Abstract

Finger millets are important coarse grains that exhibit high levels of phenolic compounds and antioxidant activities among other cereals. Grains are subjected to a number of thermal treatments and this could affect the contents and bioactivities of phenolic compounds. The aim of the present study was to determine the phenolic contents and antioxidant activities of finger millet flour and foods, namely porridges and Pittu subjected to several thermal treatments such as roasting, parboiling, and parboiled roasting of flour and open boiling and steaming of foods prepared using flour. The effect of the addition of spices on phenolic content and antioxidant activities to open boiled foods was determined. Antioxidant activities of phenolic extracts obtained from finger millet flour and foods were studied for their total phenolic, flavonoids and proanthocyanidins contents, radical scavenging capacities, reducing power, ferrous ion chelating capacity, and antioxidant activity in a β-carotene/linoleate emulsion. The roasted flour and foods had higher total phenolic content (TPC) than other counterparts and ranged from 21.58 to 28.63 µmol ferulic acid equivalents/g dry matter. All flour and food preparations exhibited effective inhibition of radicals, reducing power, ferrous ion chelating activity, and antioxidant activity in the β-carotene/linoleate emulsion and the degree of activity depended on the processing conditions adopted in food preparations.

Foods prepared using steaming showed lower phenolic content and antioxidant activities in general than those of open-boiled counterparts. The addition of spices, namely garlic and cinnamon improved the phenolic contents and antioxidant activities of open-boiled porridges. The knowledge generated from this study may help to exploit the use of finger millets as a functional food ingredient to promote health and wellness.

Graphical abstract

Similar content being viewed by others

Introduction

Millets are among the first domesticated cereals that were cultivated at the beginning of human civilization. They are a group of cereals belonging to the family Poaceae and consist of grains with different shapes, sizes, and colours. Millet group includes finger millet (Eleusine coaracana), proso millet (Panicum miliaceum), brown top (Panicum ramosum), Japanese barnyard (Echinochloa crusgalli), kodo millet (Paspalum scrobiculatum), little millet (Panicum sumatrense), pearl millet (Pennisetum glaucum) and foxtail (Setaria italica) millet. They are useful as future crops to ensure food security among people due to their ability to face unfavourable global climatic changes. Millets thrive in marginal fertile soils with limited input of water with fewer diseases compared to major commercialized cereals. However, at present even in the countries millets are produced, they are underutilized crops used by population segments belonging to low-income levels. In the western world, millets are mainly utilized for bird and animal feed. The contemporary scientific knowledge generated on millets as a rich source of essential nutrients and non-nutrient compounds possessing a myriad of health benefits has attracted the interest of food producers and consumers to their potential use in a variety of food usage (Bora et al. 2018, 2019; Devi et al. 2014; Shahidi & Chandrasekara 2013; Shahidi et al. 2012). Nowadays millets have been included as one of the grains in multigrain cereal products and their usage in gluten-free food applications has expanded in the western world.

Non-communicable diseases (NCDs) have increased steadily in every society and have become a leading cause of death in many countries. Oxidative stress can cause direct injurious effects in the biological systems in addition to activation of other molecular mechanisms to initiate inflammatory responses leading to a number of NCDs. Oxidative stress results when the balance between oxidants and antioxidants change negatively due to excess exposure to endogenous and exogenous oxidants or inadequacy of antioxidants in the body (Shahidi et al. 2012).

Millets possess varied levels of phenolics and antioxidant activities depending on the variety, location of production, and processing method (Kumari et al. 2017). Phenolic compounds of millet grains serve as potential antioxidant compounds in food and biological systems and are present in soluble and bound forms (Chandrasekara & Shahidi 2010, 2011a, 2011b, 2011c; Kumari et al. 2019a).

Finger millets (Eleucine coracana) rank fourth in importance among coarse grains, namely sorghum, pearl millets, and foxtail millets, and are produced mainly in the arid and semi-arid areas on continents of Asia and Africa (Gupta et al. 2012). Finger millet, locally known as Kurakkan, is the most known millet type in Sri Lanka, among others, and is used in several traditional cuisines. Three improved finger millets varieties grown in Sri Lanka are Ravi, Ravana, and Oshadha and are good sources of dietary fiber, resistant starch, and major minerals such as potassium, calcium, phosphorus, and iron (Jayawardana et al. 2019). Furthermore, finger millets contain phenolic acids of which 71% are in the soluble form and are a rich source of flavonoids, among others (Chandrasekara & Shahidi 2011a; Chandrasekara and Shahidi 2013; Shobana et al. 2013).

Finger millet flour is used to prepare steamed foods (Halape and Pittu), non-fermented flatbreads, as well as thin and thick porridges, among others, in different food cultures. Previous studies have reported that processing changes the content of phenolics of millets (Pradeep & Guha 2011; Chandrasekara et al. 2012). A recent study reported that thin and thick porridges had more bioaccessible phenolic compounds that can contribute to high postprandial antioxidant activities compared to other finger millet food preparations (Kumari et al. 2019b). Furthermore, the ferulic acid content of finger millet porridges is mainly in the soluble form of phenolic compounds (Kumari et al. 2019b). Ferulic acid is the most abundant hydroxycinnamic acid in finger millet grains (Chandrasekara & Shahidi 2011a; Chandrasekara 2019). Ferulic acid and its derivatives play a pivotal role in preventing and attenuating NCDs due to their hypoglycaemic, chemopreventive, hypotensive, and antioxidant activities, among others (Chandrasekara 2019).

Parboiling is a hydrothermal treatment that is used for paddy to improve its milling and nutritional qualities. The limited published information is available on finger millet parboiling and the effects on phenolic content, antioxidant activities, and glycemic response (Bora et al. 2018; Dharmaraj et al. 2011; Kumari et al. 2020). Recent work has demonstrated that finger millet porridges prepared with differently processed flour showed a low glycemic index thus they had the potential for use in therapeutic diets for the management of hyperglycemia (Kumari et al. 2020).

Roasting is a dry heat treatment usually used for cereals, legumes, nuts and oilseeds to improve their taste and flavour before the preparation of foods. Roasting can change the phenolic level, composition as well as antioxidant activities of finger millet foods. However, little research has so far been reported in this area.

The use of different processing conditions may render advantages. These include improving the phenolic contents as well as antioxidant activities of finger millet foods while imparting variety, health benefits, and favourble attributes leading to increased popularity among consumers in modern societies.

Spices are used in foods to add flavours in addition to enriching them with beneficial bioactive components to improve their value as functional foods. The addition of spices to cereal-based foods is an effective and simple way of enriching them with antioxidant compounds. Spices are a rich source of phenolic compounds and thermal processing during cooking may affect the content and bioactivities of the phenolics in the food formulation. There is limited published information on the addition of spices to finger millet foods and their processing effects.

In this study, the phenolic contents and antioxidant activities of finger millet foods prepared using parboiled and roasted flour were monitored. Furthermore, the phenolic content and antioxidant activities of finger millet porridges added with different spices were evaluated as functional foods.

Materials and methods

Finger millet samples

Finger millet (Eleucine coracana), variety Ravi was used in the present study. Whole grain finger millets were procured from the Field Crops Research and Development Institute, Department of Agriculture, Mahailuppallama, Sri Lanka.

