Abstract

Background

Komagataella phaffii (Pichia pastoris) has emerged as a common and robust biotechnological platform organism, to produce recombinant proteins and other bioproducts of commercial interest. Key advantage of K. phaffii is the secretion of recombinant proteins, coupled with a low host protein secretion. This facilitates downstream processing, resulting in high purity of the target protein. However, a significant but often overlooked aspect is the presence of an unknown polysaccharide impurity in the supernatant. Surprisingly, this impurity has received limited attention in the literature, and its presence and quantification are rarely addressed.

Results

This study aims to quantify this exopolysaccharide in high cell density recombinant protein production processes and identify its origin. In stirred tank fed-batch fermentations with a maximal cell dry weight of 155 g/L, the polysaccharide concentration in the supernatant can reach up to 8.7 g/L. This level is similar to the achievable target protein concentration. Importantly, the results demonstrate that exopolysaccharide production is independent of the substrate and the protein production process itself. Instead, it is directly correlated with biomass formation and proportional to cell dry weight. Cell lysis can confidently be ruled out as the source of this exopolysaccharide in the culture medium. Furthermore, the polysaccharide secretion can be linked to a mutation in the HOC1 gene, featured by all derivatives of strain NRRL Y-11430, leading to a characteristic thinner cell wall.

Conclusions

This research sheds light on a previously disregarded aspect of K. phaffii fermentations, emphasizing the importance of monitoring and addressing the exopolysaccharide impurity in biotechnological applications, independent of the recombinant protein produced.

Similar content being viewed by others

Background

Komagataella phaffii (K. phaffii), formerly referred to as Pichia pastoris, has gained recognition for its remarkable capability to efficiently secrete recombinant proteins into the surrounding medium. This not only reduces downstream processing efforts but also ensures a high purity of the expressed proteins, making it a preferred system of choice for various industrial applications. Furthermore, a mutation in the HOC1 gene, present in most commercially used K. phaffii strains, leads to a thinner cell wall, enhancing protein secretion [1]. Moreover, K. phaffii is characterized by low secretion of host proteins, also contributing to cost-effective protein purification [2, 3].

However, an unexplored aspect of this established system demanding careful consideration is the presence of extracellular polysaccharides. This goes in hand with challenges for the protein production process, as the exopolysaccharides (EPS) need to be separated from the target protein, leading to higher purification costs. The existence of EPS was first mentioned by Trimble et al. [4]. An analysis of the produced glycoprotein revealed the presence of 3–4 times more carbohydrates in the supernatant than expected. Furthermore, Denton et al. [5] detected substantial quantities of an undefined and unknown EPS, significantly hindering protein crystallization and crystallographic analysis. Additional remarks of the EPS existence can be found in the works of Vinogradov et al. [6] and Włodarczyk-Biegun et al. [7]. Here, it was noted that the EPS is mainly composed of mannose units. It is also worth mentioning that the presence of the EPS will remain undetected when applying protein quantification methods like PAGE or liquid UV detectors. Although EPS quantification remains a relatively underexplored area in the literature, Werten et al. [8] emphasize the significance of EPS as the major impurity in K. phaffii culture broths. From data presented by Denton et al. [5], a rough estimate of the relative EPS concentration leads to 0.05–0.06 g/gCDW (gram per gram of cell dry weight). To our knowledge, no further quantification of EPS related to K. phaffii is available in the existing literature. EPS byproduct formation is not limited to K. phaffii. For instance, other organisms such as Vibrio natriegens can produce up to 157 mg/L EPS as a byproduct at a cell density of 28 g/L [9]. Moreover, microbial EPS with potential industrial applications include xanthan from Xanthomonas campesteris, succinoglycan from Rhizobium, bacterial alginates from Azotobacter vinelandii and pullulan from Aureobasidium pullulans [10]. For pullulan 22 g/L can be reached, for Bacillus polymyxa, concentrations as high as 54 g/L are achievable [11,12,13].

Moreover, the research in protein purification from cultivations broths containing polysaccharide impurities remains limited, with two notable methods being lectin affinity chromatography [14, 15] and protein precipitation with ammonium sulfate [7] or acetone [4]. For pullulan purification, melanin separation is performed through adsorption on activated charcoal [10].

This study explores the origin of the unidentified EPS in high cell density K. phaffii fermentations, examining possible factors influencing the formation of the EPS. Therefore, several fermentations were performed varying the used strain, the carbon source, and the induction with methanol. Biomass and EPS formation were measured over the fermentation time to determine the relative EPS concentration and establish a relation with the examined factors.

Methods

Strains

The following three strains were used for experiments: First, K. phaffii MutS BSYBG11 (BG11) obtained from Bisy GmbH (Hofstaetten a. d. Raab, Austria). This strain is a derivative of strain K phaffii NRRL Y-11430/CBS 7435 and has a mutation in the HOC1 gene leading to a truncated version of Hoc1 [16]. Second, strain BG11 has been used as host for the genomic integration of an expression cassette for a recombinant structural protein under control of the PCAT promotor, in the following designated as strain I. It resulted in five target protein expression cassettes in the yur1 locus. The original sequence of the native host protein was codon optimized for K. phaffii to increase product titers. The strain is deposited at DSMZ as DSM 33957 and available under reasonable request. Third, the wildtype (Mut+) strain K. phaffii MUCL 46514 (NRRL Y-7556; CBS 2612; NRRL YB-4290) obtained from BCCM, hereafter referred to as Y-7556 was included into the study. This strain has an intact HOC1 gene. The strain genealogy can be found in Additional file 1: Fig. S1.

Media

All chemicals applied for media preparation were of analytical grade and purchased from Carl Roth GmbH (Karlsruhe, Germany), if not stated differently.

