Abstract—

The design of a subnanosecond accelerator composed of three sections and a gas-filled diode and results of its testing are presented. The three sections of the accelerator are a double forming line, a ferrite line, and a line with a variable wave impedance. A beam current amplitude of ≈2.7 kA has been measured behind the anode foil at a pulse width at half-maximum of ≈370 ps. Using this accelerator and a standard spectrometer, Cherenkov radiation and pulsed cathodoluminescence have been investigated in KU-1 fused silica, polymethyl methacrylate, and KBr crystal samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Electron accelerators with a short current-pulse duration and generator voltages of 102–103 kV have been widely used in various fields of science and technology and have been consistently improved, e.g., see [1–11]. Electron beams are usually formed in a vacuum diode by short-duration voltage pulses applied to it, and thin-foil anodes are used to eject the beam current into air and other gases [1–7]. An increased interest has been observed in recent studies of Cherenkov radiation (CR) produced by electron beams with energies of hundreds of kiloelectronvolts at nanosecond and subnanosecond durations of the beam-current pulse [12].

An accelerator has been recently created on the basis of a high-voltage unit of the ARSA accelerator that embodies the Marx circuit, a gas-filled former, and a step line loaded into an sealed-of accelerator tube [9, 10]. The upgraded accelerator [10] has made it possible to obtain a 0.27-ns half-height duration of the beam current pulse at its amplitude of 1.5 kA and at a maximum electron energy of 0.95 MeV. However, this accelerator is very difficult to manufacture and adjust. The mere gas-filled former for obtaining a short voltage pulse has three discharge gaps filled with nitrogen to a pressure of 0.4 MPa.

Another approach to the formation of subnanosecond and picosecond high-voltage pulses consists in the use of ferrite lines, usually at least two, which are placed in a longitudinal magnetic field of solenoids [13, 14]. In such facilities, a voltage pulse from a primary generator with a relatively long duration of both the voltage pulse and its leading edge is fed to lines with ferrite rings with diameters decreasing stepwise. Such an accelerator design has made it possible to obtain a voltage pulse with an amplitude of 1.12 MV at a half-height duration of 0.65 ns and a power rise rate of 110 GW/ns at a matched load [15].

We created the GIN-500 electron accelerator with an sealed-off R-49 spark gap with an idle voltage of up to 500 kV, which consisted of two sections and a gas-filled diode [11]. The pulse duration and the beam current density were controlled and the voltage amplitude across the gap was varied by changing the air pressure in the diode. At a 1.3-ns half-height duration of the beam-current pulse and a diode voltage of ≈350 kV, the amplitude of the beam current behind the foil was 700 A, and the current density was ≈250 A/cm2. It was also demonstrated that an additional line with a simple design and a variable wave impedance helped to increase the voltage across the gap and, hence, the electron energy. A generator with an sealed-off RO-49 spark gap, which operated at a hydrogen pressure of 1.2 MPa, was described in a recent paper [16]. It was used in a compact X-ray unit with a voltage of 100–400 kV.

The use of the electron beam of the GIN-500 accelerator for exciting the glow of KU-1 fused silica, sapphire, and synthetic diamond has made it possible to detect CR using a off-the-shelf HR2000+ES spectrometer [11, 12]. However, the beam-current amplitude decreased significantly with a decrease in the duration of the beam current pulse, which was achieved by increasing the air pressure in the gas-filled diode. In addition, the advantages of the second section were incompletely used, since the rise time of the voltage pulse was relatively long (≈2 ns at a level of 0.1–0.9). For the contributions of CR and pulsed cathodoluminescence (PCL) to the emission spectra of various samples to be separated, it is desirable that the pulse duration of the beam current be reduced and its density be increased. As is known, the CR pulse duplicates the current pulse of the electron beam in its shape [12].

As noted above, it is promising to use coaxial lines with ferrite rings (the ferrite lines) that are placed in a magnetic field of a solenoid with the aim of reducing the duration of the voltage pulse and increasing its amplitude (e.g., see [13–15]).

The purposes of this work were to reduce the duration of the beam-current pulse, increase the voltage across the gas-filled diode, and increase the beam-current amplitude and density by using the third section based on a ferrite line with a solenoid in the generator of the GIN-500 electron accelerator. An additional task was to test the created accelerator with a subnanosecond duration of the beam-current pulse in experimental investigations of CR and PCL at an electron energy of hundreds of kiloelectronvolts.