Chemicals

β-carotene, ferrous chloride, vanillin, 2,2-diphenyl-1-picrylhydrazyl (DPPH), 2,2 azinobis (3-ethylbenzothiazoline-6-sulfonate diammonium salt) (ABTS), 2,2-azobis(2-methylpropionamidine) dihydrochloride (AAPH), sodium chloride, ferulic acid, catechin, butylated hydroxyanisole (BHA), trolox, diethyl ether, ethyl acetate, methanol, potassium ferricyanide and acetone were purchased from Sigma-Aldrich Co, (St. Louis, MO, USA). Ethylenediaminetetraacetic acid (EDTA) trisodium salt was purchased from Needham Market (Suffolk, England). The compound 3-(2-pyridyl)-5,6-diphenyl-1,2,4-triazine-4,4-disulfonic acid sodium salt (Ferrozine) was procured from SERVA Electrophoresis GmbH, (Heidelberg, Germany). Linoleic acid, tween 80 (polyoxyethylene sorbitan monopalmitate), Folin-Ciocalteu’s reagent, and sodium nitrite were purchased from Research Lab Fine Chem Industries, (Mumbai, India). Sodium carbonate, and ferric chloride were purchased from Thomas Baker (Chemicals) Ltd. (Bombay, India). Aluminum chloride, trichloroacetic acid (TCA), and dibasic potassium phosphate were purchased from Techno Pharmchem, (Delhi, India). Sodium hydroxide, monobasic potassium phosphate, and potassium hydroxide, were purchased from Loba Chem Pvt Ltd, (Mumbai, India).

Methods

Sample preparation

Finger millet sample was cleaned to remove debris and soil particles. Grains were dehulled using a rice polishing machine (Rice husker and polisher PM 500, Satake Engineering Co Ltd, Japan).

Parboiling

Whole finger millet grains were soaked in distilled water for 10 h followed by draining excess water using a sieve. Steaming of soaked finger millet grains was performed using a rice cooker under atmospheric conditions. Steaming was carried out by placing the sieve on the rice cooker which contained boiling water. The duration of steaming was 5 min and throughout the process, grains were covered with a lid. At the end of steaming grains were heaped on a metal plate and allowed to cool to ambient temperature. Grains were sun-dried up to 12% moisture content.

Grinding

Grains were ground (Phillips HR 2011, Koninklijke Phillips Electronics NV, Shanghai, China) to obtain a flour that passed through a sieve of 0.038 mm (As 200, Retsch, Haan, Germany).

Roasting

Two types of finger millet flour obtained by grinding native (non-parboiled) and parboiled grains were roasted on a heated metal pan for 5 min with continuous mixing.

Finger millet food preparation

Finger millet flour and fresh scraped coconuts were used as the main raw ingredients for the two food preparation methods used in this study. Two food types, namely steamed food, (Pittu) and a thin porridge were prepared following commonly used household procedures.

A steamed food, Pittu, was made mixing finger millet flour (100 g) with freshly scraped coconut (50 g) and 15 mL of water into small granules followed by steaming for 15 min. Salt (1 g) was added for the taste. Two types of Pittu, preparations were done using raw and parboiled flour.

A thin porridge was prepared using finger millet flour (25 g), coconut milk (150 mL extracted using 50 g of scraped coconut according to conventional procedure), and water (150 mL) followed by boiling for 20 min in an open pan with continuous stirring. Four porridges were prepared using four types of flour, namely native, roasted, parboiled, and parboiled-roasted finger millet flour. Salt (1 g) and sugar (1 g) were added as common ingredients to all porridge preparations.

Addition of condiments

Four thin porridges were prepared using cinnamon, cardamom, garlic, and, a mix of cardamom and garlic as additional ingredients. Based on sensory evaluation, two porridge preparations added with condiments [crushed fresh garlic (5 g) and cinnamon powder (1 g)] were selected for further analysis of phenolic contents and antioxidant activities.

Sensory evaluation of finger millet porridges

Sensory properties were evaluated to determine the acceptability of different processing conditions, namely parboiling and roasting and the addition of condiments in the food preparations. Fifty untrained panelists (25 males and 25 females) in the age range of 24—30 years participated in the sensory evaluation. The panelists included 90% of students and 10% of university staff of the Makandura premises of Wayamba University of Sri Lanka. The food preparations were each coded with three digits and were served randomly to each panelist. Separate sensory evaluations were carried out to determine processing effects and the addition of condiments.

Foods were served at 40—50 °C in white porcelain bowls. The panelists were asked to rinse their mouths with warm water before the commencement of tasting and in between each tasting of food preparations. The panelists waited 90 s before tasting the next sample and a cracker biscuit was provided between tastings to eliminate any carry-over effect. The panelists were instructed to keep one serving of food for 5 s in the mouth and swallow in small quantities.

The panelists scored on 9 points hedonic scale for six attributes of food preparation. These included colour, taste, texture, after taste, mouth feel, and overall acceptance. On the hedonic scale, 1 meant ‘dislike extremely’ and 9 ‘like extremely’. Porridges demonstrated high scores for the majority of favourable attributes and were selected for further experimentation according to the results of Frideman analysis.

Ethical approval for the sensory evaluation

Informed written consent was obtained from each subject participating in the sensory evaluation. Ethical approval was obtained from the Ethics Review Committee of Faculty of Livestock, Fisheries and Nutrition, Wayamba University of Sri Lanka (201509HI01).

Freeze drying and defatting

Prepared foods after cooling to room temperature were stored at -80ºC, and were freeze-dried at -55 °C, and 0.012 mbar (Alpha 1–4 LD plus CHRIST, Osterode am Harz, Germany). The lyophilized samples were ground to 0.038 mm size and then defatted by blending with hexane (1:5, w/v, 2 min two times) at ambient temperature. All defatted meals were packed in polythene pouches and stored at -80 °C until used within one week for extraction of phenolic compounds.

Extraction of soluble phenolic compounds of finger millet foods

Soluble phenolic compounds of each food preparation were extracted using 70% (v/v) aqueous acetone. Defatted meals of food (5 g) were mixed with 100 mL of 70% aqueous acetone in a screw-capped conical flask in a shaking water bath (BT 680D, YIH DER Co., Ltd, New Taipei City, Taiwan) at 50 °C and at a speed of 175 rpm for 40 min. The slurry obtained was centrifuged for 5 min at 3000 g (Refrigerated centrifuge 3-18R TOMOS Life Science Group, NJ, USA) and the supernatant was collected. The extraction was repeated two times. Combined supernatants were evaporated in a rotary evaporator (IKA RV-10, IKA®-Werke GmbH & Co. KG, Staufen, Germany) at 40 °C. During all stages, extracts were protected from light by covering the containers with aluminum foil. Concentrated samples were then freeze-dried at -55 °C, and 0.012 mbar. Lyophilized extracts were stored at -80 °C for further analysis.

Determination of the crude composition of finger millet food preparations

Moisture, ash, crude protein, crude fibre, and crude fat contents were determined according to the AOAC (2007) methods of native and parboiled flour as well as prepared finger millet foods. Carbohydrate content was calculated by difference. Results were expressed based on 100 g edible portion of food.