For shake flask precultures, the K. phaffii strains were grown in mineral Syn6-MES medium [17]. The basic Syn6-MES medium consisted of 1.0 g/L KH2PO4, 7.66 g/L (NH4)2SO4, 3.3 g/L KCl, 3.0 g/L MgSO4 × 7H2O, 0.3 g/L NaCl, 39 g/L (0.2 M) 2-(N-morpholino)-ethanesulfonic acid, 4-morpholineethanesulfonic acid (MES). All medium components were dissolved in deionized water, the pH was adjusted to 6.0 with 1 M NaOH and the medium was sterilized via autoclaving (121 °C for 20 min). Prio to use, 940 mL basic medium was supplemented with 10 mL of 100 g/L CaCl2 (sterile filtered), 10 mL of a 100 × micro-elements stock solution (sterile filtered), 10 mL of a 100 × vitamin stock solution (sterile filtered), 10 mL of a 100 × trace-elements solution (sterile filtered), and 20 mL glucose stock solution prepared with a concentration of 500 g/L (autoclaved). The stock solutions had the following compositions: micro-element stock solution: 6.65 g/L EDTA (ethylenediamine tetraacetic acid disodium sulfate), 6.65 g/L (NH4)2Fe(SO4)2 × 6H2O, 0.55 g/L CuSO4 × 5H2O, 2 g/L ZnSO4 × 7H2O and 2.65 g/L MnSO4 × H2O. Vitamin stock solution: 0.04 g/L d-biotin and 13.35 g/L thiamine chloride. The d-biotin was dissolved in 10 mL of a (1:1) mixture of 2-propanol and deionized water. Thiamin chloride was dissolved separately in 90 mL deionized water. Afterwards, the two solutions were mixed. Trace element stock solution: 0.065 g/L NiSO4 × 6H2O, 0.065 g/L CoCl2 × 6H2O, 0.065 g/L H3BO3, 0.065 g/L KI, and 0.065 g/L Na2MoO4 × 2H2O.

For stirred tank bioreactor cultivations a medium proposed by Hyka et al. [18] was prepared. The basic medium consists of 7.23 g/L H3PO4, 0.64 g/L KOH, 0.17 g/L CaSO4 × 2H2O, 2.86 g/L K2SO4, 2.3 g/L MgSO4 × 7H2O and 0.1 mL/L polypropylene glycol (PPG). The basic medium solution was sterilized via autoclaving (121 °C for 20 min) and a 650 g/L glucose or glycerol stock solution was added to a final concentration of 5 or 40 g/L. The medium was supplemented with 0.62 mL/L vitamin stock solution from Syn6-MES medium and 0.74 mL/L filter sterilized modified trace element solution PTM1. It consists of 3.84 g/L CuSO4 × 5H2O, 0.08 g/L NaI, 3 g/L MnSO4 × H2O, 0.2 g/L Na2MoO4 × 2H2O, 0.02 g/L H3BO3, 0.92 g/L CoCl2 × 6H2O, 20 g/L ZnCl2, 65 g/L FeSO4 × 7H2O and 5 mL/L 69 wt.% H2SO4. The medium components were dissolved in deionized water. The pH of the medium was titrated to 6.0 using ammonia solution (30 vol.%). Production was induced with 1 vol.% methanol (purity > 99.5%), if not stated otherwise.

The feed for bioreactor cultivations consisted of a 650 g/L glucose solution or 650 g/L glycerol solution or pure methanol (purity > 99.5%). The feed was supplemented with 12 mL/L PTM1 and 10 mL/L vitamin stock solution from Syn6-MES medium. After methanol induction of the bioreactor with 1 vol.%, the feed was also supplemented with 70 mL/L methanol. For non-induced fermentations, deionized water was added instead.

Preculture

For bioreactor cultivations, a preculture was grown in four unbaffled 250 mL shake flasks with a filling volume of 10 mL. The flasks were inoculated with 100 µL glycerol stock cell suspension stored at − 80 °C (optical density measured at 600 nm OD600 = 5) and cultivated for 18 h in a temperature-controlled hood (Climo-Shaker ISF1-X, Kuhner, Birsfelden, Switzerland) at 30 °C with a shaking frequency of 350 rpm and a shaking diameter of 50 mm.

Main culture

Fermentations were performed in a 2 L Sartorius BIOSTAT® stirred tank reactor (Sartorius, Göttingen, Germany) equipped with 4 baffles and two 6-bladed Rushton turbines (58 mm diameter and 11 mm height) mounted at heights of 30 mm and 90 mm from the bottom. A peristaltic pump (101 U/R, Watson-Marlow Pump Group, Falmouth, UK) was used for the feed. Cultivation was started in batch mode after inoculation to a starting OD600 of 0.2. Fermentation experiments were performed with an initial filling volume of 900 mL. If not stated otherwise, after glucose depletion (spike in the dissolved oxygen tension) at \({t}_{1}\), the first feed was started as a pre-programmed carbon limiting exponential feed with a pre-set growth rate µSET of 0.2 1/h to further increase biomass concentration at a growth rate near the maximal growth rate of the cells. A maximal growth rate of 0.25 1/h is given in literature [19]. The feeding rate F1 is calculated applying the formula for a set constant growth rate given by Looser et al. [20] and in Eq. (1) with µSET the pre-set growth rate, YX/S the biomass yield, mS the maintenance coefficient, V0 the filling volume and X0 the biomass concentration at the start of the feed and SF the carbon concentration of the feed.

Based on previous experiments, a biomass yield YX/S of 0.57 g/g and a maintenance coefficient mS of 0.019 g/g/h is used for feed calculation. These values are in good accordance with literature [19, 21, 22]. The applied feed F1 is given in Eq. (2).

After 5 h, at \({t}_{2}\), the cells were induced with 1 vol.% methanol and the feeding rate reduced to F2 to reduce the growth rate µSET to 0.05 1/h. The feed rate is given in Eq. (3). For non-induced fermentations, 1 vol% deionized water was added instead of methanol for induction.

