Abstract

Lead aprons are used in medical applications as a traditional shielding material, but this use was faced by many health problems including toxicity, heavyweight, and cracks, this motivated researchers to develop new shielding materials, to overcome these health problems depending on some promising materials, i.e., nanomaterials and polymers, which provide many properties that overcome the undesirable properties in lead aprons, and provide the proper or better shielding properties against ionizing radiation. Recently, nanomaterials in different forms have attracted considerable attention for radiation shielding applications, due to their prominent chemical and physical properties. This work will review the basics of radiation, radiation protection, lead aprons, nanomaterials, synthesis and characterization methods, polymers, and the scientific efforts to introduce nanocomposites as materials used in attenuation radiation beams and hence, to be used as proper radiation shielding materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Radiation is energy emitted from the nucleus in the form of waves or particles. When people hear the word radiation, they often think of atomic bomb, Hiroshima and Nagasaki, nuclear reactors, Chernobyl accident, and radioactivity, but radiation has many other forms. Visible light, infrared radiation or heat energy, ultraviolet radiation that produces a suntan, radio and television signals are all forms of radiation. All life components are living in an environment filled with radiation [1,2,3,4,5].

Radiation sources are natural and artificial. Natural sources include natural radioactive series found in earth’s crust, as well as cosmic rays. Industrial sources include artificial radionuclide used in different medical and industrial applications. One of the most important radiation sources is the X-ray which is generated from stopping fast moving electrons in X-ray machines and characteristic X-ray emitted from atomic transitions in heavy elements [1,2,3,4,5].

Past couple of years have seen remarkable developments in the medical field. Emergence of Medical physics is one such advancement wherein radiations are employed in not just diagnosing of illnesses but also in treating them. This review aims to provide a framework for the know-how of radiations and the effect it has on the human body when exposed to it. Procedures currently implemented in minimizing the effects of radiations on human life, the gaps in them, and possible alternative solutions to the challenges presently faced are reviewed.

1.1 Ionizing radiation

Depending on its ability to interact and ionize exposed matter, radiation is categorized into two main categories: ionizing and non-ionizing radiation.

-

Non-ionizing radiation has no capability to ionize atoms or molecules of matter because it has lower energy than the energy required to ionize these atoms or molecules. Thus, the term non-ionizing radiation refers to the type of electromagnetic radiation that do not carry enough energy to induce ionization, e.g., UV, visible light, IR photons, microwaves, and radio waves [1,2,3,4,5].

-

Ionizing radiation involves energy which can ionize atoms or molecules of matter, i.e., the minimum energy required to separate one electron from its orbital and let the atom ionize. Ionizing radiation has many practical uses in medicine, industry, agriculture, and research, but, at the same time, it presents a health threat, when used improperly. Medical physics is functioned on the study and use of ionizing radiation in medicine; and health physics deals with protecting the people and environment from the hazards related to the use of ionizing radiation [1,2,3,4,5].

1.1.1 Classification of ionizing radiation

According to the mode of ionization, ionizing radiation is grouped into two distinct categories: directly ionizing radiation and indirectly ionizing radiation.

-

Directly ionizing radiation: In direct ionization, radiation energy is transferred to the atoms of the absorber through a direct process involving Coulomb interactions between the radiation and the orbital electrons of the atoms in the absorber. This radiation category includes charged particles, e.g., electrons, protons, α particles, heavy ions [1,2,3,4,5].

-

Indirectly ionizing radiation: In indirect ionization, radiation energy is transferred to the atoms of the absorber through a two-step process:

-

In the first step, radiation interacts with the orbital electrons of the atoms of the absorber, freeing these electrons, as well as producing ion pairs, in the absorber [1,2,3,4,5].

-

In the second step, the free electrons and ion pairs transfer the energy they gained in the first step to the absorber through direct Coulomb interactions with orbital electrons of the atoms in the absorber. This radiation category includes photons of X rays and γ rays [1,2,3,4,5].

In practical application of the ionizing radiation in medicine, both directly and indirectly ionizing radiations are widely applied. Radiotherapy, therapeutic radiology, or radiation oncology is one of these applications of ionizing radiation in medicine that is used in cancer treatment. Medical imaging is one of these applications of ionizing radiation in medicine, that is used in diagnostic purposes, and divided into two categories wherein: diagnostic radiology uses X rays for imaging and nuclear medicine; or/and molecular imaging uses short half-live radionuclides for imaging [1,2,3,4,5].

1.1.2 Effects of ionizing-radiation on human body

When a material is exposed to ionizing radiation, it interacts with the atoms and molecules of the material, causing ionization and excitation of these atoms and molecules. As a result of this interaction, radiation loses its energy totally or partially, which is absorbed by the material, and many physical and chemical reactions are induced, causing many changes in the properties and structure of the exposed material. If the material is a human living tissue, the energy absorbed will result in biological effects in most parts of the exposed tissue down to cells and DNA, even if there may or may not be observable biological effects in the human body [1,2,3,4,5]. The biological effects that may occur can be grouped into two categories:

-

1.

Somatic effects that occur in the individuals exposed.

-

2.

Hereditary effects that occur in the offspring of the individuals exposed.

These effects can also be categorized depending on the magnitude of the absorbed dose received by the exposed person as follows:

-

1.

Deterministic effects occur in any person receiving a dose that is greater than a specific threshold dose, which may depend on the person’s physical condition, with the increase of magnitude of the dose above the threshold as the severity of the effect also increases. Radiation-induced skin burn is an example of the deterministic effect [1,2,3,4,5].

-

2.

Stochastic effects are those effects which do not depend on a specific threshold dose but appear when the probability of occurrence is a function of dose received. Hereditary effects and cancer are examples of stochastic effects [1,2,3,4,5].

1.2 Radiation protection

-

Principles

Radiation safety programs are established to limit the health risk associated with using ionizing radiation. These programs provide guidance to reduce radiation dose to the user, staff members and the public by utilizing the radiation protection principles, which are the main pillars of any radiation safety program at any facility using radiation sources [6]. These principles are:

-

1.

Justification: which means to justify any activity that involves radiation exposure to have the benefits exceed the costs as well as risks. The concept of justification, established by the International Commission on Radiological Protection, ICRP, is one of the key principles of radiation protection. The principle means that any practice involving exposures to ionizing radiation should not be adopted, approved, or licensed unless it produces satisfactory benefit to the exposed individuals or the society to balance its disadvantages or harm effects. In addition, any involvement with the purpose to delivering radiation doses should introduce more good than harm [1,2,3,4,5].

-

2.

Optimization: to maintain the radiation exposure from the activity as low as reasonably achievable, i.e., the ALARA principle. This principle states that individual and collective radiation exposures must be kept as low as reasonably achievable, ALARA, taking into account the social and economic factors. This principle is considered as being of fundamental importance in the control of occupational exposure at workplace [1,2,3,4,5].

-

3.

Dose limitation: highest doses that could be received by radiation workers is applicable. These highest doses are called dose limits, which are determined to control the radiation doses received by individuals or groups in any radiological practice, so as to not exceed defined radiation dose limits [1,2,3,4,5].

