Abstract

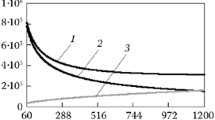

Based on constructal theory and entransy theory, a generalized constructal optimization of a solidification heat transfer process of slab continuous casting for a specified total water flow rate in the secondary cooling zone was carried out. A complex function was taken as the optimization objective to perform the casting. The complex function was composed of the functions of the entransy dissipation and surface temperature gradient of the slab. The optimal water distribution at the sections of the secondary cooling zone were obtained. The effects of the total water flow rate in the secondary cooling zone, casting speed, superheat and water distribution on the generalized constructal optimizations of the secondary cooling process were analyzed. The results show that on comparing the optimization results obtained based on the optimal water distributions of the 8 sections in the secondary cooling zone with those based on the initial ones, the complex function and the functions of the entransy dissipation and surface temperature gradient after optimization decreased by 43.25%, 5.90% and 80.60%, respectively. The quality and energy storage of the slab had obviously improved in this case. The complex function, composed of the functions of the entransy dissipation and surface temperature gradient of the slab, was a compromise between the internal and surface temperature gradients of the slab. Essentially, it is also the compromise between energy storage and quality of the slab. The “generalized constructal optimization” based on the minimum complex function can provide an optimal alternative scheme from the point of view of improving energy storage and quality for the parameter design and dynamic operation of the solidification heat transfer process of slab continuous casting.

Similar content being viewed by others

References

Cai K K, Cheng S F. Principle and Technology of Steel Continuous Casting (in Chinese). Beijing: Metallurgical Industry Press, 1994

Chen L. Continuous Casting (in Chinese). Beijing: Metallurgical Industry Press, 2004

Yin R Y. Progress and prospect of thin slab casting and rolling process in china (in Chinese). Iron & Steel, 2006, 41: 1–6

Gan Y, Tang H W, Qiu S T. The role of continuous casting in steel production process and an introduction to the modern continuous casting technology. Sci China Ser E-Tech Sci, 2008, 38: 1384–1390

Cai K K. Quality Control of Continuous Casting Billet (in Chinese). Beijing: Metallurgical Industry Press, 2010

Che F, Cheng C G, Zhao W, et al. Study on influences of physical property parameters on model calculation results of heat transfer in the continuous casting mold (in Chinese). Chin J Process Eng, 2010, 10: 221–225

Yin R, Zhang H. Progress and development direction on thin slab continuous casting and rolling technology under new situation (in Chinese). Iron Steel, 2011, 46: 1–9

Mishra P, Ajmani S K, Kumar A, et al. Review article on physical and numerical modeling of sen and mould for continuous slab casting. Int J Engng Sci Tech, 2012, 4: 2234–2243

Wang L, Vitae A, Deng C, et al. Development of continuous casting technology of electrical steel and new products. J Iron Steel Res Int, 2012, 19: 1–6

Yin R. The essence, functions, and future development mode of steel manufacturing process. Sci China Ser E-Tech Sci, 2008, 38: 1365–1377

Yin R. Metallurgical Process Engineering. New York: Springer, 2011

Lu Z W, Cai J J. The Foundations of Systems Energy Conservation (in Chinese). Shenyang: Northeastern Univ Press, 2010

Zheng P. Study on Modeling for Secondary Cooling Process in Continuous Casting and Intelligent Optimization for Cooling Water (in Chinese). Dessertation of Masteral Degree. Shenyang: Northeastern University, 2005

Chen W, Zhang Y Z, Wang B X, et al. Optimization and control of secondary cooling parameters of continuous casting (in Chinese). Iron Steel, 2007, 42: 25–29

Zheng Z, Zhan X H, Luo X G. Using a genetic algorithm to optimize secondary cooling water distribution in slab casting (in Chinese). J Chongqing Univ, 2008, 31: 1365–1370

Ji Z P, Ma J C, Xie Z, et al. Multi-criteria optimization based on chaos ant colony algorithm for secondary cooling parameters in continuous casting (in Chinese). J Northeastern Univ (Nat Sci), 2008, 29: 782–785, 806