The temperature was controlled at 28 °C, pH (EasyFerm Plus K8 225, Hamilton, Hoechst, Germany) at 6.0 with ammonia solution (30 vol.%), dissolved oxygen tension (VisiFermTM DO 225 pO2 sensor, Hamilton, Hoechst, Germany) at 30% air saturation by cascade control of stirring rate (500–1500 rpm) and aeration rate (1–3 sL/min).

Offline analysis

Samples were taken for offline analysis on regular time intervals. The OD600, cell dry weight (CDW), target protein concentration and EPS concentration were determined. OD600 was measured using a Genesys 20 photometer (Thermo Scientific, Darmstadt, Germany). Samples were diluted with 0.9% (w/v) NaCl, if necessary. Samples were centrifuged at 18,000 rcf for 10 min and the supernatant was filtered with a 0.2 µm cut-off filter (Millipore-Sigma, Burlington, USA). Protein concentration was determined using size exclusion chromatography (GPC EcoSEC, Tosoh Bioscience GmbH, Stuttgart, Germany) equipped with 3 PROTEEMA columns (PSS Polymer, Mainz, Germany) and a UV detector (214 nm). The mobile phase consisted of 0.2 M phosphate buffer at a pH of 5.3 with a flow rate of 1 mL/min. The temperature was set to 40 °C. For calibration 2 g/L BSA (bovine serum albumin) was used.

Determination of exopolysaccharide concentration

To determine polysaccharide concentrations, 200 µL 5 M HCl solution was added to 1 mL sample. The samples were incubated for 1 h at 100 °C to hydrolyze the polysaccharide. The sugar concentration of the hydrolyzed sample was analyzed via HPLC and compared to the sugar concentration of the non-hydrolyzed sample. HPLC analysis was performed with a Thermo Fisher Ultimate 3000 (Thermo Fisher Scientific Inc., Waltham, USA), equipped with an ERC RefractoMax 520 RID (Shodex, Munich, Germany). Separation was performed with an Organic Acid (300 × 7.8 mm) column (Phenomenex, Torrance, USA), heated to 80 °C and a mobile phase of 25 mM H2SO4 running at 0.8 mL/min. The procedure is schematically depicted in Fig. 1. Blank and positive controls were always measured in parallel. The positive control consisted of a 4 g/L starch solution (Merck, Darmstadt, Germany). The results from the starch hydrolysis are shown in Additional file 1: Fig. S2.

EPS concentration is referenced to CDW. CDW is determined from OD using Eq. (4). Data for the correlation is given in Additional file 1: Fig. S3.

Statistical analysis tools (OriginPro 2022, OriginLab Corporation, Northampton, USA) were used to determine the significance of the data. Normal distribution was assumed, and inhomogeneity of variance was determined using Levene’s test. Therefore, a Welch’s ANOVA with a significance level of α = 0.05 was used to determine significant differences between experiments. Games-Howell pairwise comparisons were performed, to determine between which groups the difference was significant.

Determination of cell lysis

Samples were diluted 1:1000 with 0.5 mol.% PBS buffer. The PBS buffer consisted of 137 mM NaCl, 2.7 mM KCl, 10 mM Na2HPO4 and 1.8 mM KH2PO4. Cell lysis was determined by impedance flow cytometry with Ampha Z32 (Amphasys, Root, Switzerland) at a frequency of 24 MHz immediately after sampling. The C chip (50 × 50 µm) was used for measurements. The vertical gate for lysed cells was set at a phase of 208°. For positive control, cell samples lysed for 20 min at 100 °C were used.

Results and discussion

Quantification of exopolysaccharide formation

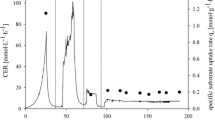

In order to quantify exopolysaccharide (EPS) formation, a reference fed-batch fermentation was conducted in a 2 L stirred tank reactor with the K. phaffii strain I. The results are shown in Fig. 2. Offline samples were collected at various time points to determine EPS concentrations, target protein concentrations and cell dry weight (CDW). Additionally, the relative EPS concentration was calculated as the ratio of the EPS to CDW. The cultivation started as a batch with 40 g/L glucose. Upon glucose depletion after 20 h (Glucose concentration shown in Additional file 1: Fig. S4), the growth phase was extended for further 5 h with an exponentially increasing feed F1. Up to induction, the cells indeed exhibit exponential growth, as evident from the exponentially increasing CDW. Notably, the target protein concentration shows a minimal increase prior to induction. A possible explanation is basal expression, already shown for recombinant protein expression under the PCAT promotor in K. phaffii under carbon limiting conditions prior to induction [23]. The PCAT promotor has even been suggested as a derepressed promotor enabling inducible, methanol-free processes [24, 25]. After 25 h, the production of the target protein was induced by methanol addition and growth was reduced via the feed rate. Following induction, a notable increase in product formation is observed, ultimately reaching a final target protein titer of 6.8 g/L and a CDW concentration of 155 g/L after 48 h. The results are comparable to other K. phaffii expression systems, as reviewed by Cereghino and Cregg [26]. The EPS concentration increases during the fermentation proportional to CDW, as indicated by the constant relative EPS concentration ranging from 0.022 to 0.040 gEPS/gCDW. The total EPS concentration at the end of the fermentation reaches 6.2 g/L, consistent with the findings presented by Denton et al. [5]. There, a ratio of 0.05–0.06 gEPS/gCDW can be estimated from the presented data. Compared to other microbial EPS byproduct producing systems, the concentration is relatively high. For Vibrio natriegens, EPS byproduct only reaches 0.005 gEPS/gCDW [9].