1.3 Management of radiation doses

To reduce the doses of radiation received during any radiological application, safety practices are implemented, which include the following three most vital factors [1,2,3,4,5]:

-

Time

Using radiation sources should be carefully planned to minimize the exposure time. The radiation dose rate from a radiation source is the measure of radiation dose per unit time, e.g., 10 msv/h at some specific distance away from the radiation source. Time is used so significantly in all uses of radiation sources, by choosing to implement the job with radiation source in the shortest applicable time. For a source with specific dose rate, the absorbed dose is a function of time of the exposure. Practicing time-reduction procedure by simulated sources is very useful for proper radiation dose management.

-

Distance

Increasing the distance from a source to an individual can be very effective in reducing the dose rate because the dose rate varies inversely with the square of the distance from a point source of radiation to the point where the exposed person stands. Thus, the dose rate may be reduced to 1% by increasing the distance 10 times. The inverse square law is applicable theoretically for a point source, and practically used for most radiation protection purposes despite the configuration of the source, as the source is smaller than the distance to the source.

-

Shielding

Many materials may serve in shielding against ionizing radiation, i.e., by attenuating the gamma beams, or interacting with particle radiation. The shield effectiveness depends on the atomic number (Z) of the shielding material, as well as sufficient thickness used to reduce the radiation doses behind the shield to acceptable doses. Each type of radiation, with specific energy requires certain materials for effective shielding. For example, ordinary sheet of paper or a few centimeters of air can stop alpha particles, and 1.5 mm of aluminum can stop beta particles with an energy of 1 MeV, but X and gamma photons require materials of high density and high-Z, such as lead as shielding material.

1.4 The interactions of ionizing radiation with matter

Depending on the energy of their photons X-ray and gamma photons interact with matter in three main processes: photoelectric effect, Compton scattering, and pair production. The degree of attenuation and the predominant mechanisms involved in the interactions are influenced by the energy of the X-ray and gamma photons and the composition of material exposed to them. Figure 1 represents the predominance of the three mechanisms of interaction as a function of photon energy.

Predominance of the three mechanisms of interaction as a function of photon energy [4]

-

Photoelectric effect

Photoelectric effect is an interaction between a photon and a tightly bound orbital electron of an absorber atom, where the photon is completely absorbed, and the electron, called a photoelectron, is ejected with kinetic energy EK. Figure 2 is a schematic representation of the photoelectric interaction between a photon of energy hν and a K-shell atomic electron. There are two major contrasts between Compton effect and the photoelectric effect. First is that the interaction occurs between a photon and a free or loosely bound electron, and the second is the incident photon loses part of its energy in the Compton effect.

-

Compton effect

Compton scattering or Compton effect implies an interaction of the X-ray or Gamma Ray photon of energy hν with a loosely bound orbital electron of an atom of the absorber. The electron which the incident photon interacts with, in Compton effect, is assumed theoretically free and stationary, and referred to as a Compton or recoil electron, which is ejected from the atom with kinetic energy gained from the incident photon. A new photon, referred to as the scattered photon with energy hν′ that has less energy than the energy of the incident photon, is produced. A typical Compton effect interaction is shown schematically in Fig. 3.

-

Pair production

For an incident photon that has energy exceeding 2mec2 = 1.02 MeV, with mec2 known as the rest mass of electron or positron, there will be a possibility for production of an electron–positron pair shown in Fig. 4 with complete absorption of the incident photon by the atom of the absorber material, conditioned with conservation of each of the three physical quantities: energy, charge, and momentum. This process occurs when the photon comes too near to the atomic nucleus, and interacts with its electromagnetic field, and it is dominant for photons with energies above 10 MeV.

1.5 Attenuation of radiation

As X-ray or gamma ray beam is passed through a material, the beam that emerges from the material varies in intensity. The variation in intensity is caused by attenuation of the original beam in the material, which depends on the penetrating characteristics of the beam and the physical characteristics of the material [1,2,3,4,5].

Attenuation is the reduction of intensity of an X-ray or gamma ray beam as it traverses matter. The reduction may be caused by:

-

1.

Absorption, where energy is transferred from the photons to atoms of the target or irradiated material.

-

2.

Deflection of photons from the beam, i.e., scattering.

As seen in Fig. 5, when a beam of X-rays passes through a foil and into a X-ray detector, some of the photons will be absorbed completely after interaction with the atoms of the foil and some photons may be scattered. Quantitative measurement of the interaction of the X-rays with the material contained in the foil is obtained by measuring the difference in the intensity of the incident beam as it strikes the detector without the foil, and when it strikes the detector after it has been attenuated by the foil.

Diagrams show an unattenuated X-ray beam (top) and an X-ray beam passing through a foil (bottom) into detectors [5]

The intensity of an X-ray beam passing through a layer of material depends on the thickness and atomic number of the material. These factors are represented in linear attenuation coefficients of the material. When the penetration of X rays needs to be reduced, a shielding material with a large linear attenuation coefficient is required [1,2,3,4,5].

Attenuation measurements of X or gamma ray beam depends on the number of photons incident on, and transmitted though, the absorbing material, as well as the absorber thickness. Attenuation is expressed mathematically according to the following equation

where,\({I}_{\circ }\) is the incident beam intensity on the surface of the absorbing material,χ is the thickness of absorbing material,I is the beam intensity transmitted through absorbing material of thickness of χ,µ is the linear attenuation coefficient, defined as:

Different radiation attenuating materials have been used to produce shields to protect humans from the effects of ionizing radiation. Important concerns that challenge researchers in finding appropriate shielding materials, include its weight, size, and cost of manufacturing the final shielding products. High density materials such as concrete and lead are used as shields for gamma radiation. Low density materials are less effective, but they can also be used as shields against radiation with increased thickness to attenuate radiation intensity.

2 Lead aprons

Due to high density, low cost, easy processability, and mainly because of its high atomic number (Z), lead (Pb) has been widely used as a shielding material against ionizing radiation, especially because it provides effective shielding against gamma radiation, which is known to be a highly penetrating radiation [7]. Ionizing radiation shields containing Lead or lead-equivalent, usually referred to as “lead aprons” or simply as “lead” in hospital slang, are protective material shields used to protect staff and patients from ionizing radiation employed during medical procedures [8].

Lead was the primary material used in radiation shielding for many years owing to its various physical and mechanical properties as an excellent radiation shielding material. However, concerns over the safety and health hazards resulting from using lead have been growing in recent times, such as the insidious hazards to workers and patients when exposed to lead that negatively affect the biological systems of the human body [9].

2.1 Lead toxicity and toxicokinetic

Lead is a ubiquitous bluish-gray metal found in the earth’s crust and has been mobilized in the environment by human activities and is present primarily in its divalent form (Pb2+). Lead has many preferable properties. Its malleability, corrosion-resistance, and ductility, allows for easy casting and addition of lead in many products like batteries, ammunition, paints, dyes, ceramic glazes, gasoline, and medical tools [10]. The toxicokinetics of Pb in humans has been extensively studied to simulate the complex absorption, distribution and elimination of Pb from different parts of human body, e.g., blood, soft tissues, and bones [11, 12].

