Abstract

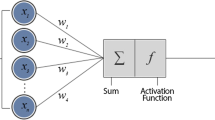

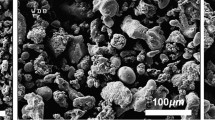

Epoxy resins are brittle because of their tight three-dimensional molecular network structures. In an attempt to overcome this issue, epoxies incorporating a combination of nanoclay (used for nano-reinforcement) and high-impact polystyrene (HIPS, used as the thermoplastic phase) were synthesized and tested in this work. The tensile, flexural, compressive, and impact strengths of these materials were evaluated. Various factors can influence these properties of hybrid nanocomposites during the preparation of such materials, so an artificial neural network (ANN) was employed to determine the effects of the clay, HIPS, and hardener loadings on the mechanical properties of the epoxy/HIPS/nanoclay nanocomposites and to develop models for predicting their mechanical behavior. A genetic algorithm (GA), a powerful optimization method, was employed to determine a fitness function that could calculate the optimum values of these mechanical properties. The results obtained indicated that the new ternary nanocomposites possess tensile, compressive, and impact strengths were improved up to 60 %, 64 %, and 402 %, respectively higher than those of the neat resin, although they did not show enhanced flexural strength. The tensile, flexural, and copmressive elongations at break were improved up to 53%, 38%, and 27% greater than those of neat epoxy, respectively. In addition, the fracture surface morphologies of the ternary nanocomposites were investigated by energy-dispersive X-ray spectroscopy (EDX) and scanning electron microscopy (SEM). The mechanical properties of the new ternary nanocomposites showed that they possess enhanced toughness compared to neat epoxy resin.

Similar content being viewed by others

References

LeBaron PC, Wang Z, Pinnavaia TJ (1999) Appl Clay Sci 15:11–29

Becker O, Varley RJ, Simon GP (2004) Eur Polym J 40:187–195

Becker O, Varley R, Simon G (2002) Polym 43:4365–4373

Liu W, Hoa SV, Pugh M (2005) Compos Sci Technol 65:307–316

Yasmin A, Luo J-J, Daniel IM (2006) Compos Sci Technol 66:1182–1189

Mirmohseni A, Zavareh S (2010) Mater Des 31:2699–2706

Mirmohseni A, Zavareh S (2011) J Polym Res 18:509–517

Mohan TP, Kumar MR, Velmurugan R (2006) J Mater Sci 41:2929–2937

Alsewailem FD, Gupta RK (2006) Can J Chem Eng 84:693–703

Garg AC, Mai Y-W (1988) Compos Sci Technol 31:179–223

Kinloch AJ, Shaw SJ, Tod DA et al (1983) Polym 24:1341–1354

Brooker RD, Kinloch AJ, Taylor AC (2010) J Adhes 86:726–741

Sultan JN, McGarry FJ (1973) Polym Eng Sci 13:29–34

Pearson RA, Yee AF (1991) J Mater Sci 26:3828–3844

Frounchi M, Mehrabzadeh M, Parvary M (2000) Polym Int 49:163–169

Chen TK, Jan YH (1992) J Mater Sci 27:111–121

Ramakrishna HV, Priya SP, Rai SK (2007) J Appl Polym Sci 104:171–177

Torres A, López-de-Ullibarri I, Abad MJ et al (2004) J Appl Polym Sci 92:461–467

Yun NG, Won YG, Kim SC (2004) Polym Bull 52:365–372

Kimoto M, Mizutani K (1997) J Mater Sci 32:2479–2483

Mimura K, Ito H, Fujioka H (2000) Polym 41:4451–4459

Rose LRF (1987) Mech Mater 6:11–15

Faber KT, Evans AG (1983) Acta Metall 31:577–584

Zaryabi A, Ben Hamza A (2012) Neural Comput Appl 21:1–9

Lim Y, Kang S (2012) Neural Comput Appl 21:1931–1936

Masri SF, Chassiakos AG, Caughey TK (1993) J Appl Mech 60:123–133

Ghaboussi J, Garrett J Jr, Wu X (1991) J Eng Mech 117:132–153

Rhim J, Lee SW (1995) Comput Mech 16:437–443

Su C-T, Wang F-F (2012) Neural Comput Appl 21:2127–2135

Song RG, Zhang QZ (2001) Mater Sci Eng C 17:133–137

Chung JS, Hwang SM (1997) J Mater Process Technol 72:69–77

Mousavi Anijdan SH, Madaah-Hosseini HR, Bahrami A (2007) Mater Des 28:609–615

Funahashi K-I (1989) Neural Netw 2:183–192

Hartman EJ, Keeler JD, Kowalski JM (1990) Neural Comput 2:210–215

Khandetsky V, Antonyuk I (2002) NDT&E Int 35:483–488

Asif A, Leena K, Lakshmana Rao V et al (2007) J Appl Polym Sci 106:2936–2946

Bakar M, Wojtania I, Legocka I et al (2007) Adv Polym Technol 26:223–231

Mirmohseni A, Zavareh S (2010) J Polym Res 17:191–201

López J, Ramírez C, Abad MJ et al (2002) J Appl Polym Sci 85:1277–1286

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rostamiyan, Y., Fereidoon, A.B., Hamed Mashhadzadeh, A. et al. Augmenting epoxy toughness by combination of both thermoplastic and nanolayered materials and using artificial intelligence techniques for modeling and optimization. J Polym Res 20, 135 (2013). https://doi.org/10.1007/s10965-013-0135-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0135-3