Fed-Batch fermentation of Komagataella phaffii recombinant protein producing strain I performed in a 2 L stirred tank reactor. After 25 h product formation is induced by methanol addition. Cell dry weight (red squares), EPS concentration in supernatant (blue diamonds), target protein in supernatant (green triangles) and relative EPS concentration determined by the ratio of exopolysaccharide (EPS) and cell dry weight (CDW) (orange bars) is depicted over time. Cultivation was performed with 40 g/L initial glucose concentration. Feeding solution consisted of 650 g/L glucose. Production was induced with 1 vol.% MeOH. 70 mL/L MeOH was added to the feeding solution after induction. Feeding rate F1 = 11 mL/h *exp(0.2 h−1 * t) from 20 h to 25 h. Feeding rate F2 = 7.5 mL/h *exp(0.05 h−1 * t) from 25 h to 48 h

A potential explanation for the presence of an EPS in the supernatant is cell lysis, considering that polysaccharides constitute a major component of yeast cell wall material. According to Roelofsen [27], the cell wall accounts for 20% (w/w) of the cell dry weight in Saccharomyces cerevisiae (S. cerevisiae), with 68% (w/w) of it being polysaccharides. Therefore, assuming a similar composition of the cell wall for K. phaffii, the maximal EPS concentration per CDW resulting from lysed cells EPSlysed is theoretically 0.136 gEPS/gCDW,lysed. For two samples from the fermentation depicted in Fig. 2, cell lysis was determined. The results are presented in Fig. 3 (cell lysis distribution is shown in Additional file 1: Fig. S5). In green, the cell lysis percentage is shown after methanol induction (Fig. 3: Induction after 25 h) and at the end of the fermentation (Fig. 3: EoF after 48 h). The highest cell lysis percentage xlysed of 4.8% is measured after 48 h at the end of the fermentation (EoF). In blue, the maximal theoretical relative EPS concentration originated from cell lysis EPSth,max is plotted. This is calculated considering the maximal polysaccharide amount of the cells with Eq. (5):

Cell lysis percentage during fermentation process and derived maximal theoretical relative exopolysaccharide concentration. Cell lysis determined by impedance flow cytometry. Results are compared to measured relative EPS concentration. Samples at induction time (25 h) and the end of fermentation (EoF, 48 h) for the process shown in Fig. 2 are compared. Cell distribution is shown in Additional file 1: Fig. S4. Maximal theoretical relative exopolysaccharide concentration calculated from Eq. (5)

For highest measured cell lysis after 48 h, an EPS concentration of 0.0065 gEPS/gCDW can be calculated (Eq. 6).

In orange, the measured relative EPS concentration from Fig. 2 is depicted. Clearly, the EPS concentration explainable through cell lysis, is significantly lower than the measured EPS in the samples. Cell lysis can only account for 16% of the measured EPS. Therefore, cell lysis cannot be the cause for the high EPS concentration.

Influence of process conditions on exopolysaccharide formation

The only possible alternative explanation is the production and secretion of EPS by K. phaffii. However, the causative relation between target protein production and EPS formation remains unclear. In order to understand this, two additional fermentations were conducted in 2 L stirred tank reactors: first, using strain I without inducing product formation, and second, utilizing the host strain BG11 without the expression cassette. Measurements of protein concentration, EPS concentration and CDW were conducted throughout the fermentation. In Fig. 4, protein concentration and EPS concentration from all three fermentations were plotted relative to the CDW. The protein concentration exhibits a substantial reduction in non-induced processes (Strain I and BG11) compared to the reference fermentation (Strain I induced). This is expected, as protein production is induced by methanol. However, some basal expression of the target protein is observed, as is the case in the reference fermentation (Fig. 2) before methanol induction.

Relative exopolysaccharide and protein concentration determined in 2 L stirred tank fermentations with strain I with 40 g/L glucose batch and glucose feed (not induced), BG11 strain with 40 g/L glucose batch and glucose feed (not induced) and strain I in a methanol (1 vol.%) induced process with 40 g/L glucose batch and mixed glucose/methanol feed. Relative EPS concentration averaged through fermentation time. Relative protein concentration determined at the end of the fermentation

The relative EPS concentration was averaged over the fermentation time and ranges between 0.03 and 0.04 gEPS/gCDW. Notably, statistical comparison of the data reveals no significant differences in relative EPS concentration among the three cultivations. Therefore, neither the integration of protein expression cassettes nor methanol induction appears to induce EPS formation in K. phaffii. Moreover, it is evident that the polysaccharide is not covalently linked to the expressed recombinant protein, as its secretion occurs independently of protein expression. This observation aligns with the findings of O'Leary et al. [15], who similarly concluded that the polysaccharide is not covalently linked to the expressed protein. It cannot be excluded, that the EPS is partially linked to native secreted background proteins.

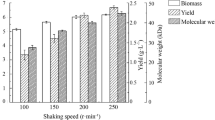

To exclude the carbon source as a cause for EPS formation during fermentation, a comparison was made between fermentations using glycerol, sole methanol, and the reference fermentation employing glucose. Relative EPS and protein concentrations for these fermentations are presented in Fig. 5. The relative EPS concentration was averaged over the fermentation time. The fermentation with glycerol involved a glycerol/methanol feed to induce product formation. The fermentation with a pure methanol feed utilized methanol as the sole carbon source, after the initial batch phase with 40 g/L glucose. In this case, the feeding rate was reduced to F2, MeOH (Eq. 7) due to the lower growth rate on pure methanol for MutS strains [28, 29].