-

Absorption: Inorganic Pb can be absorbed by means of inhalation, oral, and dermal exposure, resulting in Pb being absorbed in different organs:

-

Respiratory tract: due to its submicron particle size, Pb is completely absorbed through the respiratory tract. If available in larger particle sizes, after deposition in the respiratory tract it may move by mucociliary clearance toward the oropharynx and swallowed.

-

Gastrointestinal tract (GIT): Many factors control the fraction of ingested Pb absorbed from the GIT, including age, diet, nutrition, and physiological characteristics of Pb in the medium ingested. GI absorption of inorganic Pb occurs mainly in the duodenum by saturable mechanisms. For oral dose of water-soluble Pb, children can absorb 40–50% whereas adults can only absorb 3–10%.

-

Dermal: dermal exposure to Pb is a much less efficient route than the other two routes of uptake. Many studies have shown that organic Pb is absorbed through the skin in animals [11].

-

Distribution:

-

Inside the body, Pb distribution is route-independent and due to its + 2 equivalence, approximately 94% of the total body burden of Pb is found in the bones in adults, while it is approximately 73% in children.

-

In blood, Pb is primarily in red blood cells. Increasing bone resorption and consequently an increase of Pb in blood is controlled by conditions like pregnancy, lactation, menopause, and osteoporosis.

-

Transfer of Pb from the mother to the fetus, and from the mother to infants via maternal milk is possible [11].

-

Metabolism:

-

Inorganic Pb is metabolized through formation of complexes with a variety of protein and nonprotein ligands.

-

Organic compounds of Pb are actively metabolized in the liver by oxidative dealkylation by P-450 enzymes [11].

-

Excretion:

-

Regardless of the route of exposure, Pb is excreted primarily in urine and feces. Also, there are minor routes of excretion that include sweat, saliva, hair, nails, breast milk, and seminal fluid.

-

Elimination of Pb is a multiphasic process with varying retention times, reflecting pools of Pb in the body, and depends on the elimination half-time in blood, which ranges from 1 week to 2 years and varies with age and exposure history. The apparent half-time elimination of Pb from bone is about 1–2 decades [11].

2.2 Issues with lead as radiation shielding material

-

Lead dust

Lead aprons, as well as any other radiation shielding material containing lead, represent a health risk due to formation of lead dust, which may become airborne and be accidentally inhaled or ingested by humans [13]. Large exposures of lead dust on the skin and the clothes of workers is taken home, which is known as take-home exposure; and may be inhaled or ingested by young children with normal mouthing behaviors [8]. Hulbert et al. (2009), have shown that lead dust is a major source of lead doses in children [13]. Lead dust uptake is through the lungs and gastrointestinal tract. As children have a higher respiratory rate, they tend to respire and inhale more airborne lead dust. Lead then enters the child's bloodstream, and it becomes a powerful and versatile toxic material. Lead can affect many systems and organs of the body, e.g., central, and peripheral nervous systems, immune systems, bone marrow, kidneys, myocardium, and endocrine. Furthermore, contamination with lead dust also reaches floors and any nearby work surfaces [14, 15]. Thus monitoring Airborne lead dust is required, and exposure to it should be minimized as much as possible by reducing the uses of lead to the maximum extent we can [9, 16].

-

Lead shields—cause of back pain

The major cause of low-back pain in radiologists, who use lead aprons and other types of lead shields, is continuous overuse of back muscles. The heavy weight of lead bricks used in the clinical setting has caused numerous types of cumulative trauma disorder in the clinical setting in nuclear medicine. Examples of which include Myalgia wherein there is pain in one or more muscles, tendonitis is inflammation of a tendon, and epicondylitis which involves inflammation of and pain in certain bony prominences in the area of the elbow, as a result of excessive strain on the forearm [9]. In two surveys on radiologists using lead aprons, many types of pain were reported [17, 18]. Back pain was reported by 52% of those who used their lead apron more than or equal to 10 h per week. Orthopedic problems included spine problems in 42% of responders. Hip, knee, or ankle problems were noted in 28% of radiologists. Spine problems were connected to the procedural caseload and the number of years in practice [17, 18].

-

Cracks in lead aprons

Lead sheets and covering layers may be fragmented and gaps will grow with daily use, bending, or improper handling, thus lead aprons will lose their effectiveness in protection against scattered ionizing radiation. Shields should undergo regular radiographic assessment for gaps and cracks, and those found unacceptable should be removed from use [19].

Many studies were conducted to assess the integrity of lead aprons used in department of radiology. Researchers in one of these studies examined 63 lead aprons and 62.5% of the lead aprons had one or more defects. The size of the defects was found to range from 1 to 8 cm [20]. Another study that was conducted to assess the integrity of ten lead aprons used in department of radiology, with thicknesses 0.25, 0.35 and 0.50 mm of lead, were investigated by checking for defects so as to evaluate the mean personnel dose rate and to compare the percentage mean absorbance of the apron. Results showed that 70% of the lead aprons showed defects, and only 30% of them were not defective. Some of the defective areas in the lead aprons, that had cracks and tears were found in certain areas close to the critical organs of human body [21].

3 Lead replacing shielding materials

3.1 Nanomaterials

Nanoscience is the study of phenomena and manipulation of materials at nanoscales, i.e. atomic, molecular and macromolecular. Size range of Nanomaterials is between 1 and 100 nm. At the nanoscale the properties of the material are significantly different from those at the macroscopic scale. Figure 6 shows a scale to the relative dimension of various objects including nanoscale [22]. Nanotechnology is the science and engineering of materials, devices and systems at nanometer scale, which involves design, synthesis, characterization and use in different applications [22]. Nanotechnology is based on detection of new properties and behavior of particles less than the size of 100 nm that impart to nanostructures built. Because these particles are smaller than the characteristic lengths connected with particular phenomena, they regularly display new chemistry and physics depending on the size that leads to new behavior [23]. The term “nano” is referred to the Greek word “nanos” which means dwarf, but here nanometer means 10–9 m, which is one billionth of a meter. The basic idea of nanoscience and nanotechnology relies on the fact that properties of substances significantly change when they are in the nanometer range size compared to their bulk form. Also, Nanomaterials with different sizes ranges, i.e. low, intermediate, and large nano range have different behavior [24]. The dependence of the behavior on the particle sizes can allow one to engineer their properties like in the field of electronics. When particles become smaller than a critical size, they have been observed to change their structure, conductivity, reactivity, melting temperature, and mechanical properties.

Nano scale compared with various object [26]

Nanotechnology has been developed at several stages, using different materials, devices and systems and it still is undergoing continuous development, for usage in both scientific research and in commercial applications [25]. Compared to other concepts and applications of science, the concepts of nanoscience and nanotechnology are relatively new, but the existence of structures and functional devices of nanometer dimensions is very old and have existed on Earth as life itself.

3.1.1 Difference between nanomaterials and bulk materials

Primary factors that causes unique structures and properties exhibited by nanomaterials as compared to the corresponding bulk materials are:

-

1.

Surface to volume ratio: compared to micro particles or bulkmaterials, nanoparticles have a very large surface area to volume ratio because fraction of surface atoms in nanoparticles increases [27,28,29,30,31].

-

2.

Quantum confinement effects: quantum effects in materials with delocalized electrons shows discontinuous behavior [28].