Total phenolic content (TPC)

The total phenolic contents of finger millet flour and food crude extracts were determined according to the method of Singleton and Rossi (1965) with slight modifications (Chandrasekara et al. 2016). The lyophilized crude extract of food preparations dissolved in methanol to obtain a concentration of 1 mg/mL was used to determine TPC. Into a 50 mL centrifuge tube containing 0.25 mL of extract, 0.25 mL of Folin Ciocalteu’s reagent was added and the contents were vortexed thoroughly. To the reaction mixture, 0.5 mL of saturated sodium carbonate solution was added and diluted with 4 mL of distilled water followed by thorough mixing. Tubes were left at room temperature in the dark for 35 min followed by centrifugation at 4000 × g for 10 min (Refrigerated centrifuge 3-18R TOMOS Life Science Group, Belmont, MA, USA). The absorbance of the blue colour supernatant was read at 725 nm (UV–VIS Spectrophotometer, Labomed Inc, Culver City, CA, USA). Appropriate blanks were used for background subtraction. The TPC in the extract was determined using a standard curve prepared for ferulic acid and expressed as µmol ferulic acid equivalents (FAE) per gram of dry matter (dm).

Determination of total flavonoid content (TFC)

Total flavonoid content was determined using a colorimetric method (Chandrasekara & Shahidi 2010). In brief, a known volume (1 mL) of an aliquot of the extract, dissolved in methanol (1 mg/mL), was mixed with 4 mL of distilled water in a 50 mL centrifuge tube and 0.3 mL of 5% NaNO2 was added to the tube and allowed to react for 5 min. Subsequently, 0.3 mL of 10% AlCl3 was added to the reaction mixture and allowed to stand for 1 min. Finally, 2 mL of 1 M NaOH and 2.4 mL of distilled water were added and mixed immediately. Centrifuge tubes were kept in the dark at room temperature for 15 min followed by centrifugation at 4000 × g for 5 min. The absorbance was read at 510 nm against a blank prepared in a similar manner by replacing the extract with distilled water. A standard curve prepared with catechin was used to calculate TFC as µmol catechin equivalents (CE) per gram of dm.

Determination of proanthocyanidin content (PC)

The vanillin assay was used to determine the PC content as described by Chandrasekara and Shahidi (2010). To 0.5 mL of a methanolic solution of the extract, 2.5 mL of 0.5% vanillin-HCl reagent [0.5% vanillin (w/v) in 4% concentrated HCl in methanol] was added and incubated for 20 min at room temperature. A separate blank for each sample was read with 4% HCl in methanol. The absorbance was read at 500 nm, and the content of proanthocyanidin expressed as micromoles of CE per gram of dm.

Reducing power (RP)

The RP of the sample was determined spectrophotometrically by using the method explained by Kumari et al. (2017). Briefly, the extract (0.5 mL) was mixed with 1.25 mL of phosphate buffer solution (0.2 M, pH 6.6) and 1.25 mL of potassium ferricyanide solution in a centrifuge tube. The mixture was incubated for 20 min at 50ºC and 1.25 mL of 10% TCA was added followed by centrifugation at 1750 × g for 10 min. The supernatant (1 mL) was transferred into a tube containing 1.25 mL of deionized water and 0.25 mL of 0.1% (w/v) FeCl3, and the absorbance was read using a spectrophotometer at 700 nm. The results were expressed as µmol ascorbic acid equivalents (AAE) per gram of dm using a standard curve prepared with ascorbic acid.

DPPH radical scavenging activity (DRSA)

The DPPH radical scavenging activity was determined according to the method of Lee et al. (2007) as explained by Kumari et al. (2019b). The sample of 0.04 mL of extract (1 mg/mL in methanol) was added to the 1.96 mL of methanolic DPPH (60 µM) solution. The mixture was vortexed and allowed to stand at room temperature in the dark for 20 min. The absorbance of the solutions was read at 517 nm with using an appropriate blank. The DPPH radical scavenging activity was expressed as µmol trolox equivalents (TE) per gram of dm.

Trolox equivalent antioxidant capacity (TEAC)

The TEAC of the extract was determined as previously explained (Kumari et al. 2019b). AAPH (2.5 mM) was mixed with ABTS (100 mM) in saline phosphate buffer (PBS) (pH 7.4, 0.15 M NaCl) to prepare the ABTS•+ solution. The solution was kept in a water bath at 60ºC for 16 min and the flask was covered with aluminum foil to protect ABTS•+ solution from light. The prepared ABTS•+ solution was filtered using medium porosity filter papers before mixing with the extract. A separate blank was used to reduce the diminished absorbance of the radical solution. PBS solution was used to prepare finger millet food extract (1 mg/mL) and further diluted to fit within the range of 6.25 -50 μM of the standard trolox curve. To measure the TEAC, 40 μL of the extract were mixed with 1960 μL of the ABTS•+ solution. The absorbance of the reaction mixture was read at 734 nm immediately at the point of mixing (t0) and after 6 min (t6). The decrease in absorbance at 734 nm after 6 min of addition of trolox and extract was calculated using the equation: ΔA trolox = (At0, trolox—At6, trolox)—(At0, blank -At6, blank), where ΔA is the reduction of absorbance and A is the absorbance at a given time. TEAC values were expressed as µmol trolox equivalents (TE) /g of dm.

Ferrous ion chelating activity (FICA)

The ferrous ions chelating activity was measured as explained by Chandrasekara and Shahidi (2010). The crude extracts of finger millet flour and food preparations in distilled water (1 mg/mL) were used to measure the chelating activity of ferrous ions. Briefly, 0.4 mL of extracts was added to a solution of 2 mM FeCl2 (0.05 mL) and the mixture was added of 5 mM ferrozine (0.2 mL). The total volume was made to 4 mL with distilled water. The mixture was vortexed and allowed to stand for 10 min at room temperature. The absorbance of the reaction mixture was read at 562 nm. Distilled water was replaced the extract in the control. Appropriate blanks were prepared with 0.4 mL of the sample and 3.6 mL of distilled water for background subtraction. The inhibition percentage of ferrozine-ferrous ion complex formation was calculated using the following equation. Metal chelating effect (%) = {1-(Absorbance of the sample / Absorbance of the control)} × 100. The results were expressed as µmol EDTA equivalents/ per gram of dm.

Antioxidant activity using β -carotene-linoleate model system

The antioxidant activity of finger millet flour and food extracts was evaluated using a β-carotene-linoleate model system (Kumari et al. 2017). β-carotene (1 mL; concentration1 mg/ mL) dissolved in chloroform was transferred into a 100 mL round bottom flask. The chloroform was removed under vacuum using a rotary evaporator at room temperature. To the flask was added 40 mg of linoleic acid, 100 mg of Tween 80 emulsifier, and 100 mL of distilled water with vigorous agitation to form an emulsion. The emulsion was freshly prepared for each experiment. A Blank sample devoid of β-carotene was prepared for background subtraction. The extracts in methanol (200 µL) were added to the boiling tube containing 5 mL of emulsion. The samples were kept in a water bath which maintained the temperature at 50ºC. The absorbance values were read spectrophotometrically at 470 nm immediately at zero time, 30 min and 60 min. Butylated hydroxyanisole (BHA) (200 ppm) in methanol was used as a reference standard. The antioxidant activity coefficient (AAC) after 60 min of incubation was calculated using the following equation: AAC = (Aa(60)—Ac(60))/(Ac(0)—Ac(60)), where Aa(60) and Ac(60) are the absorbance values measured at 60 min for the sample and the control, respectively, and Ac (0) is the absorbance value of the control at 0 min. The results were expressed as AAC per g of dm.