DESCRIPTION OF THE SETUP AND MEASUREMENT METHODS

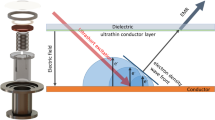

The design of the high-voltage unit of the accelerator with a gas-filled diode is shown in Fig. 1. The third section based on a ferrite line was added to the generator of the GIN-500 accelerator [11]. The gas-filled diode used air, which was pumped out by a forevacuum pump. The first section of the accelerator included a double forming line with an industrial two-electrode high-pressure R-49 spark gap, which was connected to an internal high-voltage electrode. The wave impedances of each of the two forming lines in the first section were ≈20 Ω. The transmission line connected to the second section had a wave impedance of 50 Ω. The second section with the ferrite rings, which was 49 cm long, was placed in a solenoid (not shown in Fig. 1). Rings of two sizes were simultaneously used; they were made of 55VNP-1 ferrite. The location of these rings in the ferrite line is shown in Fig. 1. The outer and inner diameters of the larger rings were 80 and 50 mm, respectively; these diameters of the smaller rings were 45 and 28 mm. The thickness of each ring was 7.5 mm. The third section consisted of an 18-cm-long inhomogeneous coaxial line, whose wave impedance varied smoothly from 50 to 100 Ω. The positions of the second and third sections could be changed. All the three sections of the accelerator were filled with transformer oil.

A diode was placed at the generator output; it was pumped out by a forevacuum pump. The wave impedance of the diode gradually increased on a length of 4.5 cm; it was ≈150 Ω in the region of the tubular cathode. The tubular cathode with an inner diameter of 8 mm was made of 100-µm-thick stainless-steel foil. A cone collector with a 20-mm-diameter receiving part was used to measure the beam current; its time resolution was 100 ps or better [17]. The internal volume of the collector housing was pumped out by a forevacuum pump. The accelerator performance was investigated at interelectrode gaps of 4.0, 11.5, 15.0, and 18.0 mm. The beam current was outputted through a 40-µm-thick AlMg foil, and brass meshes were used to attenuate it. The voltage pulses at the output of the first, second, and third accelerator sections were measured using capacitive dividers U2, U3, and U4. It should be noted that the use of an inhomogeneous line has made it possible to increase the gap between its electrodes near the gas-filled diode and, therefore, reduce the electric field strength in the feedthrough insulator.

The double forming line was charged from the secondary winding of a pulse transformer developed for the RADAN-220 generator [3]. The pulse transformer was located between two coaxial aluminum cylinders with built-in magnetic cores. When the spark gap was triggered in the primary circuit of the transformer (not shown in Fig. 1), the double forming line was charged. When the voltage approached the maximum, the high-pressure R-49 spark gap was triggered. A nanosecond voltage pulse with a ≈190 kV amplitude in the transmission line was formed in the first section and was fed to the second section, where its amplitude increased by a factor of ≈1.3. The voltage pulse was then fed over the line with a variable wave impedance to the tubular cathode of the gas-filled diode. This made it possible to obtain voltage pulses with a duration of 0.5 ns or less and with a maximum amplitude in the idle mode as high as ∼1000 kV. The air pressure in the diode could vary from 0.05 to 760 Torr. The duration of the beam current pulse was adjusted by changing the air pressure [18].

The signals from the capacitive dividers and collector were fed to the Keysight DSO X6004A digital oscilloscope (6 GHz, 20 samples/ns) via 1.2-m-long high-frequency 5D-FB PEEG (Radiolab) cables. The signals were attenuated by 142-NM attenuators (Barth Electronics, 30 GHz). The beam-current energy per pulse was measured by a TPI-2M.1 calorimeter, which had been used earlier to measure the energy of both electron beams and laser pulses [19].