Gold is a clear example wherein the bulk and nanoparticles of the material have different properties, such as magnetic, electrical, optical, mechanical, and chemical, as their particle size changes. Bulk gold does not react with most chemicals as a noble metal, but nanogold have catalytic role in many reactions. Thus, by confining gold particles in the nanoscale, a fundamental chemical property has changed dramatically. Change in physical properties of carbon is another significant example when carbon atoms form nanotubes. Carbon shows notable change in its conductivity, from carbon as a poor conductor of electricity as a bulk material; to many times stronger than steel wire with an ability to carry more electricity than a copper wire as carbon nanotubes, e.g., fullerenes. Nanotubes are also used to hold hydrogen for fuel cells, and carbon Bucky balls are used to contain other useful molecules, such as drugs.

Nanoparticles are synthesized from various types of large organic molecules, and from polymers. One type of nanoparticles that have attracted extensive interest in biology and medicine, due to their exceptional optical and electronic properties, are the semiconductor quantum dots, QDs. QDs exhibit size-dependent behavior, i.e., particle size dictates the electronic band gap of the material, which in turn controls the shift in the photo- and electroluminescence of the material. Consequently, the optical properties of the quantum dots are adjusted through variation of the size of the nanoparticle [32].

3.2 Polymers

A polymer is a compound composed of macromolecules formed from repeating subunits called monomers of high molecular weight [33]. The word “polymer” comes from Greek origin which means “many members.” Another type of polymer is the oligomer, which is a molecule formed by joining monomers with smaller number of repeating units than that of a polymer [34]. Synthesis of polymers from monomers is done through a chemical reaction termed as polymerization. Several chemical mechanisms are used in polymerization reactions. The monomer generally has a precursor compound bonded with a double chemical bond that forms a single bond during polymerization to generate a polymer [33]. Polymers are naturally available since the early times on Earth, e.g., cellulose, lignin, starch, and natural rubber. Macromolecules which are essential to all known forms of life, such as deoxyribonucleic acid (DNA), ribonucleic acid (RNA), and proteins; linked polymers to life itself. Natural polymers were known and used by people of primary civilizations to produce simple artifacts. In the nineteenth century, chemical modification interferences with natural polymers resulted in producing many new materials, such as gun cotton, vulcanized rubber, and celluloid. In the first decades of the twentieth century, relatively modern materials known as synthetic polymers entered the technological and practical scene. Thus they appear very different from many other materials known to humanity for centuries [35]. Synthetic polymers are mainly found by chemical reactions, which ensures endless opportunities of finding different polymers, but are restricted by the laws of chemistry and thermodynamics as well as by the imagination of polymer chemist. These endless opportunities have increased the number and diversity of synthetic polymers that are applicable in almost all possible fields of human life. The flexibility of polymer molecular structure, that is derived from the rich synthetic options, transfers into materials with various tunable properties and applications. Polymer is characterized by enough multi-repetitions of one or more species linked to each other, hence it provides a set of physical and chemical properties that do not vary significantly with the addition of any repeating unit. Its physical, chemical, electrical and optical properties may be changed by changing the physical parameters, e.g., solvent environment, temperature, pressure, or magnetic field. The characteristics of these properties plays a very important role in their application in our daily life as well as in the chemical industry, pharmaceuticals, and many other fields of science [34]. For example, some polymers may be good conductors of electricity and hence they are called conductive polymers or organic metals, such as polyacetylene [33].

Polymers are found as components of many of the objects that surround us, in a broad diversity of applications in an endless list of daily life applications. These applications provide an idea of the importance of synthetic polymers to modern life, in their usefulness and the economic value they represent. They include; clothing, shoes, personal care products, furniture, electrical and electronic appliances, packaging, utensils, automobile parts, coatings, paints, adhesives, tires, and so on [35].

3.2.1 Classification of polymers

-

Classification based on structure

The oldest and most important classification criteria of polymers, which divide polymers into two major types is: addition polymers and condensation polymers. The main product of the reaction in both types is called a “repeating unit”. In the addition polymer, the repeating unit has the same composition as that of the monomer, with the only difference observed in the chemical bonds with respect to that of the monomer. In condensation polymer, some atoms of the monomer are lost as a condensation compound when the monomers react to form the repeating unit of the polymer [35].

-

Classification based on kinetic mechanism of the polymerization reaction

According to this classification, polymers are divided into two types as follows:

-

A.

Step-growth polymerization involves the reaction of a difunctional monomer AB, which contains both functional groups, A and B in the molecule. Another scheme involves the reaction between two difunctional monomers of the type AA and BB. Examples of step-growth polymers include polyurethane, polyamide, and polyester [35].

-

B.

Chain polymerization involves propagation of the active centers. It requires an initiator or generator for active centers, usually free radicals, anions, or cations. A monomer only reacts with an active center and does not react with other monomers and will be present till the end of the reaction. The conversion is measured in terms of the monomer already incorporated in a polymer chain [35].

-

C.

Classification according to chain topology

Different chain topology of polymers will exhibit profound differences in crystallinity, physical properties, rheological behavior, and so on. For example, LDPE and HDPE clearly presents differences in density, crystallinity, mechanical and rheological properties derived from the presence of long and short branches along the polymer chain even though these two polymers have the same chemical composition [35].

3.2.2 Mechanical properties

Long chains with high molecular weights offer unique properties to polymers. Relatively low molecular weight compounds, C6–C10, are relatively volatile liquids, e.g., gasolines. With an increase in the number of ethylene units, the compounds start to behave as waxes with low melting points. However, as the number of ethylene units exceed some 200–300 units, the molecular weight of the chains will be in the order of 5000–8000 and the material behaves as a solid, exhibiting higher mechanical properties. In general, above some minimum molecular weight, polymers are considered “high polymers” exhibiting increased mechanical properties, corresponding to their higher molecular weight. Stress—force per unit area, and strain—percentage increase or elongation of the original length, are the characteristic quantities of a polymer. Stress is needed to stretch the material to a certain elongation. Thus, the stress—strain plot represents highly significant mechanical behavior of a polymer [35].

3.2.3 Polymer states

Polymers can be observed at numerous scales. The repeating unit in a polymeric chain is of few angstroms, while the single polymer molecule or chain has a length of a few to some tens of nanometers. Polymer morphology shows order or disorder regions exhibited by the chains. Ordered regions are called crystalline and disordered regions are called amorphous in nature. Polymer chains, in the crystalline regions, are packed in regular arrangements termed crystallites, e.g., polyethylene and polyamides. Crystalline morphology in addition to chain flexibility is a result of structural regularity in the polymer chain, held by strong forces between molecules. Usually, both ordered and disordered regions are found in a crystalline polymer; thus, the crystalline polymers are semi-crystalline. Completely amorphous polymers with their disordered morphology, which refers to bulky substituents and rigid chains, e.g., atactic polystyrene and polymethyl methacrylate (PMMA) are a common occurrence.