Statistical analysis

All in vitro experiments were performed in triplicates and data were reported as mean ± standard deviation. The significant differences in mean values among different processing conditions and different food preparations were determined using a one-way analysis of variance (ANOVA) followed by Tukey’s Honestly Significant Difference (HSD) multiple rank test at p ≤ 0.05. Friedman analysis was performed to determine the mean ranking of sensory scores (Milton 1937). All statistical analyses were performed by using SPSS version 23 (IBM Analytics, USA).

Results and Discussion

In this work, we assessed the phenolic content and antioxidant activities of finger millet flour and foods submitted to different processing conditions to appreciate the finger millet flour preparations as functional foods. The level of macronutrients and dietary fiber in the edible portion of the food is needed to calculate the energy level and to use them in the therapeutic meal planning. The crude composition of finger millet flour and food preparations are summarized in Table 1. Significant differences were not existed among the crude compositions of food preparations used native and processed flour. The sensory data analysis of finger millet porridges showed that the basic porridge scored the highest median value and average mean rank whereas the cardamom-added porridge scored the least (Data not shown). Therefore, cardamom-added porridges were not selected for further analyses in this study. The knowledge generated in this study showed that hydrothermal processing and dry heat processing of native finger millet grains or flour and the addition of condiments influence the phenolic content and antioxidant activities of prepared foods, thus having the potential for use in therapeutic meals for the management of non-communicable diseases.

Phenolic contents

Total phenolic content

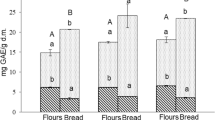

The TPC of the soluble phenolic extracts of finger millet flour (FMF), finger millet porridge (FMP), garlic added finger millet porridge (FMPg), cinnamon added finger millet porridge (FMPc), and finger millet flour pittu (FMFpi) submitted to different processing conditions are presented in Table 2. Among flour preparations, roasted flour showed a 13% (p ≤ 0.05) higher TPC. Roasting is a common process used for cereals, pulses, nuts, and some oilseeds as it develops desirable organoleptic properties by changing the colour, aroma, and flavour of the prepared foods. In agreement with the present work, several studies have shown that roasting increases the TPC of a number of food ingredients such as cashew, wheat germ, peanuts, and sesame seeds (Chandrasekara & Shahidi 2011d; Hassan et al. 2021; Jannat et al. 2013; Win et al. 2011; Zou et al. 2018).

During roasting polyphenolic compounds undergo oxidation and polymerization, degradation of proteins, and Maillard reactions (Pradeep & Yadahally 2015). An increase in TPC during roasting could be due to the liberation of phenolic compounds due to the damage to the cell structures and released phenolics could be more soluble in methanol. Heat treatments, on the other hand, during roasting, favour Maillard reactions due to the low water activity of nuts, pulses, and seeds and lead to the formation of a number of by-products, intermediates, and melanoidins which may contribute to the TPC of the roasted product (Chandrasekara & Shahidi 2011d). According to Chandrasekara and Shahidi roasting increased the TPC of cashew kernels from 1.14 to 5.28 mg gallic acid equivalents/ g of defatted meal when roasted at 130 °C for 33 min a forced air convection oven. In accordance with the present results, Sandhu et al (2017) reported that toasted oats had higher TPC than those of native flour. Hassan et al. (2021) showed that upon roasting of peanut pods the TPC increased by 25 and 19% for Sodari and Ghabiash cultivars, respectively. Jannat et al. (2013) demonstrated that roasting increased the TPC of sesame seed varieties and the content depended on the temperature and duration of roasting. In the present work, roasting was carried out using a heated pan which was the common local household method for roasting cereal flour before food preparation. However, in contrast to the present findings, Pelvan et al. (2012) reported a decrease of TPC, condensed tannin and phenolic acids of roasted Turkish hazelnut varieties. This could be due to difference of plant materials, moisture content and degree of heat treatment received.

The present study demonstrated that the TPC of prepared foods was generally lesser than those of the respective native and processed flour used. The reduction of TPC of the phenolic extracts of FMF upon FMP preparation was 29, 23, 47, and 25% for native, roasted, parboiled, and parboiled- roasted flour, respectively. Furthermore, 45 and 37% of TPC reduction was shown for FMFpi prepared with native and parboiled flour, respectively. All porridges were submitted to open boiling whereas FMFpi which was similar to ‘Couscous’ was prepared by steaming. In accordance with present results in a previous study Chandrasekara and Shahidi (2012) demonstrated that open boiling decreased the TPC of finger millet grains by 11 to 36%. Hithamini and Sirinivasan (2014) showed that TPC of native finger millet flour was reduced upon different processing conditions such as sprouting, pressure cooking and open boiling. Furthermore, Min et al. (2014) reported that wet cooking reduced the TPC of brown rice by 16–57%. However, a previous study reported that depending on the heat treatment received some foods showed a reduction of TPC whereas others reported an increase (Kumari et al. 2019b). In agreement with the results of the present study, Rotti and Pittu prepared with native flour of finger millet variety of Oshada had 4 and 9% reduction of TPC, respectively (Kumari et al. 2019b). However, contradictorily to present results thick and thin porridges showed 68 and 145% increase of TPC, respectively. Phenolic contents of the same food group vary with the variety, cultivated location, season, climatic condition, cultural practices adopted, and stress conditions, among others (Shahidi & Naczk 2004). The findings of the present study further support that variety of millet, type and duration of the heat treatment may influence the TPC of finger millet foods.

The results in the present work showed that in general, the TPC of foods prepared after subjecting to roasting, had significantly higher level compared to those of the food counterparts of native or parboiled flour preparations. FMP, FMPg, and FMPc prepared using roasted flour had 22, 14, and 13% more TPC than those of porridges that used native flour. This could be due to the presence of heat-stable phenolic compounds and MRPs incorporated during the roasting process.

Condiments are used to add flavour to food. In the present work, addition of condiments to porridges prepared with native and processed flour significantly increased TPC (Table 2). FMPg had 35, 12, 42 and 33% higher TPC of porridges prepared with native, roasted, parboiled, and parboiled-roasted flour, respectively compared to those counterparts of FMP. Garlic bulbs are rich sources of phenolic compounds and increase the content of phenolics in porridges in addition to their taste effect (Chen et al. 2013). According to Alide et al. (2020), cooking of garlic increased the TPC of garlic aqueous extracts irrespective of the cooking duration.

FMPc had 11, 17, 2 and 15% more TPC in porridges that used native, roasted, parboiled and parboiled-roasted flour, respectively compared to their respective FMP. The cinnamon bark is a rich source of a number of phenolic compounds and is among the spices used commonly for cooking for its flavour (Rao & Gan 2014). Cinnamon contains a wide variety of compounds such as cinnamaldehyde, cinnamic acid, catechins, and procyanidins (Rao & Gan 2014). The results of the present study evidenced that the addition of spices could compensate for the loss of bioactive compounds during thermal processing of finger millet foods.

Total flavonoid content (TFC)

Flavonoids are the major constituents in the soluble fraction of finger millet phenolic extracts and exist in free, esterified, and etherified forms. Catechin was the predominant flavonoid among the free phenolic compounds of the soluble fraction of finger millet and its contribution to the TFC was 85% (Chandrasekara & Shahidi 2011a). Flavonoids possess several bioactivities such as antioxidant, anticancer, antiallergic, and anti-inflammatory effects, among others. The results of the present study showed that the TFC of native finger millet flour was 9.63 µmol CE/ g of dry matter and roasting increased TFC by 17% (Table 2). In agreement, Pushparaj and Urooj (2014) demonstrated that thermal treatments increased the TFC of pearl millet grains.

