Abstract

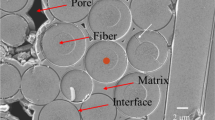

Microcomposites based on polyamide 66 (PA66) reinforced with bronze powder in low contents (3, 5 and, 7 wt%) were prepared in a co-rotating twin-screw extruder. Mechanical performance, including tensile characteristics, impact resistance, and Shore D hardness, was evaluated. The results indicated that the elongation at break and impact strength decreased with the increase in bronze loading, while the hardness reached a maximum (15% enhancement) when using 7 wt% of bronze powder. Scanning electron microscopy (SEM) was utilized to analyze the fracture surface and study the toughening mechanisms. The thermal expansion coefficient, as a good indicator of dimensional stability, was measured by applying thermomechanical analysis (TMA). The experimentally measured mechanical and thermal properties were modeled by an artificial neural network (ANN) method. The network was trained by Levenberg–Marquardt back-propagation (LMBP) in a single hidden layer which is consist of five neurons. Based on the excellent consistency between the ANN predictions and empirical results, ANN models can be considered as a reliable tool to estimate and evaluate material properties before synthesis and manufacturing.

Similar content being viewed by others

References

AL-Oqla FM (2017) Investigating the mechanical performance deterioration of Mediterranean cellulosic cypress and pine/polyethylene composites. Cellulose 24:2523–2530. https://doi.org/10.1007/s10570-017-1280-3

AL-Oqla FM (2021) Flexural characteristics and impact rupture stress investigations of sustainable green olive leaves bio-composite materials. J Polym Environ 29:892–899. https://doi.org/10.1007/s10924-020-01889-3

AL-Oqla FM, El-Shekeil YA (2019) Investigating and predicting the performance deteriorations and trends of polyurethane bio-composites for more realistic sustainable design possibilities. J Clean Prod 222:865–870. https://doi.org/10.1016/j.jclepro.2019.03.042

AL-Oqla FM, Hayajneh MT, Fares O (2019) Investigating the mechanical thermal and polymer interfacial characteristics of Jordanian lignocellulosic fibers to demonstrate their capabilities for sustainable green materials. J Clean Prod 241:118256. https://doi.org/10.1016/j.jclepro.2019.118256

AL-Oqla FM, Salit MS, Ishak MR, Aziz NA (2014) Combined multi-criteria evaluation stage technique as an agro waste evaluation indicator for polymeric composites: Date palm fibers as a case study. BioResources 9:4608–4621. https://doi.org/10.15376/biores.9.3.4608-4621

AL-Oqla FM, Salit MS, Ishak MR, Aziz NA (2015) A novel evaluation tool for enhancing the selection of natural fibers for polymeric composites based on fiber moisture content criterion. BioResources 10:299–312. https://doi.org/10.15376/biores.10.1.299-312

AL-Oqla FM, Sapuan SM (2018) Investigating the inherent characteristic/performance deterioration interactions of natural fibers in bio-composites for better utilization of resources. J Polym Environ 26:1290–1296. https://doi.org/10.1007/s10924-017-1028-z

AL-Oqla FM, Sapuan SM (2014) Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry. J Clean Prod 66:347–354. https://doi.org/10.1016/j.jclepro.2013.10.050

AL-Oqla FM, Sapuan SM, Anwer T, Jawaid M, Hoque ME (2015) Natural fiber reinforced conductive polymer composites as functional materials: a review. Synth Met 206:42–54. https://doi.org/10.1016/j.synthmet.2015.04.014

AL-Oqla FM, Sapuan SM, Ishak MR, Nuraini AA (2016) A decision-making model for selecting the most appropriate natural fiber—polypropylene-based composites for automotive applications. J Compos Mater 50:543–556. https://doi.org/10.1177/0021998315577233

AL-Oqla FM, Sapuan SM, Ishak MR, Nuraini AA (2015) A model for evaluating and determining the most appropriate polymer matrix type for natural fiber composites. Int J Polym Anal Charact 20:191–205. https://doi.org/10.1080/1023666X.2015.990184

AL-Oqla FM, Sapuan SM, Ishak MR, Nuraini AA (2015) Predicting the potential of agro waste fibers for sustainable automotive industry using a decision making model. Comput Electron Agric 113:116–127. https://doi.org/10.1016/j.compag.2015.01.011

AL-Oqla FM, Sapuan SM, Jawaid M (2016) Integrated mechanical-economic–environmental quality of performance for natural fibers for polymeric-based composite materials. J Nat Fibers 13:651–659. https://doi.org/10.1080/15440478.2015.1102789

Alaaeddin MH, Sapuan SM, Zuhri MYM, Zainudin ES, Al-Oqla FM (2019) Development of photovoltaic module with fabricated and evaluated novel backsheet-based biocomposite materials. Materials. https://doi.org/10.3390/ma12183007