3.3 Examples of nanomaterials and polymers used for photon beam attenuation

3.3.1 Titanium oxide (TiO2)

Due to high photochemical stability and low cost, Titanium Oxide is a promising material as a semiconductor [36]. TiO2 has been widely employed as pigment, and paint additive, due to its photostability, light dispersion, and simultaneously strong UV light filtering sunscreen. Hence it has been manufactured in millions of tons. TiO2 is also one of most investigated material in the last decades, for possible applications in the fields of energy and environment [37]. TiO2 nanoparticles follow the anatase structure due to its low surface energy, thus making it possible for the nanoparticles consisting of a few TiO2 units to have structures completely different than the structures of bulk material [38]. Fine sizes of TiO2 nanoparticles have promising applications in pigments, catalytic supports, and adsorbents. TiO2 nanoparticles are synthesized using many methods, the most used and highly studied among these are the sol–gel method and the hydrothermal method [36].

-

Sol–Gel method: This method is based on inorganic polymerization reactions. It comprises of four phases: hydrolysis, polycondensation, drying and thermal decomposition as illustrated in Fig. 7.

Hydrolysis of the precursors of the metal or non-metal alkoxides takes place with water or alcohols.

where \(R = alkyl group\)

In addition to water and alcohol, an acid or a base also helps in the hydrolysis of the precursor. After condensation of the solution to a gel, the solvent is removed.

Calcination at higher temperature is required to decompose the organic precursor. Sol particle size depends on many factors, such as, solution composition, pH, and temperature. The size of the particles is tuned by controlling these factors.

This method has major advantages like proper control on particle shape, size and size distribution, homogeneity of the product, low temperature of sintering, ease of making multi-component materials, and ambient temperature of sol preparation and gel processing [39].

-

Hydrothermal method: in this method, precursors used are reagents analytical grade titanium tetrachloride and sodium hydroxide. The aqueous solution of titanium is obtained by mixing one molar stoichiometric ratio of Titanium (IV) isopropoxide, TTIP, in 50 ml of distilled water. The solution is then added to 2–3 mol of NaOH with stirring at several minutes, to result in a white colloidal sol. Using distilled water, the final volume is adjusted to 90 ml, which needs to be transferred to a 100 ml Teflon lined auto clave sealed vessel. After heating the vessel to 240 °C for 12 h, the resultant precipitate is to be dried at 450 °C for 2 h to get TiO2 nanoparticles [36].

3.3.2 Bismuth

Bismuth, Bi, is a diamagnetic semimetal, that has many properties such as high magnetoresistance, thermal conductivity, and high anisotropic electronic behavior. Bismuth has many advantages comparing with other elements of high atomic number. These advantages are: (1) Bi is the top of all non-radioactive elements, with Z = 83, i.e., it has an excellent nuclear-sensitization possibility; (2) Bi confers an important X-rays opacity, high absorption and a very high X-ray attenuation coefficient, µ = 5.74 cm2/g, at 100 keV [40, 41], (3) Bi demonstrates low toxicity, good biocompatibility, and increased cost effectiveness in comparison to other high-Z elements [42] and (4) Bi is easily eliminated from the body because of its favorable reactivity and dissolution properties [43].

As a stable high Z number, Bismuth nanoparticles, BiNPs, have gained an increased interest in X- ray imaging in the past few years. Bi2O3 and Bi2S3 were studied as X-rays contrast agents, XCA. To obtain optimal XCA, a high quantity of metal atoms must be contained inside the NPs. Due to favorable behavior appreance in using Bi2O3 or Bi2S3, the use of metallic Bi as NPs are preferable [41].

-

Synthesis of metallic bismuth NPs

Recently, different synthesis methods of metallic bismuth NPs have been published [44]. Most techniques approaches synthesis of metallic bismuth using chemical synthesis, where bismuth is obtained by a reduction from bismuth (III) or more rarely bismuth (V) using a proper capping agent, such as D-glucose, polymer dextran, starch or sodium oleate to control the growth of metallic bismuth NPs and to stabilize them after the reduction reaction [45]. As an example, BiNPs are formed after the reduction reaction between Bi(NO3)3 and borane morpholine, C4H12BNO, in presence of D-glucose as a capping agent, under proper stirring and temperature. Synthesis of BiNPs is implemented under different temperature conditions, from room temperature up to 350 °C [44]. Few synthesis methods depend on green chemistry to produced metallic bismuth NPs coated by hydrophilic moieties using biocompatible solvent 1,2-propanediol (PPD) and D-glucose as capping agent [46].

3.3.3 Polymethyl methacrylate (PMMA)

PMMA is a linear amorphous thermoplastic polymer with properties that make it satisfactory for most applications. It has many advantages including its availability and easy preparation, which are common to several other polymers, but the added advantage of PMMA is that it is produced from a nonvolatile liquid with low-cost monomers [47]. PMMA has high surface gloss, high transparency, and it transmits light almost without loss in the range of 360–1000 nm. It has an extraordinarily resistance to oxidative photo-degradation, is remarkably stable to sunlight, and displays unusually good weathering behavior. PMMA has an appropriate tensile, compressive, and flexural strengths. It is classified as a hard, rigid but brittle material. It is also resistant to many inorganic reagents, non-polar solvents, aliphatic hydrocarbons, dilute aqueous acids and alkaline [47]. Special coatings or addition of suitable fillers can be used to enhance scratch resistance of PMMA. It has large hydrolytic resistance to both acidic and alkaline media [47]. PMMA is polymerized using different polymerization techniques e.g., free radical and anionic initiations by bulk, solution, suspension, and emulsion techniques. PMMA may also be used to enhance the behavior at the interface between carbon nanotubes and the copolymer [48].

3.3.4 Preparation for polymer composites

Considerable efforts are drawn in a new challenging area to make good samples of polymer matrix nanocomposites. A wide variety of processing techniques has been tried by researchers to make polymer matrix nanocomposites and nanoblends [49,50,51]. Creating a single universal technique for synthesis of polymer nanocomposites is not an easy one for researchers, owing to the huge physical and chemical differences between each structure and numerous types of equipment available or needed. Each polymer structure requires a distinct set of synthesis conditions to be formed, based on the synthesis effectiveness, and desired properties of the final product, as different processing techniques will not generally produce equivalent products.

In situ polymerization is a familiar technique that is used in synthesis of polymer nanocomposites matrix. In this method, particles are dispersed in monomer and then the mixture is polymerized, as shown in Fig. 8 [52, 53]. This technique produces a well-dispersed polymer nanocomposite matrix when the inclusions are about 50 nm in size. However, for small size particles of about 12 nm, aggregation occurs due to the increase in surface energy for smaller particles, which favors further particle segregation in the absence of a stabilizer [53].

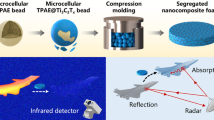

3.3.5 Literature review on using nanocomposites in photon beam attenuation

Nanostructured materials have shown attractive properties for radiological protection applications, particularly as lighter and lead-free aprons for individual protection. Many publications considered using polymeric nanocomposites i.e., nanoparticles and nanostructures embedded in a polymeric matrix, for shielding purposes against X-rays and γ-rays. However, there still is a need to evaluate the applicability of polymeric nanocomposites for radiological shielding purposes, to investigate if these nanocomposites with improved specifications such as light weight, and low price can attenuate the X-ray and γ -ray beams like the conventional materials currently used.