In contrast to present results, previous studies have shown a reduction of TFC upon roasting. Roasting of barley at 327 °C decreased the catechin content significantly (Duh et al. 2001). Sandhu et al. (2017) showed that toasting oats at 115 °C for 3 h in an oven reduced TFC by 23 to 41%. This could be due to the nature of constituent flavonoid compounds of the food material used, their thermal stability, and degree of heat treatment, as well as the time period used in the present work.

The results of our work showed that parboiling decreased the TFC of FMF by 18% compared to native flour. In the parboiling process soaking of finger millet grains was done for 10 h and soluble flavonoids may leach into the water which was discarded before steaming, thus leading to their loss. In addition, during steaming heat-labile flavonoids of foods may degrade. Several authors have demonstrated that thermal processing can decrease the TFC depending on the degree of heat treatment and its duration (Duan et al. 2021; Yadav et al. 2018).

In the present work, the foods so prepared showed 1.9 to 7.8 folds (p ≤ 0.05) lesser TFC compared to the corresponding flour used (Table 2). FMP prepared with parboiled FMF showed the highest reduction of TFC among different foods. The hydrothermal treatment used during the preparation of foods may affect the content of phytochemicals (Towo et al. 2003; Zielinski et al. 2006). Previous studies have reported a reduction of TFC after hydrothermal treatments (Hithamini & Sirinivasan 2014; Min et al. 2014). According to Hithamini and Sirinivasan (2014), pressure cooking for 15–20 min and open pan boiling for 15 min reduced the TFC of finger millet flour by 68 and 10%, respectively. Min et al. (2014) showed that wet cooking of brown rice reduced the TFC by 12–61%. The changes noted in TFC of millet foods could be due to the oxidation of phenolics in the presence of oxygen and moisture, polymerization, thermal degradation, as well as depolymerization of high molecular weight phenolics (Shahidi & Chandrasekara 2015).

In addition, roasted as well as parboiled roasted FMP had 61 and 121% TFC, respectively compared to the corresponding non-roasted FMP in the present work (Table 2). The formation of MRPs in the roasting process may contribute to the apparent increased TFC of foods.

The TFC of FMPg varied from 1.02 to 5.40 µmol CE/ g of dry matter and showed higher TFC than counterpart FMP preparations. However, the TFC of FMPc prepared with native, roasted and parboiled flour was lesser than those of counterpart FMP and the TFC of FMPc prepared with parboiled roasted flour, which had 91% higher TFC than that of FMP used the native flour. The present results further suggest that enhancement of bioactive compounds through the addition of spices depend on the type of spices and thermal treatments received by foods.

Proanthocyanidins content (PC)

Proanthocyanidins are present as bioactive constituents of finger millets (Chandrasekara & Shahidi 2010; Kumari et al. 2017; Siwela et al. 2007) Proanthocyanidins are flavan-3-ol oligomeric or polymeric flavonoids present in a number of food items such as cereals, nuts, herbs, and berries. They are often regarded as anti-nutrient compounds as they may lower the bioavailability of proteins and minerals when present in adequate quantities (Chavan et al. 2001). Proanthocyanidins have also been reported to possess several health benefits, including anti-inflammatory, hypoglycemic, hypolipidemic, antiviral, antibacterial and antioxidant properties, among others (Yang et al. 2021). PC of finger millet flour and foods, expressed as µmol CE/g dry matter, are presented in Table 2. Among the finger millet flour and food preparations used in this study, parboiled FMFpi had the highest PC (11.18 ± 0.39 µmol CE/g dry matter). Low amounts of PC were detected in FMP roasted and parboiled roasted. The results of the present study showed that roasting of native and parboiled FMF reduced the PC by 43 and 12%, respectively. On the other hand, parboiled FMF had 22% more PC than that of native sample. Furthermore, FMFpi, native and parboiled had 23 and 17% more of PC, respectively than that of counterpart FMF. In accordance with the results noted for TPC and TFC in the present work, FMP prepared by open boiling had lesser PC compared to those of corresponding FMF and, in general, FMPg and FMPc had higher PC than FMP except FMPc prepared with native flour (Table 2).

Consistent with the present results, Chandrasekara and Shahidi (2011a, 2011b, 2011c, 2011d) demonstrated that roasting of cashew kernels decreased the content of assayable tannins and this may partly be due to the degradation of tannins during dry heat treatment. According to the present results, open boiling reduced the PC and may be due to the degradation during the hydrothermal treatments. However, the steaming process used in the preparation of FMFpi did not reduce the PC for both native and parboiled types. In agreement, Kessy et al. (2016) also showed that steam blanching of Litchi pericarp had 27% higher PC compared to that of its non-blanched counterpart.

Antioxidant activities

Reducing power (RP)

Reducing power (RP) of soluble phenolic extracts of finger millets flour and foods ranged from 5.72 ± 1.25 to 23.45 ± 0.55 µmol AAE/g dry matter (Table 3). Compounds with RP donate electrons thus reducing the oxidized intermediates of peroxidation, thus acting as antioxidants. Reductants in the finger millet extracts reduce the ferric/ferricyanide complex to the ferrous form. Finger millet phenolic extracts used in the present study demonstrated a considerable RP thereby acting as effective reductones. The FMF roasted had the highest RP whereas FMPc prepared with roasted flour showed the least.

The RP of roasted FMF was 21% higher (p ≤ 0.05) than that of the native sample. The present results showed that roasting increased the TPC and TFC of FMF. Increased RP of the roasted FMF could be due to the increased phenolic contents and the MRPs such as 5-hydroxymethyl-2- furaldehyde which demonstrate high antioxidant activities (Duenas et al. 2006). FMP showed lower RP than those of corresponding flour used in this study. In agreement with TPC, TFC, and PC of the flour and foods in this study RP of FMF was quite higher than FMP investigated. The phenolic compounds present in finger millets are mainly phenolic acids and flavonoids and are found in the free, conjugated, and insoluble-bound forms (Chandrasekara & Shahidi 2011a; Shahidi & Chandrasekara 2013). According to Shahidi and Chandrasekara (2013) 71 and 90% of phenolic acids and flavonoids, respectively, of finger millets exist in the free form. Degradation of free phenolic compounds upon open boiling and steaming could lead to the reduction of RP of FMP and FMFpi compared to FMF in the present work. FMPg and FMPc phenolic extracts exhibited a higher RP than their FMP counterparts. The results of the present work further demonstrate that the addition of spices is a practical way of improving antioxidant activities, which may be compromised by thermal treatment during food preparation in addition to enhancing flavour and taste.

DPPH Radical scavenging activity (DRSA)

DPPH is a synthetic stable organic radical and DRSA is commonly used to determine the antiradical capacity of isolated bioactive compounds and food extracts. DRSA assay measures the reducing ability of antioxidant compounds of the extract toward DPPH. This is monitored by measuring the reduction of the absorption at 517 nm.

DPPH radical scavenging activities of finger millet flour and food extracts are presented in Table 3. DPPH radical scavenging activities of finger millets flour and food extracts ranged from 130.4 ± 2.27 to 311.82 ± 2.32 and 110.37 ± 2.41 to 240.95 ± 2.39 µmol trolox equivalents/g dry matter, respectively. The DRSA of soluble phenolic extracts of flour significantly (p ≤ 0.05) increased with roasting, parboiling, and parboiled-roasted. FMP showed significantly (p ≤ 0.05) lesser DRSA than that of the corresponding flour. In agreement with the results of the present work, an earlier study showed that cooked finger millets had 11–36% lesser DRSA than that of the native dehulled grains (Chandrasekara et al. 2012). This could be due to several reasons such as degradation of phenolic compounds or formation of phenolic-protein complexes leading to poor extractability of phenolics due to hydrothermal treatments ( Yeo & Shahidi 2017). In the present study, FMPg had higher DRSA than those of counterpart FMP.

