Abstract

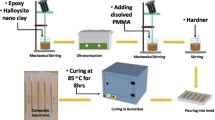

Epoxy resins have low impact strength and poor resistance to crack propagation, which limit their many end use applications. The main objective of this work is to incorporate both acrylonitrile-butadiene-styrene copolymer (ABS) and organically modified clay (Cloisite 30B) into epoxy matrix with the aim of obtaining improved material with the impact strength higher than neat epoxy, epoxy/clay and epoxy/ABS hybrids without compromising the other desired mechanical properties such as tensile strength and modulus. Impact and tensile properties of binary and ternary systems were investigated. Tensile strength, elongation at break and impact strength were increased significantly with incorporation of only 4 phr ABS to epoxy matrix. For epoxy/clay nanocomposite with 2.5% clay content, tensile modulus and strength, and impact strength were improved compared to neat epoxy. With incorporation of 2.5% clay and 4 phr ABS into epoxy matrix, 133% increase was observed for impact strength. Ternary nanocomposite had impact and tensile strengths greater than values of the binary systems. Morphological properties of epoxy/ABS, epoxy/clay and epoxy/ABS/clay ternary nanocomposite were studied using atomic force microscopy (AFM) phase imaging, scanning electron microscopy (SEM) and wide angle X-ray diffraction (WAXD). New morphologies were achieved for epoxy/ABS and epoxy/ABS/clay hybrid materials. Exfoliated clay structure was obtained for epoxy/clay and epoxy/ABS/clay nanocomposite.

Similar content being viewed by others

References

Muskopf JW, Mccollister SB (2002) In: Bohnet M, Brinker J, Cornils B et al (eds) Ullmann’s encyclopedia of industrial chemistry, 6th edn. Wiley, New York

Lee H, Neville K (1967) Handbook of epoxy resins. McGraw Hill, New York

Arias ML, Frontini PM, Williams RJJ (2003) Polymer (Guildf) 44:1537. doi:10.1016/S0032-3861(02)00829-7

Chikhi N, Fellahi S, Bakar M (2002) Eur Polym J 38:251. doi:10.1016/S0014-3057(01)00194-X

Hwang J-F, Manson JA, Hertzberg RW et al (1989) Polym Eng Sci 29:1466. doi:10.1002/pen.760292008

Thomas R, Yumei D, Yuelong H et al (2008) Polymer (Guildf) 49:278. doi:10.1016/j.polymer.2007.11.030

Yun NG, Won YG, Ch KS (2004) Polym Bull 52:365. doi:10.1007/s00289-004-0293-x

Kimoto M, Mizutani K (1997) J Mater Sci 32:2479. doi:10.1023/A:1018577712329

Mimura K, Ito H, Fujioka H (2000) Polymer (Guildf) 41:4451. doi:10.1016/S0032-3861(99)00700-4

Bonnaud L, Pascault JP, Sautereau H (2004) Eur Polym J 40:2637. doi:10.1016/j.eurpolymj.2004.05.029

Lopez J, Ramirez C, Abad MJ (2002) J Appl Polym Sci 85:1277. doi:10.1002/app.10715

Müller Y, Häußler L, Pionteck J (2007) Macromol Symp 254:267

Abad MJ, Barral L, Cano J et al (2001) Eur Polym J 37:1613. doi:10.1016/S0014-3057(01)00036-2

Ramakrishna HV, Priya SP, Rai SK (2007) J Appl Polym Sci 104:171. doi:10.1002/app.25115

Torres A, Lopez-de-Ullibarri I, Abad MJ et al (2004) J Appl Polym Sci 92:461. doi:10.1002/app.20014

Wang L, Wang K, Chen L et al (2006) Composites. Part A 37:1890. doi:10.1016/j.compositesa.2005.12.020

Kinloch AJ, Taylor AC (2006) J Mater Sci 41:3271. doi:10.1007/s10853-005-5472-0

Zunjarrao SC, Sriraman R, Singh RP (2006) J Mater Sci 41:2219. doi:10.1007/s10853-006-7179-2

Miyagawa H, Foo KH, Daniel IM et al (2005) J Appl Polym Sci 96:281. doi:10.1002/app.21357

Mohan TP, Kumar MR, Velmurugan R (2006) J Mater Sci 41:2929. doi:10.1007/s10853-006-5164-4

Asif A, Leena K, Rao VL (2007) J Appl Polym Sci 106:2936. doi:10.1002/app.26774

Bakar M, Wojtania I, Legocka I et al (2007) Adv Polym Technol 26:223. doi:10.1002/adv.20103

Park HM, Misra M, Drzal LT et al (2004) Biomacromolecules 5:2281. doi:10.1021/bm049690f

Park HM, Liang X, Mohanty AK et al (2004) Macromolecules 37:9076. doi:10.1021/ma048958s

Schauer E, Berglund L, Pena G et al (2002) Polymer (Guildf) 43:1241. doi:10.1016/S0032-3861(01)00683-8

Miyagawa H, Rich MJ, Drzal LT (2004) J Polym Sci. Part B. Polym Phys 42:4391. doi:10.1002/polb.20289

Bar G, Thomann Y, Brandsch R et al (1997) Langmuir 13:3807. doi:10.1021/la970091m

Kornmann X, Thomann R, Mulhaupt R et al (2002) J Appl Polym Sci 86:2643. doi:10.1002/app.11279

Zilg C, Mulhaupt R, Finter JJ (1999) Macromol Chem Phys 200:661. doi:10.1002/(SICI)1521-3935(19990301)200:3<661::AID-MACP661>3.0.CO;2-4

Acknowledgments

The authors are most grateful for the continuing financial support of this research project by the University of Tabriz.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirmohseni, A., Zavareh, S. Epoxy/acrylonitrile-butadiene-styrene copolymer/clay ternary nanocomposite as impact toughened epoxy. J Polym Res 17, 191–201 (2010). https://doi.org/10.1007/s10965-009-9305-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-009-9305-8