-

Attenuation of gamma-ray beams using nanocomposites

Lead is thought to be the best shielding material against gamma ray, but many issues such as lead toxicity began the need to look for other materials. Introducing new environmentally friendly materials has become an interesting research area. Table 1 summarizes the observations on attenuation of gamma-ray beams by various researchers using different nanomaterials/polymers combinations with varying sizes of nanoparticles and thickness of the synthesized shields.

Harish et al. studied particulate polymer composites of Isophthalate based unsaturated polyester resin filled with filler weight % of 0, 5, 10, 20, 30, 40, and 50. They found a linear attenuation coefficient at the highest value of \(\mu = 0.206 {cm}^{-1}\) for 50 wt% of lead monoxide [54]. Kim et al. used Monta Carlo simulation to evaluate γ-ray shielding properties of 100 nm and 1 μm W-polypropylene composites containing 7.5 and 15.0 wt%. They found that, as the energy of γ-ray increased, the effect of particle size decreased, and the degree of attenuation improvement for low energy is much higher than that for high energy. The effect of particle size disappears with photon energy above 1 MeV [55]. Yu et al. prepared two WO3/E44 samples with different WO3 particle sizes, 1 μm and 50 nm. These samples showed best attenuation property around the energy of 59.6 keV and μ of the sample had a remarkable jump around the energy of 69.5 keV, which they attributed to the K absorption edge of W, 69.508 keV. The nano-WO3/E44 sample had 1–18% increase of shielding capability [56].

Higgins et al. used monoenergetic sources in a wide range of photon energies, to study radiation shielding response of 30 wt% of either WO3- and HfO2-epoxy nanocomposites. The result showed that, at low energies, 122 keV, μ of both nanocomposites was up to 5 times higher than that of pure epoxy resin, whereas at high energies, 1112 keV and 1407 keV, the enhancement was ~ 39.5–51.1% and ~ 15% respectively [57].

Chang et al. investigated effects of shielding of epoxy-based composites containing tungsten with four different weight percentages (30%, 50%, 70% and 80%) using two Co-60 different activities. Their result indicated that shielding property of nanocomposites increases with the increase of tungsten filler loading. The μ of WEP increases from 0.08 to 0.27 cm−1, when tungsten content increases from 0 to 80% [58].

Abdalsalam et al. used WinXcom program to study attenuation properties of polyethylene and bismuth oxide nanocomposite with weight ratios of 0.5, 1, 1.5, and 2 wt%. They found that the maximum values of the attenuation for all samples occur at 30.8 keV and the attenuation decreases with increasing the energy from 30.8 to 383.9 keV [59].

A recent study by Agool et al. evidenced a new type of polymer blend-nanoparticle nanocomposites of (PVA–PEG–PVP) with ZrO2 nanoparticles with different concentrations 2, 4, 6 and 8 wt%. They found that μ increased with increasing ZrO2 nanoparticles concentration [60].

-

Attenuation of X-ray beams using nanocomposites

Many researchers investigated using nanocomposites as shielding materials against X-ray beams, and their role in attenuation of these beams. Table 2 presents a summary of previous studies regarding attenuation of diagnostic X-ray radiations using different nanomaterials/polymers combinations with varying sizes of nanoparticles and thickness of the synthesized shields.

With the intention of achieving a lead-equivalent lightweight, protective textile material, against X-ray with improved wearability, Maghrabi et al. studied the suitability of microparticle size bismuth oxide, Bi2O3 coating for textiles as an alternative to lead. Efficiency of Two textile materials coated with Bi2O3 have been evaluated as X-ray shielding. The experimental parameters of the X-ray exposures were 80 kVp, 12 mAs. The researchers found that Bi2O3 can be coated on fabrics, and it is an efficient material to produce effective, flexible, and wearable lead-free aprons. Polyester fabrics coated with more than 50% Bi2O3 showed improved ability as shielding material against X-rays [61].

Nambiar et al. synthesized polymer nanocomposite of bismuth oxide, BO, and polydimethylsiloxane, PDMS, using different weight percentages BO Nano powder 28.57, 37.73, and 44.44 wt% of BO in PDMS, and each sample was 1.3 mm thick. The best attenuation capability was corresponding to the BO concentration 44.44 wt%, and the thickness 3.73 mm, used with X-rays generated at a tube potential of 60 kVp [62].

Another study used W and Bi2O3 nanoparticles as functional powder fillers with Vinyl silicone rubber, VMQ, was used as the matrix. Chai et al. reported that the VMQ/ W/Bi2O3 and VMQ/W nanocomposites displayed better attenuation for X-ray than that of VMQ/Bi2O3 and PbO/VMQ composites, especially at an X-ray energy of 87 keV [63].

Electro-spun PVA/Bi2O3 and PVA/WO3 nanofiber materials with different concentrations of PVA (10 w/w% or 15 w/w%) and variable wt% (0–40 wt%) of filler loading (Bi2O3 and WO3) were synthesized by Jamil et al. to investigate their performance as shielding materials against X-ray. The studied parameters were density, thickness, and mass attenuation coefficients, μ, of the samples. XRF unit at various X-ray energies 8.64–57.53 keV, was used to study X-ray attenuation ability of the samples. They reported the highest attenuation efficiency of all X-ray energies was corresponding to the sample of 15 w/w% PVA with 35 wt% Bi2O3. As compared to Bi2O3, WO3 showed less attenuation efficiency [64].

Aghaz et al. studied WO3 nano and micro particles merged into EPVC polymer matrix with 20%, 50% and 60% of mass proportions as radiation shielding against X-rays of energy range, 40–100 keV. The results showed a maximum attenuation of 41.27% at 70 kVp was corresponding to the sample 60% WO3 [65]. WO3-epoxy composites were investigated as shielding materials for X-rays by Azman et al. Improved performance was achieved of the nano-sized WO3-epoxy at 25–35 kV, but no effect was found at 40–120 kV [66].

X-ray attenuating ability of nano and micro CuO dispersed in beeswax or epoxy resin, was studied by two research teams, Botelho et al. [67] and Künzel et al. [68] respectively. They found that the nanocomposites with CuO concentration of 5 wt%, 10 wt% and 30 wt% were more effective in attenuating 26 and 30 kVp X-ray beams, and no significant attenuation is achieved at 60 and 102 kVp.

The investigation was conducted by Fontainha et al. to produce nanocomposites of zirconia nanoparticles and Poly vinylidene fluoride try fluor ethylene, PVDF-TrFE, copolymers, with 1, 2, 3, 5 and 10 wt% of ZrO2 nanoparticles. They found that nanocomposites with 10% of ZrO2 demonstrated radiation shielding characterization and can attenuate 60% of the X-ray beams [69].

Li et al. prepared epoxy resin matrix composites filled with dispersed gadolinium oxide, Gd2O3 at micro and nano scales with different weight contents. They found that nano-Gd2O3 composites have better ability as shielding materials against X-ray and γ-ray beams than micro-Gd2O3 composites. They also found that with Gd2O3 content of around 5 wt%, shielding properties improved by ~ 28% at 59.5 keV [70].