However, except for FMPc prepared using native flour, other samples had lesser DRSA than that of corresponding FMP. In the parboiling process, finger millet grains are soaked for 10 h before steaming. This can reduce the content of water-soluble free phenolic compounds. However, steaming can reduce heat-sensitive phenolic compounds as well as release insoluble-bound phenolics due to the thermal destruction of cell wall polymers leading to an increase of phenolics and thus the antioxidant activities of the extracts. However, in the present study bound fraction of phenolics was not determined as previous studies demonstrated that the major contribution of phenolics of finger millets was from the soluble fraction (Chandrasekara & Shahidi 2011a). This study clearly demonstrated that roasting and parboiling of finger millet has a significant effect on the DPPH radical scavenging activity of the extracts of finger millet flour and foods prepared. This could be attributed to the retention of different phenolic compounds during thermal treatments as well as MRPs produced in the roasted samples.

Trolox equivalent antioxidant capacity (TEAC)

Table 3 presents the TEAC of finger millet flour and foods subjected to different processing conditions. The TEAC assay is commonly used to determine antioxidant capacity of food matrices and the ability of antioxidant compounds in the extracts to reduce the ABTS radical anion to its non-radical form.

The TEAC values of finger millet flour and foods ranged from 12.09 ± 1.14 to 36.48 ± 0.42 µmol trolox equivalents/g dry matter. Roasting significantly reduced the TEAC of native flour by 25.4% whereas parboiling increased it by 4.3% (Table 3). In agreement with the present results, Kumari et al. (2019b) showed that dry roasting reduced TEAC by 47% compared to native flour. FMF had (p < 0.05) higher TEAC than FMP, similar to the trend observed for other antioxidant assays. Open boiling can influence the phenolic compounds and their activities due to heat, oxygen, and water. Carcea et al. (2017) showed that cooking can reduce the polyphenolic content of cereal and legume products.

The TEAC of FMPg and FMPc were higher than that of FMP. FMPg had 14, 2.8, 2.3, and 1.7 folds higher TEAC than FMP for native, roasted, parboiled, and roasted-parboiled, respectively. This further reflects the enhancement of antioxidant potential of finger millet food due to the addition of spices.

Ferrous ion chelating activity (FICA)

Ferrous ion serve as a key transition metal ion responsible for the initiation of peroxidation in biological systems, thus causing several non-communicable diseases and aging. In the body, Fenton reaction in the presence of ferrous ions generates hydroxyl radicals which damages biomolecules such as carbohydrates, proteins, and fat. Chelating agents in foods can reduce the concentration of metal ions available for catalyzing peroxidation and serve as effective secondary antioxidants. In this assay, ferrous ions form a purple colour complex with ferrozine and the intensity of colour decreases when chelating agents react with metal ions.

Table 3 presents the ferrous ion chelating activity of phenolic extracts of finger millet flour and foods subjected to different processing conditions. The ferrous ion chelating activity of phenolic extracts ranged from 86.27 ± 0.36 to 183.68 ± 0.62 µmol EDTA equivalents/g dry matter. The extracts of FMP prepared with roasted flour had the lowest FICA whereas FMF of parboiled –roasted showed the highest. In the current work, though roasted FMF showed higher TPC and TFC, FICA was significantly (p < 0.05) lower compared to native flour. However, Sandhu et al. (2017) reported that toasting of oat increased the metal chelating activity by 34–75% for different oats cultivars. Furthermore, in the present study porridge preparation, reduced the FICA than that of corresponding flour used whereas Pittu preparations increased the FICA (Table 3). In a previous study, Kumari et al. (2019a, 2019b) demonstrated the increase of FICA of differently prepared finger millet foods compared to the corresponding native flour. According to Starowicz et al. (2021), baking at 185 °C for 20 min significantly reduced the ferric reducing antioxidant power of cookies added with spices/ herbs. The reductions were more than 10 times that of their respective dough samples.

According to the results of this study, finger millet flour and food may serve as a potential source of chelating agents inhibiting radical-mediated chain reactions. As evidenced by the present study, soluble phenolic extracts of finger millet flour and foods are a potential source of proanthocyanidins which form stable complexes with metal ions acting as effective ferrous ion chelators.

β-Carotene-linoleate model system

In β-carotene-linoleate system, free radicals are produced by abstracting a hydrogen atom from the active bis-allylic methylene group of linoleic acid in C-11 between two double bonds. Free radicals generated hit the β-carotene molecule leading to the loss of its conjugation. This action causes the loss of the characteristic yellow-orange colour of the β-carotene. Phenolic compounds in the extract protect the β-carotene by reacting with linoleate free radical.

Antioxidant activity coefficients of phenolic extracts of finger millet flour and foods are presented in Table 3. Soluble extracts of FMF showed higher AAC than those of FMP and FMPg. Phenolic extracts of FMFpi prepared using parboiled flour showed the highest AAC among other foods. BHA which was used as the reference antioxidant showed 93.83 ± 5.09 percentage of absorbance AAC/ g dry matter. However, it is noteworthy that FMPc had higher AAC than FMF except for porridge prepared with parboiled flour.

In the present study, FMP of native, roasted, parboiled and parboiled-roasted showed 21.7, 24.5, 27.1 and 4% less AAC, respectively, than those of corresponding FMF. Furthermore, FMPc of native, roasted, parboiled and parboiled-roasted had 28.7, 73.1, 13.3, and 51.5% (p ≤ 0.05) higher AAC compared to those of FMP.

Conclusion

The overall effect of processing on finger millet foods appears to depend on a number of factors other than the original phenolic contents of the grains. In the present study, when comparing native and processed flour, it was generally noted that roasted flour has high phenolic content in the soluble fraction and determines the antioxidant efficacy of the extracts in different antioxidant assays. The extracts of finger millet flour demonstrated high phenolic content and stronger antioxidant efficacy compared to that of foods. However, addition of garlic and cinnamon improved the flavour as well as phenolic contents and antioxidant activities. It is noteworthy that foods prepared using steaming possessed lower phenolic content and antioxidant activities in general than those of open-boiled counterparts. It appears that analysis of phenolic profile is necessary to better understand the relationship between composition and antioxidant properties of extracts though it has not been the focus in the present work. This study demonstrated a wide variation in the phenolic contents and antioxidant capacity in flour and foods of whole finger millet grains. Processing differences existed in the contents of phenolics as well as antioxidant capacities of soluble phenolic fractions of finger millet flour and foods so prepared. The knowledge generated from this study may help to exploit the use of finger millets in different food preparations as a functional food ingredient and to promote their use in attenuating NCDs and overall wellness.

Availability of data and materials

All data supporting this study are included in this manuscript. Further details are available upon request from the corresponding author.