Samples exposed to the electron beam were shaped as plane-parallel plates. The samples were placed behind the anode foil perpendicularly to the electron beam. The emission and absorption spectra of the samples were measured using an HR2000+ES spectrometer (OceanOptics Inc.) with a known spectral sensitivity in the wavelength range of 190–1100 nm (the resolution was 0.9 nm). In comparison with the work [12], we carried out an additional calibration of the spectrometer together with the light guide and determined more precisely the spectral sensitivity in the region of 450–500 nm. A weak band was observed in this region when measuring the CR spectra in fused silica, diamond, and sapphire samples that were excited by an electron beam [20]. In [20], it was suggested that the weak band with a maximum emission at a wavelength of 490 nm could be attributed to the action of X rays on the spectrometer and the light guide. However, the test showed that this band was associated with the inaccuracy of the spectrometer sensitivity curve. Additional calibration of the spectrometer and the light guide was therefore carried out.

EXPERIMENTAL RESULTS

The conditions for obtaining maximum voltages across a gas-filled diode were initially determined. These conditions depended on the location of the ferrite and inhomogeneous lines, the current through the ferrite-line solenoid, the air pressure in the gas-filled diode, and the interelectrode gap width. When placed after the double forming line (section 1), the ferrite line provided the greatest increase in the diode voltage. This was attained owing to the increase in the operational efficiency of the inhomogeneous line with a decrease in the duration of the voltage pulse. In this regard, the comprehensive investigations of the accelerator were carried out with the arrangement of sections shown in Fig. 1. Figure 2 presents the dependence of the voltage across the gap on the magnetization current in the solenoid at an air pressure of 1 atm in the diode.

The highest voltages across the gap at all air pressures in the diode were attained in the investigations at a magnetization current of 6–7 A. Therefore, specifically these values of the magnetization current were used in the experiments with the accelerator on the CR production. The largest current amplitude of the beam of runaway electrons at atmospheric air pressure was obtained at a magnetization current of 5 A and a gas-diode voltage lower than the maximum. The low beam current of runaway electrons under these conditions was due to the relatively slow increase in the voltage during the initial part of the beam-current pulse (≈1.5 ns to a level of 0.2) and to the nonoptimal cathode design for obtaining the maximum current amplitude of runaway electrons at atmospheric air pressure. However, the beam current increased by several orders of magnitude at low air pressures in a gas-filled diode with the same cathode.

Figure 3 demonstrates the effect of the length of the interelectrode gap on the amplitudes of the voltage pulse and beam current as well as on the duration of the beam-current pulse. As expected under these conditions, the beam current decreased and the voltage across the gap increased with an increase in the interelectrode gap [18]. In comparison with the GIN-500 accelerator, the use of the third section significantly increased the amplitude of the beam current and reduced its duration to ≈370 ps.

The pressure effect on the accelerator parameters in the optimal mode, which roughly corresponds to the matching of the wave impedances of the generator and the diode, is illustrated in Fig. 4. The use of three sections in the accelerator instead of two substantially expanded the range of pressures in the gas diode at which the amplitudes of the voltage pulse and beam current, as well as the pulse duration of the beam current, changed only slightly. Based on the results of our investigations, two modes with a pressure of ≈0.057 Torr inside the gas diode were selected for the impact on the samples. In the first mode with an interelectrode gap of 15 mm, the diode voltage was ≈450 kV, and the beam current behind the foil and a 2-cm-diameter diaphragm was ∼1.7 kA. In the second mode with an interelectrode gap of 4 mm, the diode voltage was ≈370 kV, but the beam current behind the foil and the diaphragm increased to 2.7 kA.

Figure 5 shows the waveforms of the beam current and the voltage pulse as well as the footprint of the beam. The minimum half-height duration of the current pulse under these conditions was ≈370 ps. On the footprint, there is a stronger darkening in the central part of the beam and dark spots associated with breakdowns in the viniproz due to the accumulation of the electron charge. The beam current density at the center of the footprint on a diameter of 3 mm exceeded 1000 A/cm2.

The total energy of the beam electrons was measured using a TPI-2M.1 calorimeter in order to perform the additional verification of the obtained beam-current parameters. The measured electron-beam energy was ≈0.45 J at an interelectrode gap of 15 mm.