4 Conclusion

This review aimed to investigate the attempts that have been made to use nanocomposite materials in photon beam attenuation and hence as radiation shielding material. Nanomaterials in different forms, with polymers of different types i.e., nanocomposites, represents an attractive alternative of lead in shielding against ionizing radiation with considerable attention for applications, due to their prominent chemical and physical properties. Various factors should be considered when using the nanocomposites as a new radiation shielding material such as the mechanical properties of the nanocomposites, durability, stability, and resistivity against environmental conditions, the cytotoxicity of nanomaterials.

Data availability

All data generated or analysed during this study are included in this published article.

References

Podgoršak EB (2010) Radiation physics for medical physicist, Springer-Verlag Berlin Heidelberg, 2010, ISBN978-3-642-00875-7

Schauer DA, Linton OW (2009) National council on radiation protection and measurements report shows substantial medical exposure increase. Radiological Society of North America Inc

Croüail P, Drouet F (2006) Survey on the implementation of the ‘justification’,‘optimisation’and ‘limitation of doses’ radiological protection principles in national regulations in Europe

Bichsel H, Schindler H, Fabjan W, Schopper H (2020) The interaction of radiation with matter. Book Section, Particle physics reference library. Springer International Publishing. ISBN 978-3-030-35317-9

McKetty MH (1998) The AAPM/RSNA physics tutorial for residents. X-ray attenuation. Radiographics 18(1):151–163

Alrammah I, Ajlouni AW (2021) A framework and a survey analysis on nuclear security culture at various radiological facilities. Ann Nucl Energy. https://doi.org/10.1016/j.anucene.2021.108294

Mirji R, Lobo B (2017) 24. Radiation shielding materials: a brief review on methods, scope and significance

Burns KM et al (2017) Lead aprons are a lead exposure hazard. J Am Coll Radiol 14(5):641–647

AbuAlRoos NJ, Amin NAB, Zainon R (2019) Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: a review. Radiat Phys Chem 165:108439

Keil DE, Berger-Ritchie J, McMillin GA (2011) Testing for toxic elements: a focus on arsenic, cadmium, lead, and mercury. Lab Med 42(12):735–742

Abadin H et al (2019) Toxicological profile for lead: draft for public commen. Agency for Toxic Substances and Disease Registry, United States. https://doi.org/10.15620/cdc:95222

McCaffrey JP, Shen H, Downton B, Mainegra-Hing E (2007) Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med Phys 34(2):530–537

Hulbert SM, Carlson KA (2009) Is lead dust within nuclear medicine departments a hazard to pediatric patients? J Nucl Med Technol 37(3):170–172

Movahedi MM et al (2014) Novel paint design based on nanopowder to protection against X and gamma rays. Indian J Nucl Med IJNM Off J Soc Nucl Med India 29(1):18

Lewis RD et al (2012) Do new wipe materials outperform traditional lead dust cleaning methods? J Occup Environ Hyg 9(8):524–533

Hipkins KL, Materna BL, Payne SF, Kirsch LC (2004) Family lead poisoning associated with occupational exposure. Clin Pediatr (Phila) 43(9):845–849

Moore B, VanSonnenberg E, Casola G, Novelline RA (1992) The relationship between back pain and lead apron use in radiologists. AJR Am J Roentgenol 158(1):191–193

Goldstein JA, Balter S, Cowley M, Hodgson J, Klein LW (2004) Occupational hazards of interventional cardiologists: prevalence of orthopedic health problems in contemporary practice. Catheter Cardiovasc Interv 63(4):407–411

Lambert K, McKeon T (2001) Inspection of lead aprons: criteria for rejection. Health Phys 80:S67–S69

Daniel OA, Xaviera IC (2018) Integrity test of lead apron and its effect on personnel and carers. Bangabandhu Sheikh Mujib Med Univ J 11(1):34–37

Bjørkås LW, Blø S, Rekdal MK, Rusandu A (2020) Quality of radiation protection aprons and quality control routines at different diagnostic imaging modalities. Radiogr Open 6(1):64–74

Filipponi L, Sutherland D, Center I N (2010) Introduction to nanoscience and nanotechnologies. NANOYOU Teach. Train. Kit Nanosci. Nanotechnologies, pp. 1–29.

Arrasheed E, Alibwaini Y, Meaz TM, Shalaby RM, Salem BI, Ajlouni A-W, El-Bahnasawy HH, Hemeda OM, Henaish AMA (2021) 16. Structural, cation distribution, thermal properties, and electrical resistivity of nano NiAlxFe2-xO4 synthesized by flash auto combustion method. J Mol Struct. https://doi.org/10.1016/j.molstruc.2021.131273

Mishra R, Militky J (2018) Nanotechnology in textiles: theory and application. Woodhead Publishing

Salata OV (2004) Applications of nanoparticles in biology and medicine. J Nanobiotechnology 2(1):3

Devasahayam S (2017) Overview of an internationally integrated nanotechnology governance. Int J Metrol Qual Eng 8:8–22

Roduner E (2006) Size matters: why nanomaterials are different. Chem Soc Rev 35(7):583–592

Ajlouni A-W, AlAsiri AM, Adil SF, Shaik MR, Khan M, Assal ME, Kuniyil M, Al-Warthan A (2020) Nanocomposites of gold nanoparticles with pregabalin: the future anti-seizure drug. Arab J Chem 13(8):6267–6273

Ajlouni AW, Hamdan EH, Alshalawi RA, Shaik MR, Khan M, Kuniyil M, Alwarthan A, Ansari MA, Khan M, Alkhathlan HZ, Shaik JP (2023) Green synthesis of silver nanoparticles using aerial part extract of the Anthemis pseudocotula Boiss. Plant and their biological activity. Molecules. https://doi.org/10.3390/molecules28010246

Henaish AMA, Salem BI, Meaz TM, Alibwaini YA, Ajlouni A-W, Hemeda OM, Arrasheed EA (2021) Synthesize, characterization, dielectric, linear and nonlinear optical properties of Ni-Al Ferrite/PANI nanocomposite film. Optical Mater. https://doi.org/10.1016/j.optmat.2021.111397

Arrasheed EA, Hemeda OM, Alibwaini YA, Meaz TM, Shalaby RM, Ajlouni A-W, Henaish AMA, Salem BI (2022) Dielectric, electrical, magnetic, and mechanical properties of Ni-Al ferrite/PANI composite films. Phase Transitions. https://doi.org/10.1080/01411594.2022.2117043.pp.803-822

Vashist SK, Tewari R, Bajpai RP, Bharadwaj LM, Raiteri R (2006) Review of quantum dot technologies for cancer detection and treatment. AZojono J Nanotechnol Online 2:1–14

Poole CP Jr, Owens FJ (2003) Introduction to nanotechnology. Wiley

Mehrotra SC, Kumbharkhane A, Chaudhari A (2017) Binary polar liquids: structural and dynamic characterization using spectroscopic methods. Elsevier

Vivaldo-Lima E, Saldívar-Guerra E (2013) Handbook of polymer synthesis, characterization, and processing. Wiley Online Library

Vijayalakshmi R, Rajendran V (2012) Synthesis and characterization of nano-TiO2 via different methods. Arch Appl Sci Res 4(2):1183–1190