Relative exopolysaccharide and protein concentration determined in 2 L stirred tank fermentations with strain I with 40 g/L glycerol batch and mixed glycerol/methanol feed, 40 g/L glucose batch and mixed glucose/methanol feed and 40 g/L glucose batch and pure methanol feed. Production is induced with 1 vol.% MeOH. Relative EPS concentration averaged over fermentation time. Relative protein concentration determined at the end of the fermentation

The resulting relative EPS concentrations of 0.03–0.05 gEPS/gCDW exhibit no significant differences across the three fermentations, leading to the conclusion that the chosen carbon sources do not trigger or influence EPS formation in K. phaffii. Furthermore, the relative EPS concentration reaches the same level as seen in Fig. 4 (0.03–0.04 gEPS/gCDW), confirming that EPS formation is only related to biomass concentration and independent of the used carbon source and methanol induction. The influence of further fermentation conditions i.e. temperature, pH or dissolved oxygen on EPS formation is still to be assessed. Concerning product formation, the highest relative product concentration is achieved with glucose as the main carbon source and a glucose/methanol feed.

Influence of strain background on exopolysaccharide formation

The presented results show strong evidence, that the EPS formation is independent of the recombinant protein produced in this study, methanol induction or carbon source. It cannot be ruled out, that other recombinant proteins may affect EPS formation, but it seems, that the EPS formation is purely proportional to biomass. The EPS concentration is always around 0.04 gEPS/gCDW (Figs. 3, 4 and 5). Therefore, the strain's genetic background was investigated to generate an explanation for the EPS formation. The EPS formation of strain I and the host strain BG11 was compared to the genetic ancestor and true wildtype strain K. phaffii Y-7556 (K. phaffii strain genealogy can be found in Additional file 1: Fig. S1). The relative EPS and product concentrations for the three strains used in this study are shown in Fig. 6. Analogous to Figs. 4 and 5, the relative EPS concentration was determined over the course of the fermentation and averaged over all samples. The individual samples are included in the supplementary data (Additional file 1: Fig. S6). For the genetic ancestor strain Y-7556 (Fig. 6), a significant reduction of the EPS concentration of 76% from 0.03–0.04 gEPS/gCDW to 0.0083 ± 0.0018 gEPS/gCDW is measured, when compared to the BG11 strain (Fig. 6) and the strain I (Fig. 6). The remaining EPS could be explained by cell lysis. As mentioned before, a relative EPS concentration of 0.0065 gEPS/gCDW could be plausibly explained by the measured cell lysis. The main difference between the ancestral strain Y-7556 and the BG11 strain (derivative of strain NRRL Y-11430) is a single base pair deletion in the HOC1 gene in the latter strain, leading to a frameshift and a premature stop codon [16, 30]. The HOC1 gene (homolog of OCH1) codes for an α-1,6-mannosyltransferase (UniProt IDF2QVW2), required for correct cell wall construction [16, 31]. It is known, that the HOC1 mutation leads to a thinner, more permeable cell wall, enhancing protein secretion and transformation efficiency up to six times, compared to species without this frameshift [1]. This makes the HOC1 mutation essential for strain performance.

Relative exopolysaccharide and protein concentration determined in 2 L stirred tank fermentations with (a) strain I in a methanol induced process with 40 g/L glucose batch and mixed glucose/methanol feed, (b) strain BG11 in a non-induced process with 40 g/L glucose batch and glucose feed and (c) strain Y-7556 in a non-induced process with 40 g/L glucose batch and glucose feed. Relative EPS concentration averaged through fermentation time. Relative protein concentration determined at the end of the fermentation. Significant differences marked (*** for p < 0.001)

Mannose containing polysaccharide is a main part of the cell wall material in yeast cells [27]. Interestingly, Komagataella pastoris, a close relative of K. phaffii, has recently been suggested as a potential source of mannose containing polysaccharides, which can be extracted from its cell wall [32]. Specifically in S. cerevisiae, a substantial portion of N-linked glycans on cell walls and periplasmic proteins undergo modification via mannose polysaccharide addition. The polysaccharide contains a central backbone comprising around 50 α-1,6-linked mannose units. Additionally, the backbone has several branches extending from it, mainly constituted of α-1,2-linked and α-1,3-linked mannoses. The structure of the polysaccharide and the involved enzymes for the construction are shown by Munro [33]. First, a single α-1,6-mannose is added to the cell wall proteins by the mannosyltransferase Och1 in the cis Golgi. This mannose is then extended to a mannose backbone by the sequential action of two mannan polymerase (M-Pol I and M-Pol II) protein complexes, one of them (M-Pol II) containing the mannosyltransferase encoded by HOC1 [33, 34]. It is unclear, what the exact function of the Hoc1 protein is in the complex, but it may have a regulatory function of the mannan backbone length by providing an α-1,2-mannose cap [34]. Disruption of Hoc1 in S. cerevisiae has been observed to adversely affect both cell integrity and protein glycosylation [31].

The presented results show strong evidence that the frameshift in the HOC1 gene in strain BG11 and strain I (Fig. 6) also leads to the strong EPS formation. The disfunction of the mannan polymerase M-Pol II caused by the malfunction of the Hoc1 protein may be the reason for the mannose polysaccharide secretion instead of the correct linkage to the cell wall. The polymerase may have a reduced selectivity and produce free mannan polymers, corresponding to the EPS. This would explain the presence of the EPS as well as the thinner cell wall, characteristic of the K. phaffii production strains. Also, EPS formation could be related to the missing or altered regulatory function of Hoc1, leading to uncontrolled mannose polymerisation.

Strategies for exopolysaccharide removal

Different approaches for EPS avoidance could be pursued. Primarily, the function of the Hoc1 protein must be further investigated to engineer novel strains combining the thin cell wall phenotype for efficient transformation and protein secretion with the suppression of EPS formation. In Vibrio natriegens EPS byproduct formation could be halved through deletion of a single gene cluster [9]. Moreover, the ancestral K. phaffii strain Y-7556, which exhibits lower EPS formation, could be subjected to modifications aimed at enhancing cell wall permeability. Various targets for modifications have been discussed elsewhere [35, 36].