Abbreviations

- AAC:

-

Antioxidant activity coefficient

- AAE:

-

Ascorbic acid equivalent

- AAPH-2,2:

-

Azobis (2-methylpropionamidine) dihydrochloride

- ABTS-2,2:

-

Azinobis (3-ethylbenzothia Zoline-b-sulfonateddiammonium salt)

- ANOVA:

-

Analysis of variance

- AOAC:

-

Association of official analytical chemists

- BHA:

-

Butylated hydroxyanisole

- CE:

-

Catechin equivalent

- DM:

-

Dry matter

- DPPH-2,2:

-

Diphenyl-1-picrylhydrazyl

- DRSA:

-

DPPH radical scavenging activity

- EDTA:

-

Ethylenediaminetetraacetic acid

- FAE:

-

Ferulic acid equivalent

- FICA:

-

Ferrous ion chelating activity

- FMF:

-

Finger millet flour

- FMFpi:

-

Finger millet flour pittu

- FMPc:

-

Cinnamon added finger millet porridge

- FMP:

-

Finger millet porridge

- FMPg:

-

Garlic added finger millet porridge

- HSD:

-

Honestly Significant Difference

- NCDs:

-

Non-communicable diseases

- PC:

-

Proanthocyanidins content

- RP:

-

Reducing power

- TE:

-

Trolox equivalent

- TEAC:

-

Trolox equivalent antioxidant capacity

- TFC:

-

Total flavonoid content

- TPC:

-

Total phenolic content

References

AOAC International (2007). Official methods of analysis of AOAC International. 18th Edition, Association of Analytical Chemists, Rockville, MD, USA.

Bora, P., Ragaee, S., & Marcone, M. F. (2018). Effect of parboiling on decortication yield of millet grains and phenolic acids and in vitro digestibility of selected millet products. Food Chemistry, 274, 718–125.

Bora, P., Ragaee, S., & Marcone, M. F. (2019). Characterization of several types of millets as functional food ingredients. International Journal of Food Sciences and Nutrition, 70, 714–724.

Carcea, M., Narducci, V., Turfani, V., & Giannini, V. (2017). Polyphenols in raw and cooked cereals/pseudocereals/legume pasta and couscous. Foods, 6, 80. https://doi.org/10.3390/foods6090080

Chandrasekara, A., Rasek, O. A., John, J. A., Chandrasekara, N., & Shahidi, F. (2016). Solvent and extraction conditions control the assayable phenolic content and antioxidant activities of seeds of black beans, canola, and millet. Journal of the American Oil Chemists’ Society, 93, 275–283.

Chandrasekara, A., & Shahidi, F. (2010). Content of insoluble bound phenolics in millets and their contribution to antioxidant capacity. Journal of Agricultural and Food Chemistry, 58, 6706–6714.

Chandrasekara, A., & Shahidi, F. (2011a). Antiproliferative potential and DNA scission inhibitory activity of phenolics from whole millet grains. Journal of Functional Foods, 3, 159–170.

Chandrasekara, A., & Shahidi, F. (2011b). Inhibitory activities of soluble and bound millet seed phenolics on free radicals and reactive oxygen species. Journal of Agricultural and Food Chemistry, 59, 428–436.

Chandrasekara, N., & Shahidi, F. (2011c). Effect of Roasting on Phenolic Content and Antioxidant Activities of Whole Cashew Nuts, Kernels, and Testa. Journal of Agricultural and Food Chemistry, 59, 5006–5014.

Chandrasekara, A., & Shahidi, F. (2011d). Determination of antioxidant activity in free and hydrolyzed fractions of millet grains and characterization of their phenolic profiles by HPLC-DAD-ESI-MSn. Journal of Functional Foods, 3, 144–158.

Chandrasekara, A. (2019). Phenolic acids. In Melton L., Shahidi, F., Varelis, P.(Eds) Encyclopedia of Food Chemistry, 3, 535–545.

Chavan, U. D., Shahidi, F., & Naczk, M. (2001). Extraction of condensed tannins from beach pea Lathyrusmaritmus L.) as affected by different solvents. Food Chemistry, 75, 509–512.

Chen, S., Shen, X., Cheng, S., Li, P., Du, J., Chang, Y., & Meng, H. (2013). Evaluation of garlic cultivars for polyphenolic content and antioxidant properties. PLoS ONE, 8, e79730. https://doi.org/10.1371/journal.pone.0079730

Devi, P. B., Vijayabharathi, R., Sathyabama, S., Malleshi, N. G., & Priyadarisini, V. B. (2014). Health benefits of finger millet (Eleusine coracana L.) polyphenols and dietary fiber: A review. Journal of Food Science & Technology, 51, 1021–1040.

Dharmaraj, U., Parameswara, P., Somashekar, R., & Malleshi, N. G. (2011). Effect of processing on the microstructure of finger millet by X-ray diffraction and scanning electron microscopy. Journal of Food Science and Technology, 32, 1–9.

Duan, S.-C., Kwon, S.-J., & Eom, S.-H. (2021). Effect of thermal processing on color, phenolic compounds, and antioxidant activity of Faba bean (Vicia faba L.) leaves and seeds. Antioxidants, 10, 1207.

Duenas, M., Hernandez, T., & Estrella, I. (2006). Assessment of in vitro antioxidant capacity of the seed coat and the cotyledon of legumes in relation to their phenolic contents. Food Chemistry, 98, 95–103.

Duh, P. D., Yen, G. C., Yen, W. J., & Chang, L. W. (2001). Antioxidant effects of water extracts from barley (Hordeumvulgare L.) prepared under different roasting temperatures. Journal of Agricultural and Food Chemistry, 49, 1455–1463.

Gupta, A.K., Gupta, V.S., Gaur, V.S., Kumar, A. (2012) Relationship of nitrogen use efficiency with the activities of enzymes involved in nitrogen uptake and assimilation of finger millet genotypes grown under different nitrogen inputs. The Scientific World Journal.

Hassan, A.B., Maiman, S.A.A., Alshammari, G.M., Mohammed, M.A., Alhuthayli, H.F., Ahmed, I.A.M., Alfawaz, M.A., Yagoub, A.E.A., Fickak, A., & Osman, M.A. (2021). Effects of boiling and roasting treatments on the content of total phenolics and flavonoids and the antioxidant activity of peanut (Arachis hypogaea L.) Pod Shells. Processes, 9, 1542. doi.org/https://doi.org/10.3390/pr9091542.

Hithamini, G., & Sirinivasan, K. (2014). Effect of domestic processing on the polyphenol content and bioaccessibility in finger millet (Eleusinecoracana) and pearl millet (Pennisetumglaucum). Food Chemistry, 164, 55–62.

Jannat, B., Oveisi, M. R., Sadeghi, N., Hajimahmoodi, M., Behzad, M., Nahavandi, B., Tehrani, S., Sadeghi, F., & Oveisi, M. (2013). Effect of roasting process on total phenolic compounds and γ-tocopherol contents of Iranian sesame seeds (Sesamumindicum). Iranian Journal of Pharmaceutical Research, 12, 751–758.

Jayawardana, S. A. S., Samarasekera, J. K. R. R., Gooneratne, J., Hettiarachchi, G. H. C. M., Mazumdar, S. D., & Banerjee, R. (2019). Dietary fibers, starch fractions and nutritional composition of finger millet varieties cultivated in Sri Lanka. Journal of Food Composition Analysis, 82, 1–6.

Kumari, D., Madhujith, T., & Chandrasekara, A. (2017). Comparison of phenolic content and antioxidant activities of millet varieties grown in different locations in Sri Lanka. Food Science and Nutrition, 5, 474–485.