Alaaeddin MH, Sapuan SM, Zuhri MYM, Zainudin ES, Al-Oqla FM (2019) Lightweight and durable PVDF-SSPF composites for photovoltaics backsheet applications: thermal, optical and technical properties. Materials. https://doi.org/10.3390/ma12132104

Alavitabari S, Mohamadi M, Javadi A, Garmabi H (2020) The effect of secondary nanofiller on mechanical properties and formulation optimization of HDPE/nanoclay/nanoCaCO3 hybrid nanocomposites using response surface approach. J Vinyl Addit Technol. https://doi.org/10.1002/vnl.21783

Almagableh A, Al-Oqla FM, Omari MA (2017) Predicting the effect of nano-structural parameters on the elastic properties of carbon nanotube-polymeric based composites. Int J Performability Eng 13:73–86. https://doi.org/10.23940/ijpe.17.01.p6.7386

Aridi NAM, Sapuan SM, Zainudin ES, AL-Oqla FM (2016) Mechanical and morphological properties of injection-molded rice husk polypropylene composites. Int J Polym Anal Charact 21:305–313. https://doi.org/10.1080/1023666X.2016.1148316

Aridi NAM, Sapuan SM, Zainudin ES, AL-Oqla FM (2016) Investigating morphological and performance deterioration of injection-molded rice husk–polypropylene composites due to various liquid uptakes. Int J Polym Anal Charact 21:675–685. https://doi.org/10.1080/1023666X.2016.1207006

Barkoula NM, Alcock B, Cabrera NO, Peijs T (2008) Flame-retardancy properties of intumescent ammonium poly(phosphate) and mineral filler magnesium hydroxide in combination with graphene. Polym Polym Compos 16:101–113

Bigg DM (1987) Mechanical properties of particulate filled polymers. Polym Compos 8:115–122. https://doi.org/10.1002/pc.750080208

Chavarria F, Paul DR (2004) Comparison of nanocomposites based on nylon 6 and nylon 66. Polymer 45:8501–8515. https://doi.org/10.1016/j.polymer.2004.09.074

Fidan S, Oktay H, Polat S, Ozturk S (2019) An artificial neural network model to predict the thermal properties of concrete using different neurons and activation functions. Adv Mater Sci Eng. https://doi.org/10.1155/2019/3831813

Ghosh K, Maiti SN (1996) Mechanical properties of silver-powder-filled polypropylene composites. Pharm Cryst Sci Eng 60:323–331. https://doi.org/10.1002/9781119046233.ch7

Ghosh K, Maiti SN (1996) Correlation of tensile properties with crystallization parameters of PP in PP/Ag composites. Polym Plast Technol Eng 35:67–95. https://doi.org/10.1080/03602559608000082

Gomez-Romero P (2001) Hybrid organic-inorganic materials—in search of synergic activity. Adv Mater 13:163–174. https://doi.org/10.1002/1521-4095(200102)13:3%3c163::AID-ADMA163%3e3.0.CO;2-U

Gülsoy ÖH, Tasdemir M (2007) The effect of bronze particles on the physical and mechanical properties of Acrylonitrile-Butadiene-Styrene copolymer. Polym Plast Technol Eng 46:789–793. https://doi.org/10.1080/03602550701274185

Hemath M, Mavinkere Rangappa S, Kushvaha V, Dhakal HN, Siengchin S (2020) A comprehensive review on mechanical, electromagnetic radiation shielding, and thermal conductivity of fibers/inorganic fillers reinforced hybrid polymer composites. Polym Compos 41:3940–3965. https://doi.org/10.1002/pc.25703

Jiang Z, Gyurova L, Zhang Z, Friedrich K, Schlarb AK (2008) Neural network based prediction on mechanical and wear properties of short fibers reinforced polyamide composites. Mater Des 29:628–637. https://doi.org/10.1016/j.matdes.2007.02.008

Jozwik J, Dziedzic K, Barszcz M, Pashechko M (2020) Analysis and comparative assessment of basic tribological properties of selected polymer composites. Materials. https://doi.org/10.3390/ma13010075

Khanam PN, Almaadeed M, Almaadeed S, Kunhoth S, Ouederni M, Sun D, Hamilton A, Jones EH, Mayoral B (2016) Optimization and prediction of mechanical and thermal properties of Graphene/LLDPE nanocomposites by using artificial neural networks. Int J Polym Sci. https://doi.org/10.1155/2016/5340252

Kushvaha V, Kumar SA, Madhushri P, Sharma A (2020) Artificial neural network technique to predict dynamic fracture of particulate composite. J Compos Mater 54:3099–3108. https://doi.org/10.1177/0021998320911418

Lin B, Thumen A, Heim H-P, Scheel G, Sundararaj U (2009) Nylon 66/clay nanocomposite structure development in a twin screw extruder. Polym Eng Sci 49:824–834. https://doi.org/10.1002/pen