On a process level, employing mannosidases during fermentation processes presents a viable option for EPS degradation. Here, several viable products are available [37]. To circumvent the financial burden associated with enzyme acquisition, the mannosidases could be directly produced by K. phaffii [38,39,40,41,42,43]. However, it is noteworthy that concurrent expression of mannosidases alongside the target protein may entail a reduction in productivity [44]. Moreover, downstream processing necessitates the separation of the enzymes from the target protein, introducing additional complexities. Alternatively, an approach focusing on efficient downstream processing offers a solution for EPS management. Employing diverse chromatography techniques [14, 15] and protein precipitation methods utilizing ammonium sulfate [7], acetone [4] or ethanol [45] can facilitate EPS removal. Furthermore, depending on the recombinant protein size, a filtration step could be considered [46, 47].

Nonetheless, implementation of either strategy entails a substantial increase in process costs. Therefore, the complete avoidance of EPS formation should be addressed at the strain level to maximize energy efficiency and minimize production costs.

Conclusions

Komagataella phaffii secretes a polysaccharide extracellularly. This exopolysaccharide (EPS) formation is revealed to be independent of the integration of protein expression cassettes, methanol induction and carbon source selection, instead directly linked to the strain used. The amount of EPS formed correlates well with the cell mass in the cultivation. The relative EPS concentration is 0.04 gEPS/gCDW. In high cell density processes, the EPS concentration can reach substantial levels, up to 8.7 g/L in the supernatant, thus, careful consideration in biotechnological applications is mandatory. The EPS presents a challenge in downstream processes for protein purification, necessitating additional processing steps to separate it from the target protein. This contributes to increased downstream costs and operational complexity to obtain high purity protein products. Ignoring EPS formation leads to high impurity of the final product. Further, EPS formation must reduce the yield of target protein on substrate.

There is strong evidence, that in hyper protein producing K. phaffii strains the common mutation in the HOC1 gene is responsible for the high EPS formation. The fermentation of a wildtype strain, lacking this characteristic mutation resulted in a remarkable 76% reduction of free polysaccharide in the supernatant. This highlights the pivotal role of the HOC1 gene mutation on the EPS formation. Therefore, significant EPS formation will most probably appear in most common K. phaffii protein secretion systems originating from the K. phaffii NRRL Y-11430 strain, although it often goes unnoticed, due to the lack of signals during PAGE or HPLC–UV.

In conclusion, this work highlights a critical yet overlooked aspect of K. phaffii fermentations, the presence and quantification of an EPS impurity, emphasizing the necessity of monitoring and addressing EPS in biotechnological applications, particularly those requiring cost-effective downstream processes. The identification of the HOC1 gene mutation as a key determinant allows for optimizing K. phaffii strains for protein production processes and ultimately enhancing recombinant protein production efficiency and economic viability in biotechnological applications.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- BG11:

-

BSYBG11

- CDW:

-

Cell dry weight

- EoF:

-

End of fermentation

- EPS:

-

Exopolysaccharide

- Glu:

-

Glucose

- Gly:

-

Glycerol

- OD:

-

Optical density

References

Brady JR, Whittaker CA, Tan MC, Kristensen DL II, Ma D, Dalvie NC, et al. Comparative genome-scale analysis of Pichia pastoris variants informs selection of an optimal base strain. Biotechnol Bioeng. 2020;117(2):543–55. https://doi.org/10.1002/bit.27209.

Gasser B, Mattanovich D. A yeast for all seasons—is Pichia pastoris a suitable chassis organism for future bioproduction? FEMS Microbiol Lett. 2018;365(17):fny181. https://doi.org/10.1093/femsle/fny181.

Vogl T, Glieder A. Regulation of Pichia pastoris promoters and its consequences for protein production. New Biotechnol. 2013;30(4):385–404. https://doi.org/10.1016/j.nbt.2012.11.010.

Trimble RB, Atkinson PH, Tschopp JF, Townsend RR, Maley F. Structure of oligosaccharides on Saccharomyces SUC2 invertase secreted by the methylotrophic yeast Pichia pastoris. J Biol Chem. 1991;266(34):22807–17. https://doi.org/10.1016/S0021-9258(18)54426-4.

Denton H, Smith M, Husi H, Uhrin D, Barlow PN, Batt CA, et al. Isotopically labeled bovine beta-lactoglobulin for NMR studies expressed in Pichia pastoris. Protein Expr Purif. 1998;14(1):97–103. https://doi.org/10.1006/prep.1998.0924.

Vinogradov E, Petersen BO, Duus JO. Isolation and characterization of non-labeled and 13C-labeled mannans from Pichia pastoris yeast. Carbohyd Res. 2000;325(3):216–21. https://doi.org/10.1016/s0008-6215(99)00332-8.

Włodarczyk-Biegun MK, Werten MW, De Wolf FA, Van Den Beucken JJ, Leeuwenburgh SC, Kamperman M, et al. Genetically engineered silk–collagen-like copolymer for biomedical applications: production, characterization and evaluation of cellular response. Acta Biomater. 2014;10(8):3620–9. https://doi.org/10.1016/j.actbio.2014.05.006.

Werten MW, Moers AP, Vong T, Zuilhof H, van Hest JC, de Wolf FA. Biosynthesis of an amphiphilic silk-like polymer. Biomacromol. 2008;9(7):1705–11. https://doi.org/10.1021/bm701111z.

Schulze C, Hädrich M, Borger J, Rühmann B, Döring M, Sieber V, et al. Investigation of exopolysaccharide formation and its impact on anaerobic succinate production with Vibrio natriegens. Microb Biotechnol. 2024;17(1):e14277. https://doi.org/10.1111/1751-7915.14277.