Jin X. Research on Dynamic Model for Secondary Cooling Control in Continuous Slab Casting (in Chinese). Dessertation of Doctoral Degree. Beijing: University of Science and Technology Beijing, 2009

Chen W, Zhang Y Z, Zhang C J, et al. Thermo-mechanical simulation and parameters optimization for beam blank continuous casting. Mater Sci Engng A, 2009, 499: 58–63

Chen W, Zhang Y Z, Wang B X. Optimization of continuous casting process parameters based on coupled heat and stress model. Ironmaking & Steelmaking, 2010, 37: 147–154

Wang Q. Analysis and Optimization on the Secondary Cooling System of Thin Slab Continuous Casting (in Chinese). Dessertation of Masteral Degree. Shijiazhuang: Hebei University of Science and Technology, 2011

Sindhya K, Miettinen K. New perspective to continuous casting of steel with a hybrid evolutionary multiobjective algorithm. Mater Manuf Proc, 2011, 26: 481–492

Feng H J, Chen L G, Ding Z M, et al. Study on solidification heat transfer process and its heat loss of slab continuous casting based on Matlab (in Chinese). Contin Cast, 2013, 6: 17–23

Feng H J, Chen L G, Xie Z H, et al. Generalized constructal optimization for solidification heat transfer process of slab continuous casting based on heat loss rate. Energy, 2014, doi: 10.1016/j.energy.2013.12.12.067

Guo Z Y, Zhu H Y, Liang X G. Entransy-A physical quantity describing heat transfer ability. Int J Heat Mass Transfer, 2007, 50: 2545–2556

Li Z X, Guo Z Y. Field Synergy Principle of Heat Convection Optimization (in Chinese). Beijing: Science Press, 2010

Guo Z, Cheng X, Xia Z. Least dissipation principle of heat transport potential capacity and its application in heat conduction optimization. Chin Sci Bull, 2003, 48: 406–410

Han G Z, Zhu H Y, Cheng X G, et al. Transfer similarity among heat conduction, elastic motion and electric conduction (in Chinese). J Eng Thermophys, 2005, 26: 1022–1024

Han G Z, Guo Z Y. Physical mechanism of heat conduction ability dissipation and its analytical expression (in Chinese). Proc CSEE, 2007, 27: 98–102

Zhu H Y, Chen Z J, Guo Z Y. Electricity and thermal analogous experimental study for entransy dissipation extreme principle (in Chinese). Prog Natural Sci, 2007, 17: 1692–1698

Chen L G. Progress in entransy theory and its applications. Chin Sci Bull, 2012, 57: 4404–4426

Chen L G. Optimization for mass transfer processes based on mass entransy dissipation extremum principle (in Chinese). J Nav Univ Eng, 2013, 25: 1–26

Chen Q, Liang X G, Guo Z Y. Entransy theory for the optimization of heat transfer-A review and update. Int J Heat Mass Transfer, 2013, 63: 65–81

Cheng X T, Xu X H, Liang X G. Homogenization of temperature field and temperature gradient field. Sci China Ser E: Tech Sci, 2009, 52: 2937–2942

Ge L, Xu M T, Cheng L. Topology optimization for volume to point heat conduction problem based on entransy dissipation theory (in Chinese). J Eng Thermophys, 2011, 32: 993–996

Chen Q, Ren J X. Generalized thermal resistance for convective heat transfer and its relation to entransy dissipation. Chin Sci Bull, 2008, 53: 3753–3761

Chen Q, Wang M R, Pan N, et al. Optimization principles for convective heat transfer. Energy, 2009, 34: 1199–1206

Xu M T, Guo J F, Cheng L. Application of entransy dissipation theory in heat convection. Front Energy Power Eng, 2009, 3: 402–405

Yuan F, Chen Q. Two energy conversion principles in convective heat transfer optimization. Energy, 2011, 36: 5476–5485

Xu M. Variational principles in terms of entransy for heat transfer. Energy, 2012, 44: 973–977