Sang L, Zhao Y, Burda C (2014) TiO2 nanoparticles as functional building blocks. Chem Rev 114(19):9283–9318

Hamad S, Catlow CRA, Woodley SM, Lago S, Mejias JA (2005) Structure and stability of small TiO2 nanoparticles. J Phys Chem B 109(33):15741–15748

Gupta S, Tripathi M (2012) A review on the synthesis of TiO2 nanoparticles by solution route. Open Chem 10(2):279–294

De La Vega JC, Häfeli UO (2015) Utilization of nanoparticles as X-ray contrast agents for diagnostic imaging applications. Contrast Media Mol Imaging 10(2):81–95

Lee N, Choi SH, Hyeon T (2013) Nano-sized CT contrast agents. Adv Mater 25(19):2641–2660

Bi H et al (2018) Bismuth nanoparticles with ‘light’ property served as a multifunctional probe for X-ray computed tomography and fluorescence imaging. Chem Mater 30(10):3301–3307

Deng J, Xu S, Hu W, Xun X, Zheng L, Su M (2018) Tumor targeted, stealthy and degradable bismuth nanoparticles for enhanced X-ray radiation therapy of breast cancer. Biomaterials 154:24–33

Grumezescu AM (2018) Inorganic frameworks as smart nanomedicines. William Andrew

Ma D et al (2012) Synthesis of bismuth nanoparticles and self-assembled nanobelts by a simple aqueous route in basic solution. Colloids Surfaces A Physicochem Eng Asp 395:276–283

Bennett GN, San K-Y (2001) Microbial formation, biotechnological production and applications of 1, 2-propanediol. Appl Microbiol Biotechnol 55(1):1–9

Gross S, Camozzo D, Di Noto V, Armelao L, Tondello E (2007) PMMA: a key macromolecular component for dielectric low-κ hybrid inorganic–organic polymer films. Eur Polym J 43(3):673–696

Ali U, Karim KJBA, Buang NA (2015) A review of the properties and applications of poly (methyl methacrylate)(PMMA). Polym Rev 55(4):678–705

Vollenberg PHT, Heikens D (1989) Particle size dependence of the Young’s modulus of filled polymers: 1. Preliminary experiments. Polymer (Guildf) 30(9):1656–1662

Li J-X, Wu J, Chan C-M (2000) Thermoplastic nanocomposites. Polymer (Guildf) 41(18):6935–6937

Alibwaini YA et al (2021) Synthesis, characterizations, optical and photoluminescence properties of polymer blend PVA/PEG films doped eosin Y (EY) dye. Opt Mater (Amst) 111:1–15

Yang F, Ou Y, Yu Z (1998) Polyamide 6/silica nanocomposites prepared by in situ polymerization. J Appl Polym Sci 69(2):355–361

Reynaud E, Jouen T, Gauthier C, Vigier G, Varlet J (2001) Nanofillers in polymeric matrix: a study on silica reinforced PA6. Polymer (Guildf) 42(21):8759–8768

Harish V, Nagaiah N, Prabhu TN, Varughese KT (2009) Preparation and characterization of lead monoxide filled unsaturated polyester based polymer composites for gamma radiation shielding applications. J Appl Polym Sci 112(3):1503–1508

Kim J, Seo D, Lee BC, Seo YS, Miller WH (2014) Nano-W dispersed gamma radiation shielding materials. Adv Eng Mater 16(9):1083–1089

Yu D et al (2012) Effects of WO3 particle size in WO3/epoxy resin radiation shielding material. Chinese Phys Lett 29(10):108102

Higgins MCM, Radcliffe NA, Toro-González M, Rojas JV (2019) Gamma ray attenuation of hafnium dioxide-and tungsten trioxide-epoxy resin composites. J Radioanal Nucl Chem 322(2):707–716

Chang L et al (2015) Preparation and characterization of tungsten/epoxy composites for γ-rays radiation shielding. Nucl Instruments Methods Phys Res Sect B 356:88–93

Abdalsalam AH et al (2019) A study of gamma attenuation property of UHMWPE/Bi2O3 nanocomposites. Chem Phys 523:92–98

Agool IR, Kadhim KJ, Hashim A (2017) Synthesis of (PVA–PEG–PVP–ZrO2) nanocomposites for energy release and gamma shielding applications. Int J Plast Technol 21(2):444–453

Maghrabi HA, Vijayan A, Deb P, Wang L (2016) Bismuth oxide-coated fabrics for X-ray shielding. Text Res J 86(6):649–658

Nambiar S, Osei EK, Yeow JTW (2013) Polymer nanocomposite-based shielding against diagnostic X-rays. J Appl Polym Sci 127(6):4939–4946

Chai H et al (2016) Preparation and properties of novel, flexible, lead-free X-ray-shielding materials containing tungsten and bismuth (III) oxide. J Appl Polym Sci. https://doi.org/10.1002/app.43012

Jamil M, Hazlan MH, Ramli RM, Azman NZN (2019) Study of electrospun PVA-based concentrations nanofibre filled with Bi2O3 or WO3 as potential x-ray shielding material. Radiat Phys Chem 156:272–282

Aghaz A, Faghihi R, Smj M, Haghparast A, Mehdizadeh S, Sina S (2016) Radiation attenuation properties of shields containing micro and nano WO3 in diagnostic X-ray energy range. Int J Radiat Res 14(2):127

Azman NZN, Siddiqui SA, Hart R, Low I-M (2013) Effect of particle size, filler loadings and x-ray tube voltage on the transmitted x-ray transmission in tungsten oxide—epoxy composites. Appl Radiat Isot 71(1):62–67

Botelho MZ, Künzel R, Okuno E, Levenhagen RS, Basegio T, Bergmann CP (2011) X-ray transmission through nanostructured and microstructured CuO materials. Appl Radiat Isot 69(2):527–530

Künzel R, Okuno E (2012) Effects of the particle sizes and concentrations on the X-ray absorption by CuO compounds. Appl Radiat Isot 70(4):781–784

Fontainha CCP, Baptista Neto AT, Santos AP, de Faria LO (2016) P (VDF-TrFE)/ZrO2 polymer-composites for x-ray shielding. Mater Res 19(2):426–433

Li R, Gu Y, Wang Y, Yang Z, Li M, Zhang Z (2017) Effect of particle size on gamma radiation shielding property of gadolinium oxide dispersed epoxy resin matrix composite. Mater Res Express 4(3):35035

Funding

This work was carried out as part of the “University Degree Program” at Umm Al-Qura University. No funding was obtained for this work.

Author information

Authors and Affiliations

Contributions

Conceptualization, A-WA, OB, and KA; methodology, KM, HA, NA, and ZBA; resources, NA, and KA; writing—original draft preparation, A-WA, KM, HA, and ZBA; writing—review and editing, OB, ZBA, and A-WA; supervision, OB, and A-WA; project administration, OB, and A-WA. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bawazeer, O., Makkawi, K., Aga, Z.B. et al. A review on using nanocomposites as shielding materials against ionizing radiation. J.Umm Al-Qura Univ. Appll. Sci. 9, 325–340 (2023). https://doi.org/10.1007/s43994-023-00042-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43994-023-00042-9