Singh RS, Saini GK, Kennedy JF. Pullulan: Microbial sources, production and applications. Carbohyd Polym. 2008;73(4):515–31. https://doi.org/10.1016/j.carbpol.2008.01.003.

Lee KY, Yoo YJ. Optimization of pH for high molecular weight pullulan. Biotech Lett. 1993;15:1021–4.

Lin Y, Zhang Z, Thibault J. Aureobasidium pullulans batch cultivations based on a factorial design for improving the production and molecular weight of exopolysaccharides. Process Biochem. 2007;42(5):820–7. https://doi.org/10.1016/j.procbio.2007.01.013.

Lee IY, Seo WT, Kim GJ, Kim MK, Ahn SG, Kwon GS, et al. Optimization of fermentation conditions for production of exopolysaccharide by Bacillus polymyxa. Bioprocess Eng. 1997;16(2):71–5. https://doi.org/10.1007/s004490050290.

Palczewska M, Batta G, Groves P. Concanavalin A—agarose removes mannan impurities from an extracellularly expressed Pichia pastoris recombinant protein. Cell Mol Biol Lett. 2003;8(3):783–92.

O’Leary JM, Radcliffe CM, Willis AC, Dwek RA, Rudd PM, Downing AK. Identification and removal of O-linked and non-covalently linked sugars from recombinant protein produced using Pichia pastoris. Protein Expr Purif. 2004;38(2):217–27. https://doi.org/10.1016/j.pep.2004.08.010.

Van Herpe D, Vanluchene R, Vandewalle K, Vanmarcke S, Wyseure E, Van Moer B, et al. OPENPichia: building a free-to-operate Komagataella phaffii protein expression toolkit. https://doi.org/10.1101/2022.12.13.519130.

Hellwig SSC, Gellissen G, Büchs J. Comparative fermentation. In: Production of recombinant proteins: novel microbial and eukaryotic expression systems. 1st ed. Germany: Wiley; 2005. p. 287–317.

Hyka P, Züllig T, Ruth C, Looser V, Meier C, Klein J, et al. Combined use of fluorescent dyes and flow cytometry to quantify the physiological state of Pichia pastoris during the production of heterologous proteins in high-cell-density fed-batch cultures. Appl Environ Microbiol. 2010;76(13):4486–96. https://doi.org/10.1128/AEM.02475-09.

Dnjou MC, Daugulis AJ. A model-based feeding strategy for fed-batch fermentation of recombinant Pichia pastoris. Biotechnol Tech. 1997;11(12):865–8. https://doi.org/10.1023/A:1018449930343.

Looser V, Bruhlmann B, Bumbak F, Stenger C, Costa M, Camattari A, et al. Cultivation strategies to enhance productivity of Pichia pastoris: a review. Biotechnol Adv. 2015;33(6 Pt 2):1177–93. https://doi.org/10.1016/j.biotechadv.2015.05.008.

Zhang W, Inan M, Meagher MM. Rational design and optimization of fed-batch and continuous fermentations. In: Cregg JM, editor. Pichia protocols. Totowa: Humana Press; 2007. p. 43–63.

Dietzsch C, Spadiut O, Herwig C. A dynamic method based on the specific substrate uptake rate to set up a feeding strategy for Pichia pastoris. Microb Cell Fact. 2011;10(1):14. https://doi.org/10.1186/1475-2859-10-14.

Wollborn D, Müller RL, Munkler LP, Germer A, Blank LM, Büchs J. Auto-induction screening protocol for ranking clonal libraries of Pichia pastoris. Biotechnol Bioprocess Eng. 2022;27:572–85. https://doi.org/10.1007/s12257-022-0006-z.

Vogl T, Sturmberger L, Fauland PC, Hyden P, Fischer JE, Schmid C, et al. Methanol independent induction in Pichia pastoris by simple derepressed overexpression of single transcription factors. Biotechnol Bioeng. 2018;115(4):1037–50. https://doi.org/10.1002/bit.26529.

Vogl T, Sturmberger L, Kickenweiz T, Wasmayer R, Schmid C, Hatzl A-M, et al. A toolbox of diverse promoters related to methanol utilization: functionally verified parts for heterologous pathway expression in Pichia pastoris. ACS Synth Biol. 2016;5(2):172–86. https://doi.org/10.1021/acssynbio.5b00199.

Cereghino JL, Cregg JM. Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev. 2000;24(1):45–66. https://doi.org/10.1111/j.1574-6976.2000.tb00532.x.

Roelofsen PA. Yeast mannan, a cell wall constituent of baker’s yeast. Biochem Biophys Acta. 1953;10:477–8. https://doi.org/10.1016/0006-3002(53)90280-7.

Hang H-F, Chen W, Guo M-J, Chu J, Zhuang Y-P, Zhang S. A simple unstructured model-based control for efficient expression of recombinant porcine insulin precursor by Pichia pastoris. Korean J Chem Eng. 2008;25(5):1065–9. https://doi.org/10.1007/s11814-008-0174-3.

Garrigós-Martínez J, Nieto-Taype MA, Gasset-Franch A, Montesinos-Seguí JL, Garcia-Ortega X, Valero F. Specific growth rate governs AOX1 gene expression, affecting the production kinetics of Pichia pastoris (Komagataella phaffii) PAOX1-driven recombinant producer strains with different target gene dosage. Microb Cell Fact. 2019;18(1):187. https://doi.org/10.1186/s12934-019-1240-8.

Offei B, Braun-Galleani S, Venkatesh A, Casey WT, O’Connor KE, Byrne KP, et al. Identification of genetic variants of the industrial yeast Komagataella phaffii (Pichia pastoris) that contribute to increased yields of secreted heterologous proteins. PLoS Biol. 2022;20(12): e3001877. https://doi.org/10.1371/journal.pbio.3001877.