Kumari, K.D.D., Madhujith, W.M.T., & Chandrasekara, G.A.P. (2019a). Millet phenolics as natural antioxidants in food model systems and human LDL/VLDL cholesterol in vitro Tropical Agricultural Research, 30, 13–26.

Kumari, D., Chandrasekara, A., & Shahidi, F. (2019b). Bioaccessibility and antioxidant activities of finger millet food phenolics. Journal of Food Bioactives, 6, 100–109.

Kumari, D., Chandrasekara, A., Athukorale, P., & Shahidi, F. (2020) Finger millet porridges subjected to different processing conditions showed low glycemic index and variable efficacy on plasma antioxidant capacity of healthy adults. Food Production Processing and Nutrition, 2, 13.

Lee, W. Y., Emmy, H. K. I., Abbe Maleyki, M. J., & Amin, I. (2007). Antioxidant capacity and phenolic content of selected commercially available cruciferous vegetables. Malaysian Journal of Nutrition, 13, 71–80.

Milton, F. (1937). The use of ranks to avoid the assumption of normality implicit in the analysis of variance. Journal of the American Statistical Association, 32, 675–701.

Min, B., McClung, A., & Chen, M.-H. (2014). Effects of hydrothermal processes on antioxidants in brown, purple and red bran whole grain rice (Oryza sativa L.). Food Chemistry, 159, 106–115.

Pelvan, E., Alasalvar, C., & Uzman, S. (2012). Effects of roasting on the antioxidant status and phenolic profiles of commercial Turkish hazelnut varieties (Corylus avellana L.) Journal of Agricultural and Food Chemistry, 60, 1218–1223.

Pradeep, P. M., & Yadahally, N. S. (2015). Impact of processing on the phenolic profiles of small millets: Evaluation of their antioxidant and enzyme inhibitory properties associated with hyperglyceamia. Food Chemistry, 169, 455–463.

Pradeep, S. R., & Guha, M. (2011). Effect of processing methods on the nutraceutical and antioxidant properties of little millet (Panicumsumatrense) extracts. Food Chemistry, 126, 1643–1647.

Pushparaj, F. S., & Urooj, A. (2014). Antioxidant activity in two Pearl millet (Pennisetum typhoideum) cultivars as influenced by processing. Antioxidants, 3, 55–66.

Rao, P.V., & Gan, S.H.(2014). Cinnamon: A Multifaceted Medicinal Plant. Evidence-Based Complementary and Alternative Medicine, http://dx.doi.org/https://doi.org/10.1155/2014/642942.

Sandhu, K. S., Godara, P., Kaur, M., & Punia, S. (2017). Effect of toasting on physical, functional and antioxidant properties of flour from oat (Avena sativa L.) cultivars. Journal of the Saudi Society of Agricultural Sciences, 16, 197–203.

Shahidi, F., & Chandrasekara, A. (2013). Millet grain phenolics and their role in disease risk reduction and health promotion: A review. Journal of Functional Foods, 5, 570–581.

Shahidi, F., & Naczk, M. (2004). Phenolics in Food and Nutraceuticals (pp. 1–82). CRC Press.

Shahidi, F., Zhong, Y., & Chandrasekara, A. (2012). Antioxidants and human health. In L LYu, R Taso & F Shahidi, (Ed.), Cereals and Pulses: Nutraceutical Properties & Health Benefits (pp. 273–308). John Wiley & Sons Inc.

Shahidi, F., & Chandrasekara, A. (2015). Processing of millet grains and effects on non- nutrient antioxidant compounds. In Processing and impact on active components in foods. (ed by Victor R Preedy), Elsevier Inc. UK pp 345–392.

Shobana, S., Krishnaswamy, K., Sudha, V., & Malleshi, N. G. (2013). Finger Millet (Ragi, Eleusinecoracana L.): A Review of its nutritional properties, processing, and plausible health benefits. Advances in Food and Nutrition Research, 69, 1–39.

Singleton, V. L., & Rossi, J. A. (1965). Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. American Journal of Enology and Viticulture, 16, 144–158.

Siwela, M., Taylor, J. R. N., de Milliano, W. A. J., & Duodu, K. G. (2007). Occurrence and location of tannins in finger millet grain and antioxidant activity of different grain types. Cereal Chemistry, 84, 169–174.

Starowicz, M., Arpaci, S., Topolska, J., & Wronkowska, M. (2021). Phytochemicals and antioxidant activity in oat-buckwheat dough and cookies with added spices or herbs. Molecules, 26, 2267. https://doi.org/10.3390/molecules26082267

Towo, E. E., Svanberg, U., & Ndossi, G. D. (2003). Effect of grain pre-treatment on different extractable phenolic groups in cereals and legumes commonly consumed in Tanzania. Journal of the Science of Food and Agriculture, 83, 980–986.

Win, M. M., Abdul-Hamid, A., Baharin, B. S., Anwar, F., & Saari, N. (2011). Effects of roasting on phenolics composition and antioxidant activity of peanut (Arachishypogaea L.) kernel flour. European Food Research and Technology, 233, 599–608.

Yadav, N., Kaur, D., Malaviya, R., Singh, M., Fatima, M., & Singh, L. (2018). Effect of thermal and non-thermal processing on antioxidant potential of cowpea seeds. International Journal of Food Properties, 21, 437–451.

Yang, H., Tuo, X., Wang, L., Tundis, R., Portillo, M. P., Simal-Gandara, J., Yu, Y., Zou, L., Xiao, J., & Deng, J. (2021). Bioactive procyanidins from dietary sources: The relationship between bioactivity and polymerization degree. Trends in Food Science & Technology, 111, 114–127.

Yeo, J., & Shahidi, F. (2017). Effect of hydrothermal processing on changes of insoluble-bound phenolics of lentils. Journal of Functional Foods, 38, 716–722.

Zielinski, H., Michalska, A., Piskula, M. K., & Kozlowska, H. (2006). Antioxidants in thermally treated buckwheat groats. Molecular Nutrition and Food Research, 50, 824–832.

Zou, Y., Gao, Y., He, H., & Yang, T. (2018). Effect of roasting on physico-chemical properties, antioxidant capacity, and oxidative stability of wheat germ oil. LWT- Food Science & Technology, 90, 246–253.

Acknowledgements

This research was supported by the National Research Council of Sri Lanka (NRC 12-096) through a research grant to AC.

Funding

This research was supported by the National Research Council of Sri Lanka (NRC 12–096) through a research grant to Anoma Chandrasekara.

Author information

Authors and Affiliations

Contributions

AC conceptualized the study, designed experiments, supervised data collection and the study, analyzed data, prepared the draft manuscript, IS and DK collected and analyzed data. FS read and edited the manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participation

Informed written consent was obtained from each subject participating in the sensory evaluation. Ethical approval was obtained from the Ethics Review Committee of Faculty of Livestock, Fisheries and Nutrition, Wayamba University of Sri Lanka (201509HI01).

Consent to publication

Not applicable.

Competing interests

Author Dr. Fereidoon Shahidi is editor-in-chief of Food Production, Processing and Nutrition and he was not involved in the journal's review of, or decisions related to this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chandrasekara, A., Senanayake, I., Kumari, D. et al. Effect of processing on the antioxidant activities of porridges and Pittu prepared from finger millets (Eleusine coracana). Food Prod Process and Nutr 4, 18 (2022). https://doi.org/10.1186/s43014-022-00097-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-022-00097-x