Wu J, Liang X G. Application of entransy dissipation extremum principle in radiative heat transfer optimization. Sci China Ser E-Tech Sci, 2008, 51: 1306–1314

Cheng X T, Xu X H, Liang X G. Radiative entransy flux in enclosures with non-isothermal or no-grey, opaque, diffuse surfaces and its application. Sci China Tech Sci, 2011, 54: 2446–2456

Cheng X, Liang X. Entransy flux of thermal radiation and its application to enclosures with opaque surfaces. Int J Heat Mass Transfer, 2011, 54: 269–278

Wu J, Cheng X. Generalized thermal resistance and its application to thermal radiation based on entransy theory. Int J Heat Mass Transfer, 2013, 58: 374–381

Liu X B, Meng J A, Guo Z Y. Entropy generation extremum and entransy dissipation extremum for heat exchanger optimization. Chin Sci Bull, 2009, 54: 943–947

Xia S J, Chen L G, Sun F R. Optimization for entransy dissipation minimization in heat exchanger. Chin Sci Bull, 2009, 54: 3587–3595

Chen L, Chen Q, Li Z X, et al. Optimization for a heat exchanger couple based on the minimum thermal resistance principle. Int J Heat Mass Transfer, 2009, 52: 4778–4784.

Guo Z Y, Liu X B, Tao W Q, et al. Effectiveness-thermal resistance method for heat exchanger design and analysis. Int J Heat Mass Transfer, 2010, 53: 2877–2884

Guo J F, Xu M T, Cheng L. Principle of equipartition of entransy dissipation for heat exchanger design. Sci China Tech Sci, 2010, 53: 1309–1314

Xu M T. The thermodynamic basis of entransy and entransy dissipation. Energy, 2011, 36: 4272–4277

Guo J F, Xu M T. The application of entransy dissipation theory in optimization design of heat exchanger. Appl Therm Engng, 2012, 36: 227–235

Chen Q. Entransy dissipation-based thermal resistance method for heat exchanger performance design and optimization. Int J Heat Mass Transfer, 2013, 60: 156–162

Wu J, Guo Z Y. Conversion potential energy and its application to thermodynamic optimization. Sci China Tech Sci, 2012, 55: 2169–2175

Cheng X T, Wang W H, Liang X G. Optimization of heat transfer and heat-work conversion based on generalized heat transfer law. Sci China Tech Sci, 2012, 55: 2847–2855

Cheng X T, Chen Q, Hu G J, et al. Entransy balance for the closed system undergoing thermodynamic processes. Int J Heat Mass Transfer, 2013, 60: 180–187

Wang W H, Cheng X T, Liang X G. Entropy and entransy analyses and optimizations of the Rankine cycle. Energy Convers Mgmt, 2013, 68: 82–88

Zhou B, Cheng X T, Liang X G. Power and heat-work conversion efficiency analyses for the irreversible Carnot engines by entransy and entropy. J Appl Phys, 2013, 113: 124904

Sun C, Cheng X T, Liang X G. Analyses of the constitution and application for entransy loss (in Chinese). J Eng Thermophys, 2013, 34: 914–917

Wei S H, Chen L G, Sun F R. “Volume-point” heat conduction constructal optimization with entransy dissipation minimization objective based on rectangular element. Sci China Ser E: Tech Sci, 2008, 51: 1283–1295

Xie Z H, Chen L G, Sun F R. Constructal optimization for geometry of cavity by taking entransy dissipation minimization as objective. Sci China Ser E-Tech Sci, 2009, 52: 3504–3513

Xie Z H, Chen L G, Sun F R. Constructal optimization on T-shaped cavity based on entransy dissipation minimization. Chin Sci Bull, 2009, 54: 4418–4427

Wei S H, Chen L G, Sun F R. Constructal optimization of discrete and continuous-variable cross-section conducting path based on entransy dissipation rate minimization. Sci China Tech Sci, 2010, 53: 1666–1677

Xiao Q H, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for “disc-to-point” heat conduction. Chin Sci Bull, 2011, 56: 102–112