Liu W, Cao C (2009) Artificial neural network prediction of glass transition temperature of polymers. Colloid Polym Sci 287:811–818. https://doi.org/10.1007/s00396-009-2035-y

Moghri M, Shahabadi SIS, Madic M (2016) Modeling tensile modulus of (polyamide 6)/nanoclay composites: response surface method vs. taguchi-optimized artificial neural network. J Vinyl Addit Technol 22:29–36. https://doi.org/10.1002/vnl

Mysiukiewicz O, Kosmela P, Barczewski M, Hejna A (2020) Mechanical, thermal and rheological properties of polyethylene-based composites filled with micrometric aluminum powder. Materials 13:1242–1259. https://doi.org/10.3390/ma13051242

Pourrahmani H, Golparvar M, Fasihi M (2020) A new evaluation criterion for optimizing the mechanical properties of toughened polypropylene/silica nanocomposites. Chin J Polym Sci 38:877–887. https://doi.org/10.1007/s10118-020-2399-5

Sharma A, Anand Kumar S, Kushvaha V (2020) Effect of aspect ratio on dynamic fracture toughness of particulate polymer composite using artificial neural network. Eng Fract Mech 228:106907–106918. https://doi.org/10.1016/j.engfracmech.2020.106907

Sharma A, Kushvaha V (2020) Predictive modelling of fracture behaviour in silica-filled polymer composite subjected to impact with varying loading rates using artificial neural network. Eng Fract Mech 239:107328. https://doi.org/10.1016/j.engfracmech.2020.107328

Shen L, Phang IY, Liu T, Zeng K, Chen L, Liu T, Zeng K (2004) Nanoindentation and morphological studies on nylon 66/organoclay nanocomposites. II Effect of strain rater. Polymer 45:3341–3349. https://doi.org/10.1016/j.polymer.2004.09.062

Taşdemir M, Gülsoy HÖ (2008) Mechanical properties of polymers filled with iron powder. Int J Polym Mater Polym Biomater 57:258–265. https://doi.org/10.1080/00914030701473656

Tavman IH (1996) Thermal and mechanical properties of aluminum powder-filled high-density polyethylene composites. J Appl Polym Sci 62:2161–2167. https://doi.org/10.1002/(sici)1097-4628(19961219)62:12%3c2161::aid-app19%3e3.3.co;2-a

Tavman IH (1997) Thermal and mechanical properties of copper powder filled poly(ethylene) composites. Powder Technol 91:63–67. https://doi.org/10.1016/S0032-5910(96)03247-0

Wani I, Kumar H, Rangappa SM, Peng L, Siengchin S, Kushvaha V (2021) Multiple regression model for predicting cracks in soil amended with pig manure biochar and wood biochar. J Hazardous, Toxic, Radioact Waste 25:04020007. https://doi.org/10.1061/(asce)hz.2153-5515.0000561

Wani I, Sharma A, Kushvaha V, Madhushri P, Peng L (2020) Effect of pH, volatile content, and pyrolysis conditions on surface area and O/C and H/C ratios of biochar: towards understanding performance of biochar using simplified approach. J Hazardous Toxic Radioact Waste 24:04020048. https://doi.org/10.1061/(asce)hz.2153-5515.0000545

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116:2658–2667. https://doi.org/10.1002/app

Yoon PJ, Fornes TD, Paul DR (2002) Thermal expansion behavior of nylon 6 nanocomposites. Polymer 43:6727–6741. https://doi.org/10.1016/S0032-3861(02)00638-9

Zhang Z, Barkoula NM, Karger-Kocsis J, Friedrich K (2003) Artificial neural network predictions on erosive wear of polymers. Wear 255:708–713. https://doi.org/10.1016/S0043-1648(03)00149-2

Zhang Z, Cao M, Chen P, Yang B, Wu B, Miao J, Xia R, Qian J (2019) Improvement of the thermal/electrical conductivity of PA6/PVDF blends via selective MWCNTs-NH2 distribution at the interface. Mater Des 177:107835–110745. https://doi.org/10.1016/j.matdes.2019.107835

Zhang Z, Friedrich K (2003) Artificial neural networks applied to polymer composites: a review. Compos Sci Technol 63:2029–2044. https://doi.org/10.1016/S0266-3538(03)00106-4

Zhang Z, Klein P, Friedrich K (2002) Dynamic mechanical properties of PTFE based short carbon fibre reinforced composites: experiment and artificial neural network prediction. Compos Sci Technol 62:1001–1009. https://doi.org/10.1016/S0266-3538(02)00036-2

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohamadi, M., Alavitabari, S. & Aliasghary, M. Prediction of mechanical and thermal properties in bronze-filled polyamide 66 composites using artificial neural network. Polym. Bull. 79, 4905–4921 (2022). https://doi.org/10.1007/s00289-021-03751-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03751-5