Neiman AM, Mhaiskar V, Manus V, Galibert F, Dean N. Saccharomyces cerevisiae HOC1, a suppressor of pkc1, encodes a putative glycosyltransferase. Genetics. 1997;145(3):637–45. https://doi.org/10.1093/genetics/145.3.637.

Farinha I, Araújo D, Freitas F. Optimization of medium composition for production of chitin-glucan complex and mannose-containing polysaccharides by the yeast Komagataella pastoris. J Biotechnol. 2019;303:30–6. https://doi.org/10.1016/j.jbiotec.2019.07.007.

Munro S. What can yeast tell us about N-linked glycosylation in the Golgi apparatus? FEBS Lett. 2001;498(2):223–7. https://doi.org/10.1016/S0014-5793(01)02488-7.

Jungmann J, Rayner JC, Munro S. The Saccharomyces cerevisiae protein Mnn10p/Bed1p is a subunit of a golgi mannosyltransferase complex. J Biol Chem. 1999;274(10):6579–85. https://doi.org/10.1074/jbc.274.10.6579.

Gao L, Meng J, Dai W, Zhang Z, Dong H, Yuan Q, et al. Deciphering cell wall sensors enabling the construction of robust P. pastoris for single-cell protein production. Biotechnol Biofuels Bioprod. 2023;16(1):178. https://doi.org/10.1186/s13068-023-02428-7.

Marx H, Sauer M, Resina D, Vai M, Porro D, Valero F, et al. Cloning, disruption and protein secretory phenotype of the GAS1 homologue of Pichia pastoris. FEMS Microbiol Lett. 2006;264(1):40–7. https://doi.org/10.1111/j.1574-6968.2006.00427.x.

Moreira L, Filho E. An overview of mannan structure and mannan-degrading enzyme systems. Appl Microbiol Biotechnol. 2008;79:165–78.

Rustler S, Motejadded H, Altenbuchner J, Stolz A. Simultaneous expression of an arylacetonitrilase from Pseudomonas fluorescens and a (S)-oxynitrilase from Manihot esculenta in Pichia pastoris for the synthesis of (S)-mandelic acid. Appl Microbiol Biotechnol. 2008;80(1):87–97. https://doi.org/10.1007/s00253-008-1531-1.

Prielhofer R, Barrero JJ, Steuer S, Gassler T, Zahrl R, Baumann K, et al. GoldenPiCS: a golden gate-derived modular cloning system for applied synthetic biology in the yeast Pichia pastoris. BMC Syst Biol. 2017;11(1):123. https://doi.org/10.1186/s12918-017-0492-3.

Fischer JE, Glieder A. Current advances in engineering tools for Pichia pastoris. Curr Opin Biotechnol. 2019;59:175–81. https://doi.org/10.1016/j.copbio.2019.06.002.

Ávila-Fernández Á, Montiel S, Rodríguez-Alegría ME, Caspeta L, López MA. Simultaneous enzyme production, Levan-type FOS synthesis and sugar by-products elimination using a recombinant Pichia pastoris strain expressing a levansucrase-endolevanase fusion enzyme. Microb Cell Fact. 2023;22(1):18. https://doi.org/10.1186/s12934-022-02009-7.

Wang Y, Zheng J, Lin F-L, Zhou H-B. Improved extracellular endo-1,4-β-mannosidase activity of recombinant Pichia pastoris by optimizing signal peptide. J Central South Univ. 2015;22(6):2088–95. https://doi.org/10.1007/s11771-015-2733-1.

Fliedrová B, Gerstorferová D, Křen V, Weignerová L. Production of Aspergillus niger β-mannosidase in Pichia pastoris. Protein Expr Purif. 2012;85(2):159–64. https://doi.org/10.1016/j.pep.2012.07.012.

Sha C, Yu X-W, Zhang M, Xu Y. Efficient secretion of lipase r27RCL in Pichia pastoris by enhancing the disulfide bond formation pathway in the endoplasmic reticulum. J Ind Microbiol Biotechnol. 2013;40(11):1241–9. https://doi.org/10.1007/s10295-013-1328-9.

Kachhawa DK, Bhattacharjee P, Singhal RS. Studies on downstream processing of pullulan. Carbohyd Polym. 2003;52(1):25–8.

Yamasaki H, Lee M-S, Tanaka T, Nakanishi K. Improvement of performance for cross-flow membrane filtration of pullulan broth. Appl Microbiol Biotechnol. 1993;39:21–5.

Yamasaki H, Lee M-S, Tanaka T, Nakanishi K. Characteristics of cross-flow filtration of pullulan broth. Appl Microbiol Biotechnol. 1993;39:26–30.

Acknowledgements

We thank Marielle Driller from the iAMB at the RWTH Aachen University, who provided access to the Amphasys flow cytometry and assisted in data interpretation.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

T.S. designed the study, performed the experiments, analyzed the data and drafted the manuscript. Z.H. participated in the performance of the experiments. A.G. and L.M.B. contributed in the conception, provided the strains and critically revised the manuscript. J.B., M.M. and J.B.M. initiated and supervised the study, participated in data interpretation and assisted in drafting the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1

: Figure S1. Overview of Pichia pastoris strain genealogy. Figure S2. Determination of starch concentration with the acid hydrolysis method from Figure 1. Figure S3. Data for the correlation between OD and CDW for P. pastoris. Figure S4. Fed-Batch fermentation of Komagataella phaffii recombinant protein producing strain I. Figure S5. Cell lysis distribution during fermentation. Figure S6. Combined exopolysaccharide concentration and optical density for all performed fermentations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Steimann, T., Heite, Z., Germer, A. et al. Understanding exopolysaccharide byproduct formation in Komagataella phaffii fermentation processes for recombinant protein production. Microb Cell Fact 23, 131 (2024). https://doi.org/10.1186/s12934-024-02403-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-024-02403-3