SIMULATION OF THE VOLTAGE PULSE

The results of the experiments aimed at increasing the voltage-pulse amplitude using the coaxial line with a variable wave impedance (section 3) were compared to the data of a numerical experiment that were obtained using an axisymmetric version of the KARAT code [21]. The simulation was carried out for voltage pulses of the incident wave with a flat top and different leading-edge duration during its linear increase. The simulation was performed for the leading-edge durations of 0.1, 0.3, 0.6, and 2.0 ns. The respective increase in the amplitude of the voltage pulse at the gas-filled diode in the idle mode was 3.9, 3.7, 3.0, and 2.6 times. The use of a coaxial line provided an optimal gain at a pulse rise time of 0.3 ns. An increase of 3.7 times was also obtained in the simulation with an experimental voltage pulse past the ferrite line. The performed calculation confirmed the effective operation of the coaxial line with variable wave impedance upon a preliminary reduction of the voltage-pulse rise time using the ferrite line.

As the pulse rise time was reduced further (to 0.1 ns), the voltage-pulse amplitude at the cathode of the gas-filled diode increased only slightly (by ≈5%). Since the use of a single ferrite line in the accelerator of this design is no longer sufficient for further reduction of the pulse rise time, the installation of the second ferrite line is required. This significantly complicates the accelerator design and increases its size.

DETECTION OF CHERENKOV RADIATION AND PULSED CATHODOLUMINESCENCE

Figure 6 shows the emission spectra of KU-1 fused silica and KBr samples excited by an electron beam of the created accelerator. The CR dominated in the emission spectrum of the KU-1 sample, and its intensity increased with decreasing wavelength. The radiation of the KBr sample contained both CR and a PCL band in the wavelength region of 370–500 nm. The CR band coincided with the result of the calculation using the well-known formula [12, 22].

Emission spectra of (a) KU-1 fused silica sample at the interelectrode distance in the diode of (1) 4 and (2) 15 mm and (b) the KBr sample at the interelectrode distance of (3) 15 mm as well as (4) the theoretical dependence of the spectral energy density of CR in the KBr sample normalized to the experimental dependence at a wavelength of 350 nm.

Both PCL and CR were observed during irradiation of the polymethyl methacrylate sample, but the energy in the recorded PCL band was higher than the CR energy; see the detailed description in [23].

CONCLUSIONS

The GIN-1000 electron accelerator consisting of three sections of various designs and a gas-filled diode has been created and tested. This accelerator is capable of generating voltage pulses at the gas-filled diode with an amplitude of up to 500 kV and is simple in design. The beam energy at a subnanosecond pulse duration (370 ps at half-height) was as high as ≈0.45 J, and the beam current density at the center of the footprint exceeded 1000 A/cm2. Using this accelerator, Cherenkov radiation was detected in KU-1 fused silica, polymethyl methacrylate, and KBr crystal samples.

REFERENCES

Belkin, N.V., Komyak, N.I., Peliks, E.A., and Tsukerman, V.A., Prib. Tekh. Eksp., 1972, no. 2, p. 194.

Martin, T.H., IEEE Trans. Nucl. Sci., 1973, vol. 20, no. 3, p. 289. https://doi.org/10.1109/TNS.1973.4327103

Zagulov, F.Ya., Kotov, A.S., Shpak, V.G., Yurike, Ya.Ya., and Yalandin, M.I., Prib. Tekh. Eksp., 1989, no. 2, p. 146.

Zheltov, K.A., Pikosekundnye sil’notochnye elektronnye uskoriteli (Picosecond High-Current Electron Accelerators), Moscow: Energoatomizdat, 1991.

Mehnert, R., Nucl. Instrum. Methods Phys. Res., Sect. B, 1996, vol. 113, nos. 1−4, p. 81. https://doi.org/10.1016/0168-583X(95)01344-X

Mesyats, G.A., Impul’snaya energetika i elektronika (Pulse Power and Electronic Engineering), Moscow: Nauka, 2004.

