetic algorithm. Entropy, 2020, 22: 641

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51779262 and 51579244), and the Independent Project of Naval University of Engineering (Grant No. 425317Q017).

Rights and permissions

About this article

Cite this article

Chen, C., You, J., Feng, H. et al. A multi-objective study on the constructal design of non-uniform heat generating disc cooled by radial- and dendritic-pattern cooling channels. Sci. China Technol. Sci. 64, 729–744 (2021). https://doi.org/10.1007/s11431-020-1697-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1697-7