Chen L G, Wei S H, Sun F R. Constructal entransy dissipation rate minimization of a disc. Int J Heat Mass Transfer, 2011, 54: 210–216

Xie Z H, Chen L G, Sun F R. Comparative study on constructal optimizations of T-shaped fin based on entransy dissipation rate minimization and maximum thermal resistance minimization. Sci China Tech Sci, 2011, 41: 962–970

Xiao Q H, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for a heat generating volume cooled by forced convection. Chin Sci Bull, 2011, 56: 2966–2973

Feng H J, Chen L G, Sun F R. Constructal entransy dissipation rate minimization for leaf-like fins. Sci China Tech Sci, 2012, 55: 515–526

Feng H J, Chen L G, Xie Z H, et al. Thermal insulation constructal optimization for steel rolling reheating furnace wall based on entransy dissipation extremum principle. Sci China Tech Sci, 2012, 55: 3322–3333

Chen L G, Xiao Q H, Xie Z H, et al. T-shaped assembly of fins with constructal entransy dissipation rate minimization. Int Comm Heat Mass Transfer, 2012, 39: 1556–1562

Feng H J, Chen L G, Xie Z H, et al. Constructal optimization for H-shaped multi-scale heat exchanger based on entransy theory. Sci China Tech Sci, 2013, 56: 299–307

Zhang M J, Lin X L, Huang A, et al. Field synergy analysis and fluid flow optimization of tundish for six strands (in Chinese). Special Steel, 2009, 30: 1–4

Chen L G, Zhang J M, Wu C, et al. Analysis of multi-objective decision-making for marine steam turbine stage. Int J Power Energy Systems, 1998, 18: 96–101

Wei S H, Chen L G, Sun F R. Constructal multidisciplinary optimization of electromagnet based on entransy dissipation minimization. Sci China Ser E-Tech Sci, 2009, 52: 2981–2989

Xie Z H, Chen L G, Sun F R. Constructal optimization of a vertical insulating wall based on a complex objective combining heat flow and strength. Sci China Tech Sci, 2010, 53: 2278–2290

Chen L G, Xie Z H, Sun F R. Multiobjective constructal optimization of an insulating wall combining heat flow, strength and weight. Int J Thermal Sci, 2011, 50: 1782–1789

Bejan A. Shape and Structure, from Engineering to Nature. Cambridge: Cambridge University Press, 2000

Bejan A, Lorente S. Design with Constructal Theory. New Jersey: Wiley, 2008

Chen L G. Progress in study on constructal theory and its application. Sci China Tech Sci, 2012, 55: 802–820

Rocha L A O, Lorente S, Bejan A. Constructal Law and the Unifying Principle of Design. Berlin: Spinger, 2013

Bejan A, Lorente S. Constructal law of design and evolution: Physics, biology, technology, and society. J Appl Phys, 2013, 113: 151301

Bejan A. Street network theory of organization in nature. J Adv Transp, 1996, 30: 85–107

Chen L G, Wu C, Sun F R. Finite time thermodynamic optimization or entropy generation minimization of energy systems. J Non-Equibri Thermodyn, 1999, 24: 327–359

Wu C, Chen L G, Chen J C. Recent Advances in Finite Time Thermodynamics. New York: Nova Science Publishers, 1999

Chen L G, Sun F R. Advances in Finite Time Thermodynamics: Analysis and Optimization. New York: Nova Science Publishers, 2004

Chen L G. Finite Time Thermodynamic Analysis of Irreversible Processes and Cycles (in Chinese). Beijing: High Education Press, 2005

Bejan A. How to distribute a finite amount of insulation on a wall with nonuniform temperature. Int J Heat Mass Transfer, 1993, 36: 49–56

Kang D H, Lorente S, Bejan A. Constructal distribution of multilayer insulation. Int J Energy Res, 2013, 37: 153–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, H., Chen, L., Xie, Z. et al. Generalized constructal optimization for the secondary cooling process of slab continuous casting based on entransy theory. Sci. China Technol. Sci. 57, 784–795 (2014). https://doi.org/10.1007/s11431-014-5494-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5494-4