Yalandin, M.I. and Shpak, V.G., Instrum. Exp. Tech., 2001, vol. 44, no. 3, p. 285. https://doi.org/10.1023/A:1017535304915

Tarasenko, V.F., Kostyrya, I.D., Baksht, E.K., and Rybka, D.V., IEEE Trans. Dielectr. Electr. Insul., 2011, vol. 18, no. 4, p. 1250. https://doi.org/10.1109/TDEI.2011.5976123

Yuriev, A.L., El’yash, S.L., Loiko, T.V., Pukhov, S.P., Nikolaev, D.P., and Seleznev, A.A., Instrum. Exp. Tech., 2017, vol. 60, no. 6, p. 853. https://doi.org/10.1134/S0020441217050128

Elyash, S.L., Loiko, T.V., Yuriev, A.L., and Seleznev, A.A., Instrum. Exp. Tech., 2019, vol. 62, no. 4, p. 528. https://doi.org/10.1134/S002044121903014X

Tarasenko, V.F., Alekseev, S.B., Baksht, E.Kh., Burachenko, A.G., and Lomaev, M.I., Instrum. Exp. Tech., 2020, vol. 63, no. 3, p. 359. https://doi.org/10.1134/S0020441220040090

Tarasenko, V.F., Baksht, E.Kh., Erofeev, M.V., and Burachenko, A.G., Opt. Spectrosc., 2021, vol. 129, no. 7, p. 707. https://doi.org/10.1134/S0030400X21050167

Romanchenko, I.V., Rostov, V.V., Gunin, A.V., and Konev, V.Yu., Rev. Sci. Instrum., 2017, vol. 88, no. 2, p. 024703. https://doi.org/10.1063/1.4975182

Gusev, A.I., Pedos, M.S., Rukin, S.N., and Timoshenkov, S.P., Rev. Sci. Instrum., 2017, vol. 88, no 7, p. 074703. https://doi.org/10.1063/1.4993732

Rukin, S.N., Rev. Sci. Instrum., 2020, vol. 91, no. 1, p. 011501. https://doi.org/10.1063/1.5128297

Kozlov, B.A. and Makhanko, D.S., J. Phys.: Conf. Ser., 2021, vol. 2064, no. 1, p. 012126. https://doi.org/10.1088/1742-6596/2064/1/012126

Balzovsky, E.V., Rybka, D.V., and Tarasenko, V.F., Instrum. Exp. Tech., 2015, vol. 58, no. 5, p. 640. https://doi.org/10.1134/S0020441215050024

Alekseev, S.B., Rybka, D.V., and Tarasenko, V.F., Instrum. Exp. Tech., 2013, vol. 56, no. 5, p. 571. https://doi.org/10.1134/S0020441213040131

Bugaev, S.P., Abdullin, E.N., Zorin, V.B., Koval’chuk, B.M., Loginov, S.V., Mesyats, G.A., Skakun, V.S., Tarasenko, V.F., Tolkachev, V.S., and Shchanin, P.M., Kvantovaya Elektron., 2004, vol. 34, no. 9, p. 801.

Tarasenko, V.F., Oleshko, V.I., Erofeev, M.V., Lipatov, E.I., Beloplotov, D.V., Lomaev, M.I., Burachenko, A.G., and Baksht, E.Kh., J. Appl. Phys., 2019, vol. 125, no. 24, p. 244501. https://doi.org/10.1063/1.5094956

Tarakanov, V.P., User’s Manual for Code KARAT, Berkley, VA: Springfield, 1992.

Landau, L.D., Bell, J.S., Kearsley, M.J., Pitaevskii, L.P., Lifshitz, E.M., and Sykes, J.B., Electrodynamics of Continuous Media, Oxford: Pergamon Press, 1984.

Tarasenko, V.F., Baksht, E.Kh., and Erofeev, M.V., Tech. Phys. Lett., 2021, vol. 47, no. 4, p. 313. https://doi.org/10.1134/S1063785021030305

ACKNOWLEDGMENTS

We thank I.V. Romanchenko for the useful discussions and his help in creating the accelerator section with the ferrite line and V.I. Pegel’ for conducting a numerical experiment using the KARAT code.

Funding

The accelerator development was supported by the Russian Science Foundation, project no. 18-19-00184. This paper was prepared for publication in the context of the State Assignment for the Institute of High Current Electronics (Siberian Branch, Russian Academy of Sciences), project no. FWRM-2021-0014.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by N. Goryacheva

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tarasenko, V.F., Alekseev, S.B. & Baksht, E.K. A Three-Section Subnanosecond Electron Accelerator. Instrum Exp Tech 65, 433–439 (2022). https://doi.org/10.1134/S0020441222040078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441222040078